Laminated film

A technology of laminated film and absorbing layer, applied in the field of laminated film, can solve the problem that laminated film is difficult to shield the infrared region

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

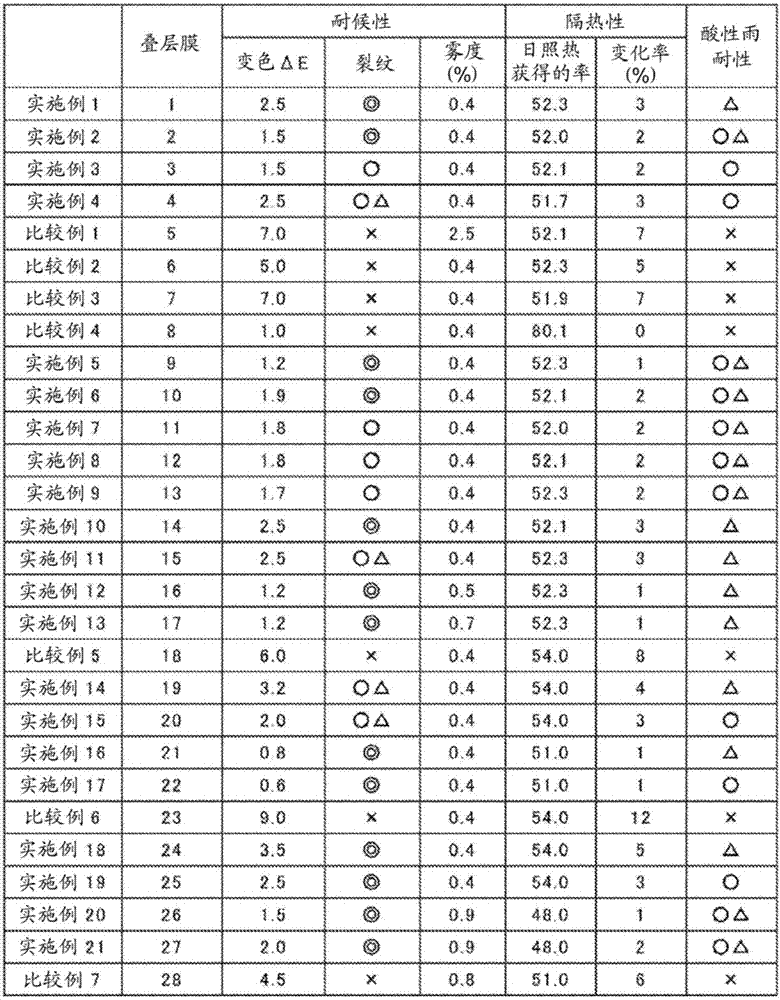

Examples

preparation example Construction

[0096] The method for preparing the coating liquid for an infrared absorbing layer is not particularly limited as long as a specific film surface pH can be obtained. The coating liquid for an infrared absorbing layer can be prepared, for example, by adding other additives such as an infrared absorbing agent, a resin, and optionally a surfactant to a solvent, followed by stirring and mixing. In the case of using an ultraviolet curable resin, a photopolymerization initiator is further added. At this time, the order of adding each component is not particularly limited, and each component may be added and mixed sequentially while stirring, or may be added and mixed at once while stirring.

[0097] As far as pH adjustment is concerned, as long as any acidic or alkaline pH adjusting agent is used, for example, in the case of an aqueous solvent, it is possible to add a base such as sodium carbonate or sodium hydroxide to the coating liquid for the infrared absorbing layer. And / or ac...

Embodiment

[0203] Hereinafter, the present invention will be specifically described with reference to examples, but the present invention is not limited thereto. In addition, in an Example, although the expression of "part" or "%" is used sometimes, unless otherwise specified, it means "part by mass" or "% by mass".

[0204] "Making of laminated film"

[0205]

[0206] (Preparation of Coating Solution 1 for Infrared Absorbing Layer)

[0207] The following materials were mixed and stirred at room temperature for 30 minutes to prepare a coating liquid 1 for an infrared absorbing layer.

[0208] Acrit 8UA-301 (urethane-modified acrylic polymer: manufactured by Taisei Fine Chemical Co., Ltd.) 633 parts by mass

[0209] YMF-02A (compound tungsten oxide containing cesium (Cs 0.33 WO 3 ), solid content 28.7% by mass, particle concentration 18.5% by mass, average particle diameter 15nm, refractive index 1.66: manufactured by Sumitomo Metal Mining Co., Ltd.) 294 parts by mass

[0210] Adek...

Embodiment 2

[0226] (Preparation of Coating Liquid 2 for Infrared Absorbing Layer)

[0227] 6.4 parts by mass of 1SX-1065 of coating solution 1 for infrared absorbing layer was changed to 2.8 parts by mass of Chelest MZ-8 (organic solvent-soluble chelating agent, pH 7.6: manufactured by Chelest Co., Ltd.) Also, the coating solution 2 for an infrared absorbing layer was prepared in the same procedure.

[0228] (Preparation of laminated film 2)

[0229] The laminated film 2 was produced in the same manner as the laminated film 1 except that the coating liquid 2 for an infrared absorbing layer was used instead of the coating liquid 1 for an infrared absorbing layer.

[0230] The film surface pH of the infrared absorbing layer of the multilayer film 2 was measured in the same manner as above, and the film surface pH was 7.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com