Microporous laminated membrane and method for producing the same

A technology for porous membranes and laminates, applied in separation methods, chemical instruments and methods, membranes, etc., can solve problems such as inability to ensure strength, and achieve the effects of sufficient strength, excellent air permeability, and high surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0155] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited by these examples. Tape peeling test, measurement of average pore diameter, measurement of average opening ratio (porosity) inside porous membrane, air permeability test, high temperature storage test, measurement of arithmetic average surface roughness Sa (surface roughness), measurement of tensile strength The measurement was performed by the following method.

[0156] (Tape Peeling Test)

[0157] (i) The following adhesive tape was pasted on the surface of the porous film of the porous film laminate, and the following roller was pressed against the bonded portion to press-bond the tape.

[0158] (ii) Using the following universal tensile testing machine, T-peeling was performed on the condition of 50 mm / min.

[0159] (iii) The presence or absence of peeling at the interface between the porous film and the heat-resistant nonwoven fabric bas...

manufacture example 1

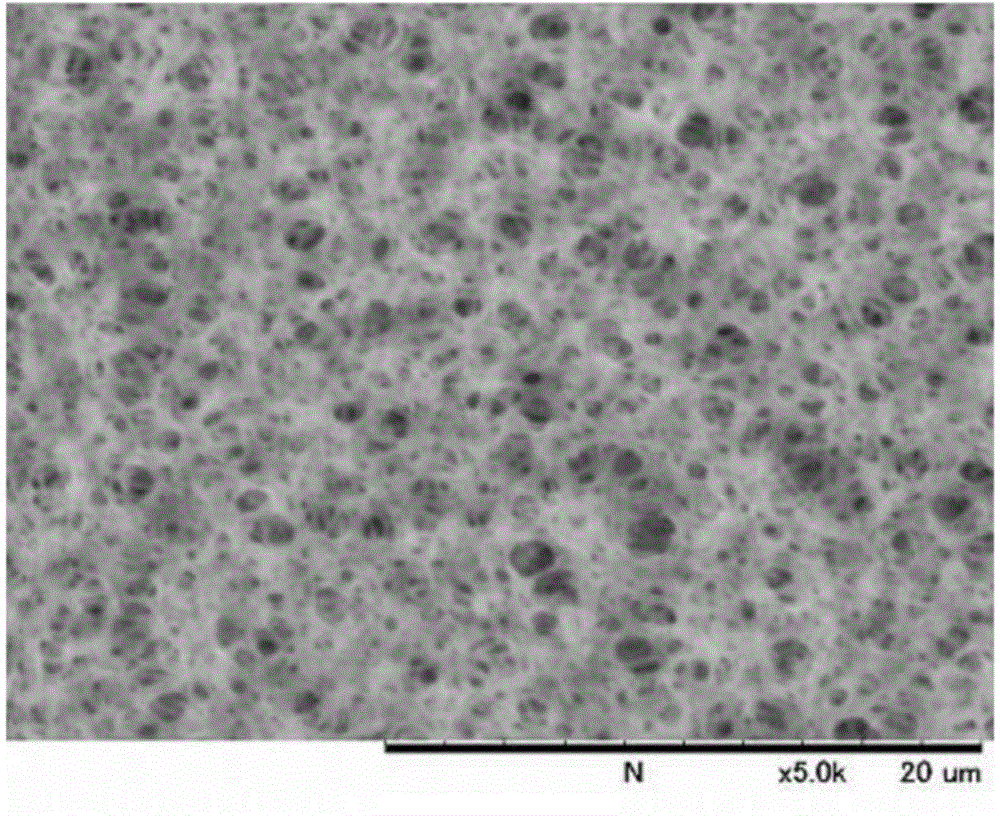

[0182] Add to 100 parts by weight of polyamide-imide resin solution (trade name "VYLOMAX (バイロマックス) HR11NN" manufactured by Toyobo Co., Ltd.; solid content concentration 15% by weight, solvent NMP, solution viscosity 20dPa·s / 25°C) 35 parts by weight of polyvinylpyrrolidone (molecular weight: 55,000) is used as a water-soluble polymer to make a film-forming stock solution. A Teijin DuPont PET film (thickness 100 μm: trade name "HS74AS") was placed on a glass plate as a base material with the easy-adhesive side facing upward, and the stock solution maintained at 25°C was cast on the PET film using a film coater. film. During casting, the gap between the film coater and the PET film was 51 μm. After casting, it was quickly kept in a container at a humidity of about 100% and a temperature of 50° C. for 4 minutes. Thereafter, when immersed in water, solidified, and washed, the porous film was naturally peeled off from the PET film.

