Silver-based alloy target material blank for vacuum magnetron sputtering and preparation method as well as application thereof

A vacuum magnetron sputtering and silver-based alloy technology, which is applied in metal material coating process, sputtering coating, vacuum evaporation coating, etc., can solve the problem of poor adhesion of the bottom plate, decreased reflectivity of the film, and silver grains. Growth and other problems, to achieve the effect of good adhesion, low resistivity, and good sulfuration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In the specific implementation process, the present invention is used for the preparation method of vacuum magnetron sputtering silver-based alloy target blank, including the following process steps:

[0028] (1) Use 10 according to the ratio -5 The precision balance accurately weighs the weight of the metal elements required for each alloy, and uses a high-frequency induction furnace with an argon protection device for alloy melting; first, put the metal copper into a graphite crucible and heat it up to melt, and then heat it up at 1120 ° C ± 50 Add zinc at about ℃ for alloying smelting. After smelting, lower the graphite crucible to the cooling platform, and cast it under the conditions of hot top protection, permanent magnetic stirring and directional forced cooling. The obtained copper-zinc alloy billet is cooled to room temperature. Afterwards, it is taken out for rolling and shearing to obtain a copper-zinc binary master alloy for future use. Before smelting, high...

Embodiment 1

[0034] After the smelting is completed, the specific chemical composition of the silver-based alloy target blank in this embodiment is as follows: the copper content is 0.5wt%; the yttrium content is 0wt% to 1.0wt%; the additional alloying elements are selected from the following elements One or more than two kinds of: Ni, Ce, Zn, Al, Mg, Nd, Si, the total addition amount is 0.035wt%-0.14wt%; the balance is silver.

[0035]

[0036] Note: Alloy content is mass percentage (wt%)

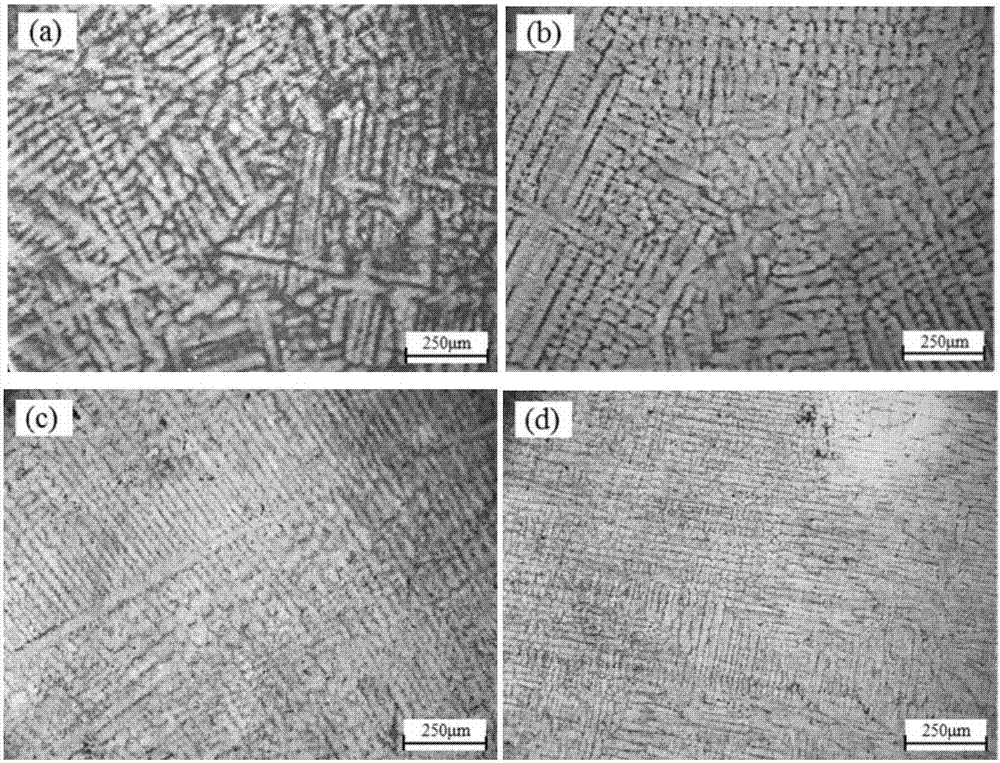

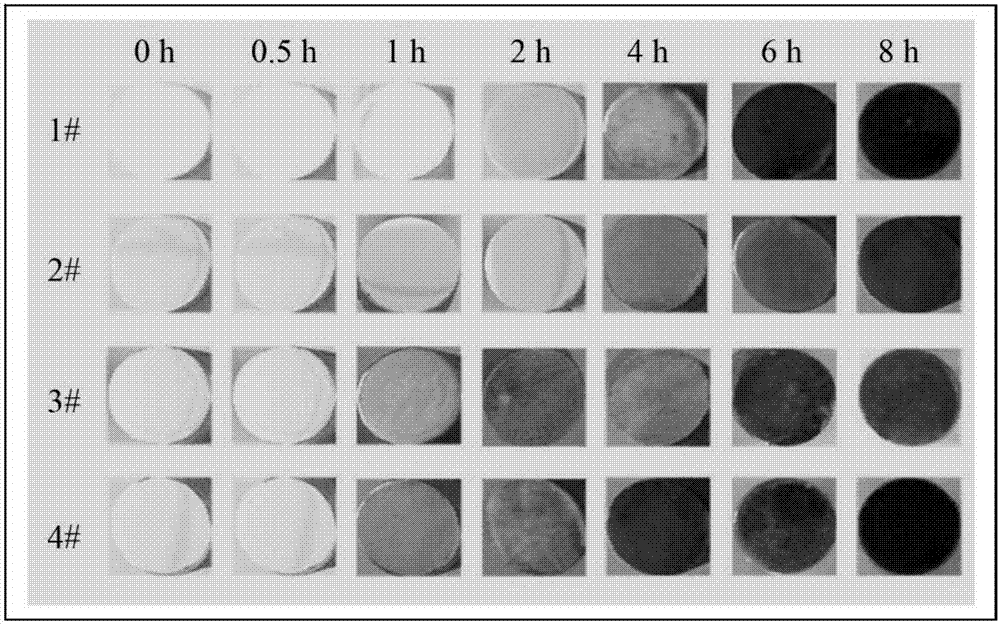

[0037] After grinding, polishing, and corrosion, the performance of the alloy blank is detected and tested. The microstructure of the silver-based alloy target blank in this example is shown in the attached figure 1, as the addition of element Y increases, the grain size of the sample becomes smaller; the grain size of the 4# sample with the addition of element Y 1.0wt% is obviously refined, but black lumps are precipitated. The surface color of each silver-based alloy target blank changes with tim...

Embodiment 2

[0040] After the smelting is completed, the specific chemical composition of the silver-based alloy target blank in this embodiment is as follows: the copper content is 1.0wt%; the yttrium content is 0wt% to 1.0wt%; the additional alloying elements are selected from the following elements One or more than two kinds of: Ni, Ce, Zn, Al, Mg, Nd, Si, the total addition amount is 0.035wt%-0.14wt%; the balance is silver.

[0041]

[0042] Note: Alloy content is mass percentage (wt%)

[0043] After grinding, polishing, and corrosion, the performance of the alloy blank is detected and tested. The microstructure of the silver-based alloy target blank in this example is shown in the attached image 3 , as the addition of element Y increases, the sample grain size of the silver-based total target blank becomes smaller; the 8# sample with the addition of element Y 1.0wt% has a black mass near the dendrite boundary of the cast structure precipitated and distributed evenly. The surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com