Polylactic acid sheet material and production equipment thereof

A polylactic acid and polylactic acid resin technology, applied in the field of manufacturing and plasticizing molding materials, can solve the problems that polylactic acid sheets are not easy to form and process, and achieve the effect of excellent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

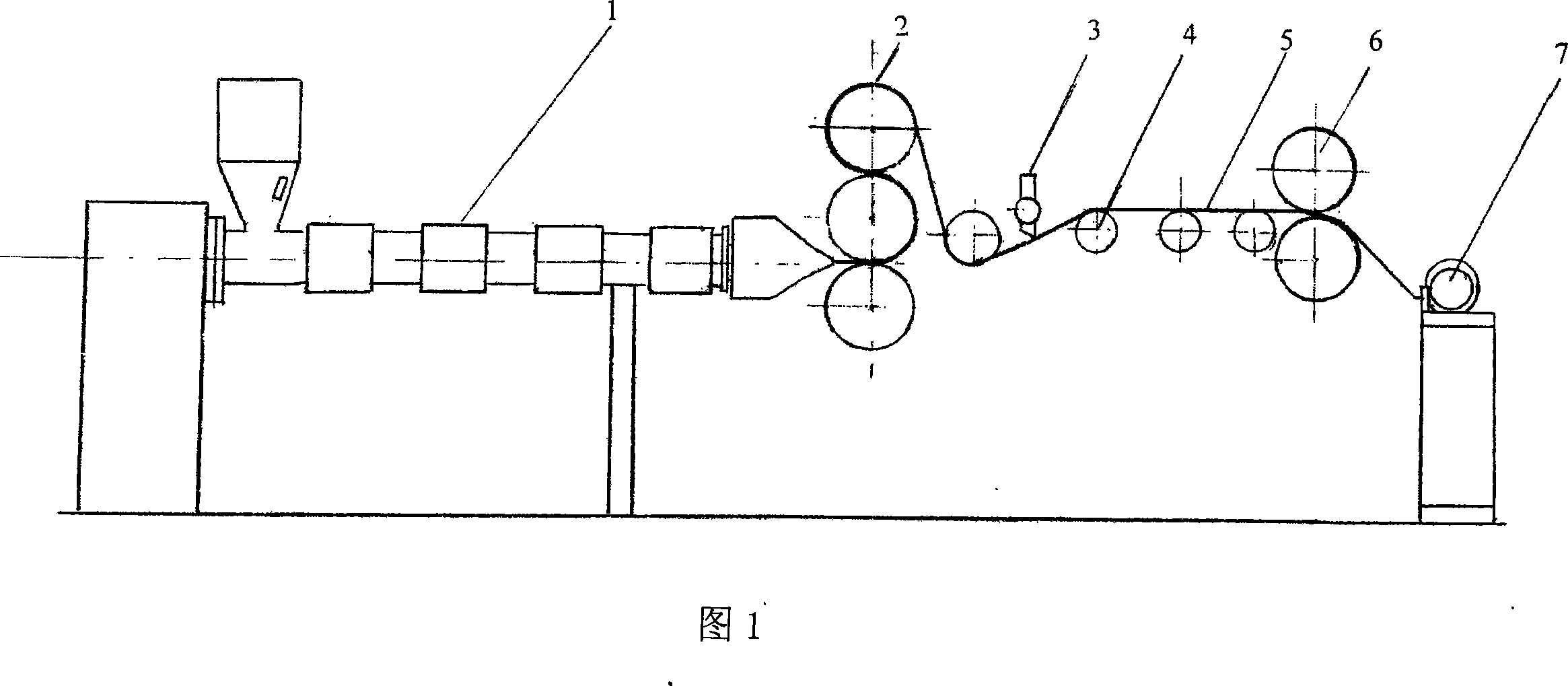

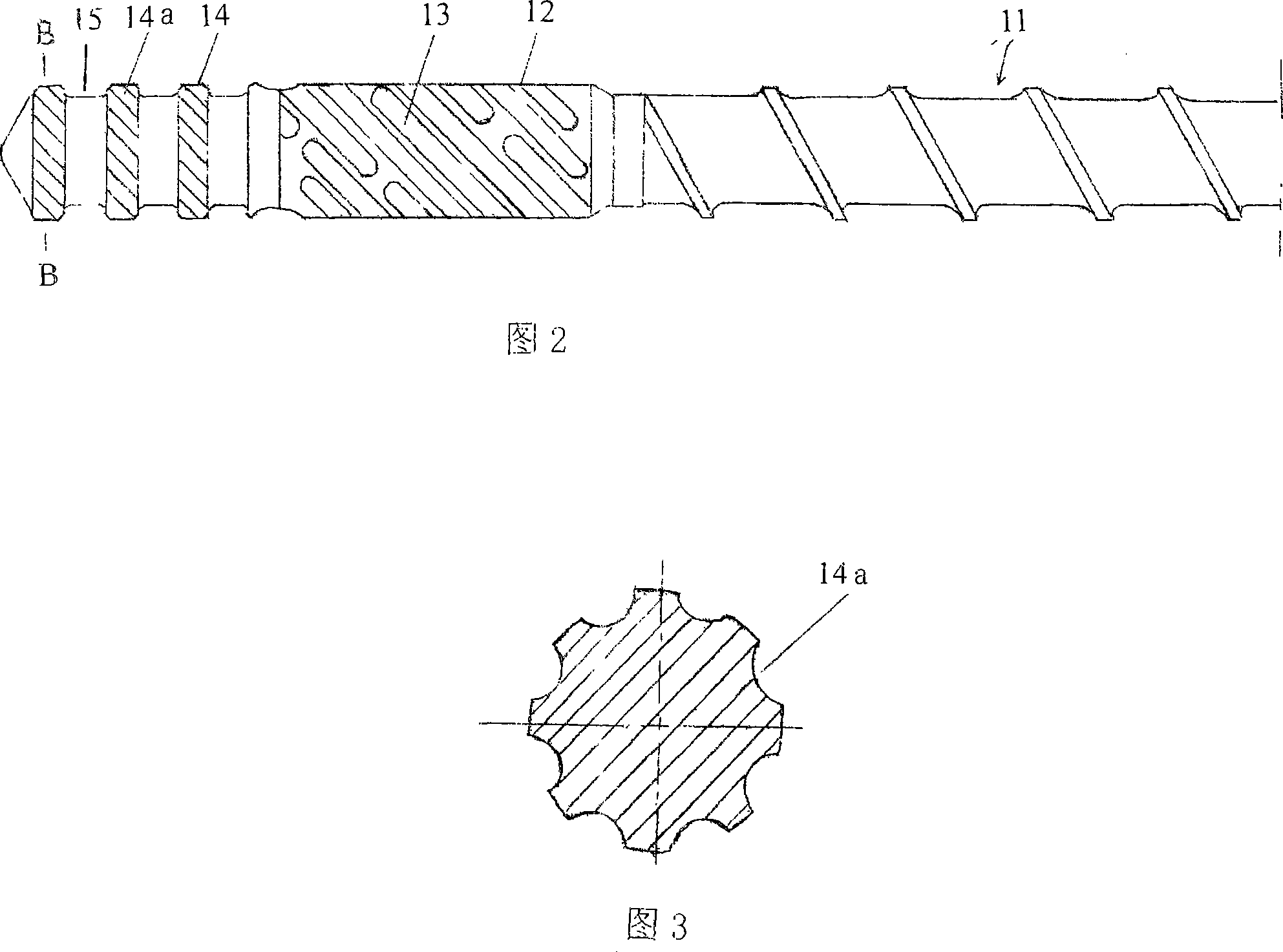

[0039] Figure 2 is a schematic diagram of the screw. Fig. 3 is a sectional view of Fig. 2B-B. As shown in Fig. 2 and Fig. 3, the screw rod 11 is a barrier type screw rod, and in front of the barrier type screw rod 11 thread, that is, on the left side of the thread in Fig. The axis forms a certain angle, and between the barrier section 12 and the top of the screw, there are three radially parallel grooves 15 that are equally spaced toward the center of the screw, and the three protruding rings 14 beside the groove 15 are all 10 mm wide. 5 mm high, the outer peripheral surface of the convex ring 14 is formed with 12 evenly distributed shallow grooves 14a that are sunken into the center of the convex ring, and the center line of the shallow grooves 14a forms a certain angle with the axis of the convex ring 14. The shape is circular, and the width and depth of the shallow groove are determined by the raw materials and products. In this embodiment, the shallow groove has a width ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com