Adhesive agent composition for attaching to polarizing plate

A composition and adhesive technology, applied in the direction of adhesive type, graft polymer adhesive, film/sheet adhesive, etc., can solve problems such as uneven color and peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

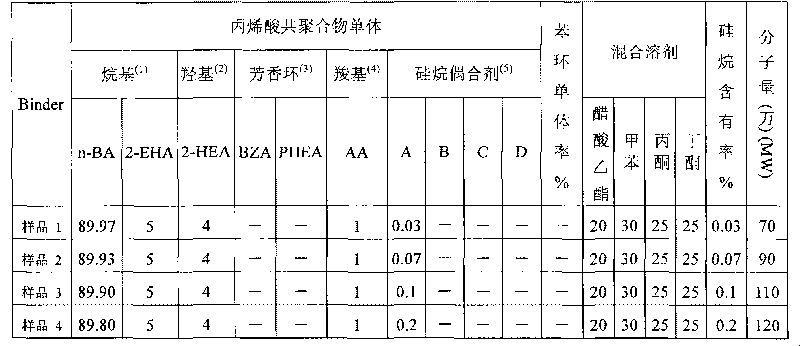

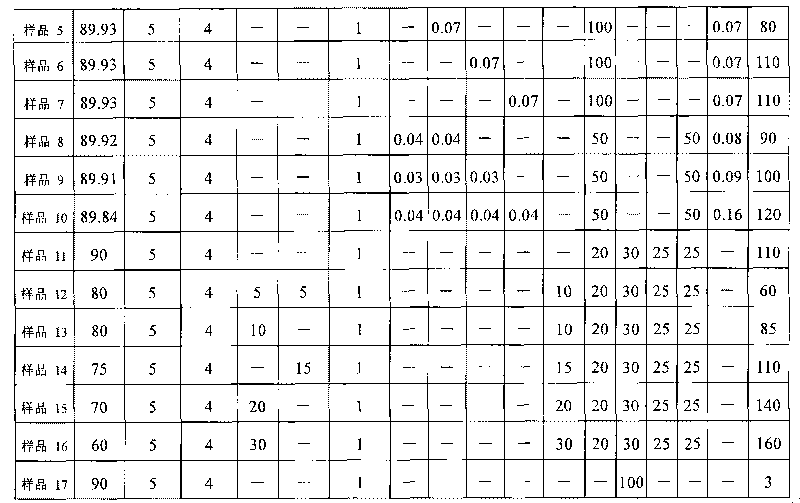

[0106] Take the solid content in the numbered sample 1 acrylic polymer solution of Table 1 as 100 parts by weight, add 0.2 parts by weight of an isocyanate crosslinking agent (sourced from Nanya Plastic Industry Co., Ltd., trade name CL isocyanate crosslinking agent) After stirring together evenly, prepare the adhesive composition solution of this embodiment.

[0107] The adhesive composition solution was coated on the surface of a 38 μm polyester film with peeling treatment, and dried to obtain an adhesive sheet having an adhesive layer with a thickness of 25 μm. The adhesive sheet was pasted on one side of the polarizing film, and aged for 7 days under the conditions of temperature 23° C. and humidity 65% RH to obtain an optical member.

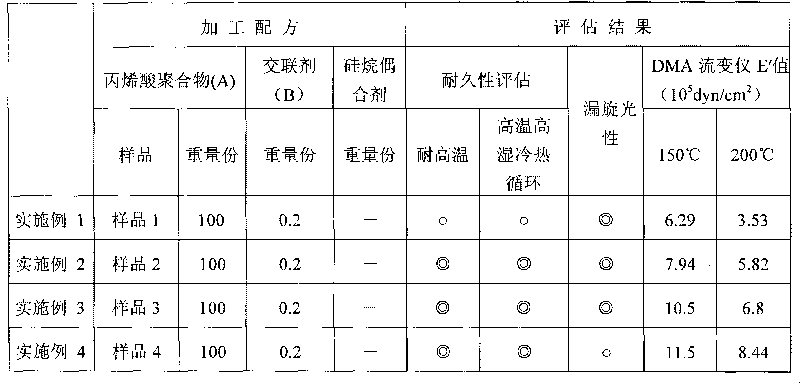

[0108] The optical components were evaluated for high temperature resistance durability, high temperature and high humidity cooling and heating cycle durability, leak-proof optical rotation and elastic modulus of rheometer, and the evalua...

Embodiment 2

[0110] Take the solid content of the numbered sample 2 in Table 1 as 100 parts by weight, add 0.2 parts by weight of the isocyanate-based crosslinking agent as in Example 1 and stir evenly, then prepare a solution of the adhesive composition.

[0111] Similar to the steps in Example 1, the obtained optical components were evaluated for high-temperature durability, high-temperature, high-humidity cold-heat cycle durability, leak-proof optical rotation, and elastic modulus of the rheometer. The evaluation results are shown in Table 2.

Embodiment 3

[0113] Take the solid content of the numbered sample 3 in Table 1 as 100 parts by weight, add 0.2 parts by weight of the isocyanate-based crosslinking agent as in Example 1, stir well, and prepare a solution of the adhesive composition.

[0114] Similar to the steps in Example 1, the obtained optical components were evaluated for high-temperature durability, high-temperature, high-humidity cold-heat cycle durability, leak-proof optical rotation, and elastic modulus of the rheometer. The evaluation results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com