Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Excellent secondary processability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crystalline polypropylene resin composition and amide compounds

InactiveUS6235823B1Low melting pointLess force for deformation under heatingOrganic chemistryOrganic compound preparationPolypropylenePolymer chemistry

Disclosed are a crystalline polypropylene resin composition comprising a crystalline polyproplylene resin and a beta-nucleating agent, and a method of increasing the proportion of beta-form crystals in a crystalline polypropylene resin molding comprising molding the composition, the beta-nucleating agent being a diamide compound.

Owner:NEW JAPAN CHEM CO

Laser-Sinterable Powder and Shaped Article Thereof

InactiveUS20110129682A1Sharp decrease of melt viscosityImproved laser sintering performanceSynthetic resin layered productsAdditive manufacturing with solidsPolymer sciencePolyolefin

A laser-sinterable resin powder, which retains properties of styrene resins such as impact resistance and low water absorption and shows sharp decrease of melt viscosity similarly to crystalline resins at a temperature not lower than the glass transition temperature can be made of a thermoplastic resin composition containing 10-80 mass % of a crystalline resin (A) with a melting point of 80-250° C. and 20-90 mass % of a styrene resin (B), and having a 50% average particle diameter of 10-100 μm. The Component (A) is preferably a polyolefin resin. The Component (B) is preferably a rubber-reinforced styrene resin composition, wherein the rubber component is preferably an ethylene-α-olefin copolymer rubber and / or a hydrogenated product of a diene rubber. The laser-sinterable powder preferably has a melt flow rate of 5-500 g / 10 min.

Owner:TECHNO POLYMER CO LTD +1

Method for preparing wood plastic composite material from waste printed circuit boards

The invention discloses a method for preparing a wood plastic composite material from waste printed circuit boards, and belongs to the technical field of industrial waste recovery. Non-metal materials of the waste circuit boards obtained by crushing and sorting are taken as raw materials to replace partial wood meal to produce the wood plastic composite material. The method comprises the following steps: preparing conveniently formed wood plastic particles from 25 to 35 portions of thermal plastic plastics, 15 to 40 portions of non-metal material grains of the waste circuit boards, 30 to 60 portions of wood meal, 2 to 4 portions of graft compatilizer, 1 to 2 portions of lubricant and 0.3 to 0.6 portion of coupling agent by metering, mixing and plasticating; and performing extrusion molding on the wood plastic particles in an extruder, and performing cutting and forming after cooling setting. The method not only can solve the problems of processing and pollution of the non-metal materials of the waste circuit boards, but also can reduce the production cost of the wood plastic composite material.

Owner:SHANGHAI JIAO TONG UNIV

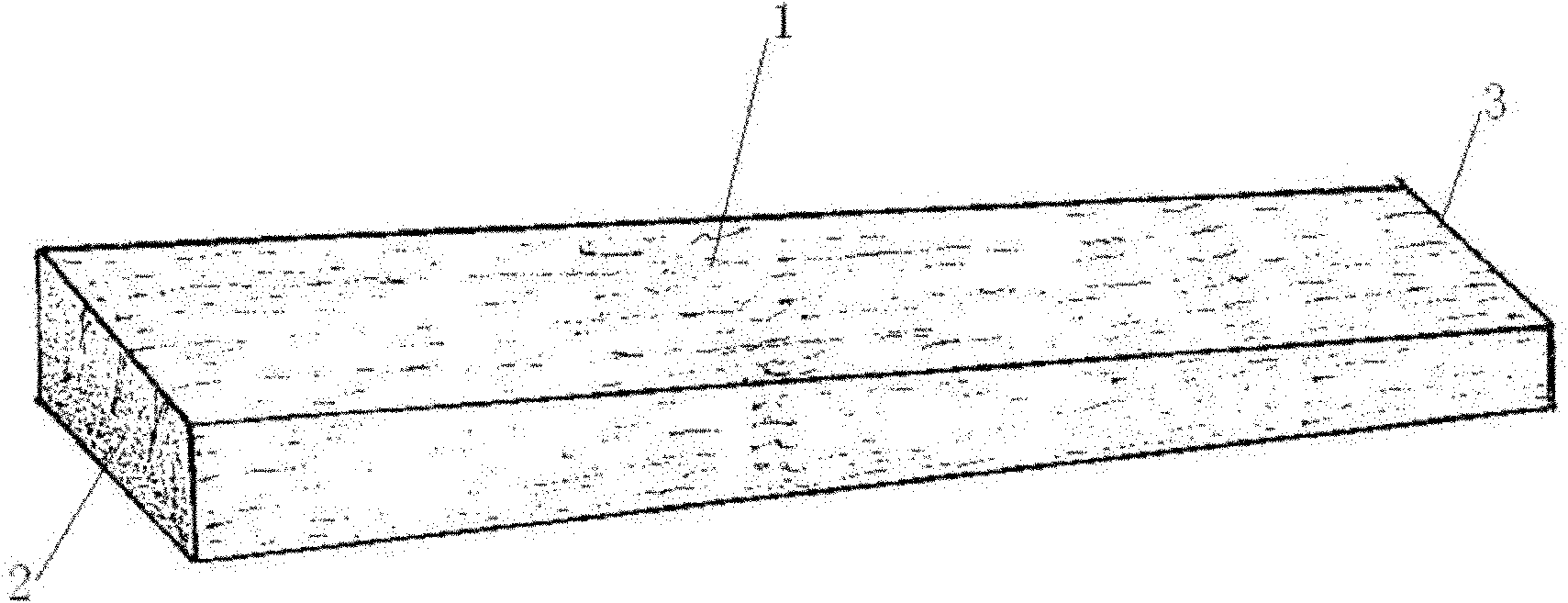

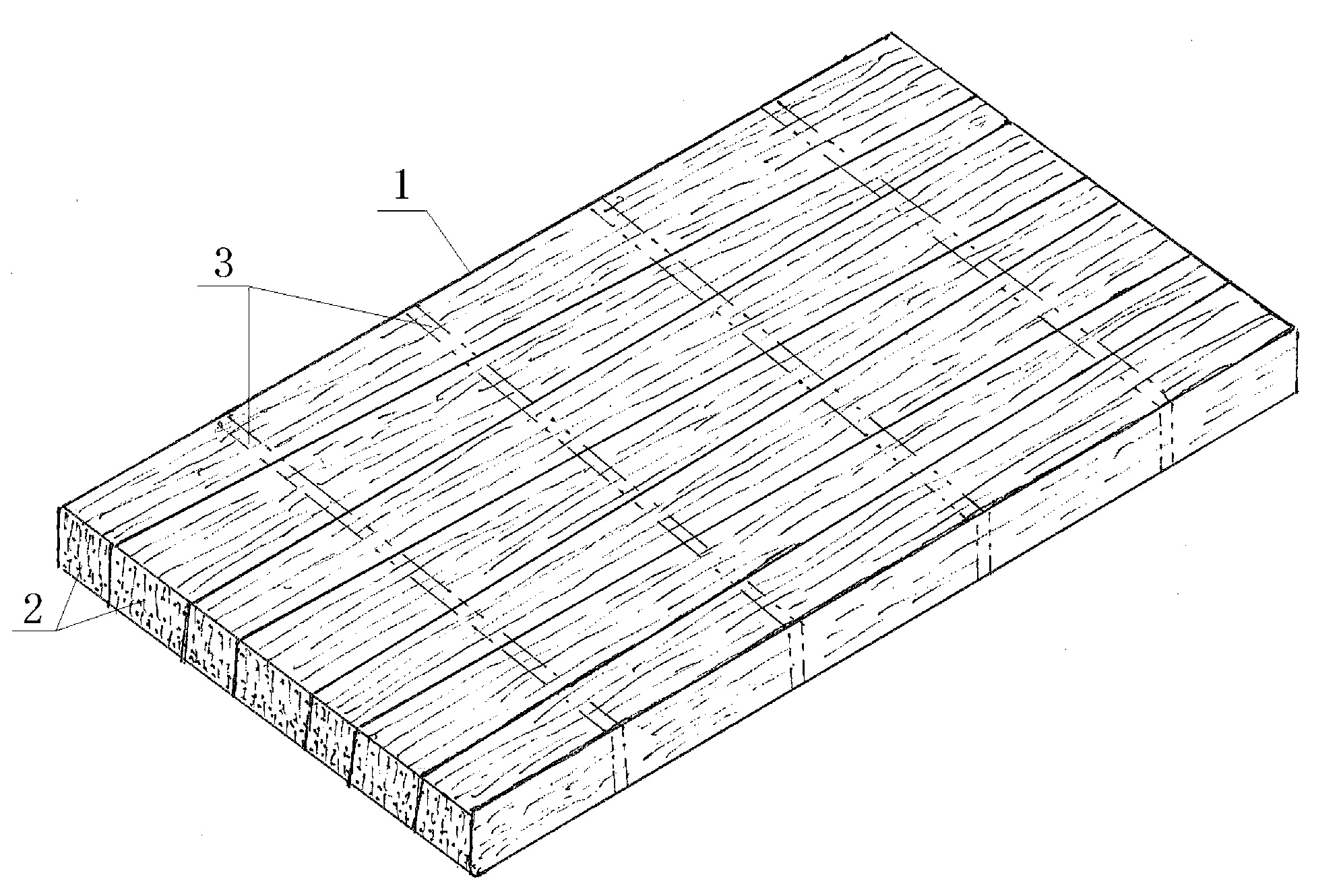

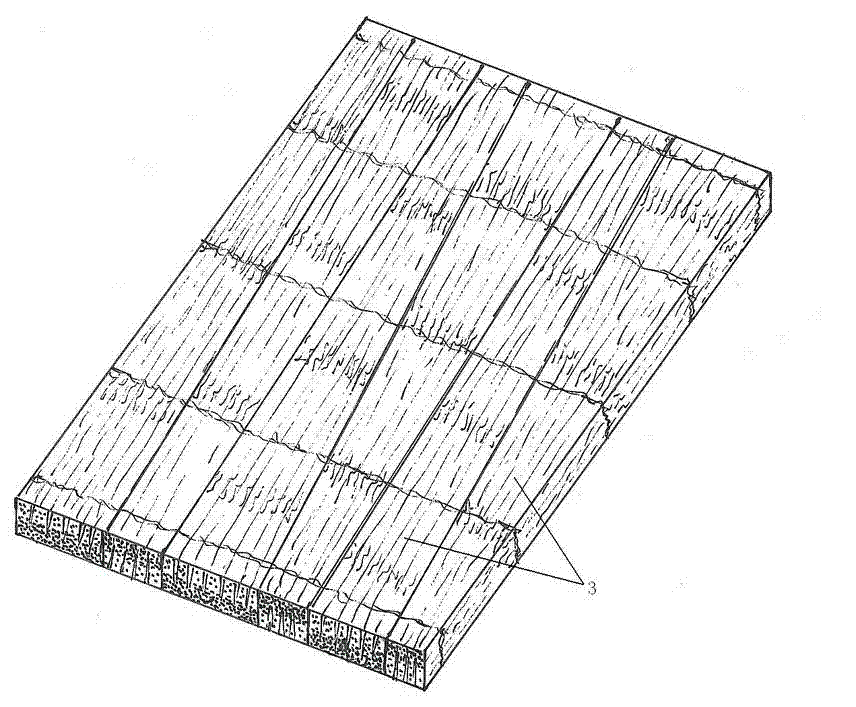

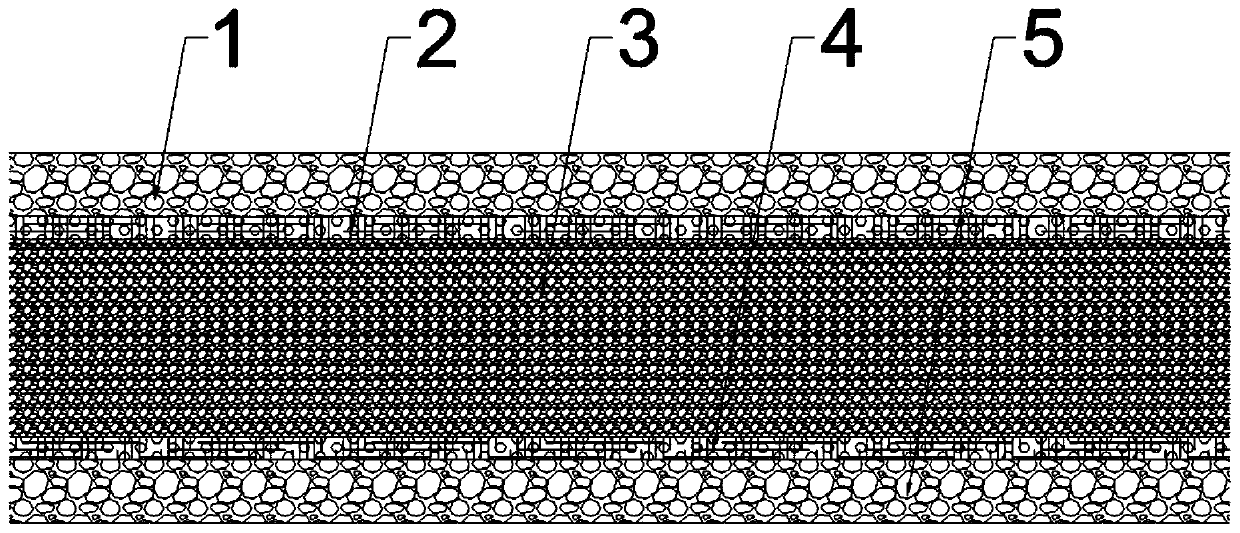

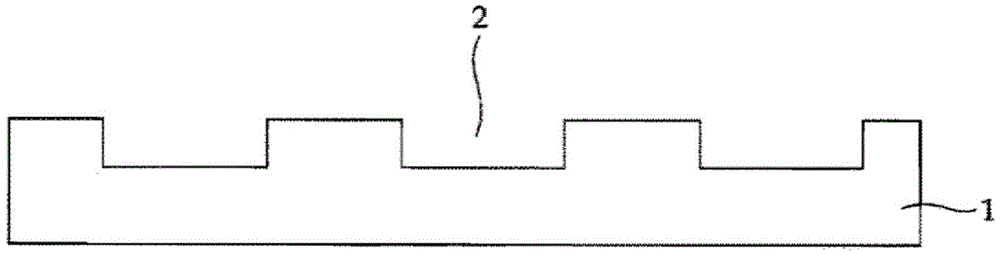

Non-uniform thickness bamboo chip integrated plate and production technology method thereof

