Non-uniform thickness bamboo chip integrated plate and production technology method thereof

A production process, non-equal thickness technology, applied in wood processing equipment, chemical instruments and methods, layered products, etc., can solve the problems of large internal stress, high cost, and easy deformation of bamboo, and achieve good secondary processability, The effect of low product cost and small internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

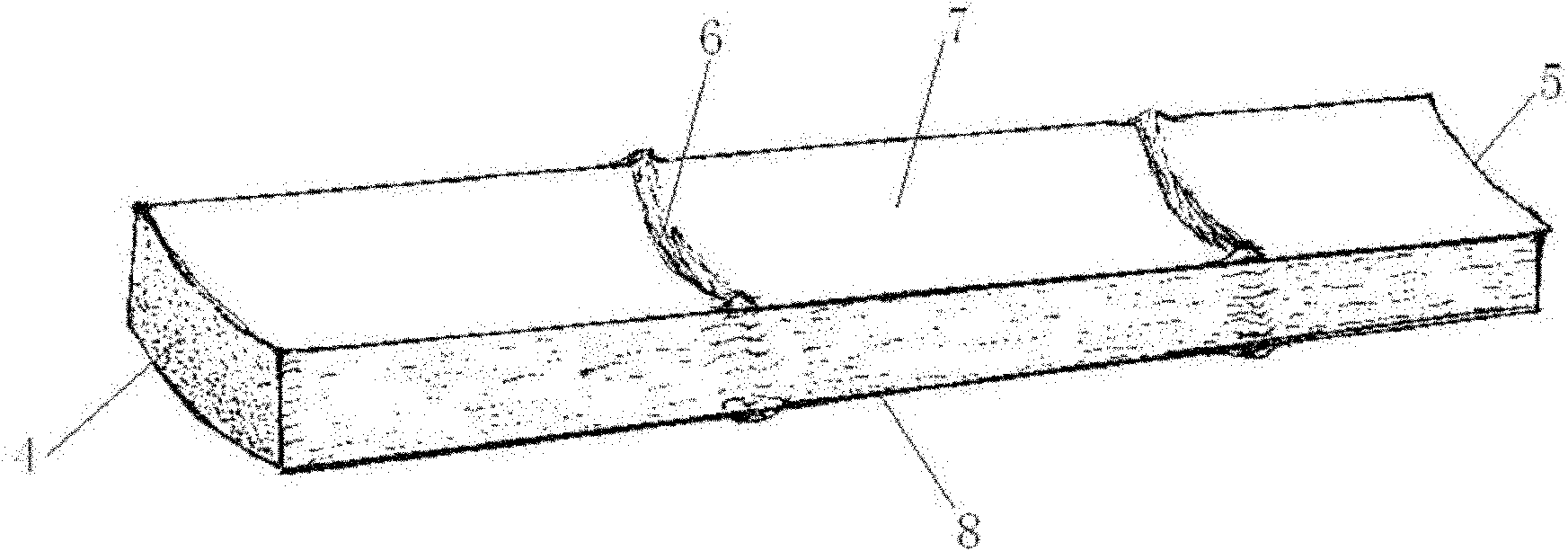

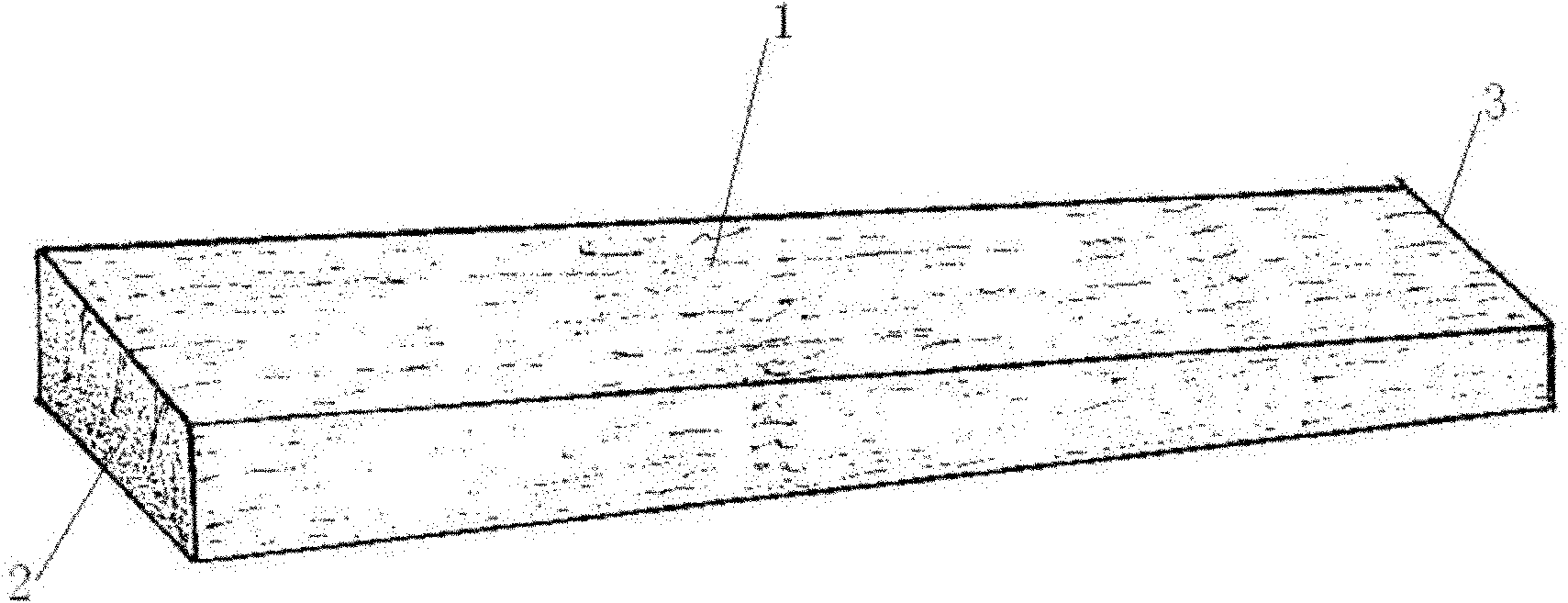

[0037] Making non-equal-thickness bamboo slice unit: First, saw moso bamboo over four years old and above eight-inch diameter class into a bamboo tube with a length of 980mm, and then cut the bamboo tube longitudinally into original arc-shaped bamboo slices with a width of 12mm, such as figure 1 As shown, the end of the bamboo stalk 4 is thick, and the end of the bamboo tail 5 is thin. Use a bamboo unfolding and milling machine to process it into planar bamboo slices, mill out the bamboo inner nodes 6, and then use a floating milling cutter to mill the bamboo yellow layer 7 and bamboo green layer 8 according to the tip of the bamboo to make the thickness of both ends Inconsistent bamboo unit body 1, the thickness of the thick end 2 of the bamboo unit body 1 is 5mm, the thickness of the thin end 3 is 3mm, the width is 12mm, and the length is 980mm, such as figure 2 shown.

[0038] Bundle the above-mentioned non-equal-thickness bamboo slice unit into small bundles, steam or ca...

Embodiment 2

