Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Excellent resistance to sulfuration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

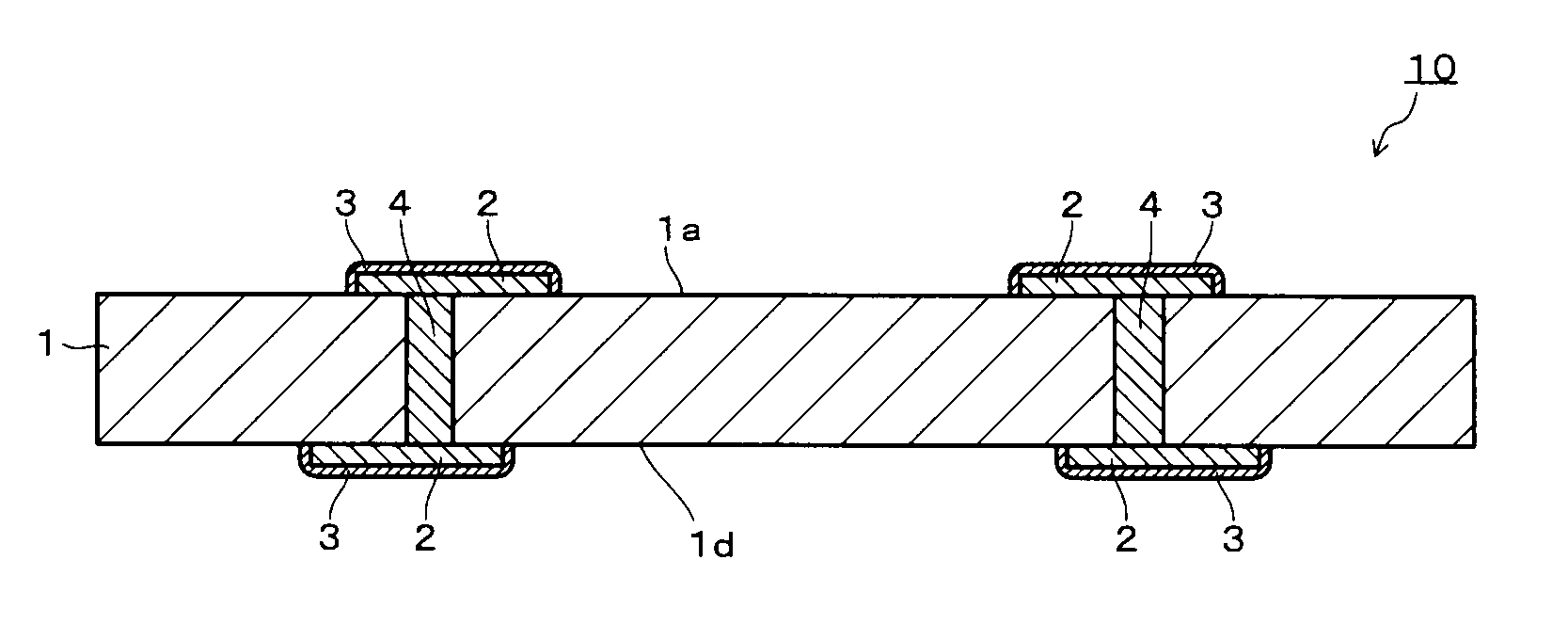

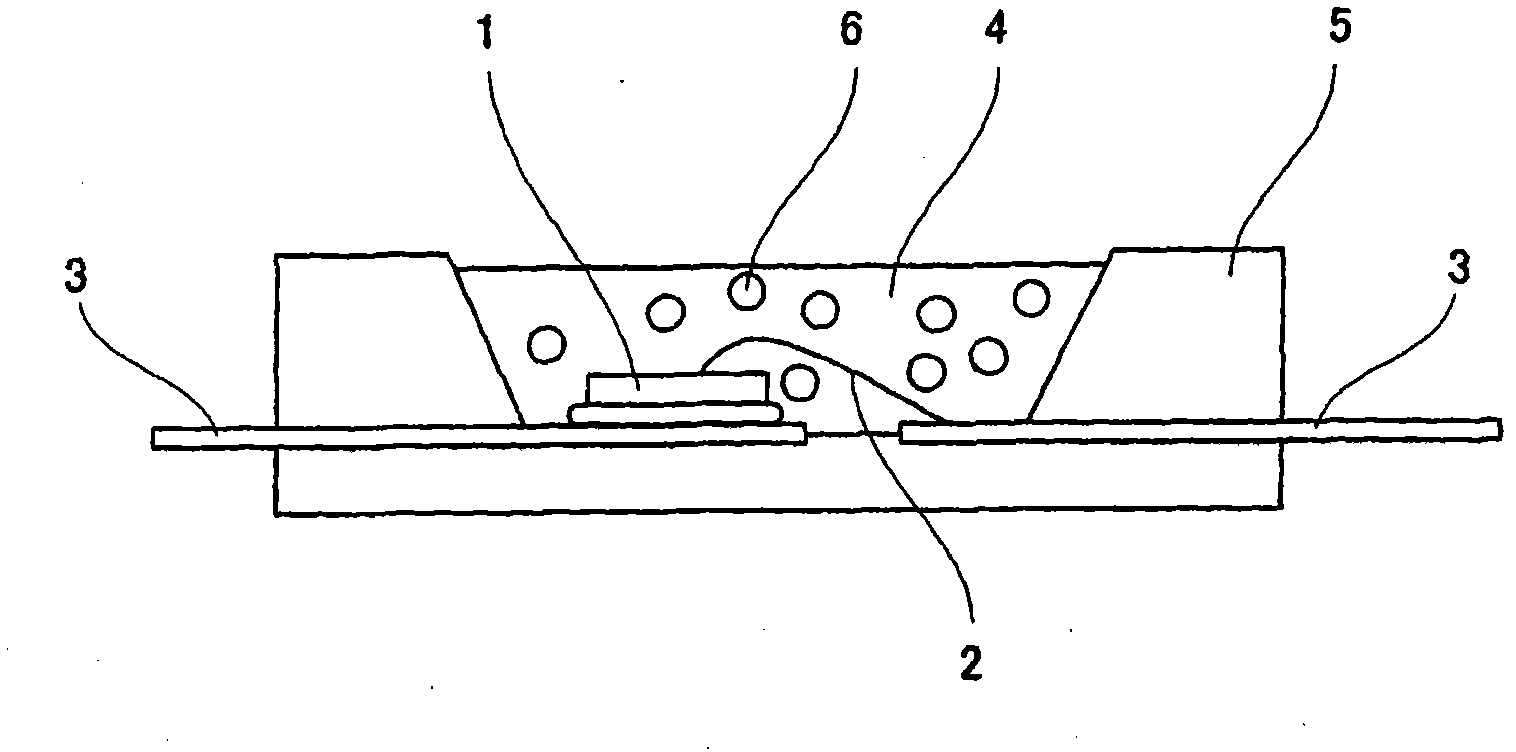

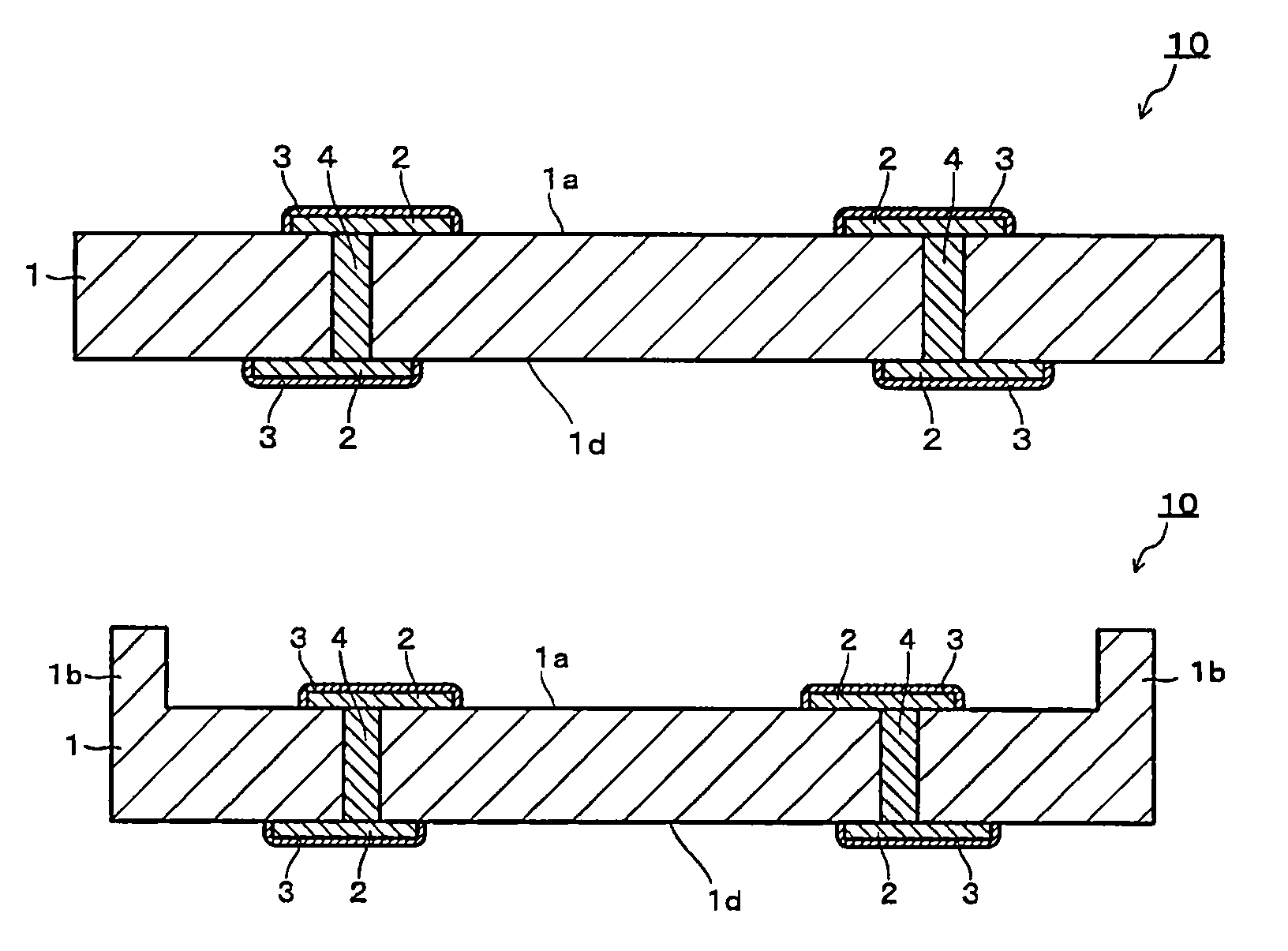

Substrate for mounting element and process for its production

InactiveUS20110186336A1Good plating propertyExcellent in sulfurization resistancePrinted circuit assemblingSemiconductor/solid-state device detailsElectrical conductorCopper