InactiveCN102172928ASave materialCompact structureWood veneer joiningWood layered productsEngineeringResin adhesive

The invention discloses a non-uniform thickness bamboo chip integrated plate and a production technology method thereof. The production technology method is characterized in that the original moso bamboo arc-shaped bamboo chip is milled into the non-uniform thickness bamboo chip of which the thickness is changed from one end to the other end, one end of the non-uniform thickness bamboo chip is thicker, and the other end is thinner; then, the non-uniform thickness bamboo chip is steamed or charred and dried, is subjected to carbon returning processing, is dipped with resin adhesive and dried again; each bamboo chip unit body is laterally and vertically arranged; bamboo green and bamboo green surface are abutted, or tabasheer and tabasheer are abutted; the thick ends and the thin ends of adjacent two bamboo chips are alternately overlaid and tightly and tidily arranged to integrate a blank plate; and environmentally-friendly urea resin adhesive is subjected to hot-pressing shaping. The non-uniform thickness bamboo chip integrated plate disclosed by the invention saves material, has the advantages of low unit product cost, compact structure, even density, small internal stress, small possibility of deforming and good size stability, usability and secondary processability, and can be widely applied to the building industry and decoration industry.

Owner:刘佐财 +1

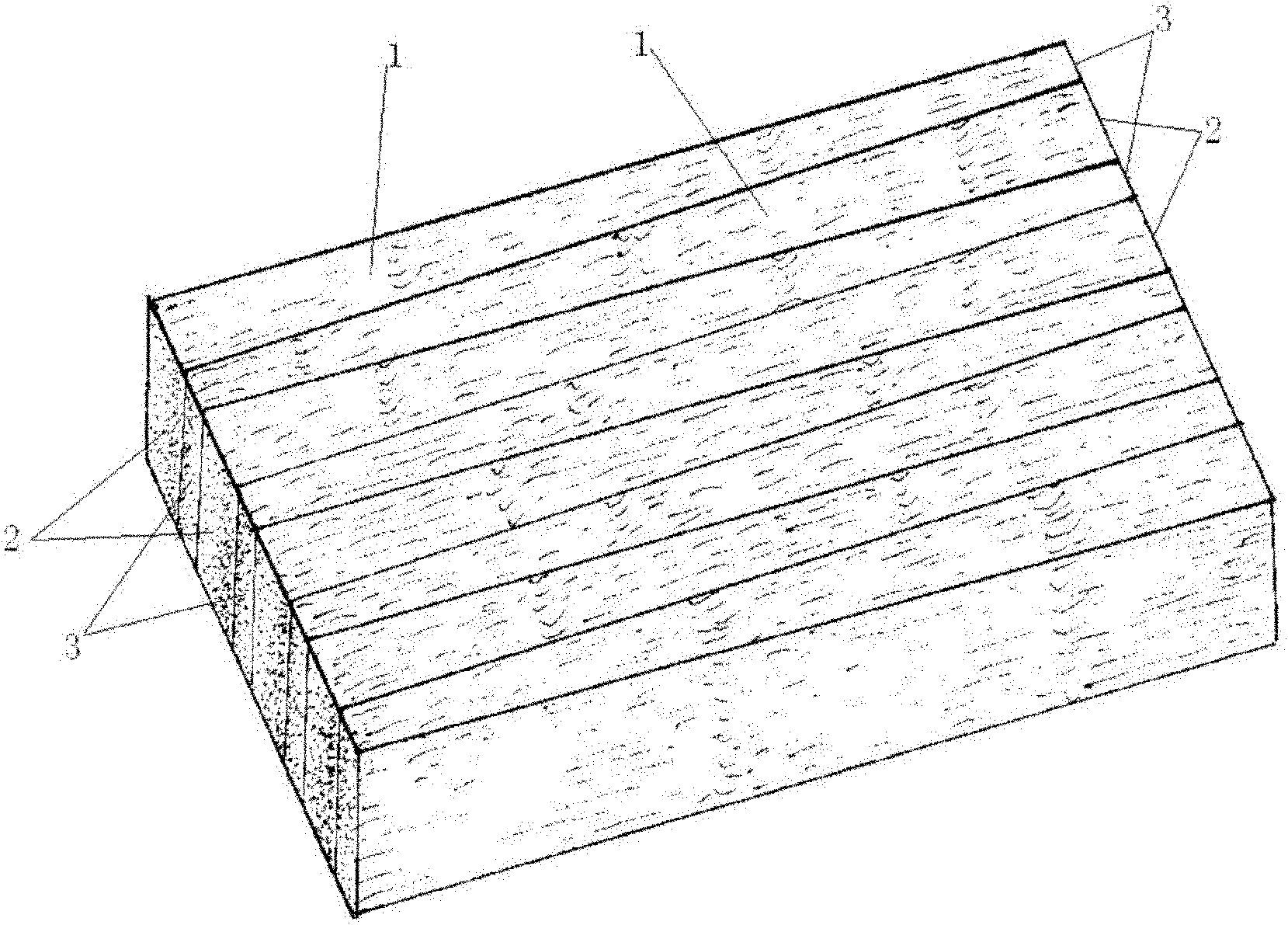

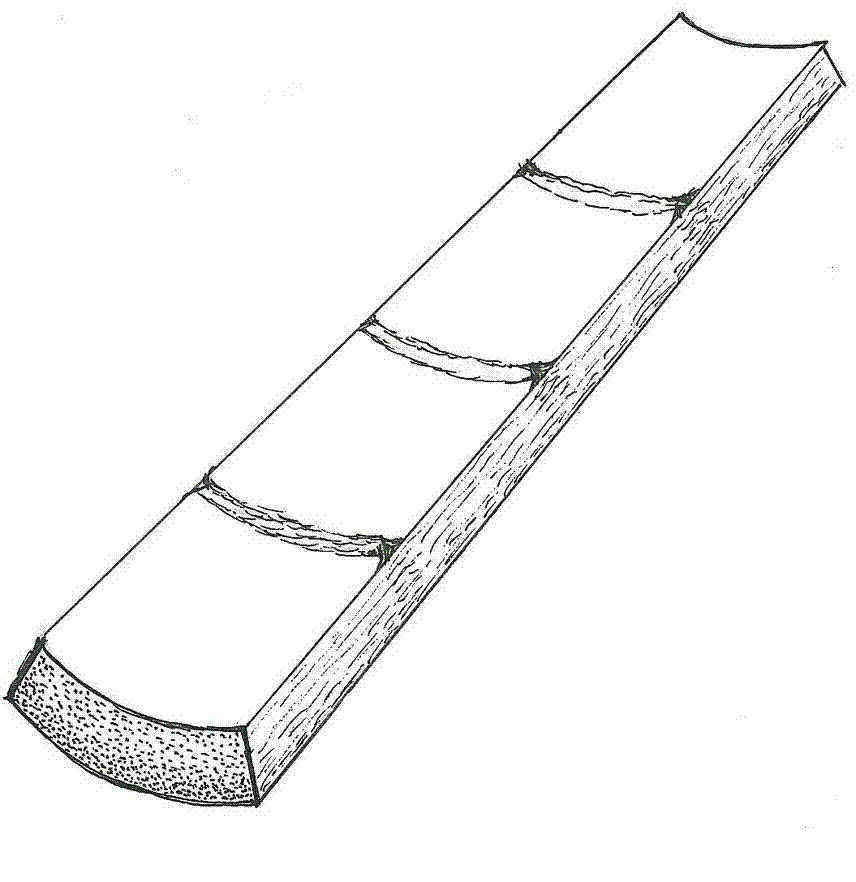

Laminated board formed by fine disintegration and rearrangement of whole raw bamboos and production technical method thereof

InactiveCN103072160AKeep natural widthLow costWood veneer joiningWood layered productsEngineeringMechanical property

The invention discloses a laminated board formed by the fine disintegration and rearrangement of whole raw bamboos and a production technical method thereof. Moso bamboos are used as raw materials. The method comprises the following steps that first, raw arc-shaped bamboo sheets are finely cut, disintegrated, rolled and unfolded by a machine to form longitudinal bamboo filaments, the bamboo filaments are laterally connected into planar trapezoid bamboo blocks of basically identical thickness, and the widths of the planar trapezoid bamboo blocks gradually change from one ends to the other ends; then, the wide ends and the narrow ends of two adjacent bamboo blocks are alternately put according to the width direction of the same end of one planar trapezoid bamboo block, the bamboo green sides or the bamboo yellow sides are arranged on the same upper side or the same lower side, and the bamboo blocks are glued to form a whole board, thereby forming a fine disintegrated bamboo filament block single-layer board; and at least two layers of fine disintegrated bamboo block single-layer boards are layered and laminated in a way that the bamboo green sides of two adjacent layers of single-layer boards are close or the bamboo yellow sides and the bamboo green sides in two adjacent layers are close, and the laminated board formed by the fine disintegration and rearrangement of the whole raw bamboos is obtained after different layers of single-layer boards are glued by an adhesive and hot-pressed into a whole. According to the invention, the bamboo bodies are stored to an utmost extent, a cut quantity is reduced, and the mechanical properties of the raw bamboo materials are exerted.

