Polyurethane adhesive and use of the same

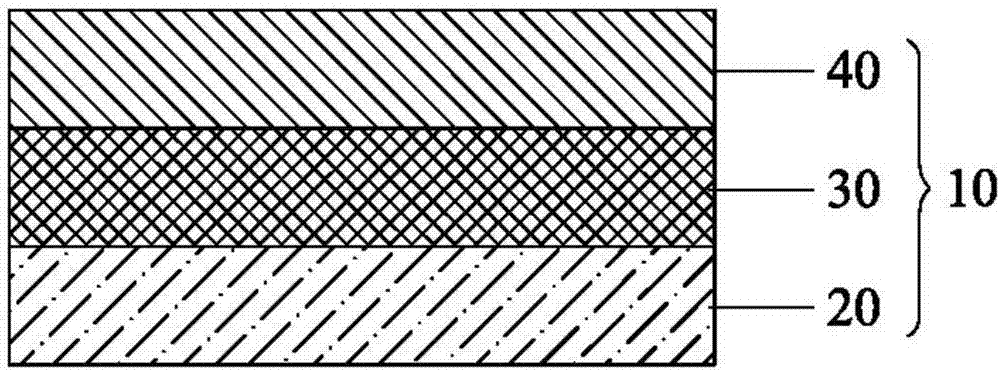

A polyurethane and adhesive technology, applied in the direction of polyurea/polyurethane adhesive, adhesive type, film/sheet adhesive, etc., to achieve excellent non-displacement, excellent resistance Static electricity, easy entanglement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

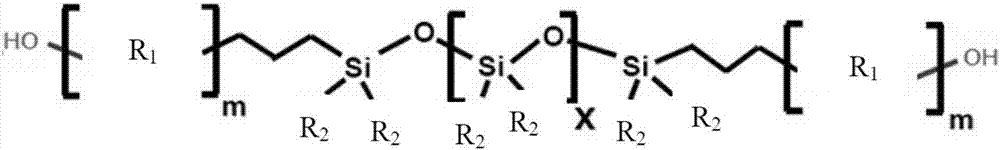

[0113] As shown in Table 1, 50 parts by weight of polyol DL3000 (polyoxypropylene glycol (polyoxypropylene glycol), referred to as PPG, Mn=3000) containing 2 OH functional groups, 30 parts by weight of polyol containing 2 OH groups Polyol Kuraray Polyol P-5010 (3-methyl-1,5-pentanediol is polyester diol (Poly[(3-methyl-1,5-pentanediol)-alt-(adipic acid)]), Mn=5000), 15 parts by weight of polyol PC3000 (polycarbonate polyol, Mn=3000) containing 3 OH groups, 8 parts by weight of polyether silicone oil SF 8427 (DOW CORNING company) containing 2 OH groups 150 parts by weight of ethyl acetate is put into the reactor as a diluting solvent, and 15 parts by weight of fatty acid ester (isopropyl palmitate, Mn=299) is added, and 11 parts by weight of isocyanate is added when the temperature rises and stirs up to 50°C Compound HDI (hexamethylene diisocyanate), after reacting for 30 minutes, add a small amount of catalyst, after reacting for 30 minutes, add the remaining 5 parts by weight...

Embodiment 2

[0116] The same method as in Example 1, but the polyether silicone oil is changed to polyether silicone oil CS3505, the fatty acid ester is changed to isopropyl myristate, and the amount of antistatic agent is changed to 0.04 parts by weight of Ionic liquid IL-P14 and 0.2 parts by weight of anionic antistatic agent EF15. The performance of the prepared surface protection film was tested, and the results are shown in Table 1.

Embodiment 3

[0118] With the method for making of embodiment 1, but polyether silicone oil is changed to use polyether silicone oil KF-6001 (Shin-Etsu Company), and, the consumption of antistatic agent is changed to use the ionic liquid IL-P14 that comprises 0.45 parts by weight and 2.25 parts by weight of anionic antistatic agent EF15. The performance of the prepared surface protection film was tested, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com