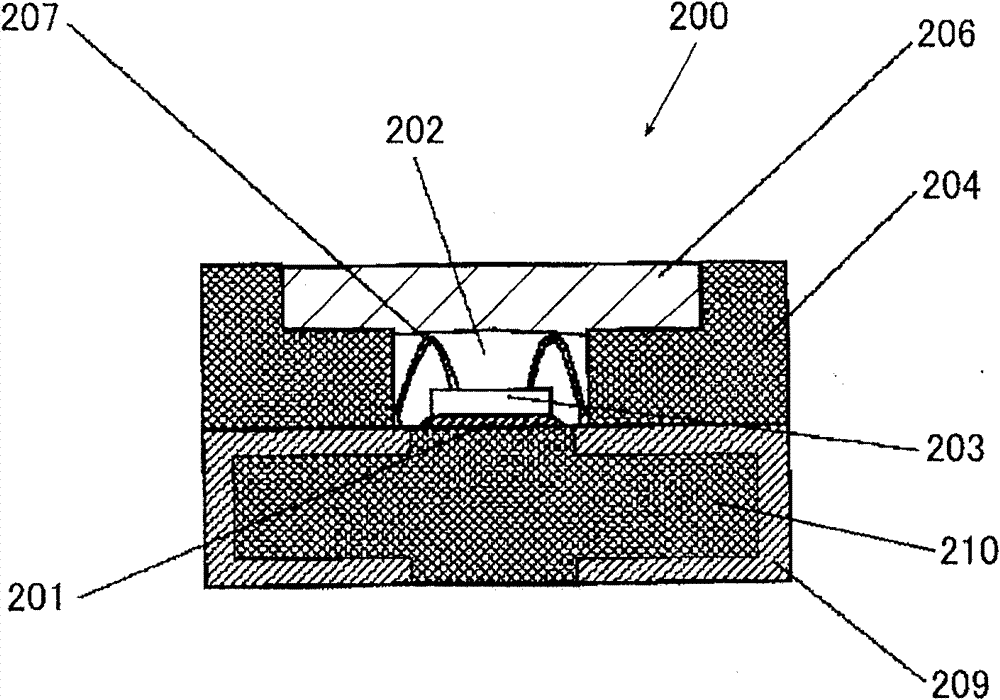

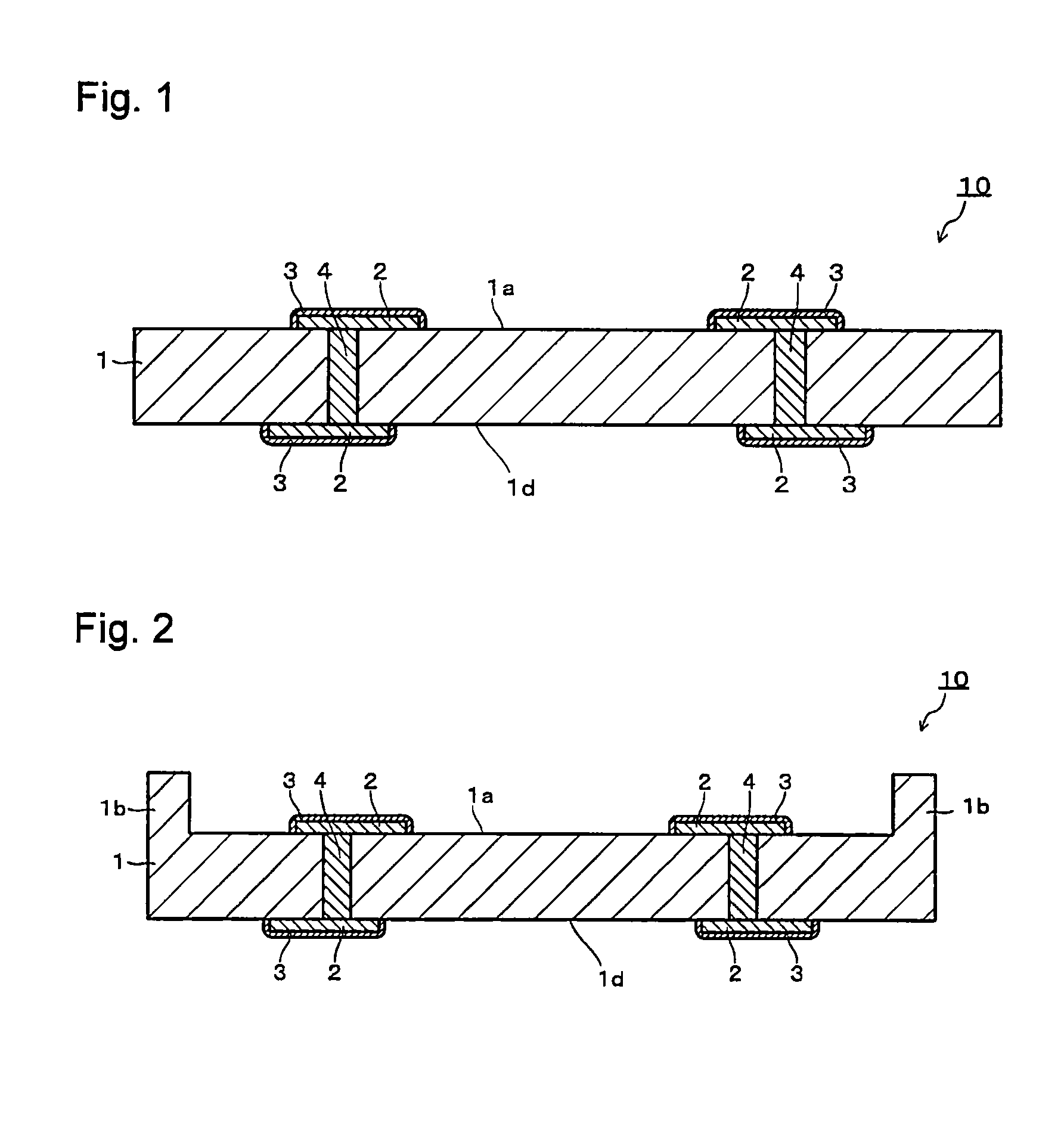

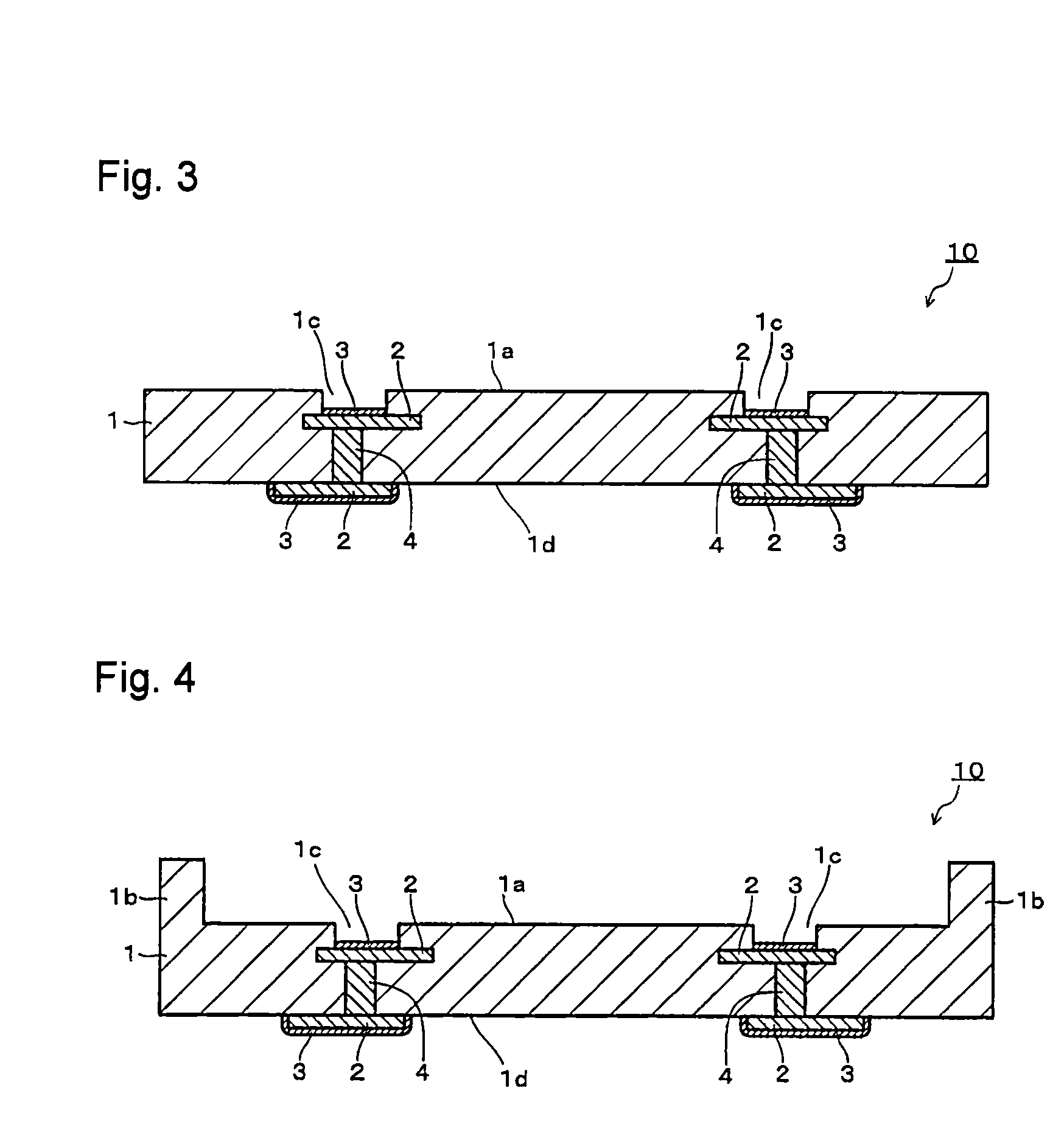

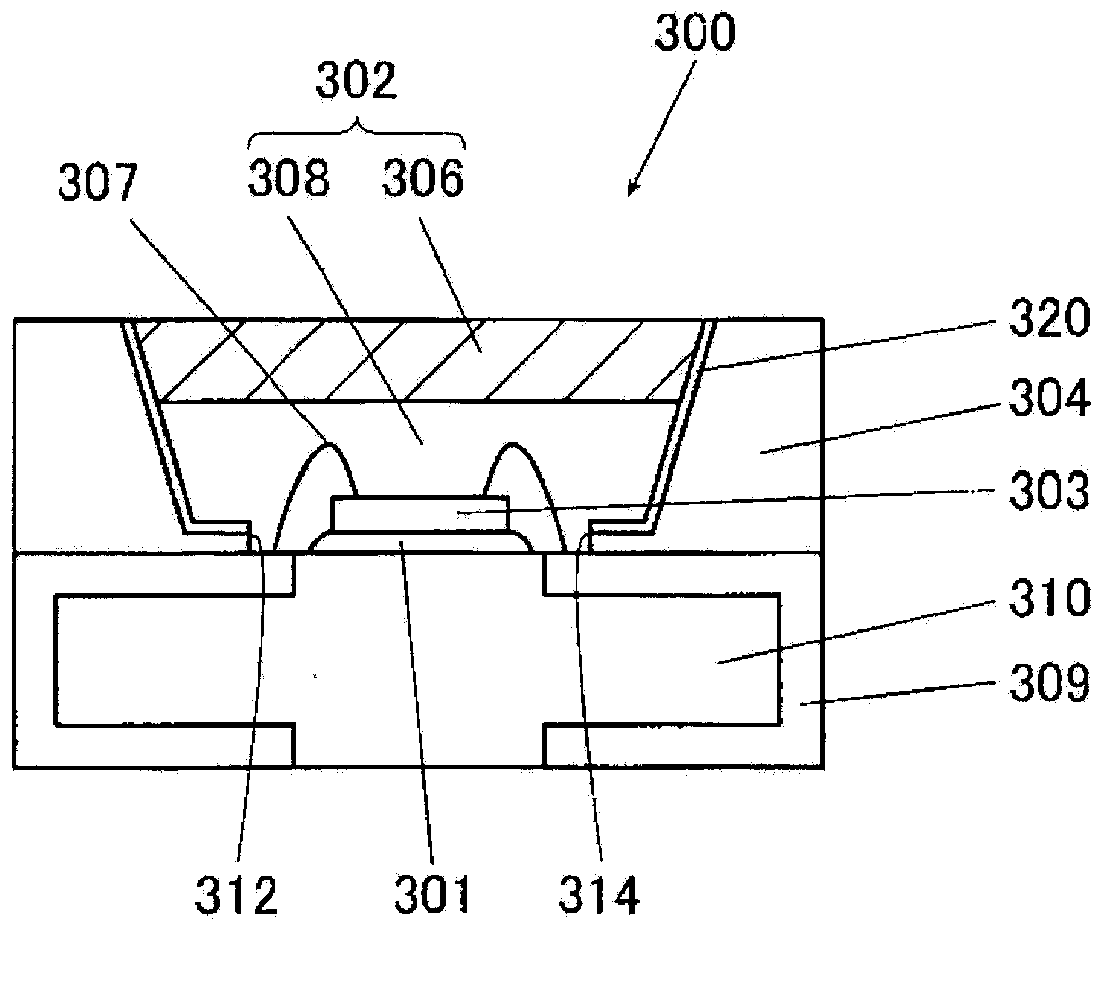

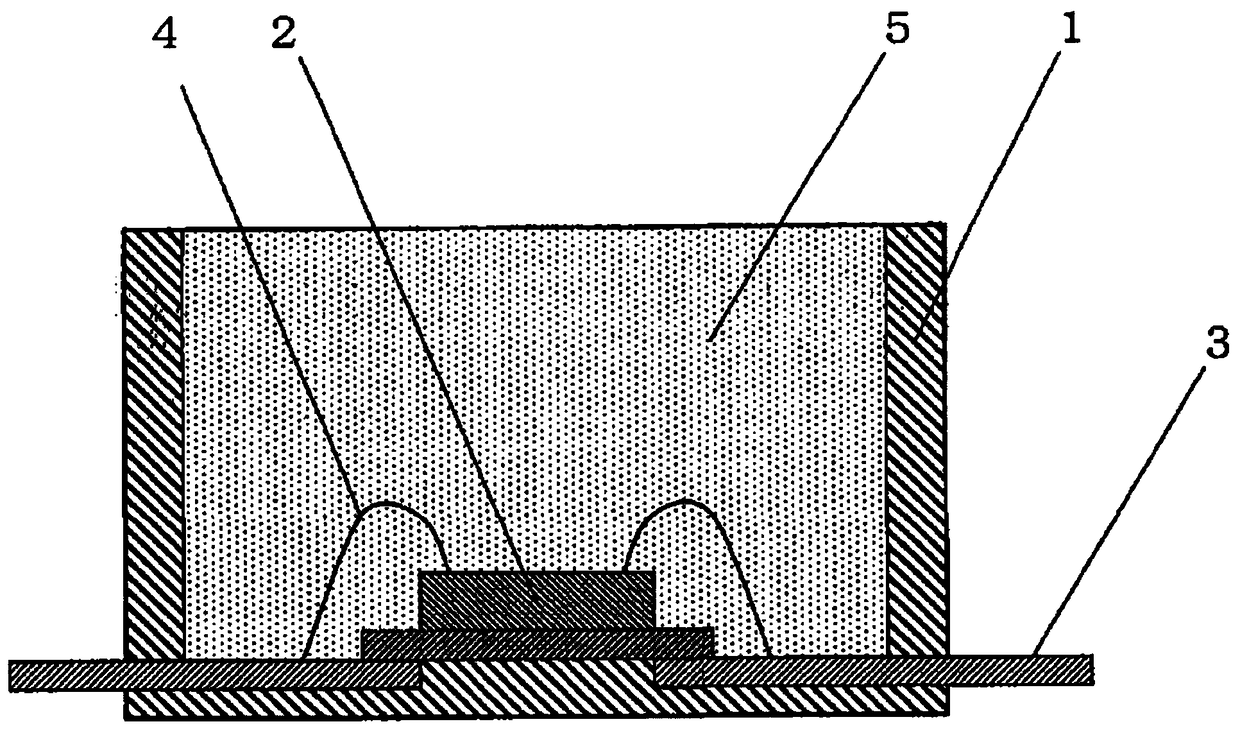

To provide a substrate for mounting element having sulfurization resistance improved by increasing planarity of the surface of a thick conductor layer.The substrate 10 for mounting element of the present invention has such a structure that on a surface of a LTCC substrate or ceramics substrate as an inorganic insulating substrate 1, a thick conductor layer 2 is formed as an element connection terminal. The thick conductor layer 2 is made of a metal composed mainly of silver (Ag) or copper (Cu) and formed by printing and firing a metal paste. This thick conductor layer has its surface planarized by wet blast treatment to a surface roughness Ra of at most 0.02 μm. A Ni / Au-plated layer 3 is formed on the thick conductor layer 2, so that the surface of the thick conductor layer 2 is completely covered without any space.

