A kind of electroplating post-treatment process of silver-plated copper wire

A technology of silver-plated copper wire and post-processing, applied in the direction of metal material coating process, etc., can solve the problems of uneven stretching of silver-plated copper wire, inability to protect silver-plated copper wire, magnifying the defects of protective film, etc. Unstable elongation, good anti-oxidation, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] see Figure 1-8 As shown, this embodiment is an electroplating post-treatment process for silver-plated copper wire, which includes the following steps:

[0040] Step 1: Add 75533 gold-silver protective agent into clear water in a volume ratio of 1:0.1-5, stir evenly to form a passivation solution for silver-plated copper wires, and transport it to the passivation chamber 121 through the liquid inlet 107 of the electroplating post-processing equipment , the clean water is transported to the washing chamber 122 through the clean water port 108;

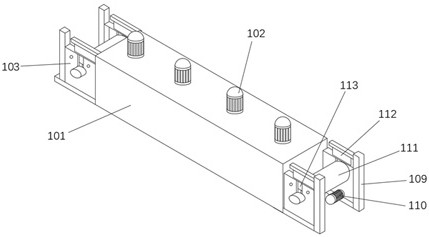

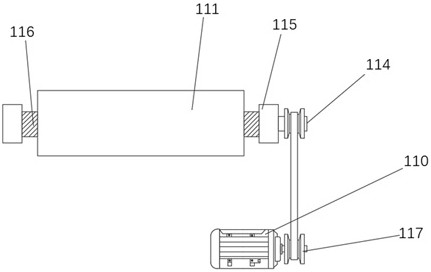

[0041] Step 2: Rewind the silver-plated copper wire onto the rewinding roller 111 of the feeding mechanism 103, insert the limit plate 112 to clamp and fix the bearing 116 on the rewinding roller 111, and then fix the limit plate 112 with bolts For fixing, pass the silver-plated copper wire through the wire inlet hole 118, and then pass through the spray chamber 135, and respectively wind each wire pulley 126 for one turn, then...

Embodiment 2

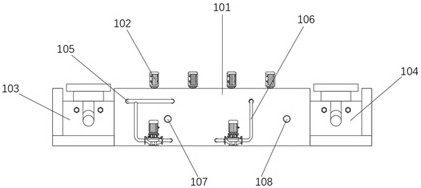

[0047] see Figure 1-8 As shown, this embodiment is an electroplating post-processing equipment, including a post-processing box 101, a feeding mechanism 103, a winding mechanism 104, a passivation mechanism 105, a washing mechanism 106, a speed regulating plate 124, a wire pulley 126, a drying The cylinder 127 and the installation box 128, the two ends of the post-processing box 101 are respectively installed with a feeding mechanism 103 and a winding mechanism 104, a number of adjusting motors 102 are installed on the top of the post-processing box 101, and both sides of the post-processing box 101 are installed There are a passivation mechanism 105 and a washing mechanism 106, the passivation mechanism 105 is located on the side close to the feeding mechanism 103, and the washing mechanism 106 is located on the side close to the winding mechanism 104;

[0048] The top of the inner cavity of the post-processing box 101 is provided with a support plate 123, and several speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com