Owner:HUNAN ACAD OF FORESTRY +1

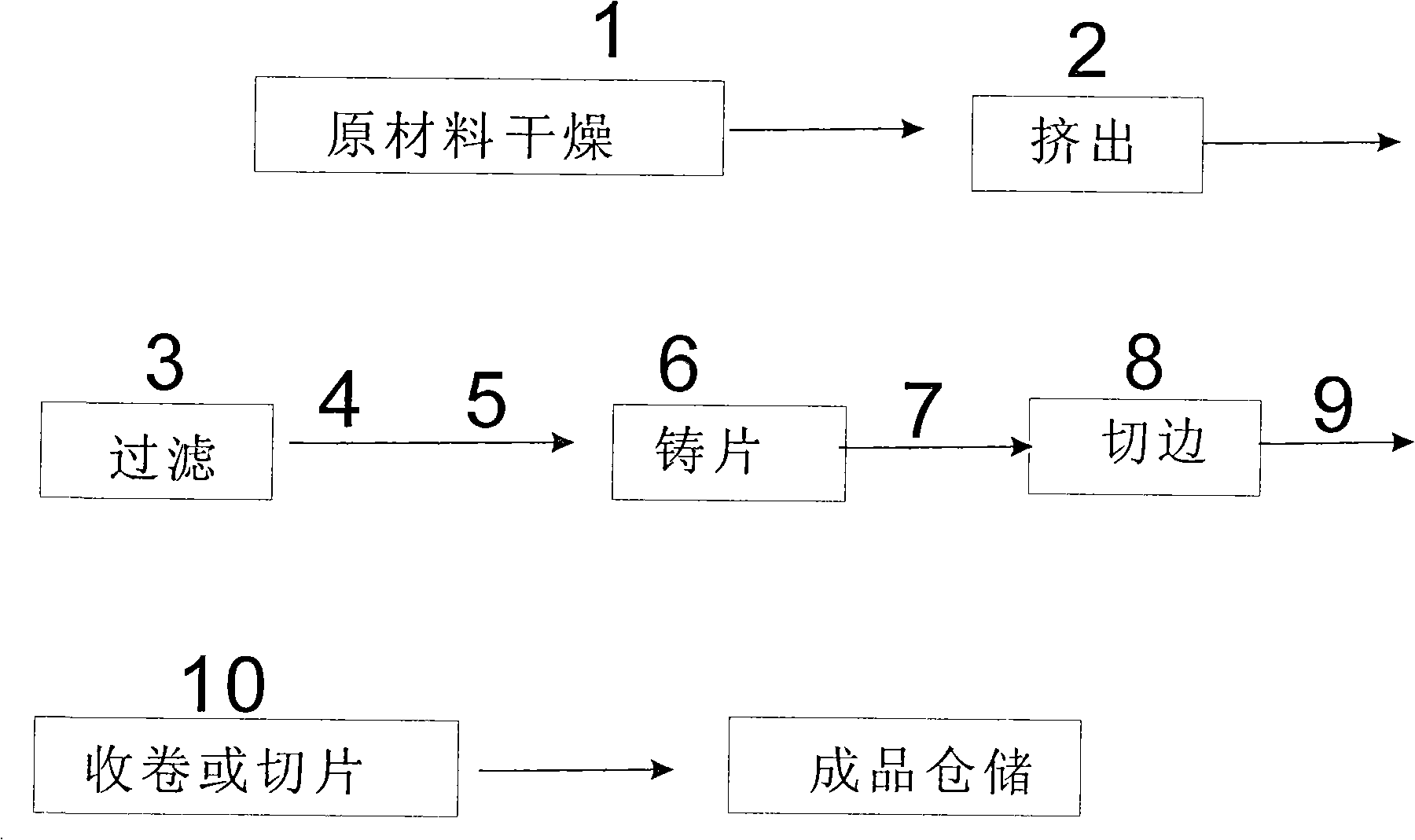

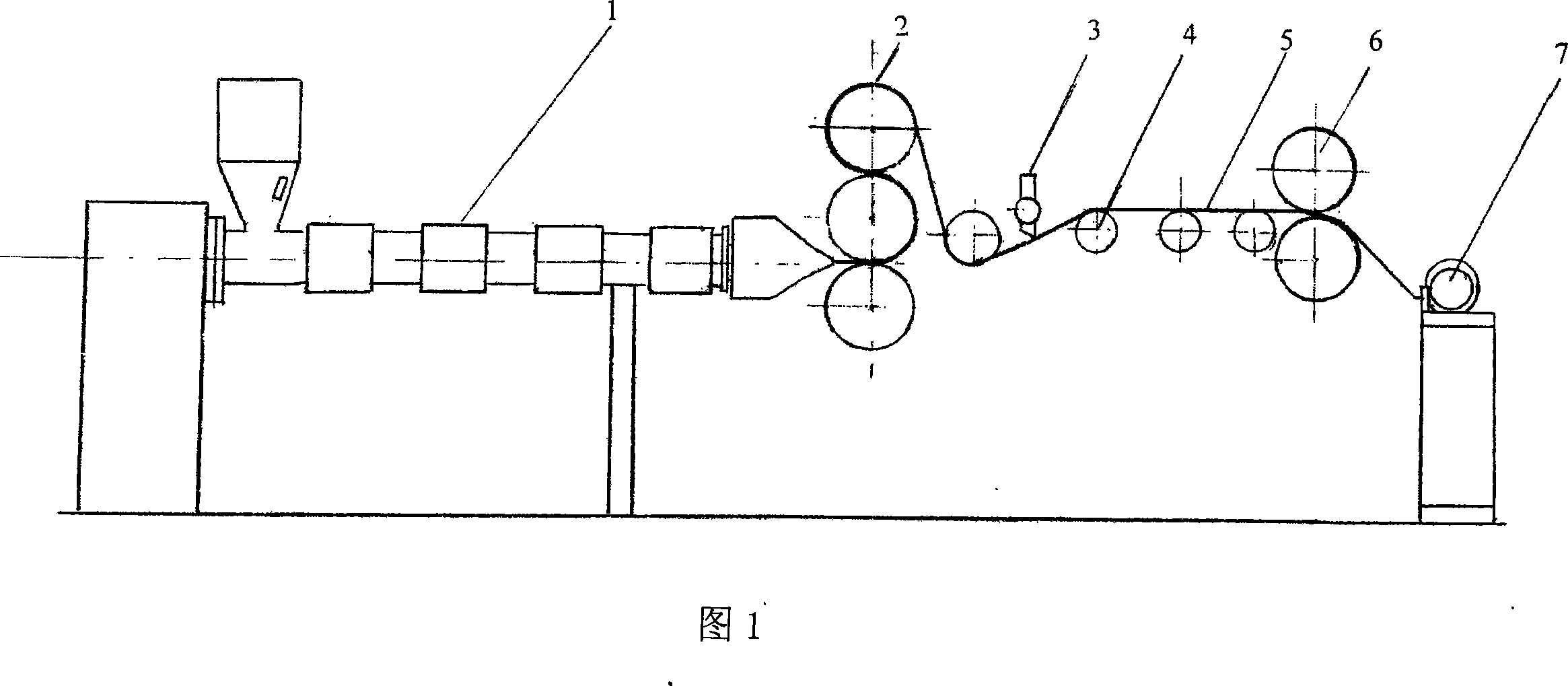

Production technique and device of polylactic acid PLA sheet material

ActiveCN101357506AExcellent secondary processabilityAuxillary shaping apparatusFlat articlesPulverizerPolylactic acid

The invention discloses a process for producing polylactic acid (PLA) sheet material and equipment thereof. The raw material of PLA resin is dried by a drier, enters an extruder for extrusion and becoming melting fluid, the impurity and non-melt substances in the melting fluid are filtered by a filter screen, by the melting fluid pump, the melting fluid is pumped to a distributor mechanism and a mold head evenly and continually, a melting film is formed by a distributor mechanism and the mold head and is cast in a cooling roller for urgent cooling, so as to form PLA sheet material, the thickness of the molded PLA sheet material is measured on line by a thickness measurement apparatus, the marginal material is cut off, the PLA sheet material is drawn to a recoiler by a drawing device and rolled to PLA sheet rolls in certain specification, or is cut into PLA flat sheets in certain specification by a section cutter on line. The entire production process comprises recycle of leftover material of frames, and the process is: the recycled leftover material of frames is crushed by a muller and enters a crystallizer with a blender; hot air is led in for carrying out crystallization.

Owner:东阳市盛林塑胶有限公司

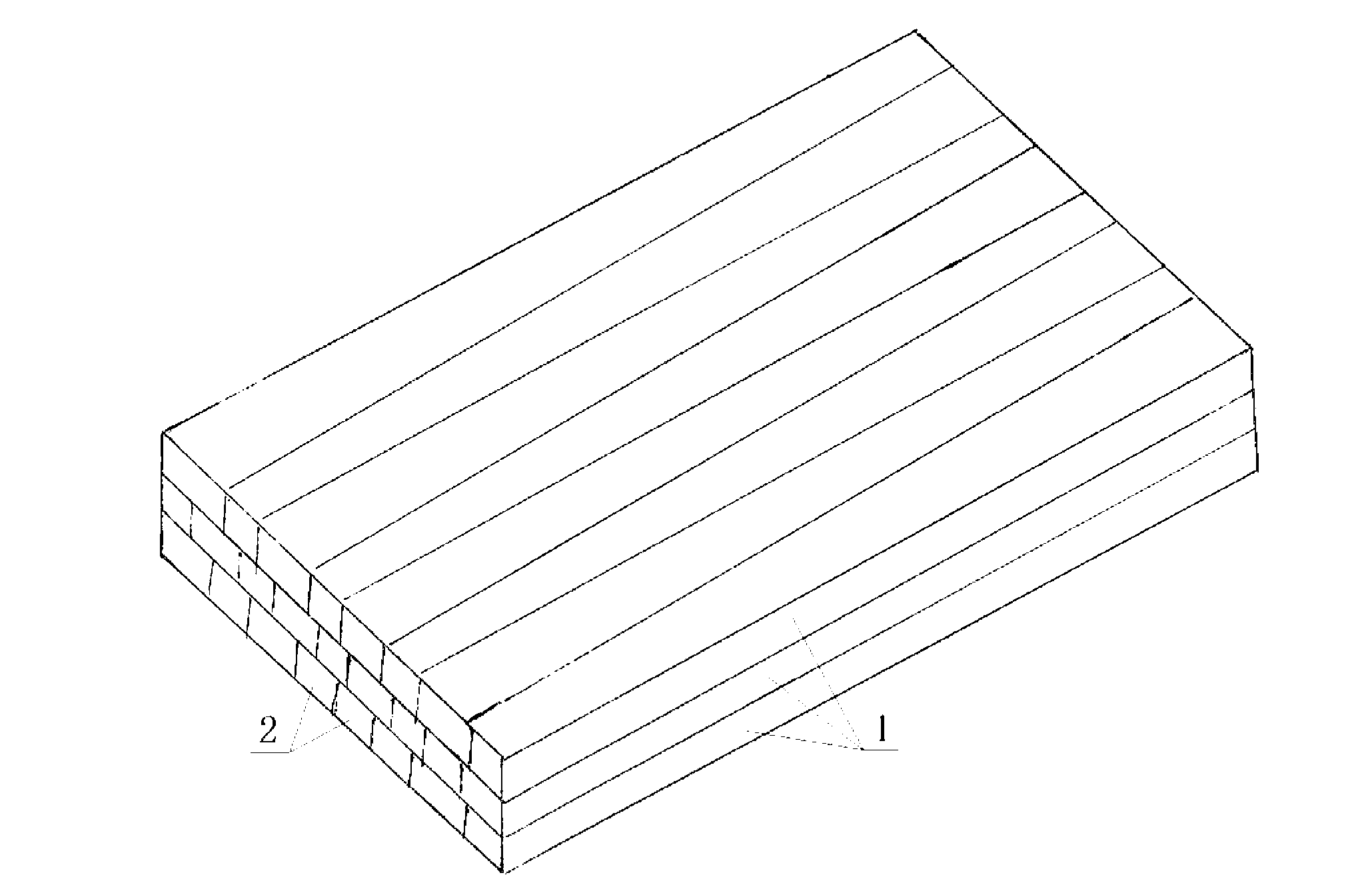

Wood and bamboo-unfolded thick veneer collection laminated material and preparation method thereof

InactiveCN102765111AIncrease profitIncrease the scope of applicationPlywood pressesVeneer pressesSurface layerMechanical property

The invention discloses a wood and bamboo-unfolded thick veneer collection laminated material with fast-growing woods and mao bamboos as raw materials and a preparation method of the wood and bamboo-unfolded thick veneer collection laminated material. The wood and bamboo unfolded thick veneer collection laminated material comprises at least three layers of odd wood laminated veneers and bamboo unfolded thick veneers, wherein the wood laminated veneers and the bamboo unfolded thick veneers are alternately and hierarchically stacked and are bonded and pressed into an integrated body through adhesive agents; the wood laminated veneers are distributed on both a surface layer and a bottom layer of the integrated body; and all the veneer layers are longitudinally arranged or horizontally and longitudinally arranged. The bamboo-unfolded thick veneers are formed in a way that every two of ladder-shaped unfolded bamboo plate unit bodies formed by unfolding original arc-shaped bamboo blocks correspond to each other in a turned way and are longitudinally laminated. According to the wood and bamboo-unfolded thick veneer collection laminated material provided by the invention, the production process is simplified, the production cost is reduced, the raw material consumption of unit product is controlled, the benefits of woods and bamboos are fully exerted, the mechanical property of wood and bamboo compound materials is improved, and the application range is widened.

Owner:刘佐财 +1

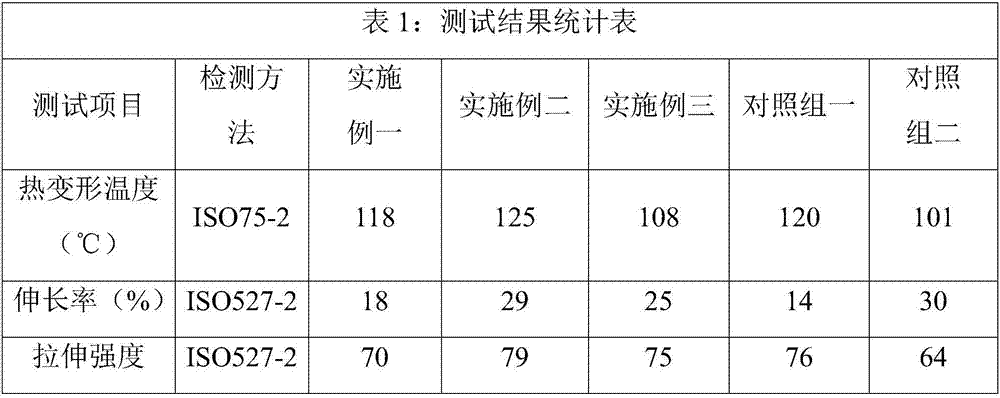

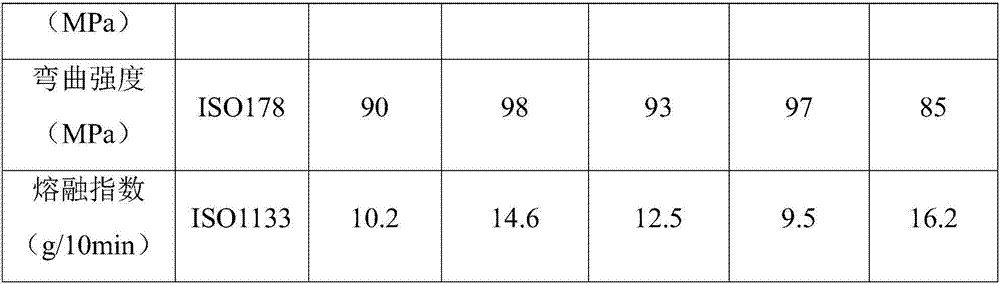

High-temperature-resistant easy-to-form PC/PCTG material and preparation method thereof

The invention relates to the field of rubber materials, in particular to a high-temperature-resistant easy-to-form PC / PCTG material and a preparation method thereof. The high-temperature-resistant easy-to-form PC / PCTG material is prepared from the following components in percentage by mass: 50-70% of PC, 20-60% of PCTG, 0.05-0.3% of a lubricating agent, and 0.2-0.4% of an anti-oxidant. The high-temperature-resistant easy-to-form PC / PCTG material is high in flowing property, is good in processing and forming property, is good in heat resistance and is high in mechanical strength.