Owner:ASAHI GLASS CO LTD

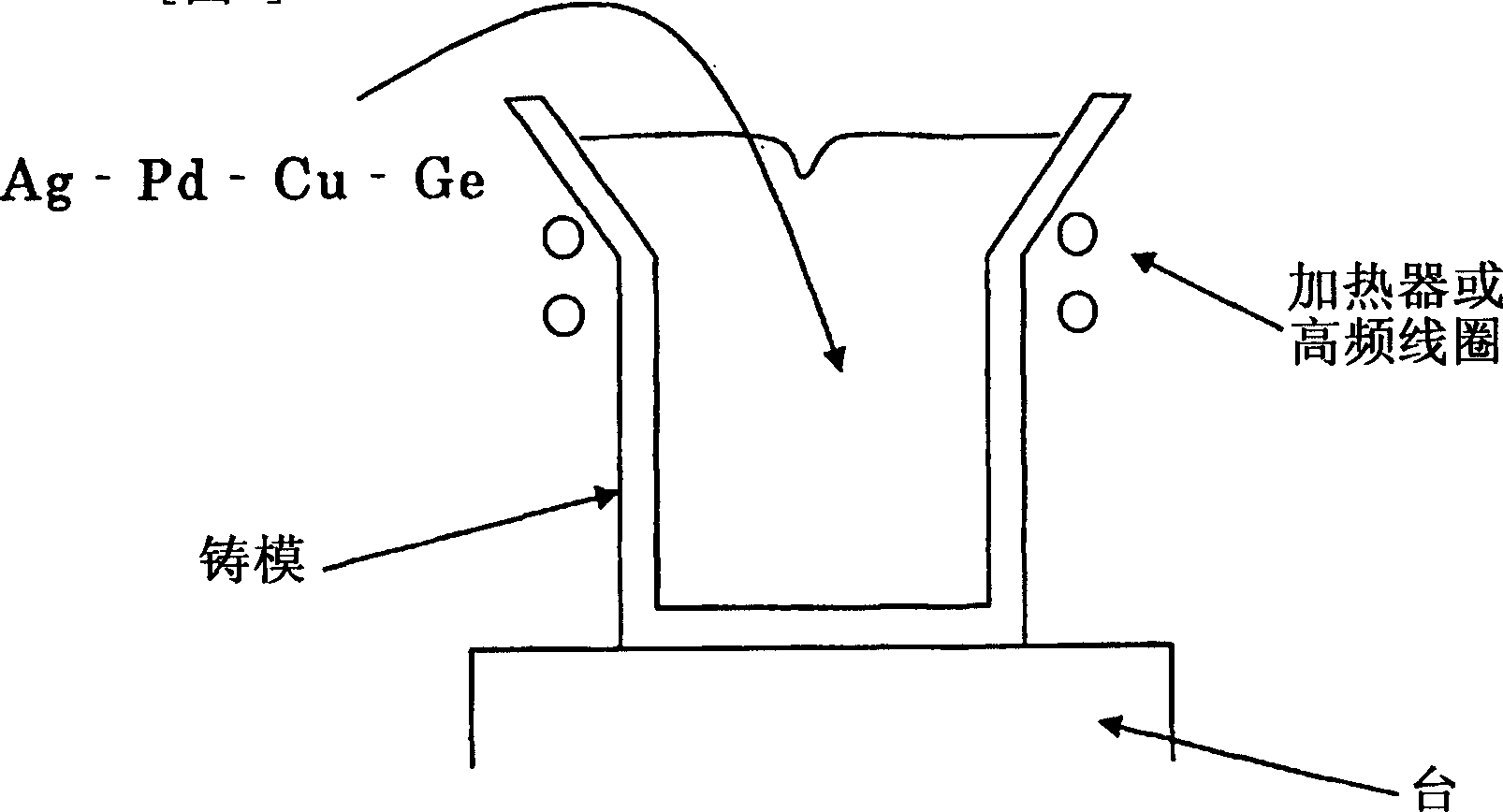

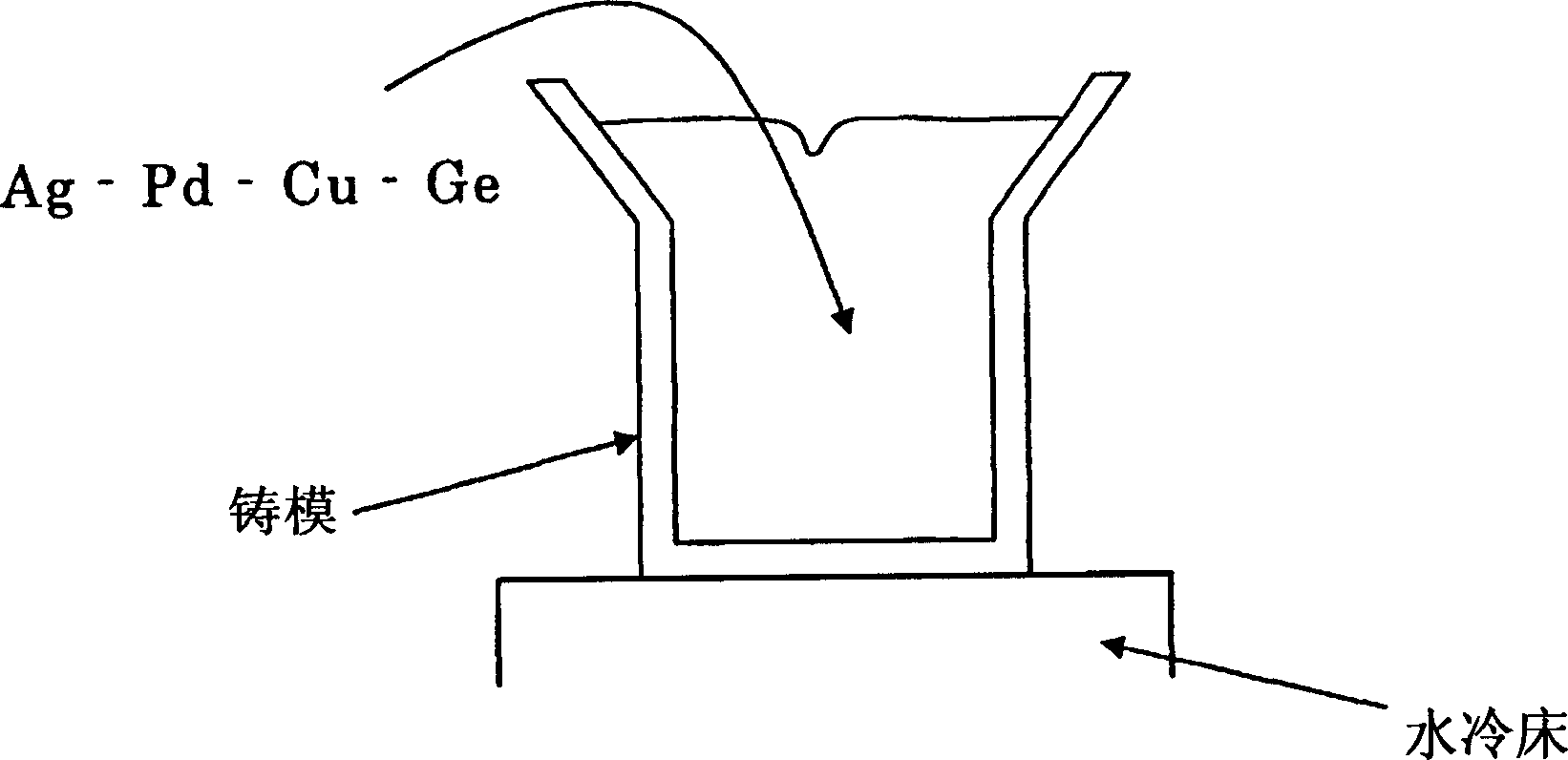

Silver alloy, sputtering target material thereof, and thin film thereof

ActiveCN1856587AImprove heat resistanceExcellent resistance to sulfurationVacuum evaporation coatingSputtering coatingLiquid-crystal displayChemical composition

An Ag-Pd-Cu-Ge silver alloy is disclosed which enables to form a reflective electrode film which has such two characteristics at the same time that decrease in the reflectance due to thermal deterioration is extremely small and yellowing due to sulfuration hardly occurs even after the heating step during production of color liquid crystal displays. The silver alloy is characterized by having a chemical composition composed of at least 4 elements wherein Ag is mainly contained, and 0.10-2.89 wt% of Pd, 0.10-2.89 wt% of Cu and 0.01-1.50 wt% of Ge are also contained such that the total content of Pd, Cu and Ge is 0.21-3.00 wt%.

Owner:FURUYA KINZOKU KK

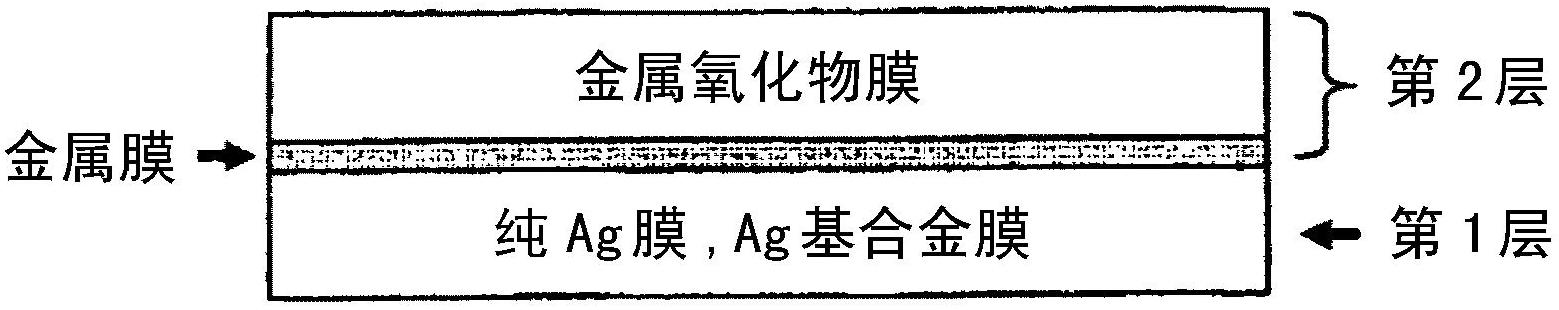

Reflective film laminate

InactiveCN102687044AImprove reflectivityHigh initial reflectivityVehicle headlampsMirrorsHeat resistanceAlloy

Disclosed is a reflective film laminate, which has a pure Ag film or an Ag-based alloy film as a first layer on a base body, and an oxide film of a metal of one or more kinds selected from among Zr, Cr, Nb, Hf, Ta, V, Ni, Mo, W, Al and Si, as a second layer on the first layer. The thickness of the second layer is 0.1-10 nm, and deterioration of the reflection ratio of the reflective film laminate is 30 % or less by having the second layer provided therein. The reflective film laminate is provided with a protection film, which has a high initial reflection ratio, excellent sulfuration resistance and heat resistance, and an extremely small number of pin holes. As a result, the reflection ratio of the reflective film laminate is not easily deteriorated due to aggregation of Ag atoms of the Ag film.

Owner:KOBE STEEL LTD

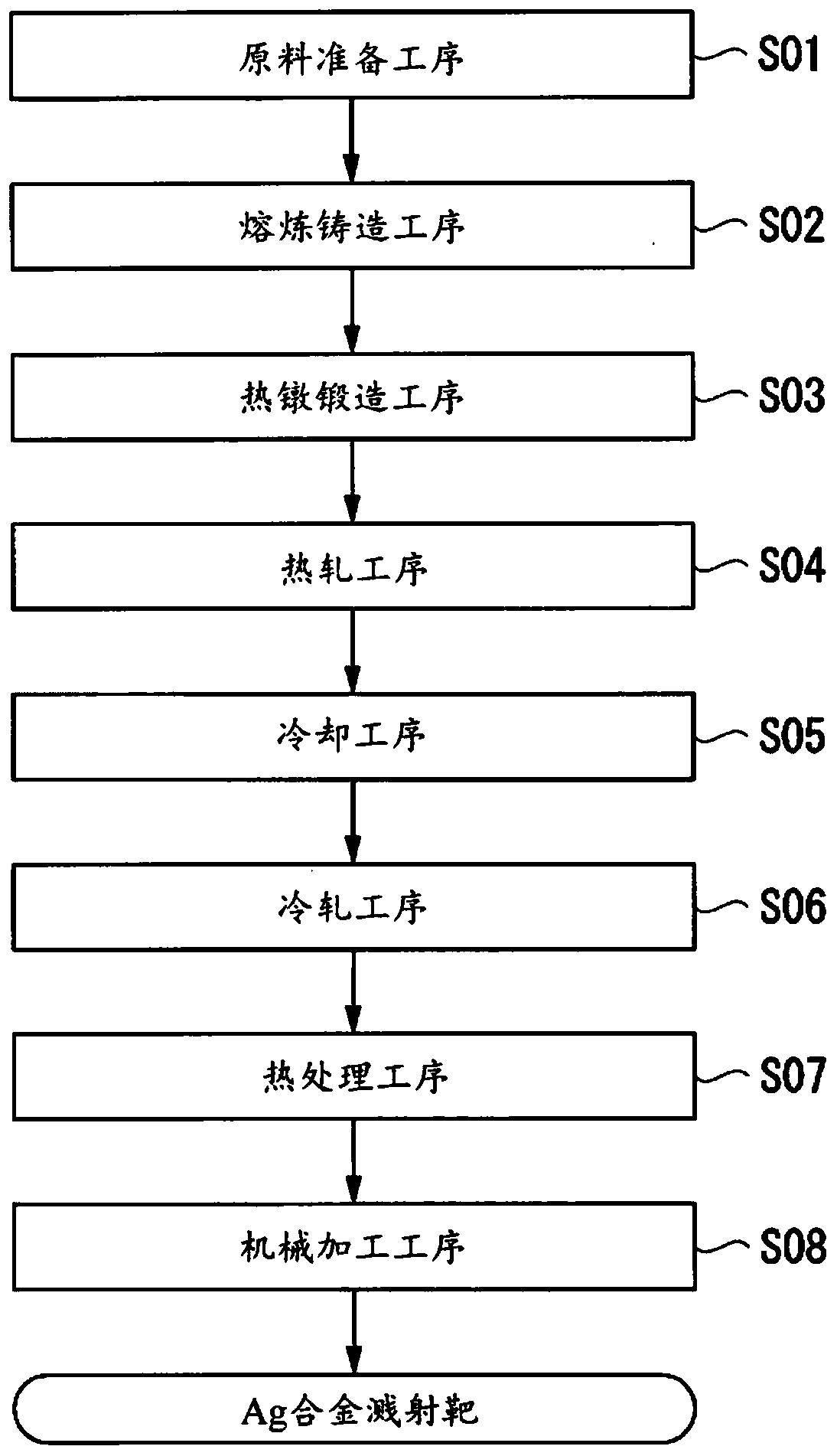

Silver-based alloy target material blank for vacuum magnetron sputtering and preparation method as well as application thereof

ActiveCN106947879AGood resistance to vulcanizationLow resistivityVacuum evaporation coatingSputtering coatingVulcanizationCerium

The invention belongs to the technical field of metal material processing, and particularly relates to a silver-based alloy target material blank for vacuum magnetron sputtering and a preparation method as well as application thereof. The silver-based alloy target material blank comprises, by weight percentage, 98.26wt%-99.465wt% of metallic silver and 0.535wt%-1.74wt% of other alloying elements, wherein the other alloying elements comprise at least one of the following elements: copper, yttrium, nickel, cerium, zinc, aluminum, magnesium, neodymium, silicon and the like. According to different alloy proportions and the preparation method, the produced silver-based target material has excellent performances such as good vulcanization resistance and low resistivity, and the silver-based target material blank is applied to the vacuum magnetron sputtering after being processed.

Owner:NORTHEASTERN UNIV

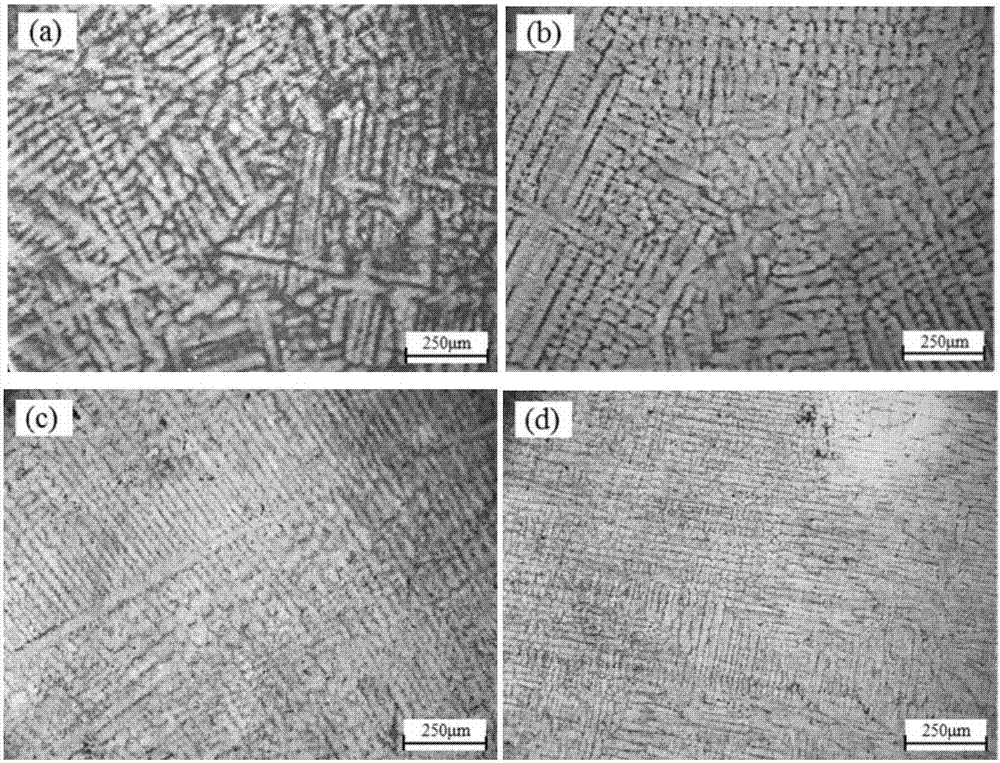

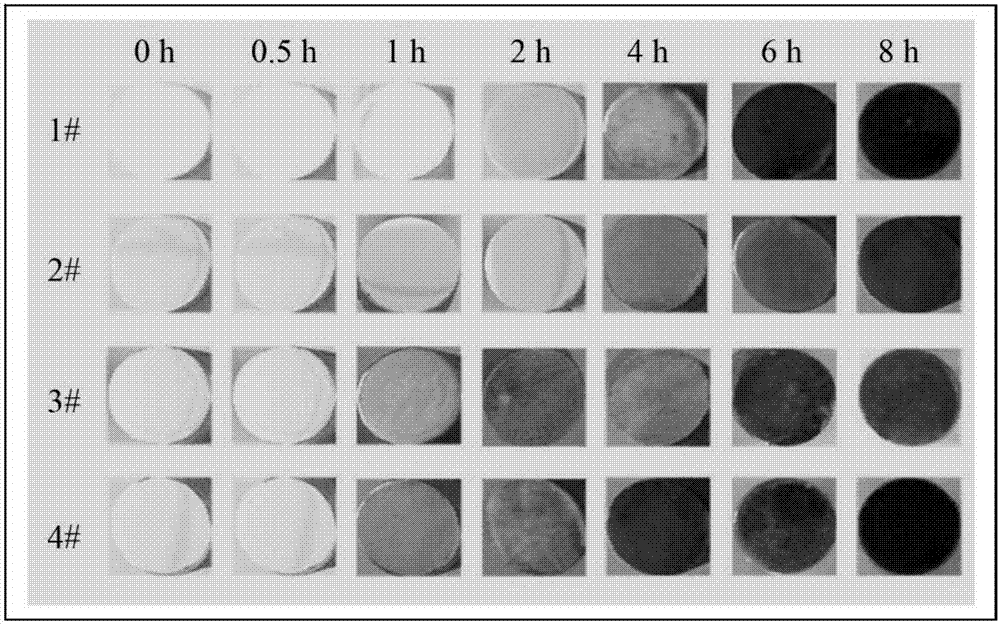

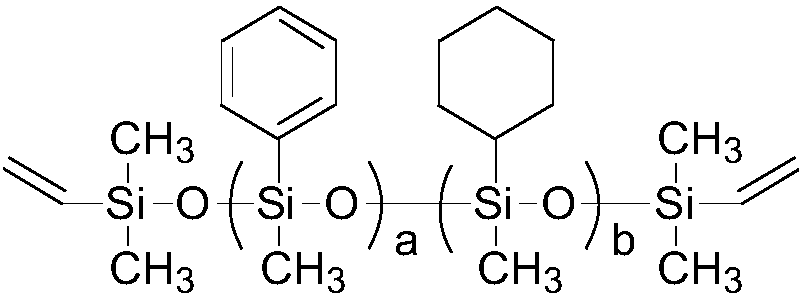

High-refraction LED packaging silicone with high gas barrier property

ActiveCN107353870AExcellent resistance to sulfurationImprove thermal shock resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesVulcanizationAdhesive

The invention relates to high-refraction LED packaging silicone with a high gas barrier property and a preparation method thereof. The silicone is composed of a component A and a component B in the weight ratio of 10:1. The component A comprises, by weight, 40-80 parts of cyclohexyl-containing cyclohexyl vinylester resin, 25-55 parts of cross-linking agent, 0.08-0.20 part of inhibitor and 0-5 parts of rare-earth metal stabilizer. The component B comprises, by weight, 60-80 parts of vinyl silicone oil, 0.05-0.20 part of catalyst and 10-50 parts of adhesive. The refractive index of the high-refraction LED packaging silicone with the high gas barrier property is larger than 1.50; compared with traditional phenyl high-refraction LED packaging silicone, the high-refraction LED packaging silicone has the advantages of being better in vulcanization-resistant effect and more excellent in cold and hot impact resistance, and is convenient to operate and good in storage stability.