[0183] A porous film was obtained by natural d...

manufacture example 2

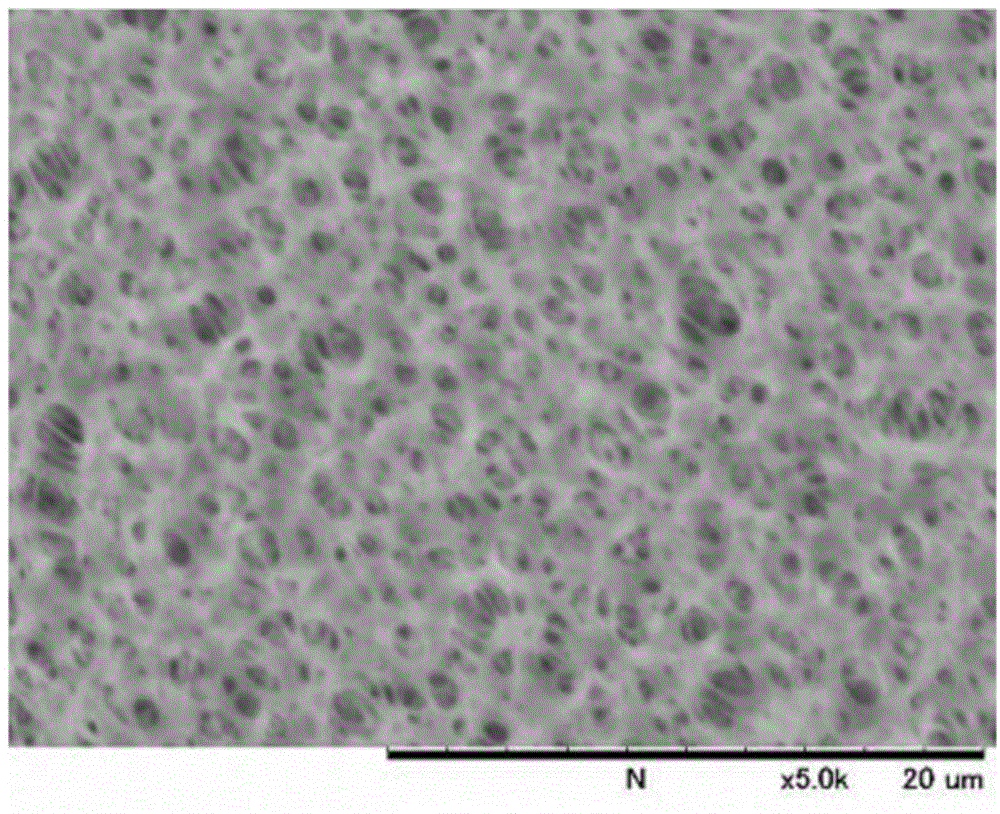

[0185] Polyvinylpyrrolidone (molecular weight: 55,000) was added to 100 parts by weight of polyetherimide resin solution (manufactured by GE Plastic in Japan, trade name "ULTEM (ultem) 1000P"; solid content concentration 18% by weight, solvent NMP) 30 Parts by weight are used as a water-soluble polymer to make a film-forming stock solution.

[0186] A Teijin DuPont PET film (thickness 100 μm: trade name “HS74AS”) was placed on a glass plate as a base material with the easy-adhesive side facing upward, and the stock solution maintained at 25° C. was cast on the glass plate using a film coater. on PET film. During casting, the gap between the film coater and the PET film was 51 μm. After casting, it was quickly kept in a container at a humidity of about 100% and a temperature of 50° C. for 4 minutes. Thereafter, the porous film was naturally peeled off from the PET film when it was immersed in water to solidify and washed. A porous film was obtained by natural drying at room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com