Ag alloy sputtering target and method for manufacturing ag alloy sputtering target

A manufacturing method and technology of sputtering target, which are applied in sputtering coating, metal material coating process, vacuum evaporation coating and other directions, can solve the problems of generating sulfide and other problems, achieve easy removal, shorten the pre-sputtering time, inhibit the warping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

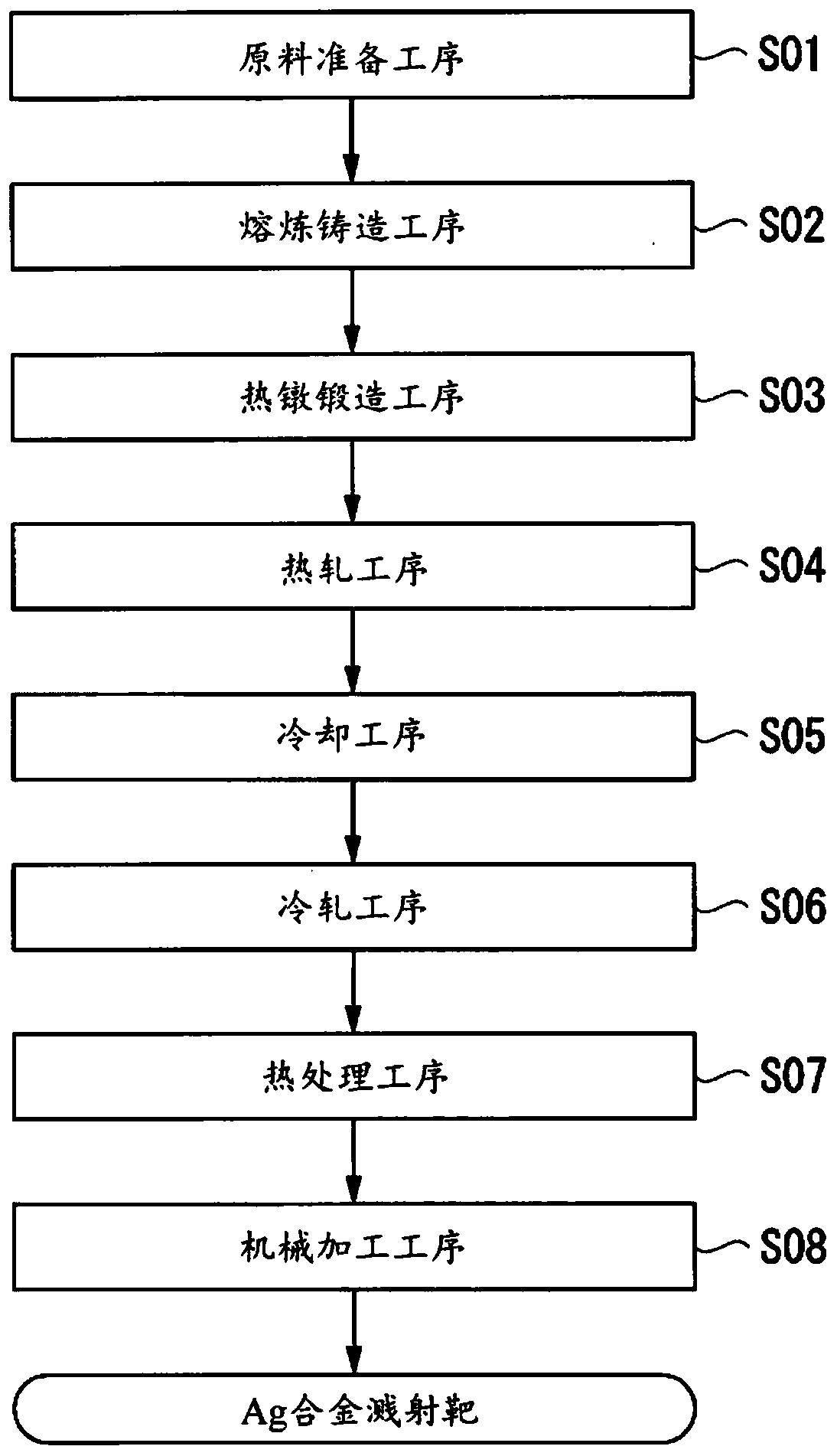

Method used

Image

Examples

Embodiment

[0102] Hereinafter, the result of the evaluation test which evaluated the Ag alloy sputtering target of this invention mentioned above is demonstrated.

[0103] First, as melting raw materials, Ag raw materials with a purity of 99.99% by mass or higher, In raw materials with a purity of 99.9% by mass or higher, Sn raw materials, and Ge raw materials were prepared. These melted raw materials were weighed so as to have the compounding compositions shown in Table 1.

[0104] Next, through a high-frequency induction heating furnace with a graphite crucible, Ag is smelted under an inert gas atmosphere after vacuum exhaust, and In, Sn, and Ge are appropriately added to the obtained Ag melt. Melting was carried out in an atmosphere.

[0105] After the Ag alloy molten metal was sufficiently stirred by the stirring effect by induction heating, a cast iron mold was cast. The shrinkage cavity portion of the obtained ingot was excised, and the surface of the ingot was ground to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com