Owner:YANTAI DARBOND TECH

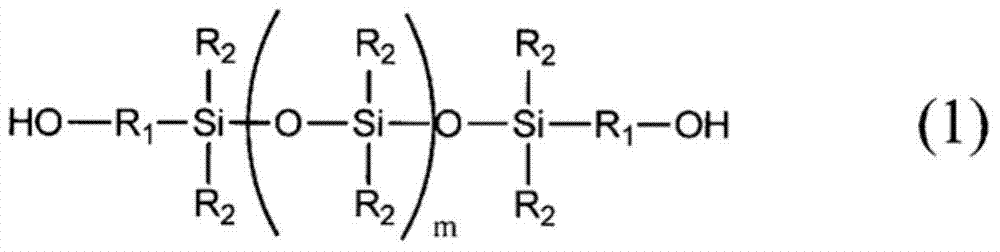

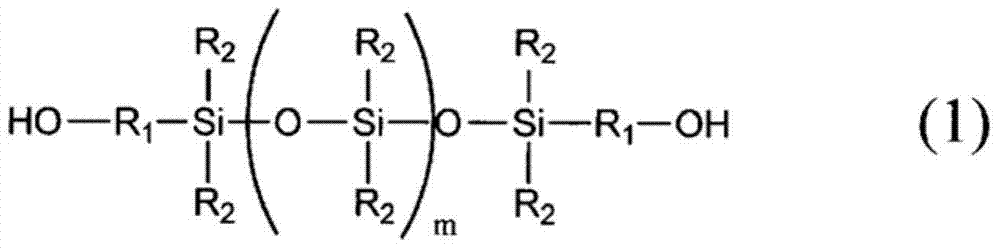

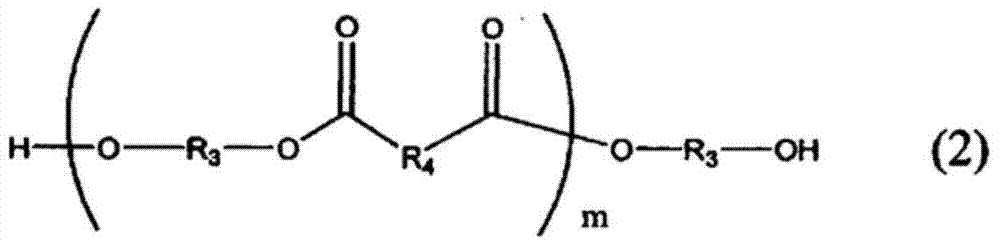

Curable resin composition for sealing optical semiconductor element and cured product thereof

InactiveCN103781815AExcellent resistance to sulfurationExcellent shelf lifeSemiconductor/solid-state device detailsSolid-state devicesEpoxyPolyol

Provided is a resin composition that is extremely useful as a sealant for an optical semiconductor (such as an LED product) having excellent pot life and sulfur resistance. The curable resin composition for sealing an optical semiconductor comprises a curing catalyst having a melting point between 40 and 200 DEG C and an epoxy resin and / or epoxy resin curing agent. Preferably the epoxy resin curing agent is, for instance, polyvalent carboxylic acid resin (A)obtained by addition reaction of a dual end-type carbinol-modified silicone oil represented by formula (1), a polyhydric alcohol compound having two or more hydroxyl groups per molecule, and a compound having one carboxylic anhydride group per molecule. In formula (1), R1 is an alkylene group, and the like, R2 is an alkyl group, and the like, and m is an average value and is between 1 and 100. The formula (1) is defined in the specification.

Owner:NIPPON KAYAKU CO LTD

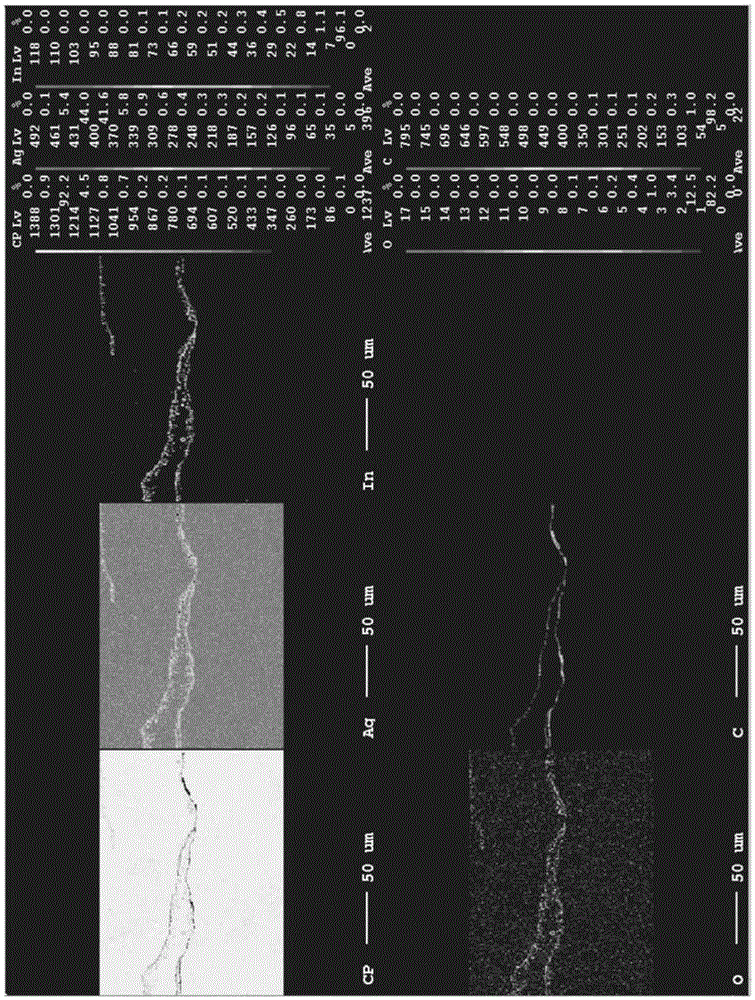

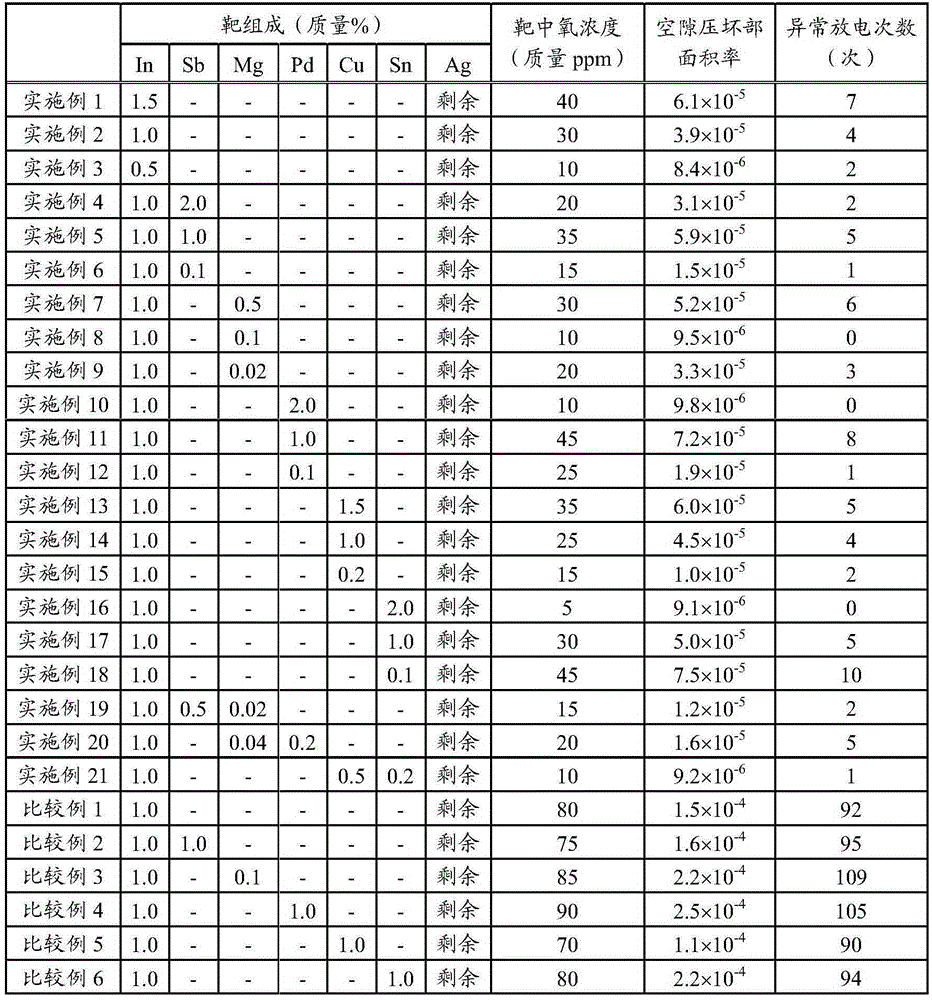

Ag alloy sputtering target

ActiveCN105378140AImprove reflectivityImprove heat resistanceElectroluminescent light sourcesSolid-state devicesSputteringMetallurgy

The present invention provides an Ag alloy sputtering target by which it is possible to perform stable DC sputtering. This Ag alloy sputtering target contains 0.1-1.5 mass% In, the balance being a composition comprising Ag and unavoidable impurities, the concentration of oxygen being 50 mass ppm or less. In the entire area in the direction of thickness of the target, the proportion of area of a crushed void portion measured by an ultrasonic damage detection device is 1.0x10-4 or less in relation to the area of the sputtering surface.

Owner:MITSUBISHI MATERIALS CORP

LED packaging adhesive composition

The invention relates to an LED packaging adhesive composition, which is prepared by mixing a component A and a component B according to a weight ratio of 1:1, wherein the component A comprises the following components in parts by weight: 50-60 parts of phenyl vinyl MQ silicon resin, 10-20 parts of methyl phenyl vinyl silicone oil and 0.1-0.3 part of an anti-poisoning platinum catalyst, and the component B comprises the following components in parts by weight: 50-70 parts of methyl phenyl hydrogen-containing silicone resin, 30-50 parts of methyl phenyl hydrogen-containing silicone oil and 0.1-0.3 part of an inhibitor.

Owner:YANTAI DARBOND TECH

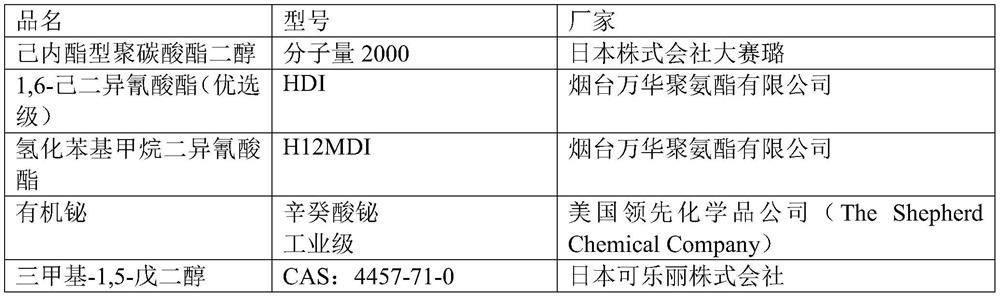

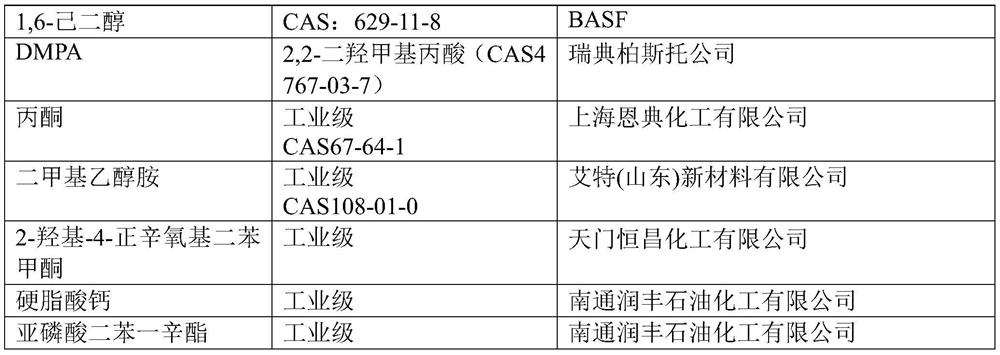

Water-based surface polyurethane resin for automobile leather and preparation method of water-based surface polyurethane resin

ActiveCN112341593AGood vulcanization resistanceExtended service lifeRoad vehiclesTextiles and paperIsocyanateBatch production

The invention relates to the technical field of polyurethane automobile leather, in particular to water-based surface polyurethane resin for automobile leather and a preparation method of the water-based surface polyurethane resin. The water-based surface polyurethane resin for automobile leather is formed by polymerizing the following raw materials in parts by weight: polyhydric alcohol, isocyanate, a chain extender, acetone, deionized water and a catalyst. The product provided by the invention can be used for automobile leather, and has the advantages of relatively good vulcanization resistance, friction resistance, weather resistance, pollution resistance and relatively long service life. The preparation method comprises the following steps of weighing polyhydric alcohol, isocyanate anda catalyst according to a formula, mixing weighed polyhydric alcohol, isocyanate and a catalyst, and reacting at 85-95 DEG C, adding a chain extender, and reacting for 1-2 hours at the temperature of70-80 DEG C, adding acetone to dilute, cooling to below 45 DEG C, and adding a salt-forming agent to neutralize and form salt, adding water for dispersion, and distilling to remove acetone to obtaina target product. The preparation method is relatively simple to operate and can be used for batch production.

