Mold release agent composition for thermocompression molding and process for producing board

A technology of hot press forming and release agent, which is applied in the field of plate manufacturing, can solve the problems of difficult manufacturing performance and failure to meet the requirements, and achieve excellent secondary processability and high productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

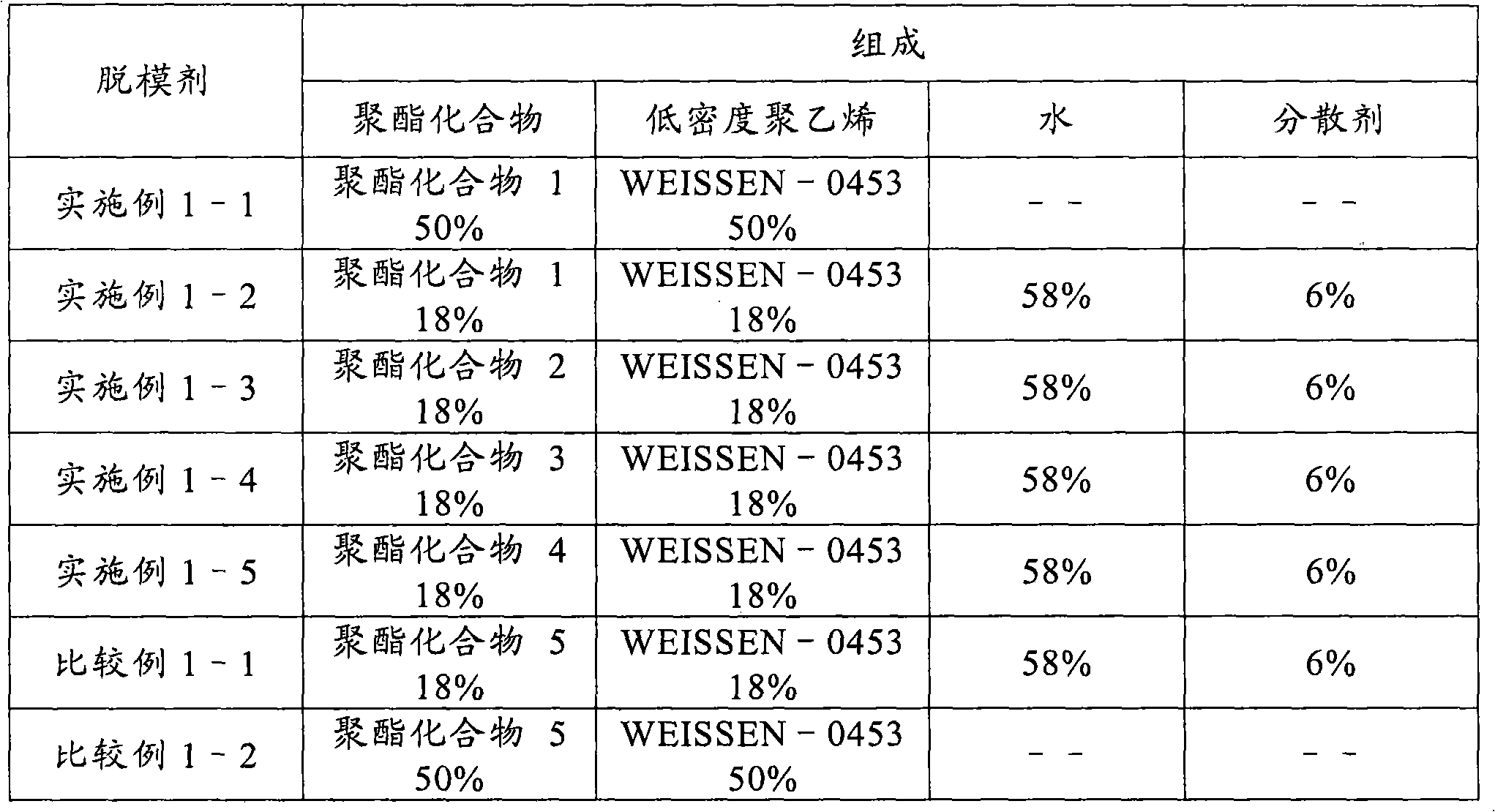

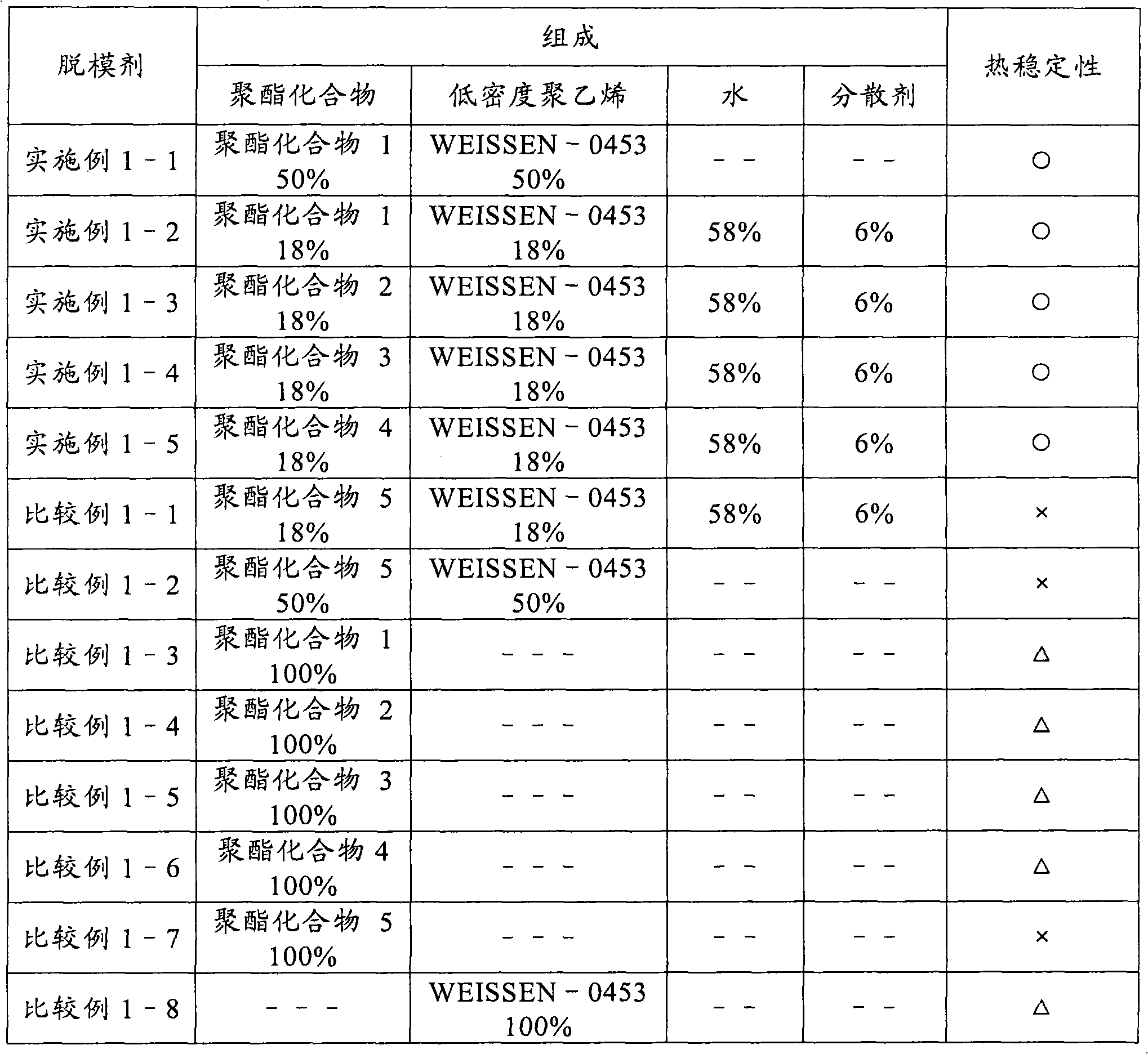

[0075] In Example 1, the manufacture and thermal stability of the release agent composition of the present invention will be described together with Comparative Examples.

[0076] (Preparation of polyester compound)

[0077] Mix polyhydric alcohol, dibasic acid, and saturated fatty acid with the contents in Table 1, use tetra-n-butyl orthotitanate as a catalyst, and make it react at a reaction temperature of 160-200° C. and a reaction time of 8-10 hours to obtain the compounds listed in Table 1. Polyester compounds 1-4 of the present invention are shown. The viscosity and number average molecular weight of the polyester compound were measured, and the results are shown in Table 1.

[0078] In addition, the situation of polyester compound 5 used for comparison is also shown in Table 1.

[0079] (test methods)

[0080] Viscosity...Viscosity at 120°C based on JIS K6662

[0081] Number average molecular weight: Molecular weight in terms of monodisperse polystyrene by gel perme...