Owner:东莞市优特美工程塑料有限公司

Bamboo-plastic composite material and preparation process thereof

The invention discloses a bamboo-plastic composite material which is characterized by comprising bamboo powder, polyethylene and additives according to the mass ratio of (20-60):(70-35):(10-5). The bamboo powder is pulverized into ultra-fine powder with 350-500 meshes. The additives include one or multiple of compatibilizers, lubricants and coupling agents. The polyethylene is pulverized into particles with the diameters ranging from 1mm to 1.5mm. The invention further provides a preparation process of the bamboo-plastic composite material. The preparation process includes steps of (1), treating the bamboo powder; (2), preparing materials and mixing the materials; and (3) granulating. The bamboo-plastic composite material has characteristics of the polyethylene and bamboos, has good damp-proof, anticorrosion and moth-proof properties, and has high strength, ductility and hardness and good secondary processing performance. By the preparation process, scraps and chips of the bamboos which cannot be used in the past can be pulverized and recovered for reutilization, wastes are recycled, and good economic benefits are achieved.

Owner:谢小良

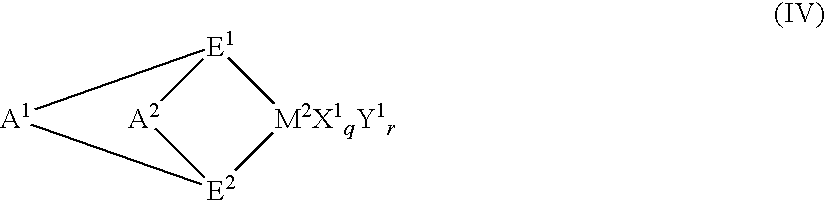

Olefin polymer wax-containing resin composition

Resin compositions of the invention contain an olefin polymer wax having higher heat resistance than achieved heretofore, high compatibility with resins and excellent mold-releasing properties.A resin composition (X) of the invention is obtained by blending a resin (A) having a melting point Tm of not less than 200° C. and an olefin polymer wax component (B), the olefin polymer wax component (B) including a cyclic olefin polymer wax (B-1) having structural units (a) and (b) described below, the cyclic olefin polymer wax (B-1) containing the structural units (b) at 0.05 to 50 mol % based on all the structural units in the polymer;(a) units derived from ethylene(b) units derived from a cyclic olefin.

Owner:MITSUI CHEM INC

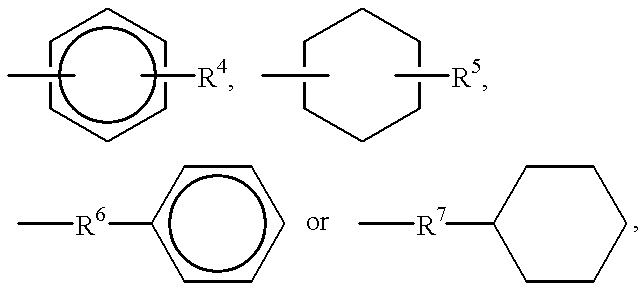

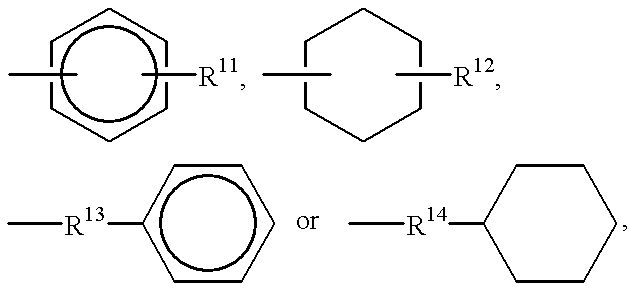

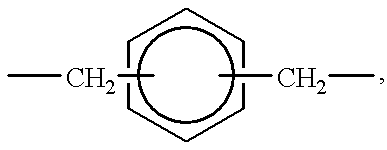

Polymerizable composition for optical material and use thereof

Provided is a polymerizable composition for an optical material including (A) an amine having two or more secondary amino groups, (B) an isocyanate having two or more isocyanato groups, and (C) a thiol having three or more mercapto groups, in which the ratio (a / b) of the molar number a of amino groups in the amine (A) with respect to the molar number b of isocyanato groups in the isocyanate (B) is in the range of 0.10 to 0.60.

Owner:MITSUI CHEM INC

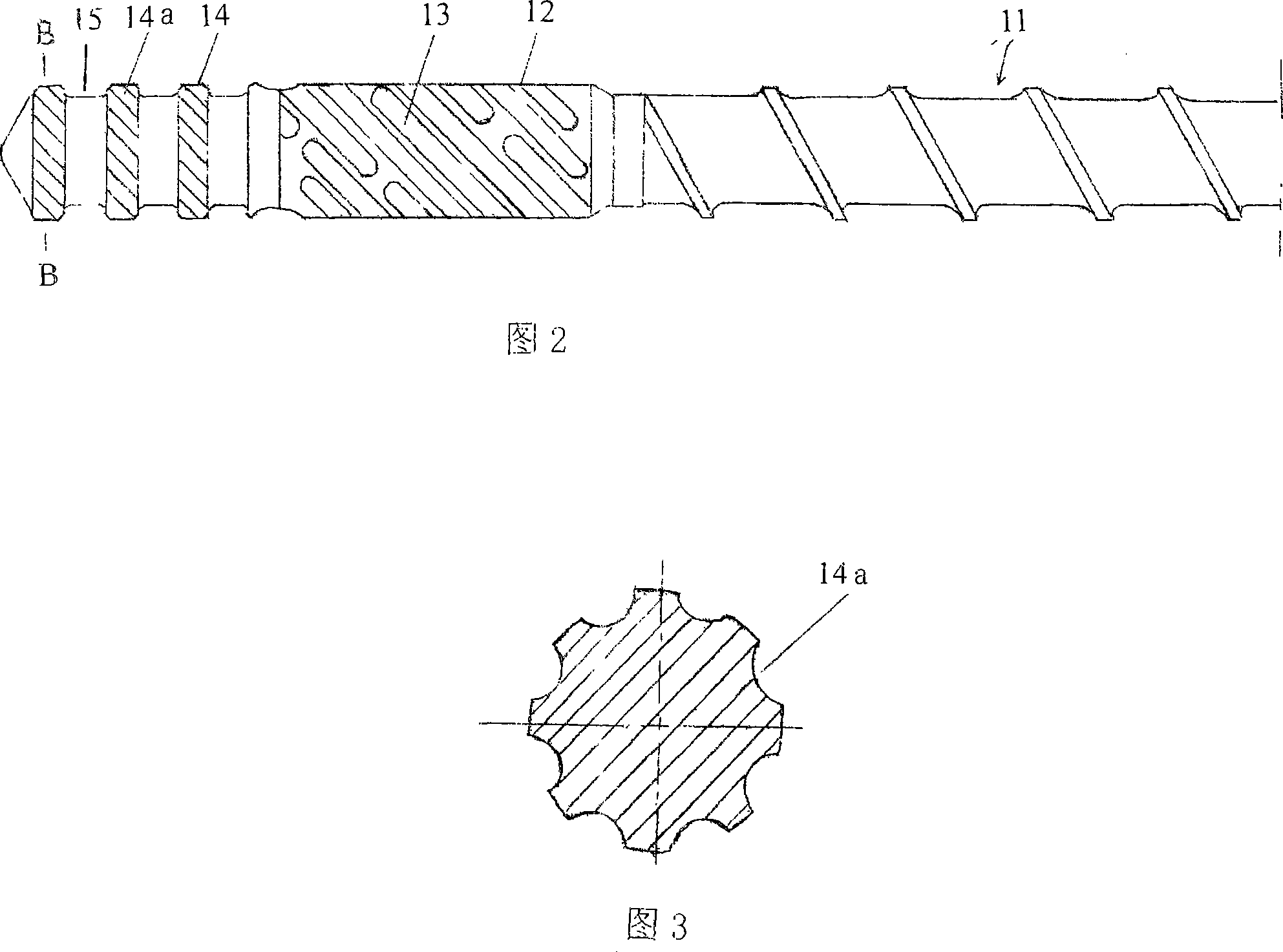

Polylactic acid sheet material and production equipment thereof

InactiveCN101134362AGood processing performanceExcellent secondary processabilityFlat articlesDrawing ratioPaper sheet

The present invention discloses one kind of polylactic acid sheet and its production apparatus, and belongs to the field of polymer sheet making and plasticizing apparatus. The polylactic acid sheet in the thickness of 0.2-2 mm and drawing ratio up to 1 to 2.3 may be adhered to paper or fiber fabric to form compound material. The polylactic acid sheet is extruded in a screw extruder with a barrier type screw bolt, which has at least one ring notch between the barrier section and the top and raised rings beside the notch with homogeneously distributed shallow slots. The cooling drum is provided with at least 3 cooling water channels. The production apparatus of the present invention can produce polylactic acid sheets with excellent performance continuously.

Owner:陈津生

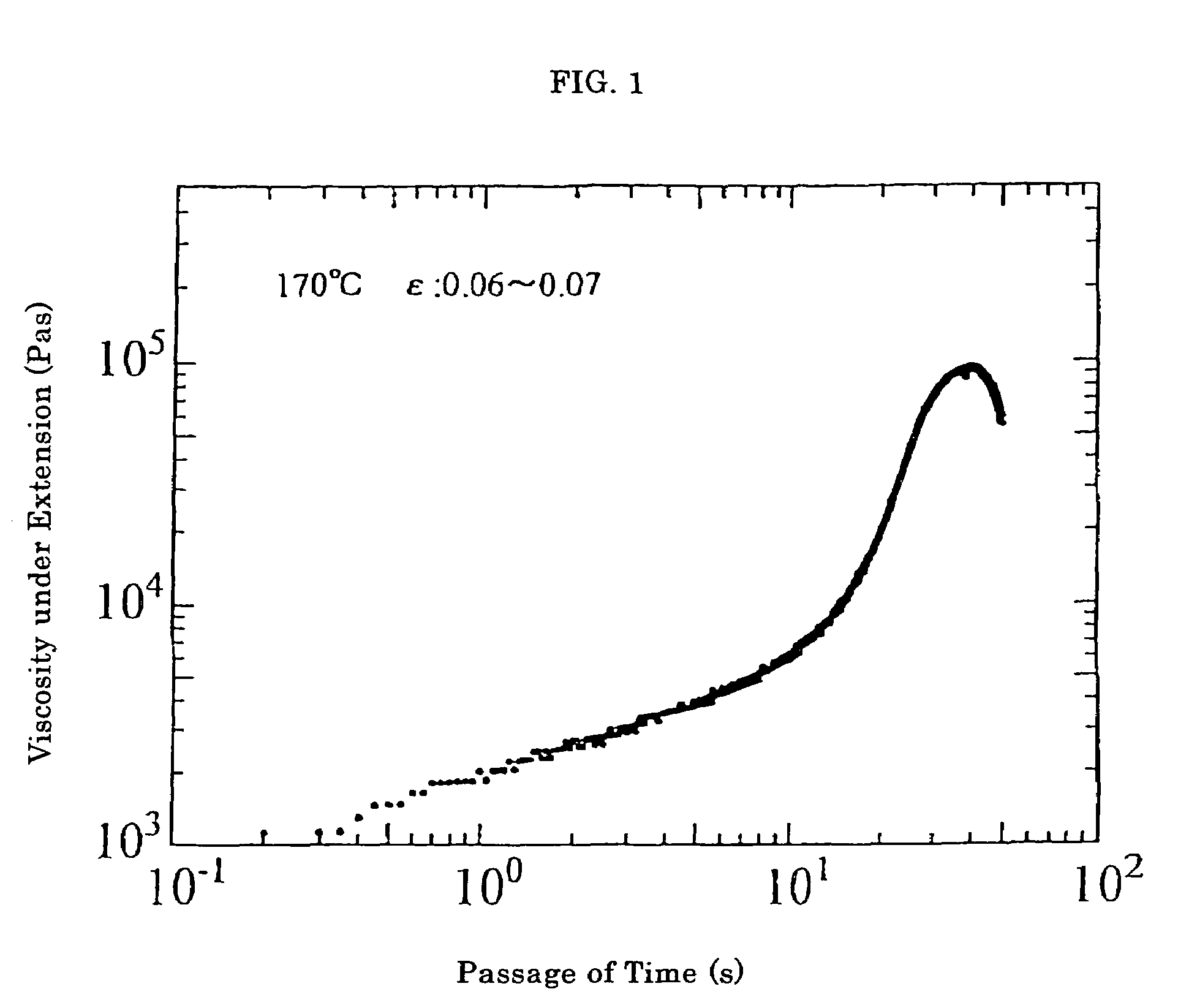

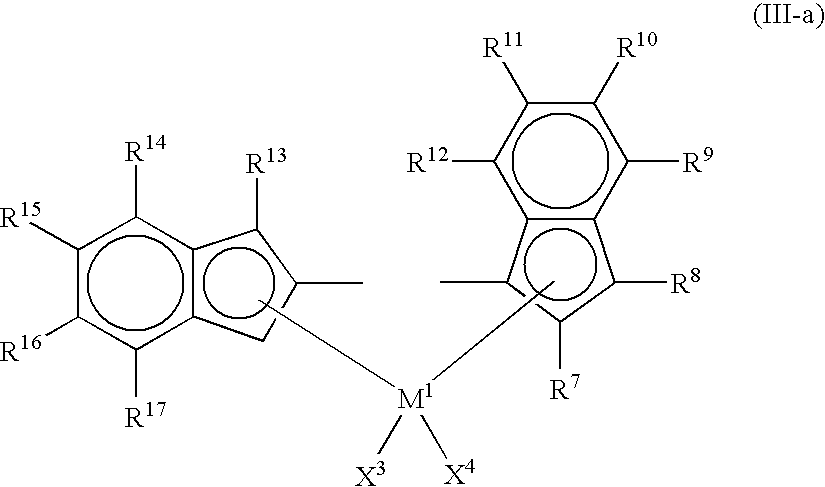

Process for producing polyolefin resin composition and polypropylene composition

A process for producing a polyolefin-based resin composition comprises, in the first polymerization stage, polymerizing an α-olefin having 4 to 20 carbon atoms, a styrene or a cyclic olefin in the presence of a specific catalyst and, in the second polymerization stage, copolymerizing the obtained polymer with an α-olefin having 2 to 20 carbon atoms, a styrene or a cyclic olefin in the presence of a polyene. A polypropylene composition has a branching parameter a and a branching index g in specific ranges. The curve showing the change in viscosity under elongation with time, the degradation parameter D or the content of a high molecular weight component is specified. The polyolefin-based resin composition exhibits excellent uniformity and improved workability in melting due to improved tension in melted condition. The polypropylene composition exhibits excellent melting elasticity and secondary workability and provides foamed molded articles, sheets and blow molded articles.