Owner:JIAXING HEXIN CHEM IND

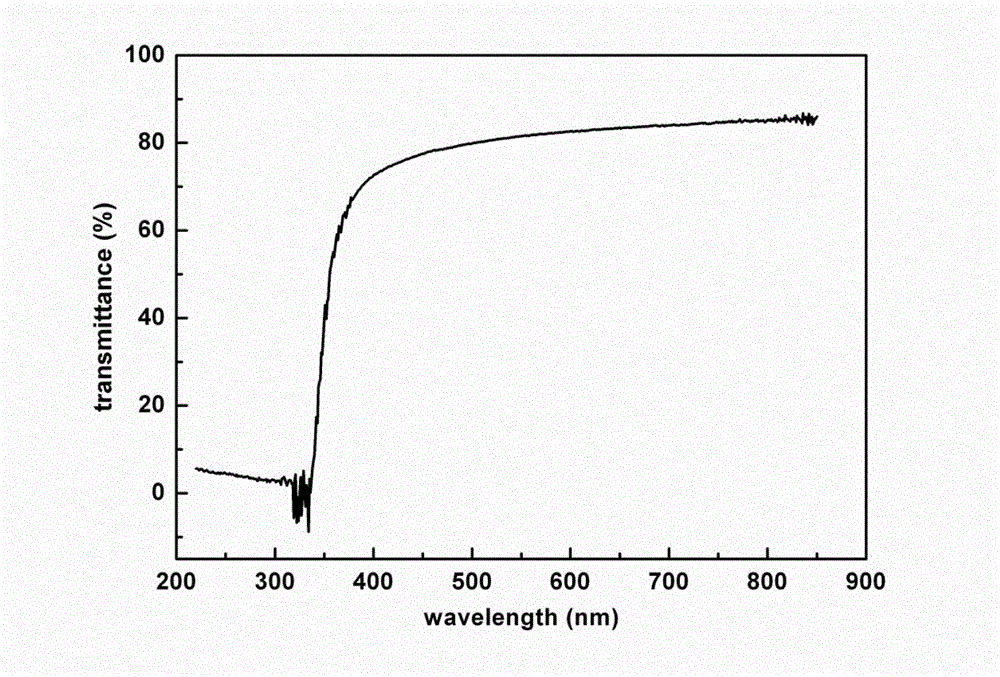

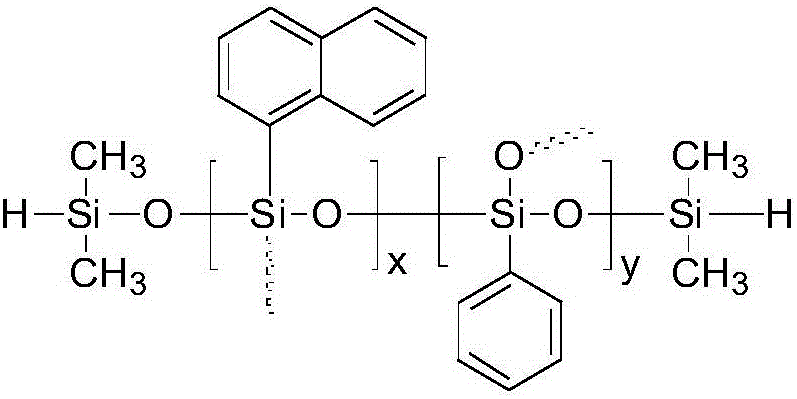

Naphthyl ultrahigh-refractive-index LED packaging silicone

InactiveCN106634807AEasy to operateGood storage stabilityMacromolecular adhesive additivesPolymer scienceVulcanization

The invention relates to naphthyl ultrahigh-refractive-index LED packaging silicone and a preparation method thereof. The naphthyl ultrahigh-refractive-index LED packaging silicone is prepared from a component A and a component B with a weight ratio of 10 to 1, wherein the component A is prepared from the following raw materials in parts by weight: 45 to 75 parts of vinyl resin, 30 to 55 parts of cross-linking agent, 0.08 to 0.20 part of inhibitor and 2 to 5 parts of adhesive; the component B is prepared from the following raw materials in parts by weight: 60 to 80 parts of vinyl silicone oil, 20 to 30 parts of vinyl resin and 0.05 to 0.20 part of catalyst. The naphthyl ultrahigh-refractive-index LED packaging silicone has a refractive index over 1.56, the refractive index is mainly 1.57 to 1.62, the adhesive property is good for various LED base materials, after colloid is cured, the hardness is wider in range, and can reach Shore 30D to 75D, the vulcanization resistance is excellent, the reliability is good, and the visible light transmittance is good; the silicone is convenient and easy to operate, and is good in storage stability.

Owner:YANTAI DARBOND TECH

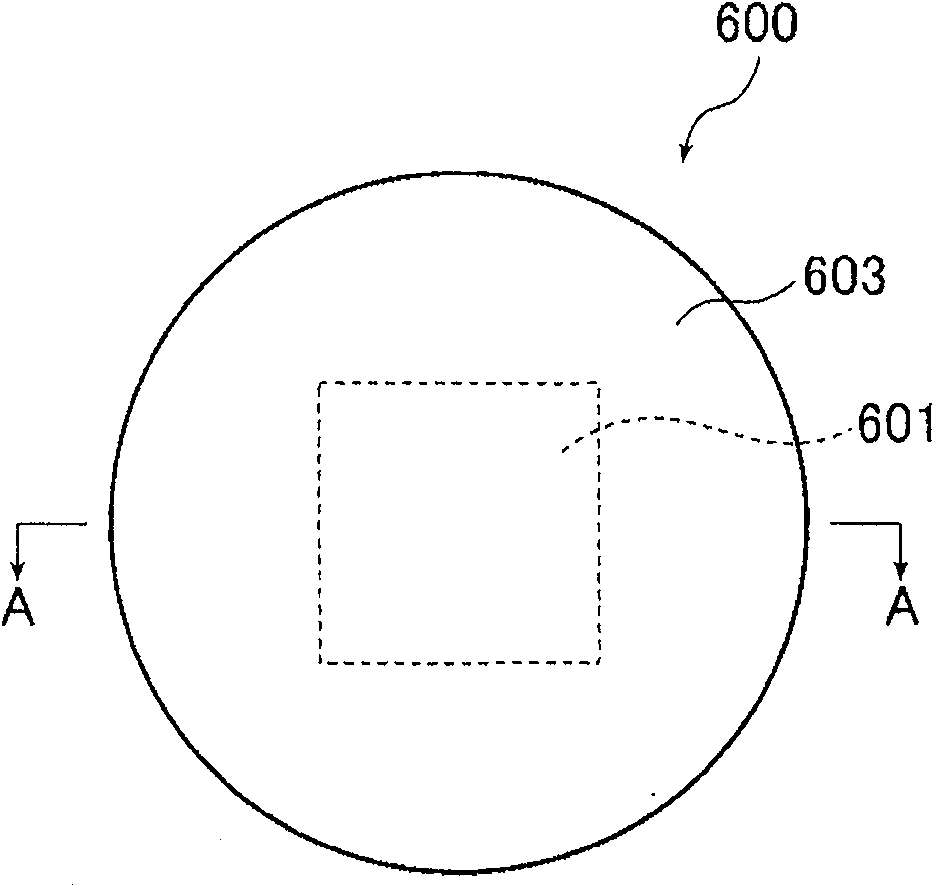

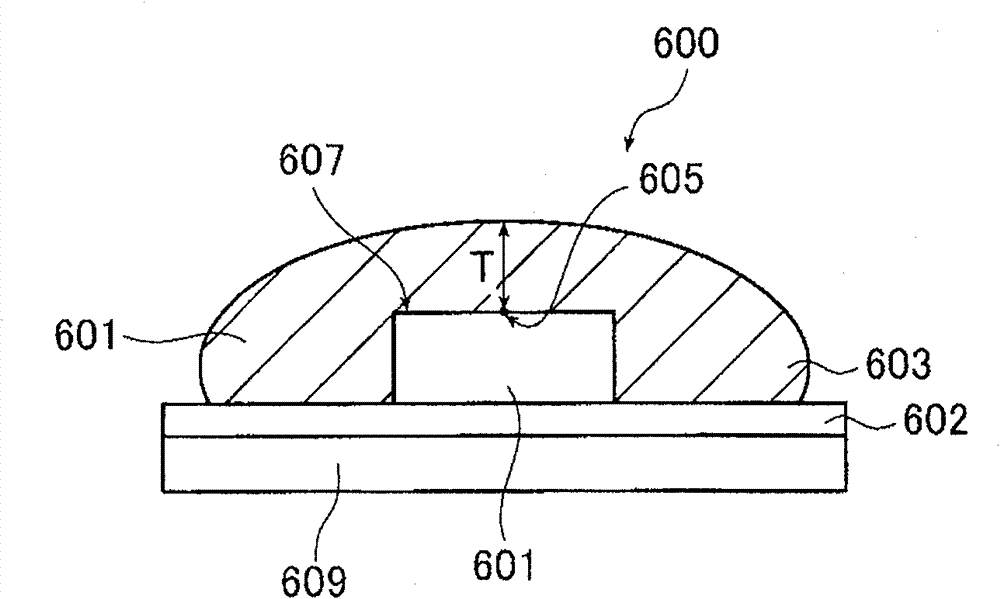

Resin Composition For Encapsulating Optical Semiconductor Element And Light Emitting Device

ActiveCN102408724AExcellent resistance to sulfurationSemiconductor/solid-state device detailsSolid-state devicesRefractive indexLight emitting device

A resin composition for encapsulating optical semiconductor element is provided to obtain the refractive index of greater than 1.45, after hardening, excellent sulfidation resistance, and long-term reliability. A resin composition(4) for the encapsulating optical semiconductor element comprises: organo polysiloxane having aliphatic unsaturated bond containing mono valent hydrocarbon group; organo hydrogen polysiloxane containing two or more hydrogen atoms combined with silicon atom per one molecule; a platinum-based catalyst; and a glass filler(7) with anisotropic shape of which aspect ratio is 1.1-50. The refractive index of the hardened material is 1.45 or greater. The glass filler of anisotropic shape is scale-like glass or chopped strands.

Owner:SHIN ETSU CHEM IND CO LTD

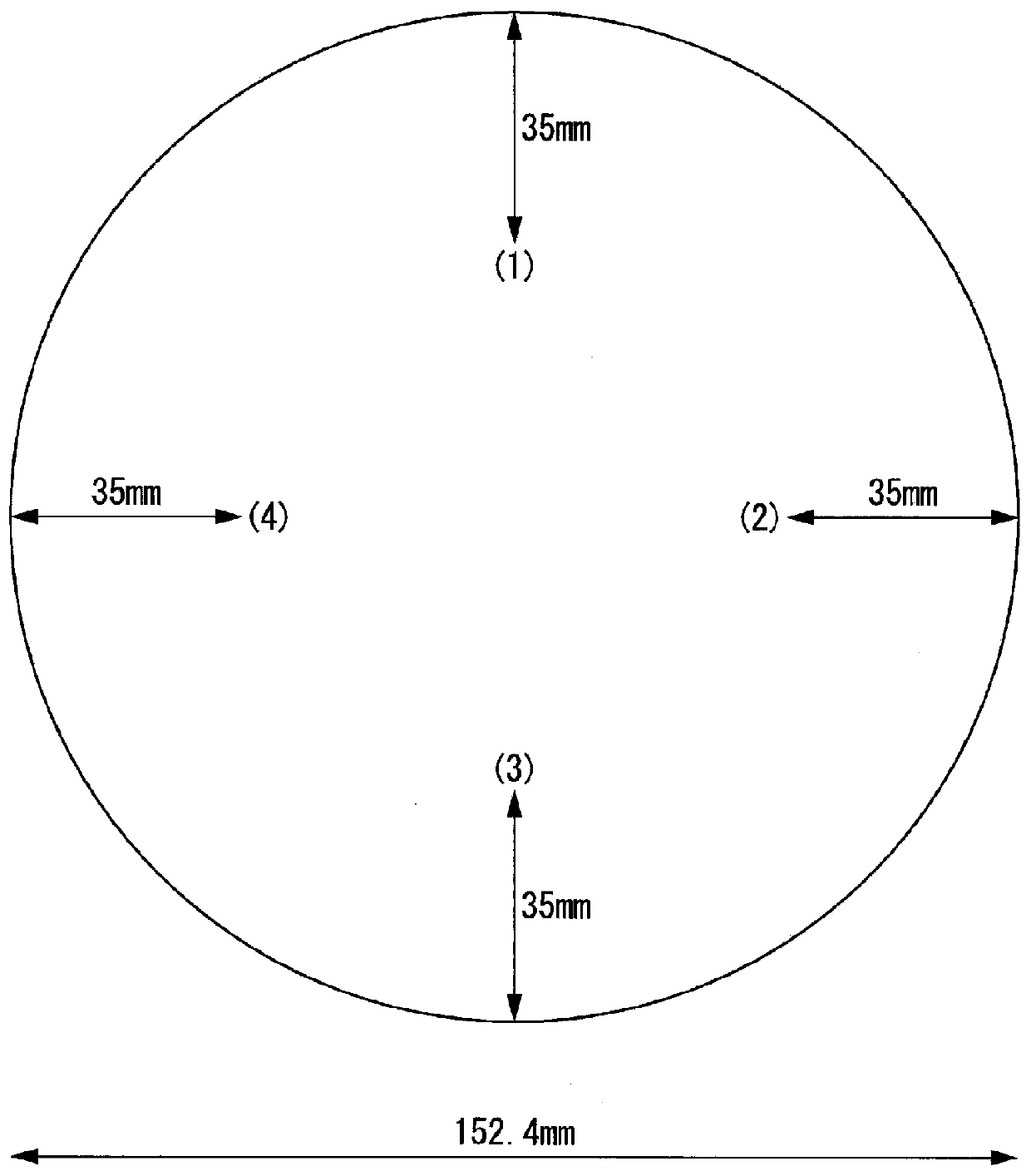

Process for producing substrate for mounting element

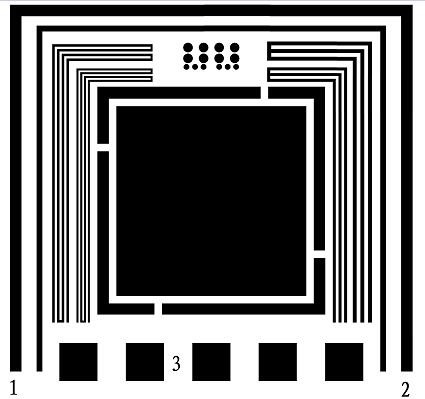

ActiveUS9504166B2Excellent resistance to sulfurationMaintain good propertiesPrinted circuit assemblingSemiconductor/solid-state device detailsElectrical conductorSurface roughness

A process for producing a substrate for mounting element includes forming a thick conductor layer-provided substrate having a thick conductor layer made of a metal composed mainly of silver (Ag) or copper (Cu), on a surface of an inorganic insulating substrate made of an inorganic insulating material, applying wet blast treatment to the thick conductor layer to planarize the surface of the thick conductor layer to a surface roughness Ra of at most 0.02 μm, and forming a nickel (Ni) / gold (Au)-plated layer on the thick conductor layer having the surface planarized by the wet blast treatment.