[0040] Making non-equal-thickness bamboo slice unit: First, saw moso bamboo over four years old and above eight-inch diameter class into a bamboo tube with a length of 1850 mm, and then cut the bamboo tube longitudinally into original arc-shaped bamboo slices with a width of 19 mm, such as figure 1 As shown, the end of the bamboo stalk 4 is thick, and the end of the bamboo tail 5 is thin. Use a bamboo unfolding and milling machine to process it into planar bamboo slices, mill out the bamboo inner nodes 6, and then use a floating milling cutter to mill the bamboo yellow layer 7 and bamboo green layer 8 according to the tip of the bamboo to make the thickness of both ends Inconsistent bamboo unit body 1, the thickness of the thick end 2 of the bamboo unit body 1 is 8mm, the thickness of the thin end 3 is 5mm, the width is 19mm, and the length is 1850mm, such as figure 2 shown.

[0041] Bundle the above-mentioned non-equal-thickness bamboo slice unit into small bundles, steam o...

Embodiment 3

[0043]Making non-equal-thickness bamboo slice unit: firstly, moso bamboo over four years old and above eight-inch diameter class is sawed into a bamboo tube with a length of 2600 mm, and then the bamboo tube is longitudinally cut into original arc-shaped bamboo slices with a width of 26 mm, such as figure 1 As shown, the end of the bamboo stalk 4 is thick, and the end of the bamboo tail 5 is thin. Use a bamboo unfolding and milling machine to process it into planar bamboo slices, mill out the bamboo inner nodes 6, and then use a floating milling cutter to mill the bamboo yellow layer 7 and bamboo green layer 8 according to the tip of the bamboo to make the thickness of both ends Inconsistent bamboo unit body 1, generally, the thickness of the thick end 2 of the bamboo unit body 1 is 11mm, the thickness of the thin end 3 is 7mm, the width is 26mm, and the length is 2600mm, such as figure 2 shown.

[0044] Bundle the above-mentioned non-equal-thickness bamboo slice unit into s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com