Owner:IDEMITSU KOSAN CO LTD

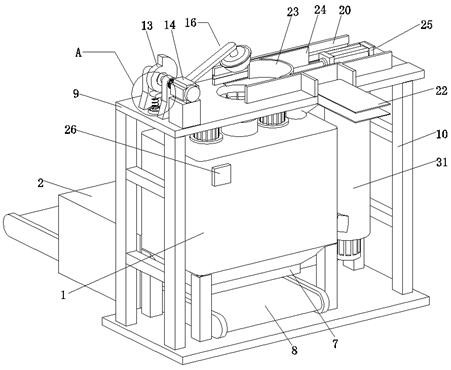

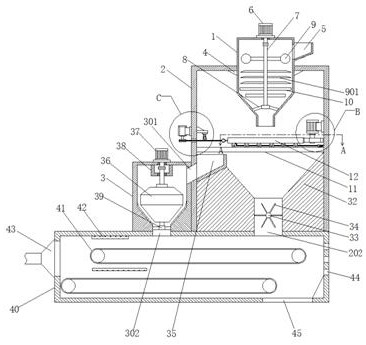

Secondary processing device for caked pig feed

ActiveCN111921590AImprove crushing effectSolve the problem of cloggingSievingFeeding-stuffAnimal scienceMedicine

The invention relates to the technical field of pig feed processing devices, and particularly discloses a secondary processing device for caked pig feed. The secondary processing device comprises a smashing box and a drying box, wherein the center of the upper surface of the smashing box is provided with a feeding hopper, the portions, on the left and right sides of the feeding hopper, of the upper surface of the smashing box are provided with smashing motors, the lower ends, extending into an inner cavity of the smashing box, of output shafts of the smashing motors are connected with smashingshafts, the two smashing shafts are each provided with a plurality of smashing blades arranged in a staggered manner, the lower end of the smashing box is provided with a discharging port, and a first conveyor belt is arranged in the drying box in a penetrating manner. The secondary processing device effectively solves the problem that at present, the feeding hopper is liable to be blocked when the caked pig feed is directly put into the smashing box from the feeding hopper, it is unnecessary to manually break the caked pig feed in advance, it is only required that an operator pours the cakedpig feed onto a second conveyor belt, and the labor intensity of the operator is effectively reduced; and besides, with the dual action of hammering breaking and blade smashing, the smashing effect on the caked pig feed is better.

Owner:申亚生物科技股份有限公司

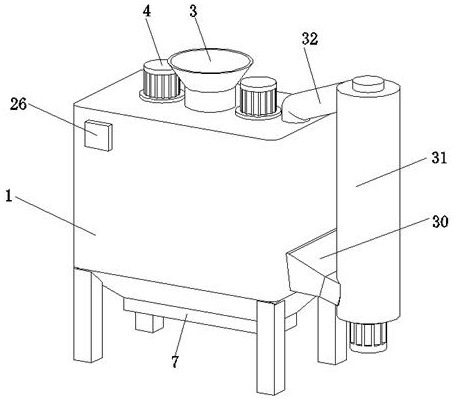

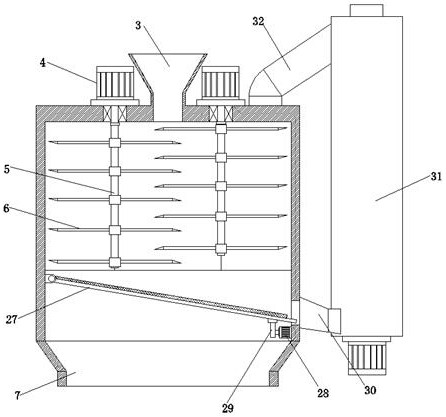

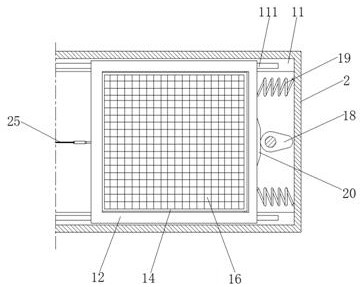

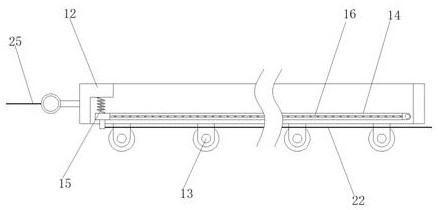

Secondary processing device for caking feed

ActiveCN112293772ASpeed up the sievingExcellent secondary processabilityFeeding-stuffDrying gas arrangementsProcess engineeringIdler-wheel

The invention relates to the technical field of feed processing, in particular to a secondary processing device for caking feed. The secondary processing device for the caking feed comprises a breaking barrel, a sieving box and a grinding barrel, wherein the front inner wall and the rear inner wall of the sieving box are independently provided with a horizontal cross bar; a rectangular frame is arranged above each horizontal cross bar; the lower surface of each rectangular frame is independently provided with idler wheels which move between left and right along a spacing groove; a sieving frame is arranged in each rectangular frame; the left end of the sieving frame and the rectangular frame are rotataly arranged; a first spring is connected between the right end of the sieving frame and the rectangular frame; and a screen mesh is arranged in the sieving frame. The whole device disclosed by the invention has an excellent secondary processing effect for the caking feed, the size of theprocessed feed can be guaranteed to be within a proper range, in addition, compared with the screening efficiency of a traditional screen mesh which is aslant arranged, the screening efficiency of thescreen mesh for feed discharged from the breaking barrel is higher, in addition, the caking feed which is not screened can be automatically added into the grinding barrel, and the secondary processing device disclosed by the invention has multiple functions, a high automation processing degree and an excellent secondary processing effect for the caking feed.

Owner:申亚生物科技股份有限公司

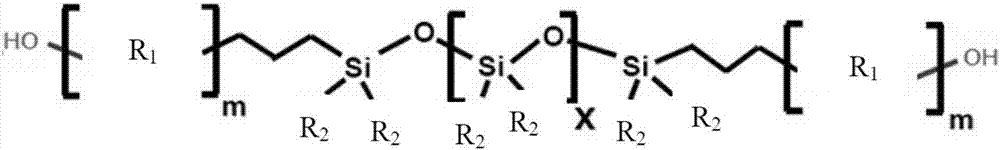

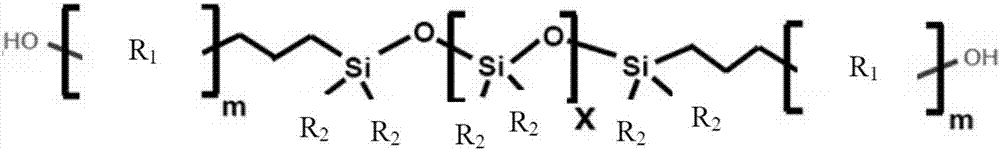

Polyurethane adhesive and use of the same

InactiveCN106905912AExcellent non-displacementImprove wetting adhesionAdhesive processesNon-macromolecular adhesive additivesPolymer sciencePolyurethane adhesive

A polyurethane adhesive is formulated using a modified polyurethane copolymer(A), a curing agent (B) and an antistatic agent(C), and the modified polyurethane copolymer (A)is grafted a polysiloxane compound to a polyurethane polymer and made by esterifying a polyol, a hydroxyl-containing polysiloxane compound, a multi-functional isocyanate compound and a fatty acid ester; since the polyurethane adhesive is not yellowish and easy to dry as well as has excellent fabricability, air bleeding performance and transparency, when attached to surfaces of an optical or electronic device, the protective film leaves no residue and protects the surface of the device keeping no flaws.

Owner:NANYA PLASTICS CORP

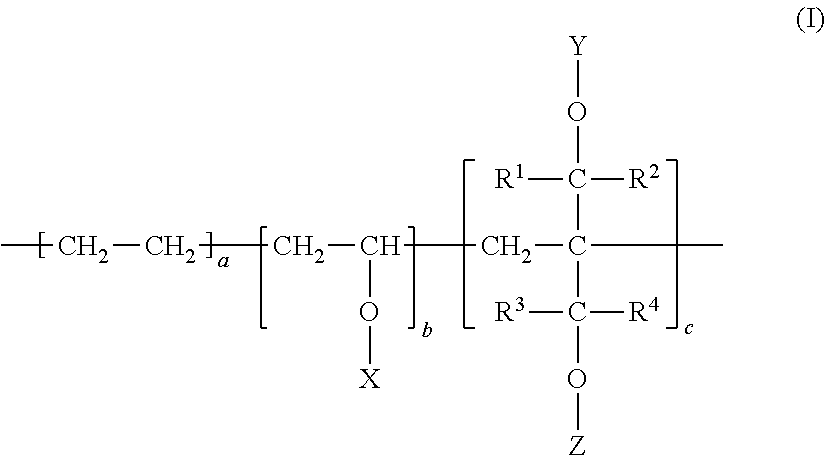

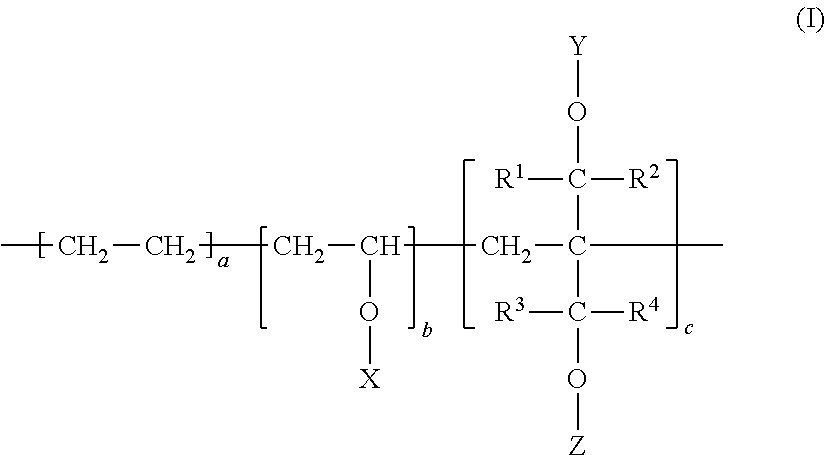

Ethylene-vinyl alcohol copolymer resin composition and method for producing same

ActiveUS20170183493A1Improve barrier propertiesImprove impact resistanceSynthetic resin layered productsDomestic containersPolymer scienceSaponification

A resin composition comprising a modified ethylene-vinyl alcohol copolymer (A) and an unmodified ethylene-vinyl alcohol copolymer (B), wherein the modified ethylene-vinyl alcohol copolymer (A) is represented by a following formula (I), contents (mol %) of a, b, and c based on the total monomer units satisfy following formulae (1) to (3), and a degree of saponification is not less than 80 mol %, thereby providing a resin composition that is excellent in a barrier property, impact resistance, and secondary processability and moreover excellent in productivity.18≦a≦55 (1)0.01≦c≦20 (2)[100−(a+c)]×0.9≦b≦[100−(a+c)] (3).