Owner:AGC INC

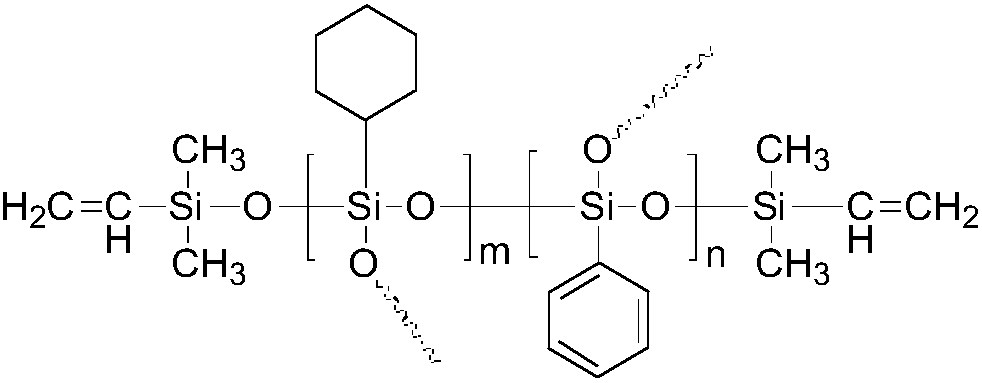

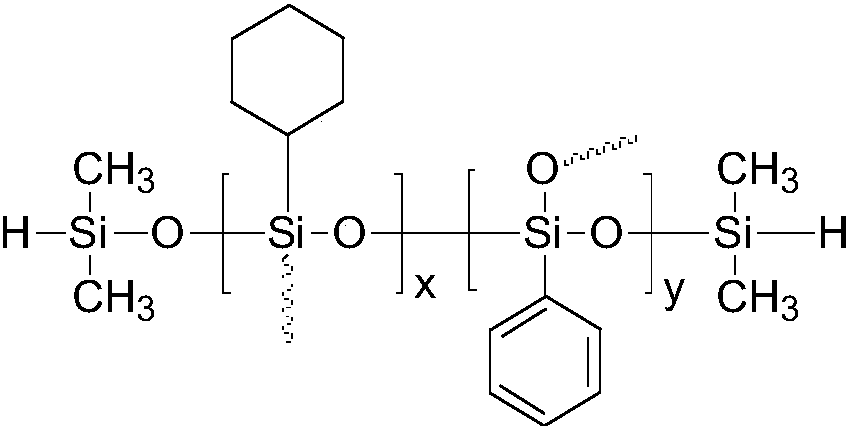

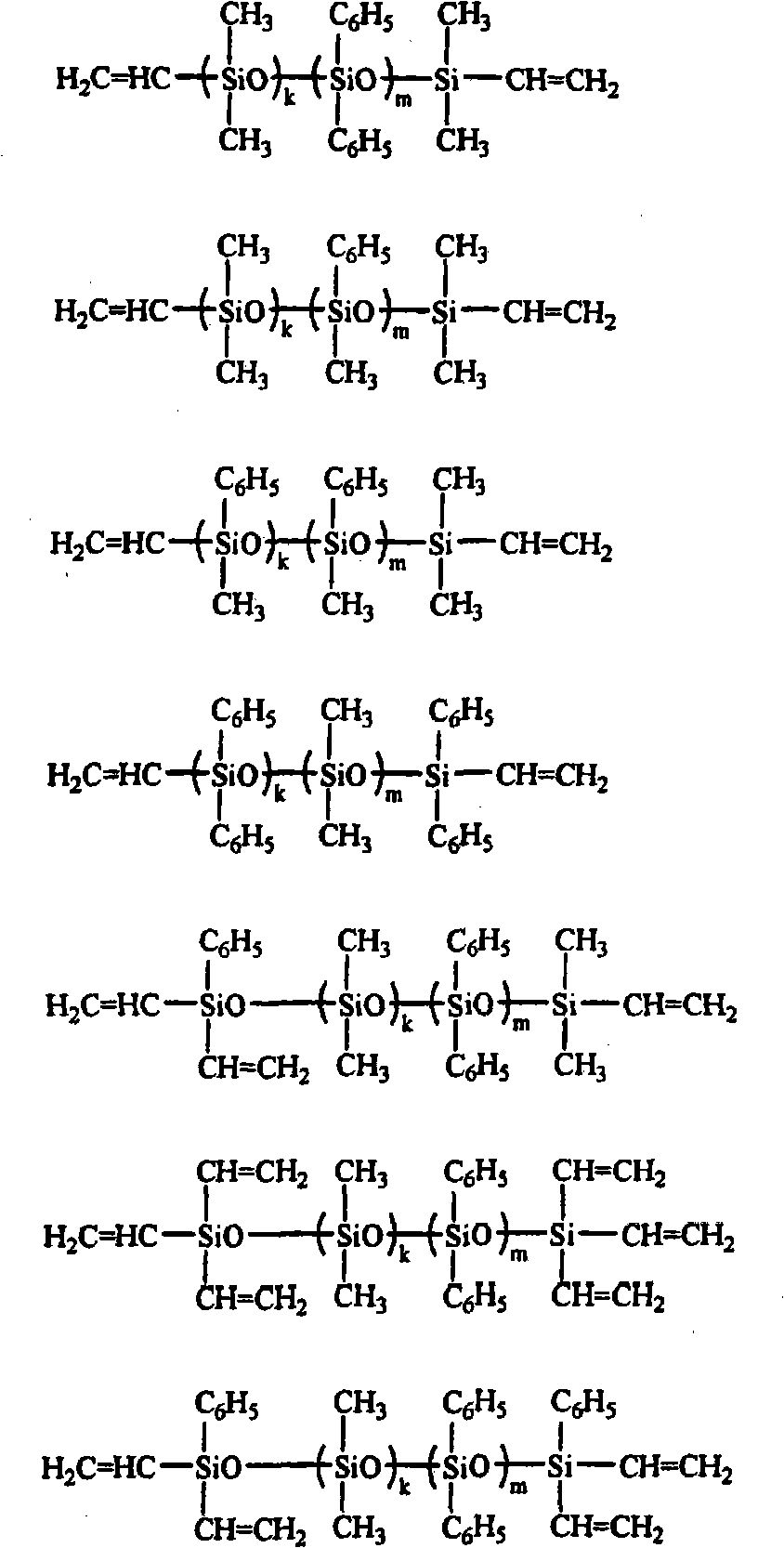

Organic silicon resin composition, using method thereof, organic silicon resin, structure comprising the same, and optical semiconductor component sealing member

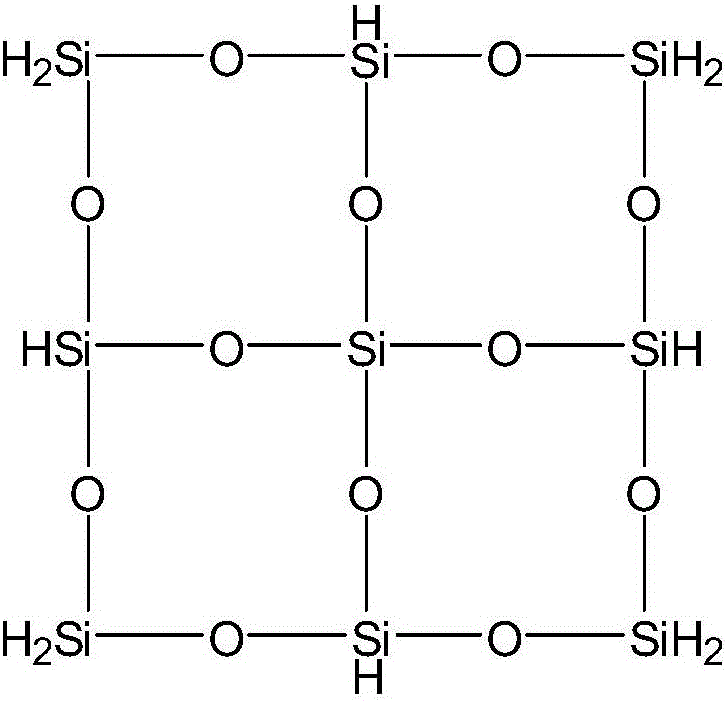

InactiveCN102190890BEnsure transparencyExcellent resistance to sulfurationSolid-state devicesSemiconductor devicesAlkyl transferHydrogen atom

A task of the invention is to provide an organic silicon resin composition which can sustain transparency and has excellent sulfidation resistance, a using method thereof, an organic silicon resin thereof, a structure comprising the organic silicon resin, and an optical semiconductor component sealing member. The task is settled through providing the organic silicon resin composition which comprises the following components: component (A): a polysiloxane which comprises at least two alkenyls that are combined with silicon atoms, component (B): a polysiloxane cross-linking agent which is provided with at least two SiH groups which is respectively obtained through combining a silicon atom and a hydrogen atom, component (C): a silane alkylation catalyst; and component (D): a zinc compound; wherein relatively to in total 100 by mass parts of component (A) and component (B), the organic silicon resin composition comprises 0.1-5 by mass parts of the component (D).

Owner:THE YOKOHAMA RUBBER CO LTD

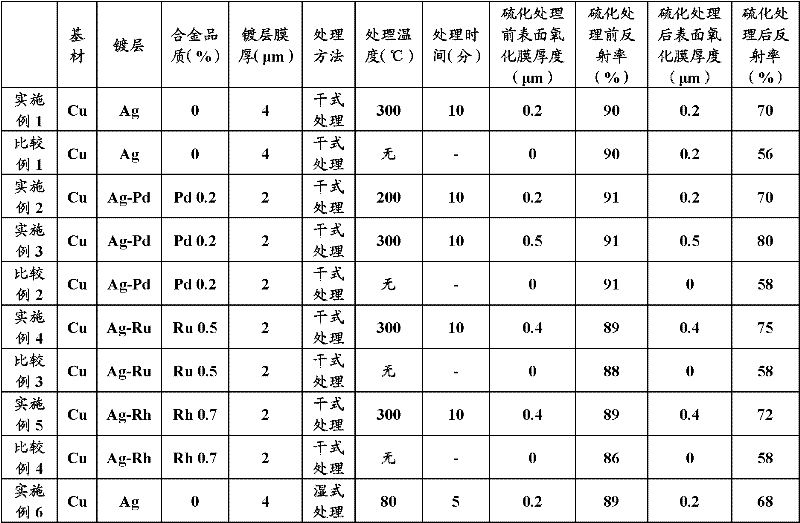

Electrolytically silver plated and/or electrolytically silver alloy plated article having oxide layer on surface

InactiveCN102471895AImprove productivityImprove reflectivityMirrorsDomestic mirrorsSilver plateAlloy

Owner:JX METALS TRADING CO LTD

Substrate for mounting element and process for its production

ActiveUS20140201993A1Excellent resistance to sulfurationMaintain good propertiesPrinted circuit assemblingSemiconductor/solid-state device detailsElectrical conductorSurface roughness

To provide a substrate for mounting element having sulfurization resistance improved by increasing planarity of the surface of a thick conductor layer.The substrate 10 for mounting element of the present invention has such a structure that on a surface of a LTCC substrate or ceramics substrate as an inorganic insulating substrate 1, a thick conductor layer 2 is formed as an element connection terminal. The thick conductor layer 2 is made of a metal composed mainly of silver (Ag) or copper (Cu) and formed by printing and firing a metal paste. This thick conductor layer has its surface planarized by wet blast treatment to a surface roughness Ra of at most 0.02 μm. A Ni / Au-plated layer 3 is formed on the thick conductor layer 2, so that the surface of the thick conductor layer 2 is completely covered without any space.

Owner:ASAHI GLASS CO LTD

Silver alloy, sputtering target material thereof, and thin film thereof

ActiveCN100443609CImprove heat resistanceExcellent resistance to sulfurationVacuum evaporation coatingSputtering coatingLiquid-crystal displayChemical composition

Owner:FURUYA KINZOKU KK

Method for improving sulfuration resistant and UV resistant performances of organosilicon material for LED packaging

InactiveCN106784270AExcellent resistance to sulfurationLuminous flux stabilityCoatingsSemiconductor devicesUltravioletLuminous flux

The invention relates to a method for improving sulfuration resistant and UV resistant performances of an organosilicon material for LED packaging. The method comprises the following steps: cleaning the surface of an LED support; preparing a coating; uniformly mixing hydrogen silicone containing resin and a solvent, wherein the weight percentage of the hydrogen silicone containing resin is 20 wt% to 25 wt%; uniformly spraying the obtained coating to a chip surface; carrying out uniform electron beam irradiation on the obtained chip surface, so that the coating is cured to form a compact silicon dioxide structure; and then removing unnecessary coating, applying the organosilicon material for LED packaging, and carrying out curing molding. The method has the beneficial effects that a packaged LED prepared and obtained by using the method disclosed by the invention overcomes the disadvantages that a traditional organosilicon material is permeable for air and moisture after being packaged and a part of the traditional organosilicon material can penetrate through a packaging material under the effect of sulfurous gas, so that the sulfuration resistance is high; after long-term ultraviolet (UV) irradiation, the stability of luminous flux can also be maintained; and the caking property of a silver layer and a silica gel interface is good, so that silver sulfide is unlikely to generate.

Owner:深圳市佑明光电有限公司 +1

Ag alloy sputtering target and method for manufacturing ag alloy sputtering target

InactiveCN111587300AReduce surface roughnessGood removal effectVacuum evaporation coatingSputtering coatingSputteringSurface roughness

The present invention is characterized in having a composition that consists of In and / or Sn in a range of 0.1 mass% to 1.5 mass% total and the balance Ag and unavoidable impurities and in that the arithmetic average surface roughness Ra of the sputtering surface of the target is not more than 7 mum after performing sputtering under conditions, wherein Ar gas pressure is 0.1 Pa, current density is1.5 W / cm2, and integrated power consumption is 0.01 kWh / cm2.

Owner:MITSUBISHI MATERIALS CORP

Blue gloss fading-resistant 958 silver alloy for jewelry and process of blue gloss fading-resistant 958 silver alloy

InactiveCN108796289APromote sheddingNo discoloration occurredSolid state diffusion coatingSocial benefitsAlloy

The invention discloses a blue gloss fading-resistant 958 silver alloy for jewelry and a process of the blue gloss fading-resistant 958 silver alloy. The alloy comprises, by weight, 0.2-0.3% of P, 0.5-0.6% of Sr, 0.6-0.8% of Mo, 0.2-0.4% of Ir, 1.0-1.5% of Co, 0.3-0.5% of In, 95.0-96.0% of Ag, and the balance copper. A new material with blue appearance is provided for the 958 silver alloy for thejewelry in China, and the material has excellent fading resistance. The implementation and industrialization of the material can effectively promote the demands of product updating and industry upgrading in the jewelry industry of China, and rich economic gains and social benefits are obtained when the industry problems are solved.