Embodiment 2

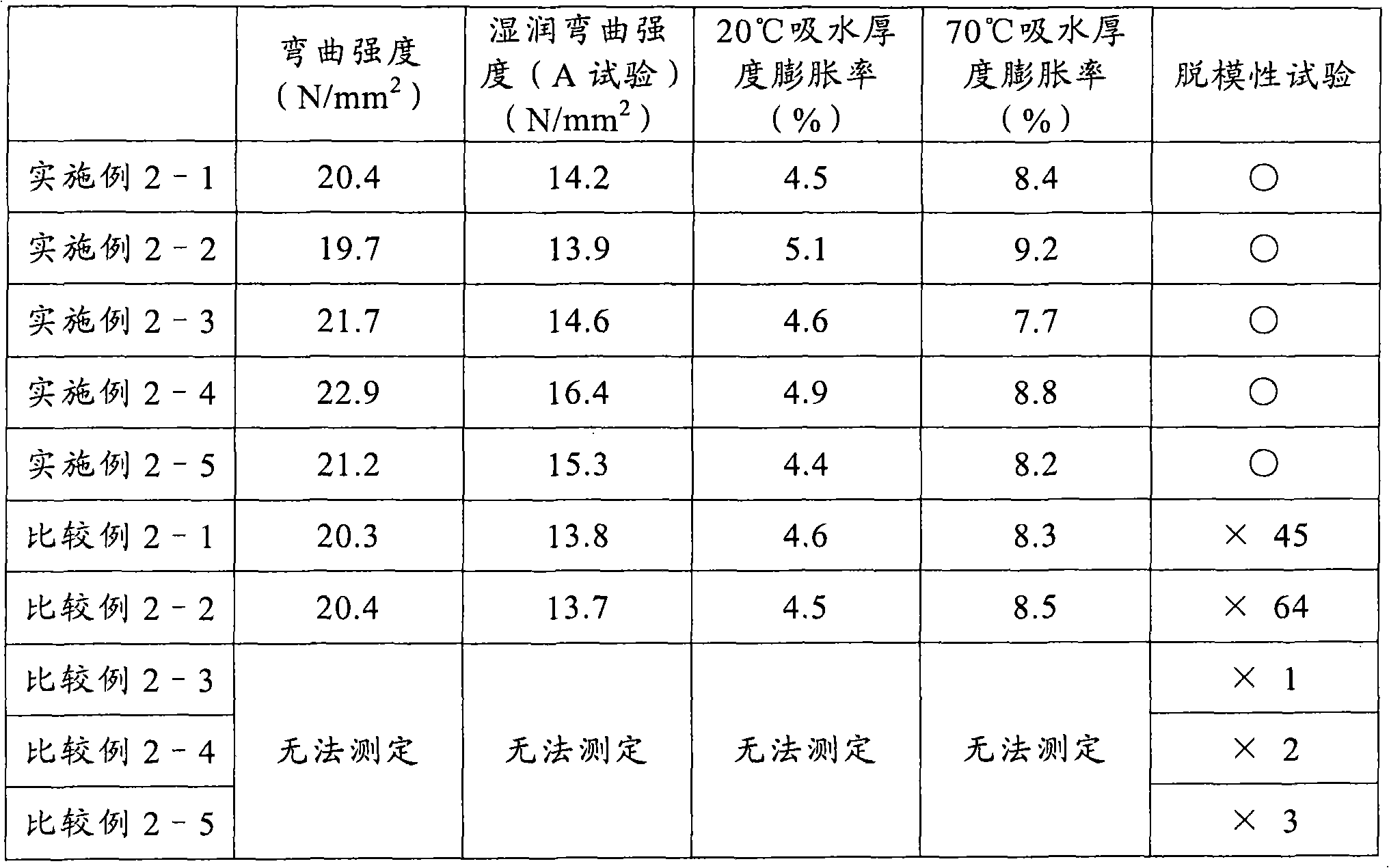

[0097] Panels were produced using the release agent composition produced in Example 1. Hereinafter, an example thereof will be described.

[0098] (board manufacturing conditions)

[0099] The production conditions of the board for performance evaluation will be described below.

[0100] Raw materials: fine chips (sawdust-like wood chips for the surface layer), strip-shaped chips (strip-like wood chips for the core layer), and brown asbestos are adjusted to a moisture content of 3% respectively

[0101] Set thickness: 18mm

[0102] Hot pressing temperature: 210°C

[0103] Pressurized pressure: 3.0MPa

[0104] Pressurization time: 4 minutes

Embodiment 2-1

[0106] Weigh an organic polyisocyanate (trade name Cosmonate M-50W manufactured by Mitsui Takeda Chemical Co., Ltd.) in an amount of 10% relative to the solid content of the fine chips, and mix the moisture content of the slab (mat) with respect to the solid content of the fine chips. Water in an amount up to 12%, and a release agent in an amount of 0.3% as an internal release agent based on the active ingredients of the release agent composition obtained in Example 1-2 were sprayed using a spray gun. on fine crumbs in a blender. Weigh the sprayed shavings so that the board density after molding is 0.75, so that it can be evenly molded to a size of 40cm×40cm on a steel tray, which is uniformly used as an external release agent on a tray at 150°C in advance. It is obtained by applying the release agent composition obtained in Example 1-1 and cooling it; and then covering the steel tray, and performing hot pressing under the above-mentioned plate manufacturing conditions, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com