Owner:KURARAY CO LTD

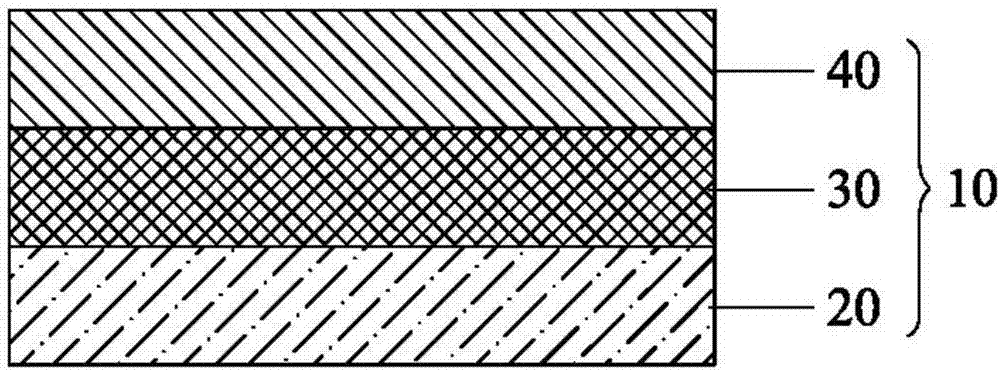

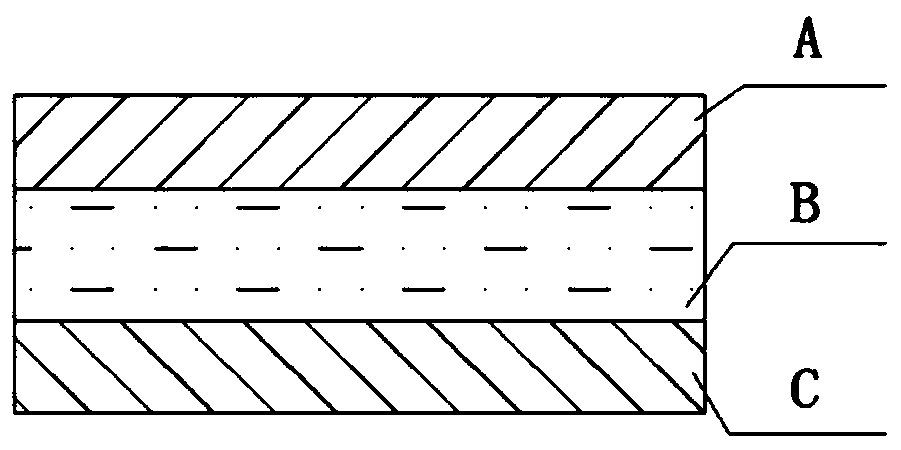

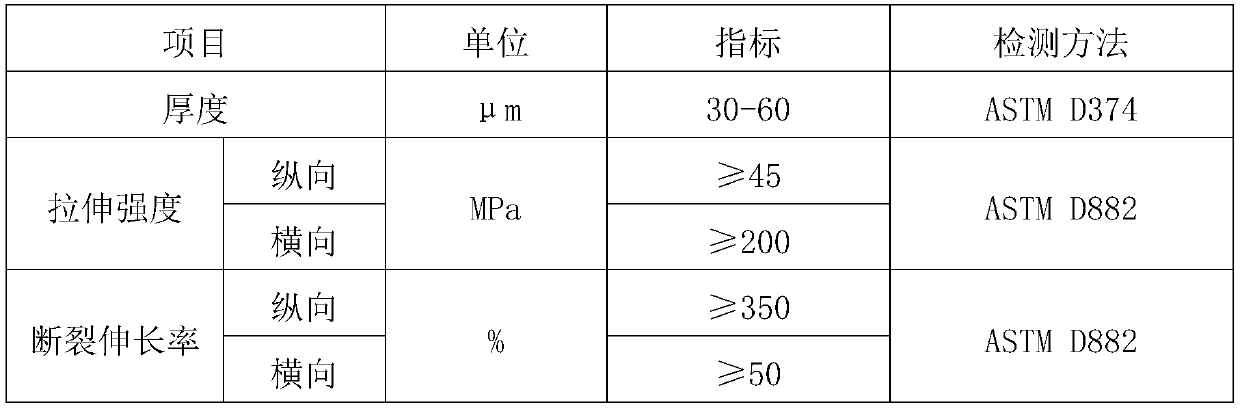

Heat-shrinkable PETG black and white composite film with light shielding performance

The invention relates to a heat-shrinkable PETG black and white composite film with light shielding performance. The film adopts an A-B-C structure, wherein the A layer is a printing layer and is madeof a mixture of PETG resin and an anti-blocking agent; the layer B is a white structural layer and is made of a mixture of PETG resin and a white additive; and the layer C is a black structure layerand is made of a mixture of PETG resin and a black additive. A preparation method comprises the following steps of: enabling the three materials to pass through three sets of extrusion and filtrationsystems to obtain three melts, converging the three melts to a T-shaped die head to extrude a cast sheet, and carrying out a two-way stretching, shaping, traction and winding process to prepare the heat-shrinkable PETG black and white composite film. According to the invention, the problem of short shelf life of the product caused by the fact that an existing common PETG transparent film cannot block infrared rays, visible light, ultraviolet rays and the like is effectively solved, so that costs of production, transportation, storage and the like of dairy products, lactic acid bacteria products, et. are greatly reduced.

Owner:河南银金达新材料股份有限公司

ABS recycled plastic modified particles

The invention discloses an ABS recycled plastic modified particle. The ABS recycled plastic modified particles are prepared from 65-75% of ABS recycled material, 15-25% of new ABS material, 10-15% of PVC resin, 5-10% of SBS resin, 10-20% of PC resin, 2-4.5% of plasticizer, 1.5-2.5% of heat stabilizer, 0.5-1.5% of lubricant and 5-7.5% of filler in percentage by weight. The invention provides the ABS recycled plastic modified particles, namely the plastic particles formed by modifying the recycled material; the ABS recycled plastic modified particles can be applied to manufacturing plastic traveling case plates instead of partial new ABS material; besides, the secondary processability can be improved, the yield can be increased and the cost can be reduced; as a result, the ABS recycled plastic modified particles have wide economic and social benefits.

Owner:苏州市涵信塑业有限公司

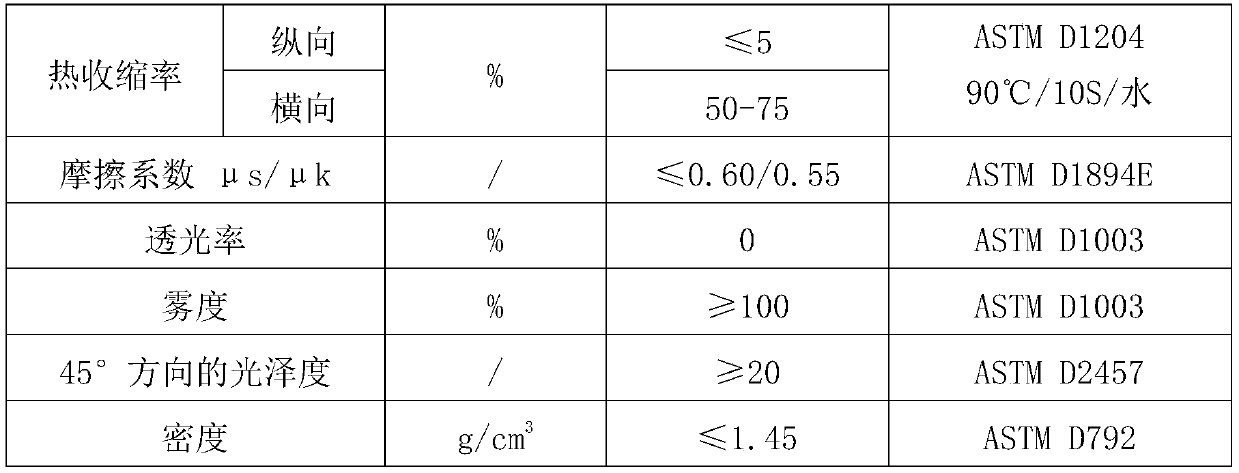

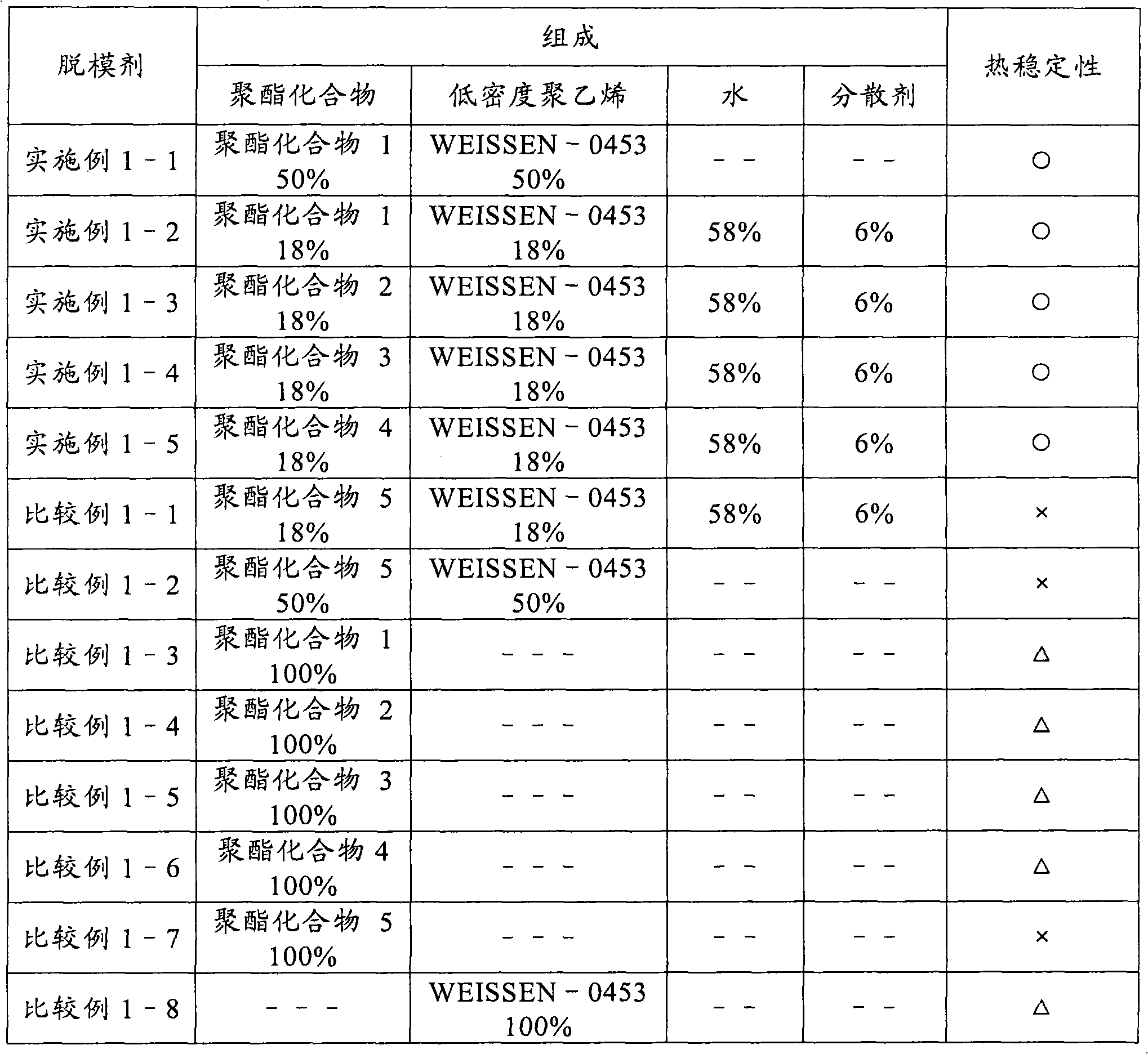

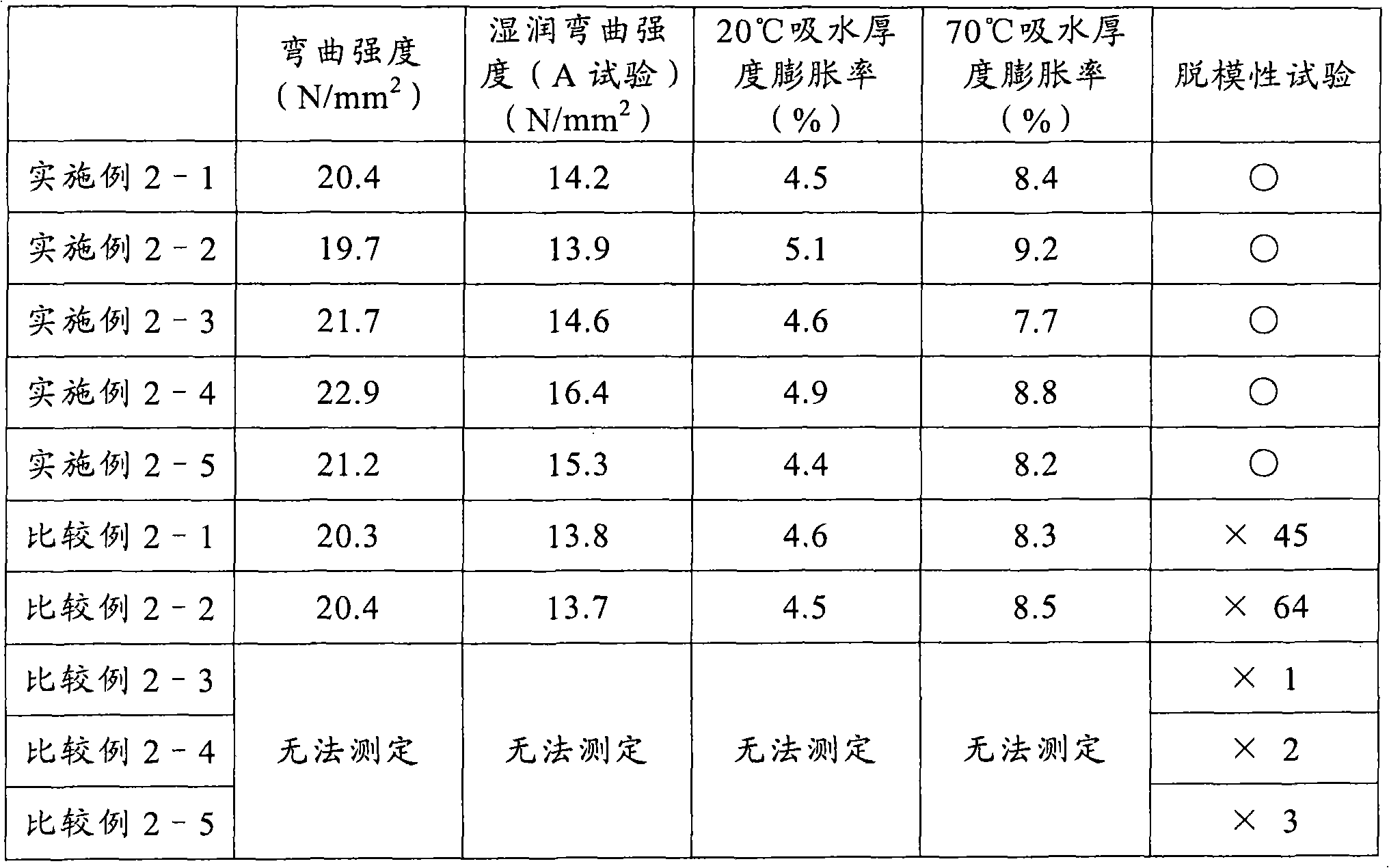

Mold release agent composition for thermocompression molding and process for producing board