Owner:GUANGZHOU YUZHI TECH CO LTD

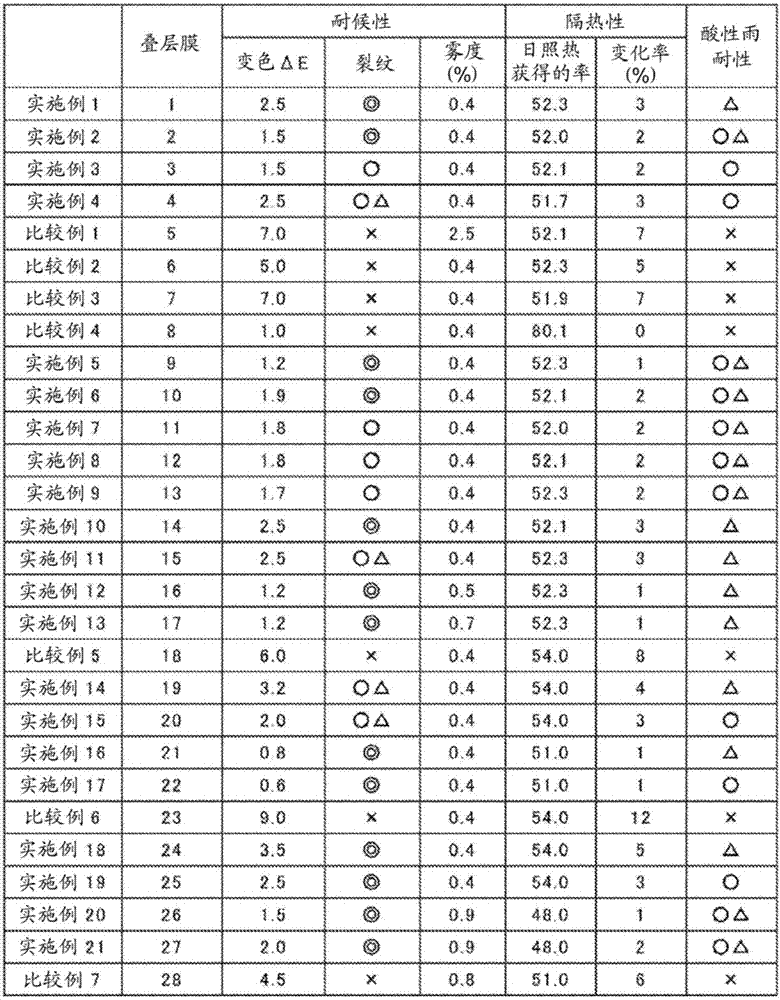

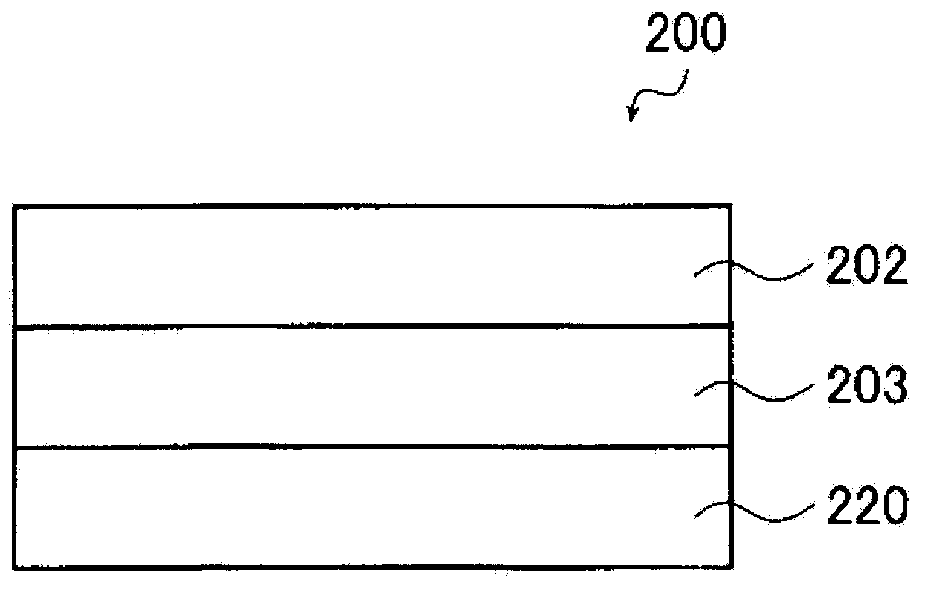

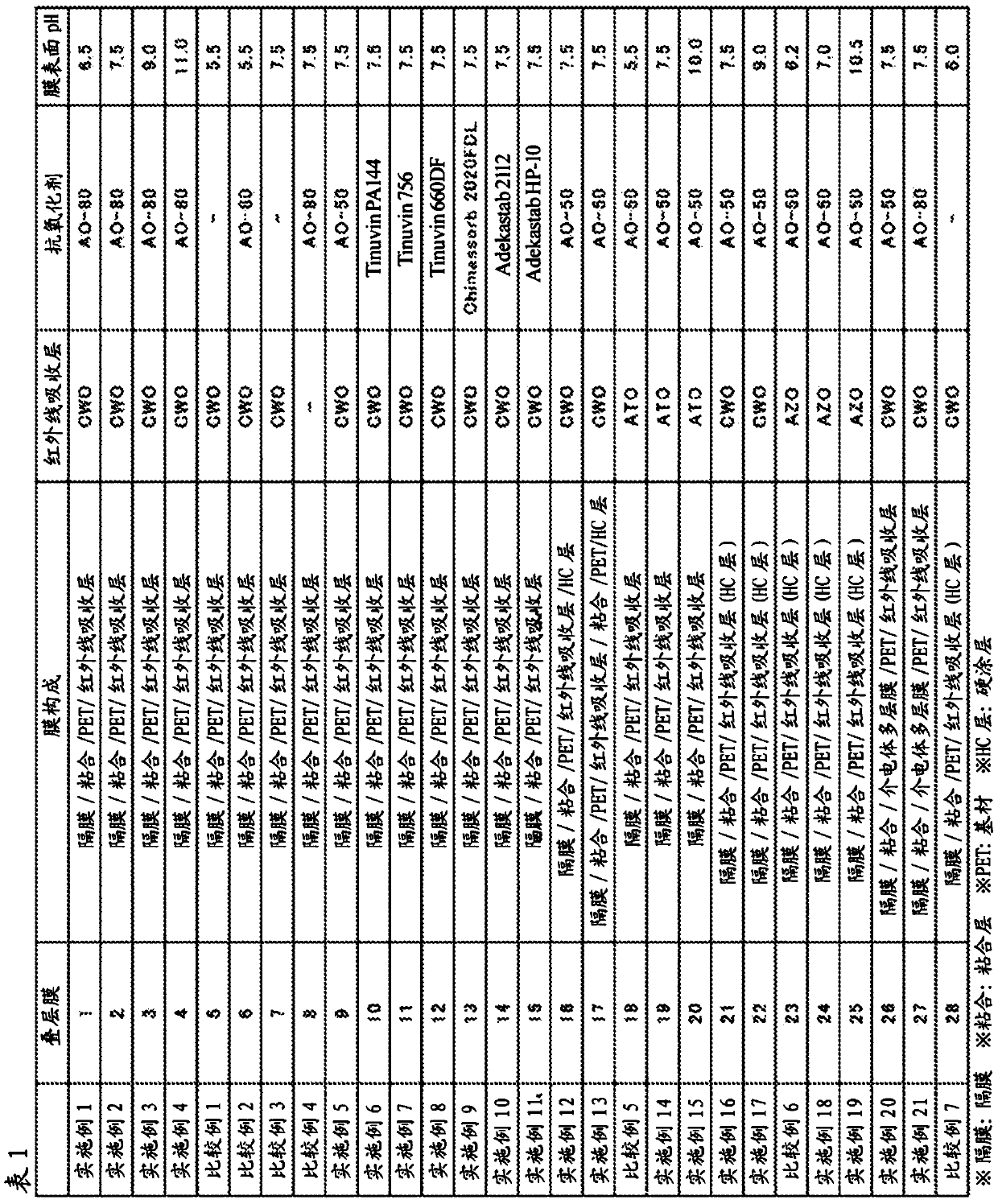

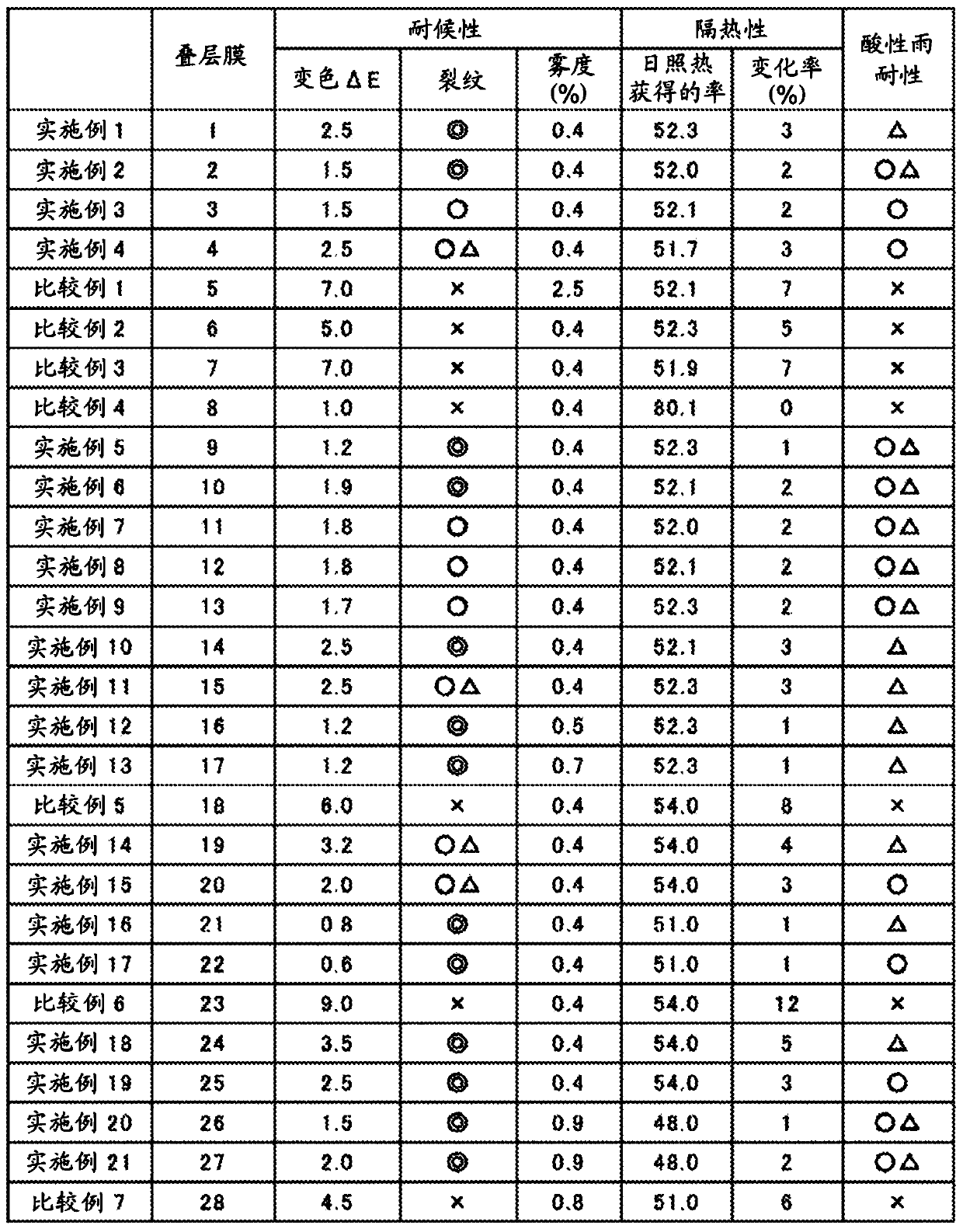

Laminated film

ActiveCN107003450AInhibitionPrevent discolorationSynthetic resin layered productsCoatingsInfraredOptoelectronics

[Problem] To provide a laminated film having a layer that contains an infrared absorbent, wherein cracking and discoloration under highly humid environments subjected to the sun's rays are minimized, and having excellent resistance to sulfurization. [Solution] The present invention pertains to a laminated film comprising a substrate, and an infrared light absorbing layer that is disposed on one surface of the substrate and contains an infrared light absorbing agent, a resin and a sulfurization prevention agent; and having a film surface pH on the front surface on the opposite side of the infrared light absorbing layer to the substrate of at least 6.5.

Owner:KONICA MINOLTA INC

Silicone resin composition, silicone resin-containing structure using same, optical semiconductor element sealing body, method of using silicone resin composition

InactiveCN103221485BLong-term sulfur resistanceExcellent resistance to sulfurationSemiconductor/solid-state device detailsSolid-state devicesZinc hydroxideZinc compounds

The purpose of the present invention is to provide a silicone resin composition with excellent transparency and sulfuration resistance. Provided is a silicone resin composition comprising 0.01-5 parts by mass, per 100 parts by mass of a curable silicone resin compound (A), of a zinc compound (B) obtained by reacting 1.5 mol or more but less than 2 mol acid with 1 mol of at least one type selected from a group comprising zinc oxide, zinc carbonate, zinc hydroxide, zinc chloride, zinc sulfate, and zinc nitrate. Also provided is a method for using a silicone resin-containing structure, an optical semiconductor element sealed body, and the silicone resin composition, that use same.

Owner:THE YOKOHAMA RUBBER CO LTD

Coating film, method for forming coating film, and light-emitting diode device

InactiveCN106164334AExcellent resistance to sulfurationImprove oxidation resistanceSolid-state devicesElectric lightingCorrosionNitrogen gas

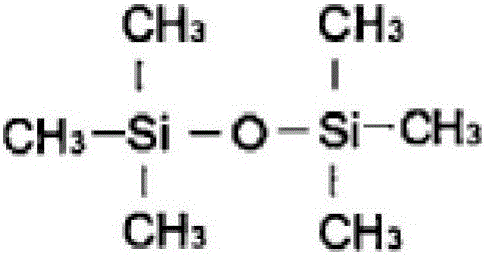

[Problem] To form, on a surface of a metallic material, a coating film which can prevent the surface of a metallic material from being discolored by corrosion due to any heat treatment during production or even due to outdoor use over a long period, and which has excellent wire bonding properties. [Solution] A hexamethyldisiloxane compound is sprayed together with nitrogen gas serving as a carrier gas under atmospheric pressure in a nitrogen plasma gas to convert the hexamethyldisiloxane compound to radicals, thereby polymerizing the compound. Thus, a polysiloxane film which has a thickness of 4-14 nm and which is constituted of a polysiloxane, the main chain of which is -(Si-O-Si)n-, is formed on a surface of a metallic material.

Owner:SUMITOMO METAL MINING CO LTD

Silylated isocyanurate compound, metal anticorrosive agent, curable silicone resin composition, and semiconductor device

PendingCN113527356AImprove heat resistanceExcellent resistance to sulfurationGroup 4/14 element organic compoundsCoatingsPolymer scienceHydrogen atom

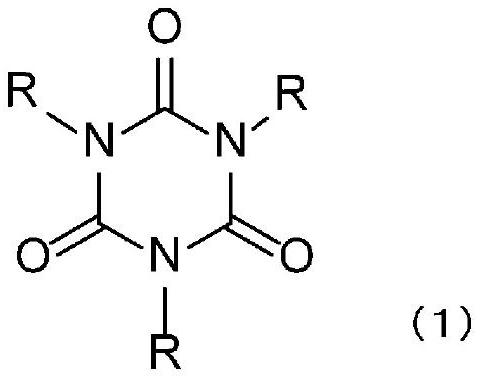

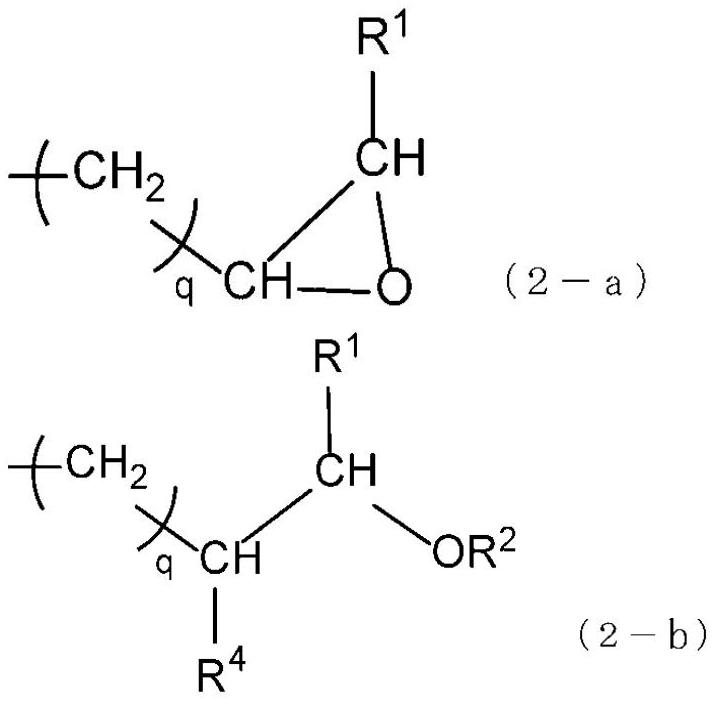

The purpose of the present invention is to provide a silylated isocyanurate compound which can function as a metal anticorrosive agent having excellent heat resistance and vulcanization resistance, i.e., a silylated isocyanurate compound represented by general formula (1). In general formula (1), R independently represents a substituent selected from a hydrogen atom, an alkyl group having 1-10 carbon atoms, an alkenyl group having 2-10 carbon atoms, and a group represented by general formula (2-a) or general formula (2-b), and at least one R represents a general formula (2-b).

Owner:SHIN ETSU CHEM IND CO LTD

Ferritic stainless steel sheet for current collectors for sulfide-based solid-state batteries, and method for manufacturing same

PendingCN114080457AExcellent resistance to sulfurationExcellent adhesionAnodisationElectrode carriers/collectorsMetallurgyElectrical battery

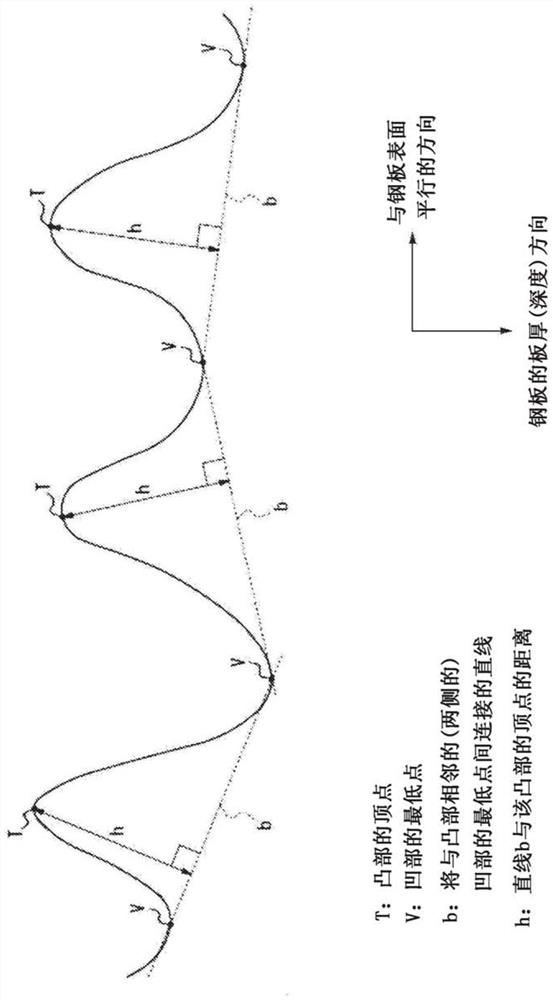

Provided is a ferritic stainless steel sheet for current collectors for sulfide-based solid-state batteries, which has excellent sulfidation resistance and adhesiveness. The ferritic stainless steel sheet has a component composition containing Cr in an amount of 16% by mass or more, wherein the surface of the ferritic stainless steel sheet has an uneven structure having recessed portions and projecting portions, the average height of the projecting portions is 20 to 50 nm inclusive, the average distance between the projecting portions is 20 to 200 nm inclusive, and the [Cr] / [Fe], i.e., the ratio of the atom concentration of Cr that is present in a form other than the metal form to the atom concentration of Fe that is present in a form other than the metal form, on the surface of the ferritic stainless steel sheet is 1.0 or more.

