Production technique and device of polylactic acid PLA sheet material

A production process, polylactic acid technology, applied in the production process and equipment field of polylactic acid PLA sheet, can solve problems that are easily overlooked or underestimated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

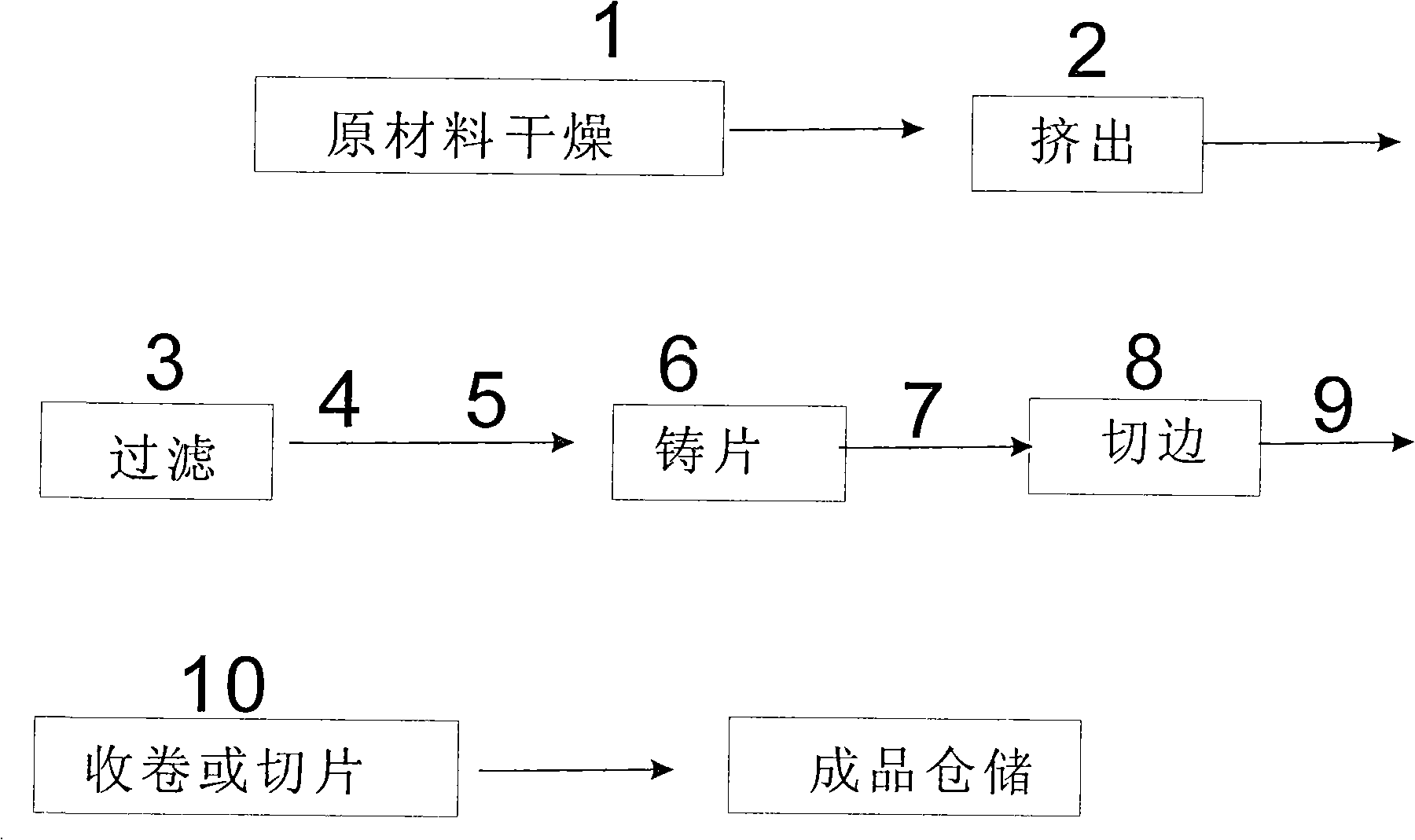

[0017] Specific embodiment one: processing polylactic acid PLA sheet material production process flow described in the present invention, the first step raw material polylactic acid PLA resin drying, raw material enters the dehumidification drier (1) drying that molecular sieve is housed, makes the water content of raw material reach Process requirements, drying process conditions are: the temperature of the drying air is between 80°C and 130°C, and the dew point of the drying air is between -20°C and 55°C. In the second step of extrusion, the dried raw material enters the extruder (2) to be heated and plasticized, and is fully melted and plasticized in the barrel of the extruder, and the extruded is a molten fluid; in the third step of filtration, the melt is filtered The net (3) filters out impurities and infusibles in the melt; then the melt is pumped to the distributor and die head evenly and continuously through the melt pump (4); the fourth step is "casting", melting The...

specific Embodiment approach 2

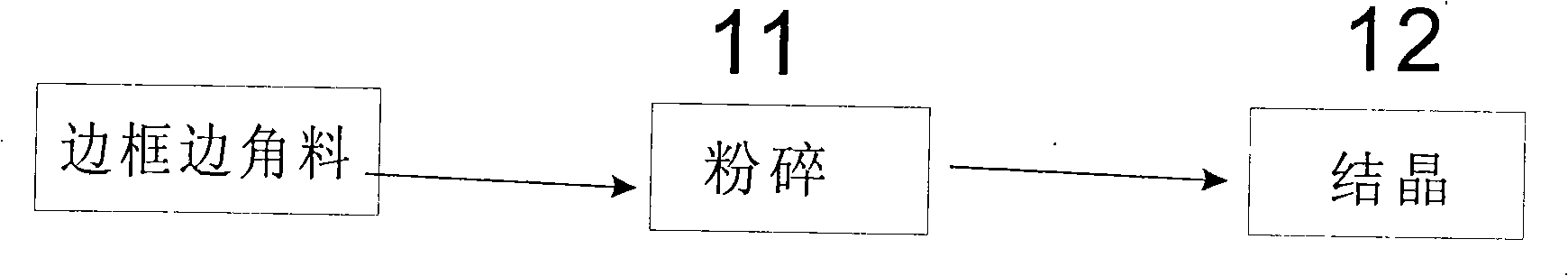

[0018] Specific implementation mode two: in the implementation process of the whole production process, a certain amount of polylactic acid PLA sheet scraps are produced, and unqualified products and frame materials will also be produced during the secondary thermoforming process, and these frame scraps are crushed and reused. Since these frame scraps are amorphous, they must be crystallized before they are put into drying to improve their heat resistance to meet the requirements of the drying process. The crystallization process flow is as follows: recycle frame scraps into a pulverizer (11) for pulverization, the pulverized material enters a crystallizer (12) equipped with a stirrer, and is heated by hot air for crystallization. The temperature of the crystallization process is 80°C-120°C, and then enters the process flow of the specific embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com