ActiveCN101827910AStable manufacturingEasy to demouldOther chemical processesPolyureas/polyurethane adhesivesLow-density polyethylenePolyester

A mold release agent composition, or adhesive, capable of permanent mold release of a board containing any of lignocelluloses and an inorganic material easily from a hot platen in thermocompression molding, excelling in not only mold release capability and productivity but also heat resistance realizing an extremely low possibility of thermal deterioration on the hot platen; and a process for producing therewith a board through thermocompression molding of a molding material containing any of lignocelluloses, which board excels in secondary processability, water absorption swell ratio and flexural modulus. The mold release agent compositionis characterized by containing (I) polyester compound produced through reaction of (A) polyhydric alcohol, (B) dibasic acid and (C) saturated fatty acid in a molar proportion such that (A):(B):(C) = 1 : 0.5 to 1 : 2 to 3 and (II) low-density polyethylene in a weight ratio such that (I):(II) = 1:4 to 4:1.

Owner:MITSUI CHEM & SKC POLYURETHANES INC

Modification preparation method of high-thermal-conductivity mica paper

InactiveCN111549567AMedium intensityGuaranteed electrical performancePlastic/resin/waxes insulatorsReinforcing agents additionElectric power equipmentHeat stability

The invention discloses a modification preparation method of high-thermal-conductivity mica paper. The modification preparation method comprises the steps: treating a mica raw material into coarse slurry and fine slurry; then, taking a mixture of nano BN and nano-scale silicon compound powder as a filler, adding a mixture aqueous solution of cationic starch, ethylenediamine tetraacetic acid and pentabromophenol to prepare a filler solution; mixing the filler solution with para-aramid chopped fibers modified by a silane coupling agent, carrying out ultrasonic dispersion, carrying out papermaking molding between a coarse slurry layer and a fine slurry layer of mica paper, and carrying out dehydration and drying to obtain the high-thermal-conductivity mica paper. The high-thermal-conductivitymica paper has excellent mechanical strength, dielectric breakdown strength and high thermal conductivity stability when applied to power equipment such as large and medium-sized high-voltage generators and motors.

Owner:湖南睿达云母新材料有限公司

PVC (Polyvinyl Chloride) building template and preparation method thereof

The invention discloses a PVC (Polyvinyl Chloride) building template, which comprises the following raw materials in parts by weight: 22 to 35 parts of chlorinated polyethylene, 12 to 18 parts of filler, 0.1 to 0.3 part of aluminum titanate coupling agent, 50 to 80 parts of polyvinyl chloride, 20 to 30 parts of straw fiber powder, 1 to 3 parts of aluminium hydroxide, 0.8 to 1.8 parts of zinc borate, 1 to 3 parts of stabilizer, 0.5 to 1 part of ultraviolet screening agent, 0.5 to 1 part of antioxidant, and 0.5 to 1 part of antibacterial agent. Compared with an existing PVC building template in the market, the PVC building template provided by the invention has higher hardness and elasticity modulus, good shock strength, heat resistance, weather fastness and acid and alkali corrosion resistance and favorable stability, is free of deformation and warping, light in self-weight and convenient to construct, has favorable secondary fabricability, high repeating utilization ratio and long service life, and is worth popularizing since a product can be recycled and reused.

Owner:六安三创建筑材料有限公司

High-insulativity capacitor mica paper and preparation method thereof

ActiveCN111395052AImprove insulation performanceEasy to usePlastic/resin/waxes insulatorsSpecial paperCellulosePaper based

The invention discloses a high-insulativity capacitor mica paper and a preparation method thereof. The mica paper comprises a mica paper base material, and the surface of the mica paper base materialis subjected to surface roughening treatment; a reinforced mica paper layer is formed on the surface of the roughened part of the mica paper base material, and is formed by hot-pressing a reinforced mica slurry layer on the surface of the mica paper base material for molding; the reinforced mica slurry layer takes refined mica slurry as a base material, the slurry is added into a conductive fillersolution and stirred uniformly to prepare a precursor slurry, nanofibrillated cellulose aerogel and nanoscale titanium dioxide particles are mixed according to a mass ratio of 3:1 to serve as reinforcing filler, then the reinforcing filler is modified through a silane coupling agent KH550, and then the modified reinforcing filler is evenly mixed with the precursor slurry to obtain the high-insulativity capacitor mica paper. The mica paper is good in insulativity, stable in performance and high in strength at the same time.

Owner:湖南睿达云母新材料有限公司

Active energy ray-curable resin composition and cured article thereof

The present invention provides an active energy ray-curable resin composition that exhibits high close-adhesiveness and excellent wear resistance even under high temperature and high humidity without virtually any warping when cured by ultraviolet rays, electron beam, or other active energy ray, and that has secondary processability such as excellent molding after curing. This active energy ray-curable composition is characterized by containing: a urethane resin having a plurality of acrylate groups or methacrylate groups; at least one amide or amide derivative selected from those having an ethylenic double bond; at least one bifunctional acrylate or bifunctional methacrylate selected from those having a cyclic skeleton containing no carbon-carbon double bond; a photopolymerization initiator; and a polymer containing no ethylenic double bond. This active energy ray-curable composition is characterized if furthermore characterized in that the polymer containing no ethylenic double bond dissolves in at least one amide or amide derivative selected from those having an ethylenic double bond.

Owner:TAIYO INK MFG

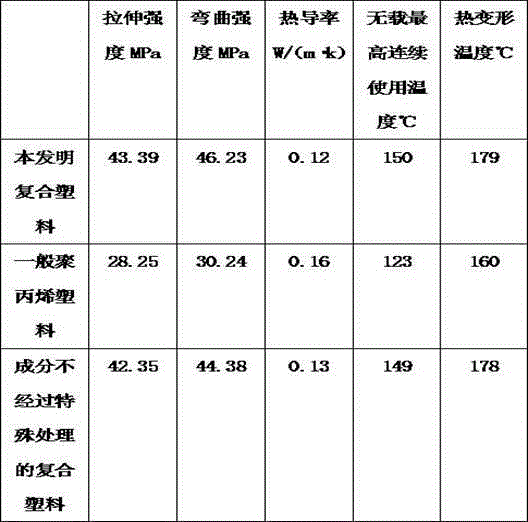

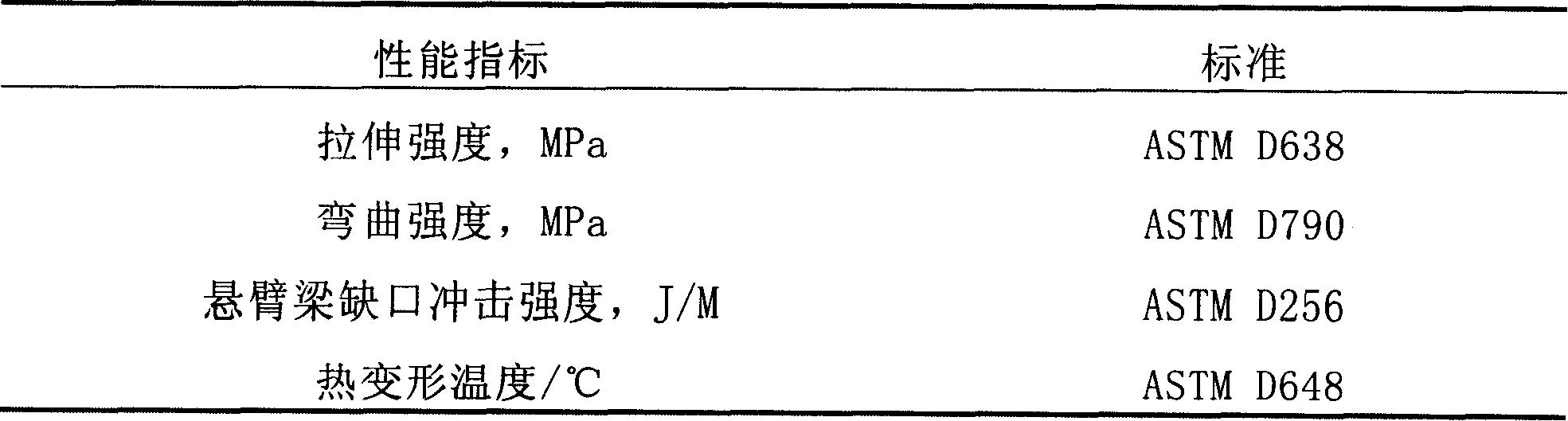

Novel modified composite plastic

The invention discloses novel modified composite plastic which is prepared from polypropylene, thermoplastic styrene-butadiene rubber, a silicon powder and aluminum powder mixture, phenolic resin, a bentonite and kaolin mixture, sodium acrylate, bamboo powder, bauxite, aluminum nitride, a dispersing agent, a plasticizer and a heat stabilizer. The novel modified composite plastic is stable in mass and good in mechanical, physical and chemical property. By adding the silicon powder and aluminum powder mixture, the heat resistance of the composite plastic is greatly improved, and the structure is improved; by means of mixing pretreatment of the phenolic resin and the aluminum nitride, plastic ingredients are more uniform; by adding the bentonite and kaolin mixture, the weather resistance of the composite plastic is greatly improved, and the secondary processing performance is improved; during processing and preparation, the polypropylene and the sodium acrylate are mixed and added to a double-screw extruder at first, accordingly, the integration between the polypropylene and other ingredients can be improved, the structural quality of plastic is improved, and the service life of the plastic is prolonged.

Owner:QUANJIAO XIANGRUI PLASTIC

Polymer matrix composite and preparation method thereof

InactiveCN106189012ASolve thermal conductivitySolve insulation problemsLayered product treatmentLaminationStable statePolymer science

The invention provides a polymer matrix composite which comprises a polymer matrix and nano-scale metal fillers, wherein the nano-scale metal fillers comprise nano-scale metal fibers and nano-scale metal grains; the nano-scale metal fibers and the nano-scale metal grains are under stable state through surface modified treatment; the nano-scale metal fillers are scattered in the polymer matrix; in the polymer matrix composite, the weight percent of the polymer matrix is 85-97% and the weight percent of the nano-scale metal fillers is 3-15%; the sum of the weight percent of the polymer matrix and the nano-scale metal fillers is 100%; in the nano-scale metal fillers, the mass ratio of nano-scale metal fibers to nano-scale metal grains is (1-3):1. The polymer matrix composite provided by the invention can effectively promote the heat conduction property of the composite, can achieve the purpose of maintaining low dielectric loss characteristic and can greatly increase the thermal and electric properties of the polymer matrix composite.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

