Automobile battery cover overturning mechanism

A technology of turning mechanism and car battery, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of low efficiency and trouble, and achieve the effect of high efficiency, good effect and convenient automatic processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

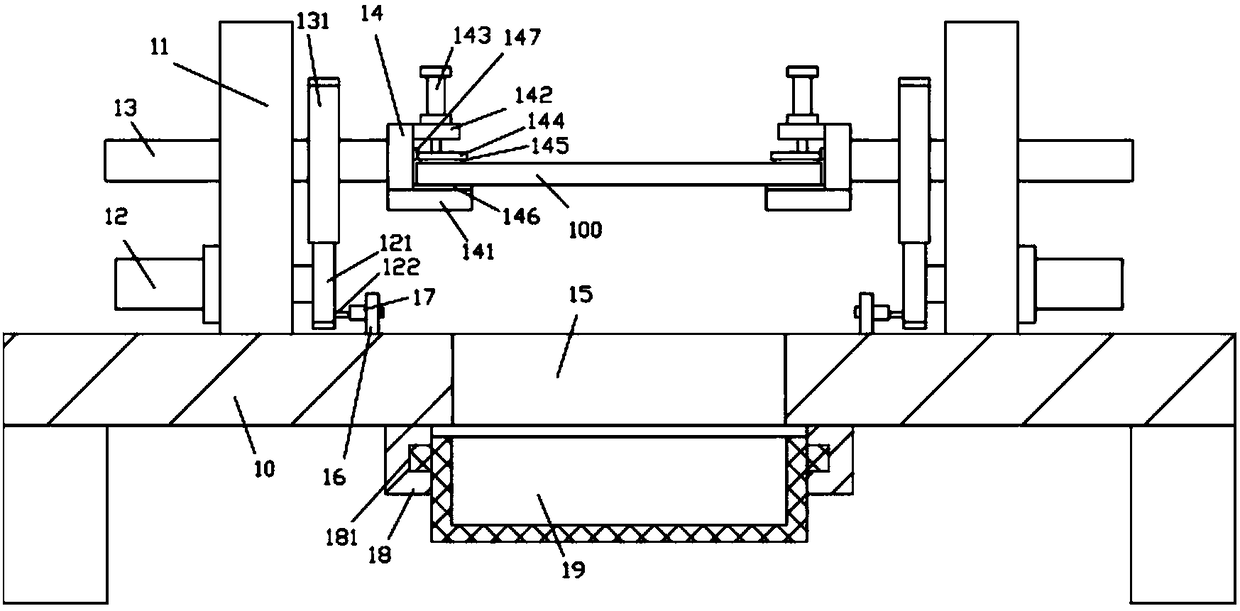

[0013] Examples, see e.g. figure 1 As shown, a kind of car battery cover turning mechanism comprises frame 10, and the both sides of the top surface of the top plate of described frame 10 are fixed with vertical support plate 11, and the bottom of the outer side wall of two vertical support plates 11 is fixed with Drive the servo motor 12, the output shaft of the drive servo motor 12 passes through the vertical support plate 11 and is fixed with a drive gear 121, the top of the vertical support plate 11 is hinged with a rotating shaft 13, and the inner end of the rotating shaft 13 stretches out the vertical support The inner side wall of the plate 11 is also fixed with a clamping plate 14, the inner end of the rotating shaft 13 is fixed with a transmission gear 131, the transmission gear 131 is meshed with the corresponding driving gear 121, and the bottom surfaces of the two clamping plates 14 are fixed with a bottom extending Plate 141, upper supporting plate 142 is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com