Owner:JFE STEEL CORP +1

Curable block type organopolysiloxane composition and semiconductor device

ActiveCN105985649BExcellent resistance to sulfurationHigh refractive indexSolid-state devicesSemiconductor devicesHydrogen atomPolymer science

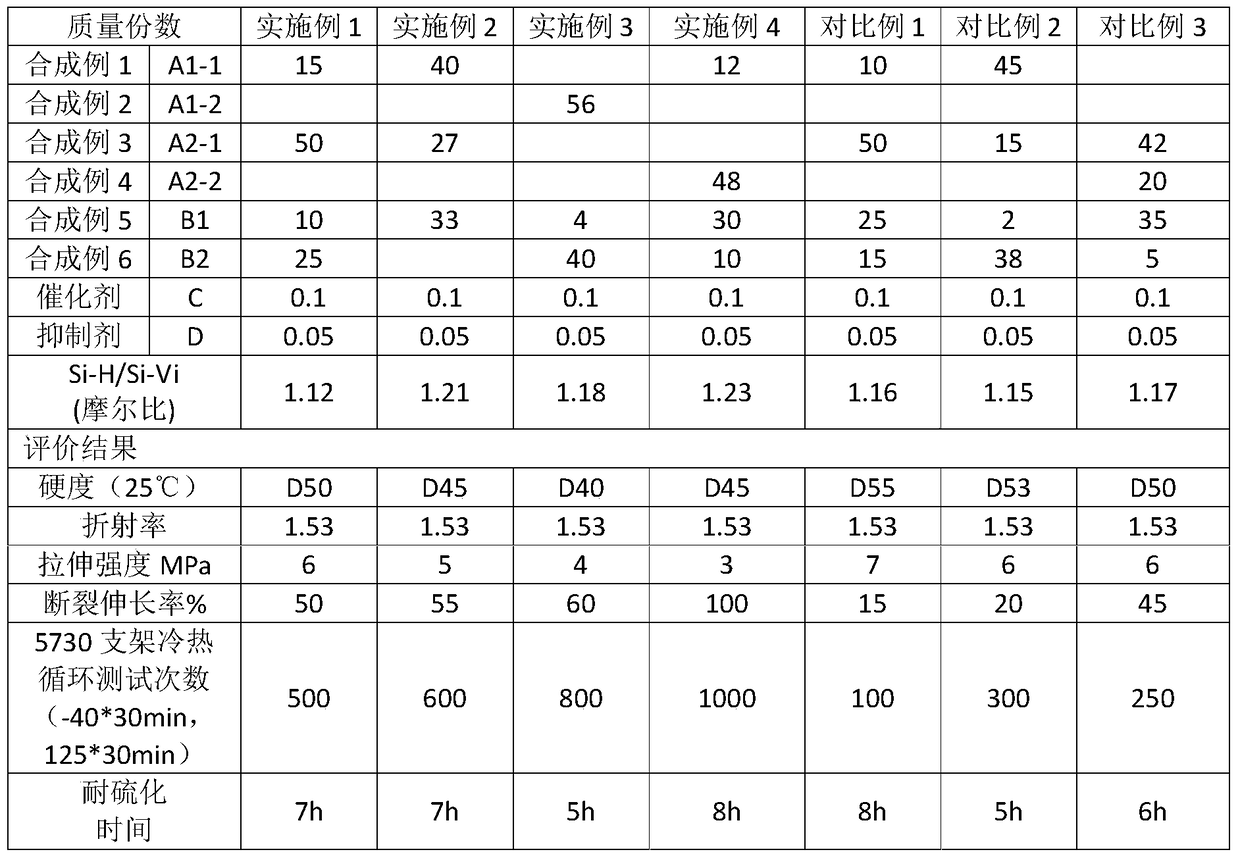

The invention provides a curable block organopolysiloxane composition and a semiconductor device to overcome the defect of poor cold and heat shock resistance in the prior art. The curable block organopolysiloxane composition has tensile strength of 1 to 8 Mpa, elongation at break of 50 to 200% and a refractive index of no less than 1.45 in a curing state under the conditions of a temperature of 25 DEG C and humidity of 60% RH. The composition comprises (A1) a block branched-chain-structured organopolysiloxane copolymer containing a R13SiO1 / 2 unit, a [R22SiO2 / 2]m unit and a [R3SiO3 / 2]n unit; (B1) straight-chain-structured polyorganohydrosiloxane, each molecule of which has at least one hydrogen atom bonding with silicon and at least one aromatic group on average; and (C) a hydrosilylation catalyst, wherein the amount of the hydrosilylation catalyst is sufficient to promote curing of the composition. Compared with the prior art, the curable block organopolysiloxane composition provided by the invention not only maintains good sulfuration resistance, a high refractive index and high hardness and has excellent cold and heat shock resistance.

Owner:GUANGZHOU HUMAN CHEM

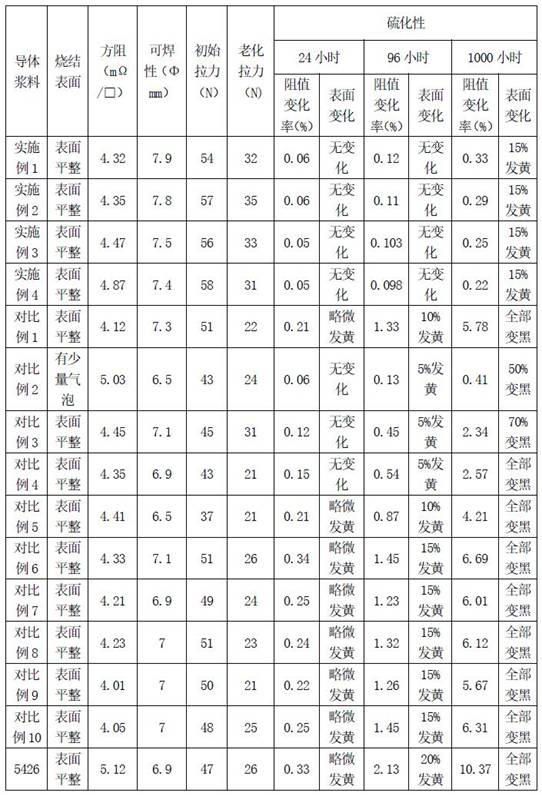

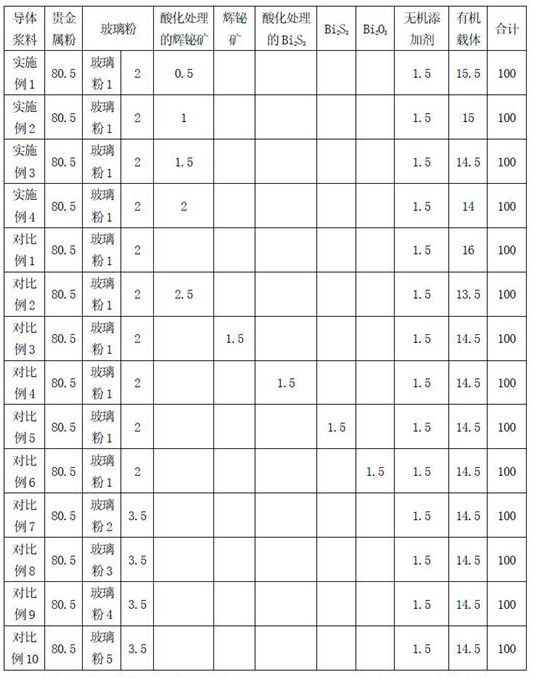

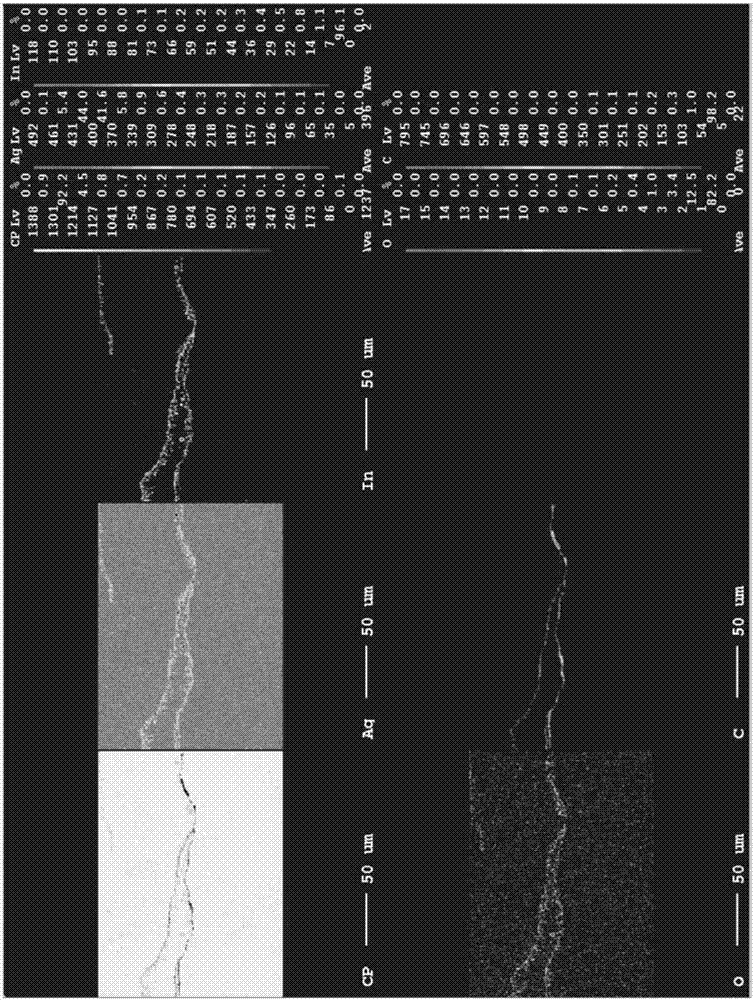

Sulfuration-resistant conductor paste

ActiveCN114360763AExcellent resistance to sulfurationSimple preparation processNon-conductive material with dispersed conductive materialCable/conductor manufactureElectrical conductorPhysical chemistry

The invention discloses a vulcanization-resistant conductor paste which is a paste with certain fluidity prepared by mixing noble metal powder, glass powder, acidized bismuthite, an inorganic additive and an organic carrier. The acidized bismuthite is added into the conductor paste, so that the performance of the conductor paste is ensured, the vulcanization resistance of the conductor paste is improved, the use reliability of the conductor paste in a sulfur-containing environment is ensured, and the use requirements of circuit products in the sulfur-containing environment can be met.

Owner:西安宏星电子浆料科技股份有限公司

Ag alloy sputtering target

ActiveCN105378140BImprove reflectivityImprove heat resistanceElectroluminescent light sourcesSolid-state devicesSputteringMetallurgy

The present invention provides a stably Ag alloy sputtering target to DC sputtering.Ag alloy sputtering target of the present invention has a composition of In and the balance comprising 0.1 to 1.5 mass% of Ag, and consisting of inevitable impurities, an oxygen concentration of 50 ppm by mass, in the entire region in the thickness direction of the target, by ultrasonic flaw detection crushing area ratio of the void portion relative to the area of ??the measuring apparatus sputtering surface is 1.0 �� 10-4 or less.

Owner:MITSUBISHI MATERIALS CORP

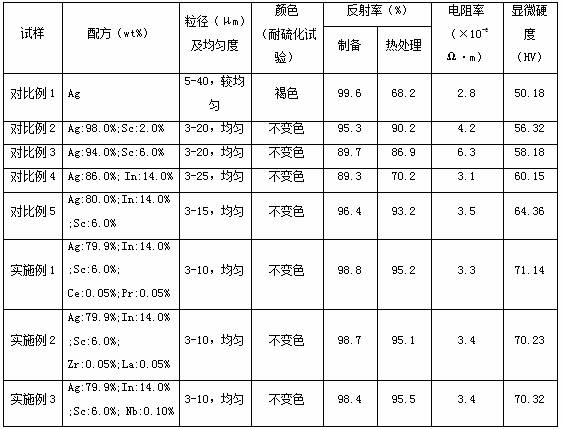

Ag-based alloy target material and preparation method thereof

ActiveCN113913761AExcellent resistance to sulfurationImprove performanceVacuum evaporation coatingSputtering coatingFilm resistanceIngot casting

The invention relates to an Ag-based alloy target material and a preparation method thereof. The Ag-based alloy target material is prepared from the following raw materials in percentage by mass: 74.90-84.95 wt% of Ag, 15-25 wt% of In + Sc and 0.05-0.15 wt% of doping elements, wherein the doping elements are selected from one or two of Ce, Pr, Zr, La and Nb. The preparation method of the Ag-based alloy target material comprises the steps of smelting and ingot casting, heating, rolling, heat treatment, shaping, machining, binding and the like. According to the novel Ag-based alloy target material, In and Sc are added into a silver base, the vulcanization resistance and heat resistance of silver-based alloy are effectively improved, meanwhile, the defects that the resistivity of a silver-based film is increased and the reflectivity is reduced due to the fact that the use amount of Sc is increased are overcome, and a synergistic effect exists between In and Sc; and on the basis, by adding other doping elements, the grain size can be further reduced, and the comprehensive performance of the target material is improved. Acquisition of the technical effects is a result of comprehensive action of a plurality of technical means such as a product formula and a preparation method.

Owner:WUHU YINGRI TECH CO LTD

Laminated film

InactiveCN107003450BInhibitionPrevent discolorationSynthetic resin layered productsCoatingsInfraredMembrane surface

The present invention provides a laminated film having a layer containing an infrared absorber that suppresses the generation of cracks and discoloration even in a high-humidity environment exposed to sunlight and is excellent in sulfuration resistance. The present invention is a laminated film having a substrate and an infrared absorbing layer, the infrared absorbing layer containing an infrared absorbing agent, a resin, and an antioxidant, and disposed on one surface of the substrate, wherein the The film surface pH of the surface of the infrared absorbing layer opposite to the substrate is 6.5 or higher.

Owner:KONICA MINOLTA INC

958 alloy for die casting and red silver jewelry and processing technology thereof

InactiveCN108796288ARelaxed Freezing Temperature RangeGood castabilitySolid state diffusion coatingSocial benefitsDie casting

The invention discloses a 958 alloy for die casting and red silver jewelry and a processing technology thereof. The alloy comprises, by weight, 0.2-0.3% of C, 0.5-0.6% of B, 1.2-1.4% of Ba, 0.4-0.8% of Ti, 0.8-1.2 % of Mo, 0.3-0.5% of Sb, 95-96% of Ag, and the balance copper. A new material with red appearance is provided for the 958 silver alloy for the jewelry in China, and the material has an excellent die casting characteristic. The implementation and industrialization of the material can effectively promote the demands of product updating and industry upgrading in the jewelry industry ofChina, and rich economic gains and social benefits are obtained when the industry problems are solved.

Owner:GUANGZHOU YUZHI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com