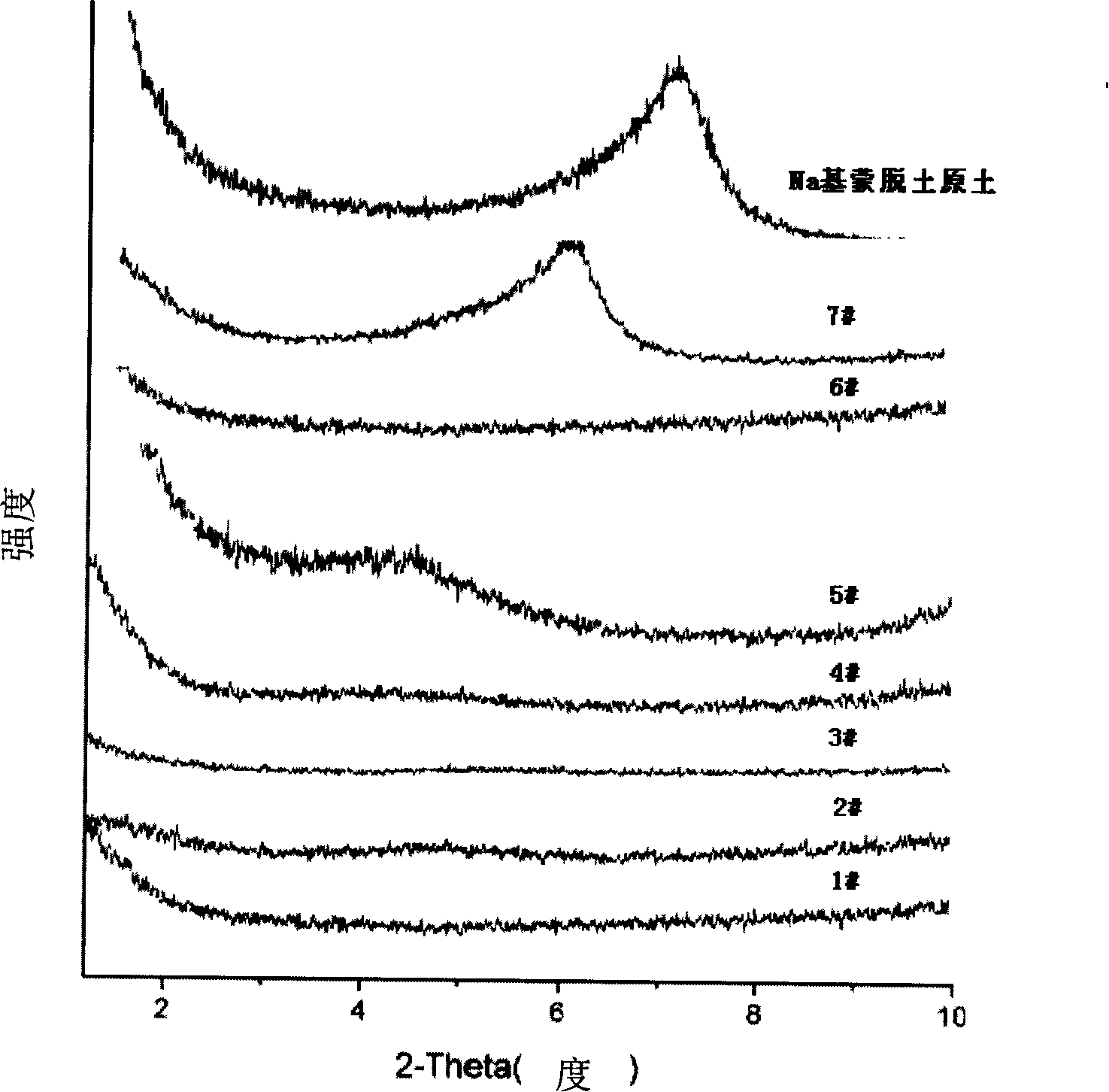

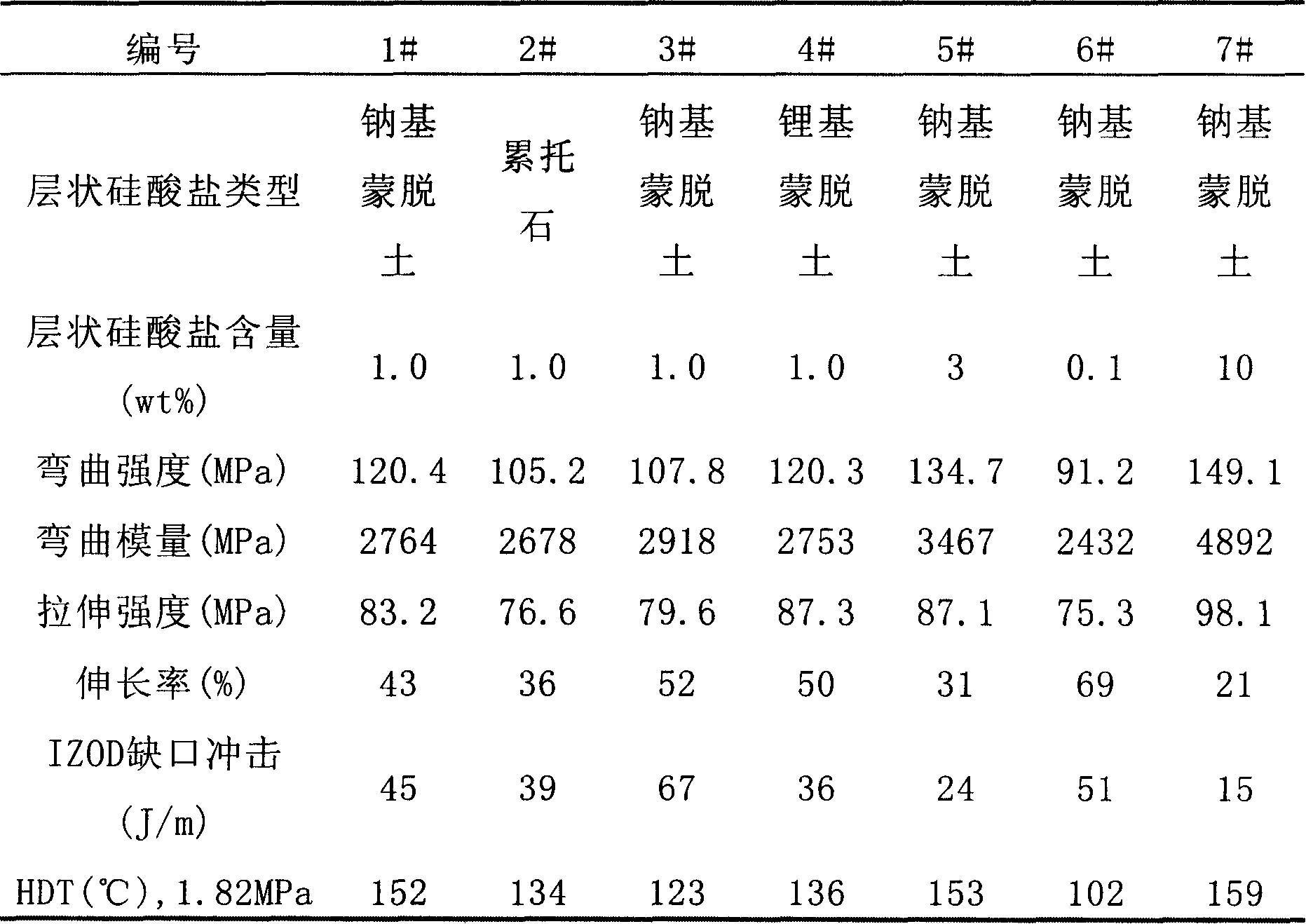

Nylon66/phyllosilicate nano composite material and preparation method thereof

The present invention provides a nylon 66 / layer-shaped silicate nanometer composite. The raw materials of the nanometer composite comprise 0.1 to 10 weight portions of layer-shaped silicate raw bentonite and 99.9 to 90 weight portions of nylon 66 salts. The present invention also provides a preparation method of the nanometer composite. The nylon 66 / layer-shaped silicate nanometer composite material of the present invention does not contain organic small molecule, and the preparation method of the present invention does not require any organized disposal to ensure that the layer-shaped silicate is peeled off well and dispersed uniformly.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

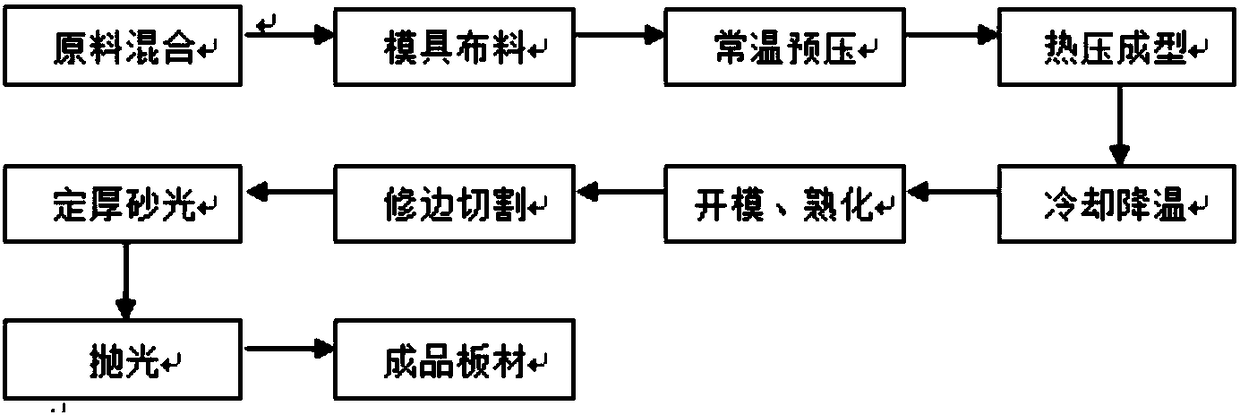

Preparation method of light weight panel

InactiveCN108069727ADensity dense and uniformNo toxicityCeramic shaping plantsCeramicwareHigh humidityMicrosphere

The invention provides a preparation method of a light weight panel. The preparation method of the light weight panel comprises the following steps of mixing the following raw materials in parts by weight: 10 to 20 parts of waste stone materials, 50 to 70 parts of microsphere particles, 10 to 20 parts of cement, and 6 to 8 parts of thermosetting phenolic resin powder so as to obtain a raw materialmixture; paving the raw material mixture, pre-pressing, hot-pressing, curing molding, cooling, and opening a mould to obtain a light weight panel blank body. The panel prepared by adopting the preparation method provided by the invention is dense and uniform in material, rich in color, uniform in color, higher strength and hardness, better in secondary processability without containing water, extra low in water absorption, and free of shrinkage and buckling deformation in a high-temperature high-humidity environment.

Owner:北京禾木之家科技发展有限公司

Method for preparing wood plastic composite material from waste printed circuit boards

Owner:SHANGHAI JIAOTONG UNIV

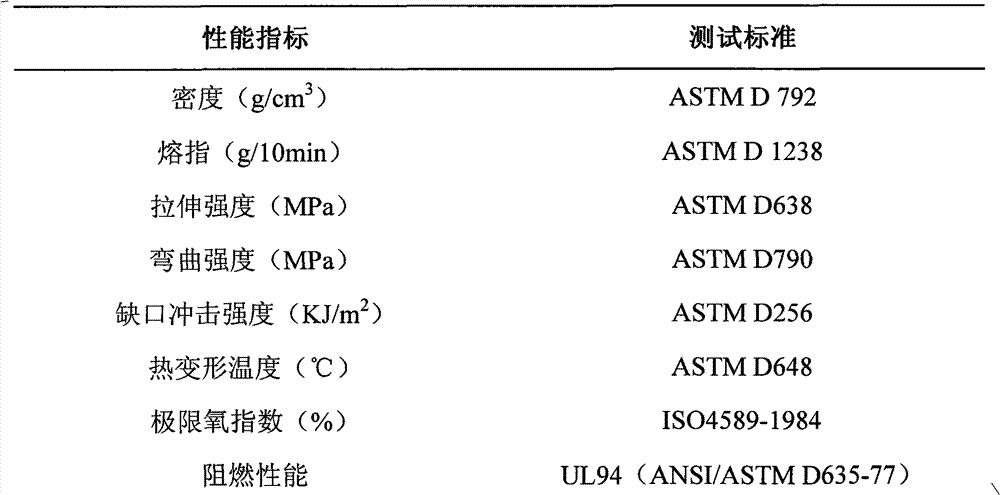

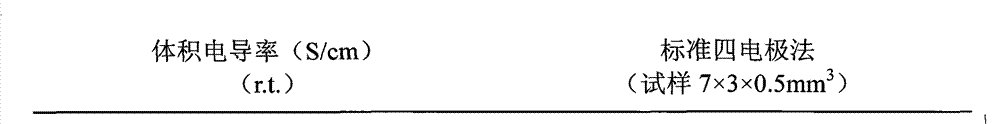

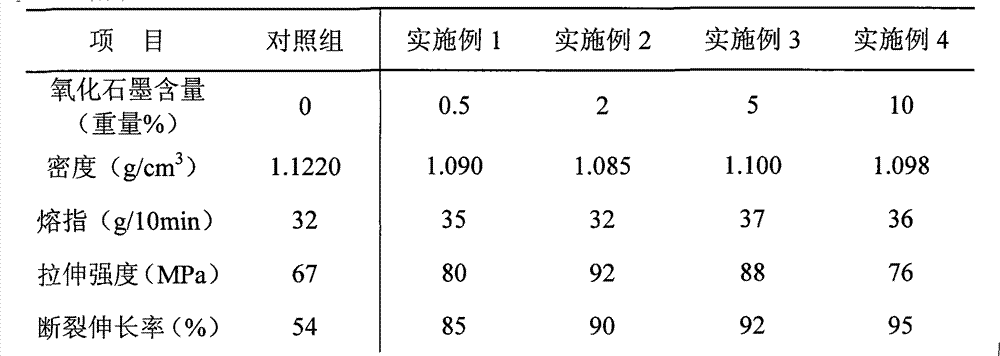

Method for preparing nylon 6/graphite oxide nanocomposite

The invention relates to a method for preparing a nylon 6 / graphite oxide nanocomposite. In the method, caprolactam is adopted for in situ hydrolysis and ring-opening polymerization to prepare the nylon 6 / graphite oxide nanocomposite, so that caprolactam monomers are easy to perform in-situ intercalative polymerization to dissociate a graphite oxide lamella, and the dispersing uniformity of the graphite oxide lamella in a polymer substrate is improved; and the composite prepared has better conductivity and high-efficiency flame retardancy. The nylon 6 substrate is converted from an insulator to a semiconductor and the flame retardant rating can reach V-0 rating of a UL94 standard, and the integral good mechanical property of the material per se is maintained simultaneously. The method has the advantage of simple and effective process; the conductivity and flame retardancy of the obtained composite are obviously improved; the material has good secondary-working character; an additive graphite oxide does not pollute the environment; and the nylon 6 / graphite oxide nanocomposite has wide application range.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com