Silver alloy, sputtering target material thereof, and thin film thereof

A silver alloy and thin film technology, applied in metal material coating process, sputtering coating, vacuum evaporation coating and other directions, can solve the problem of color liquid crystal display brightness reduction, insufficient improvement of sulfidation resistance, and reduced reflectivity, etc. problems, to achieve the effect of improved weather resistance, excellent heat resistance, and excellent vulcanization resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

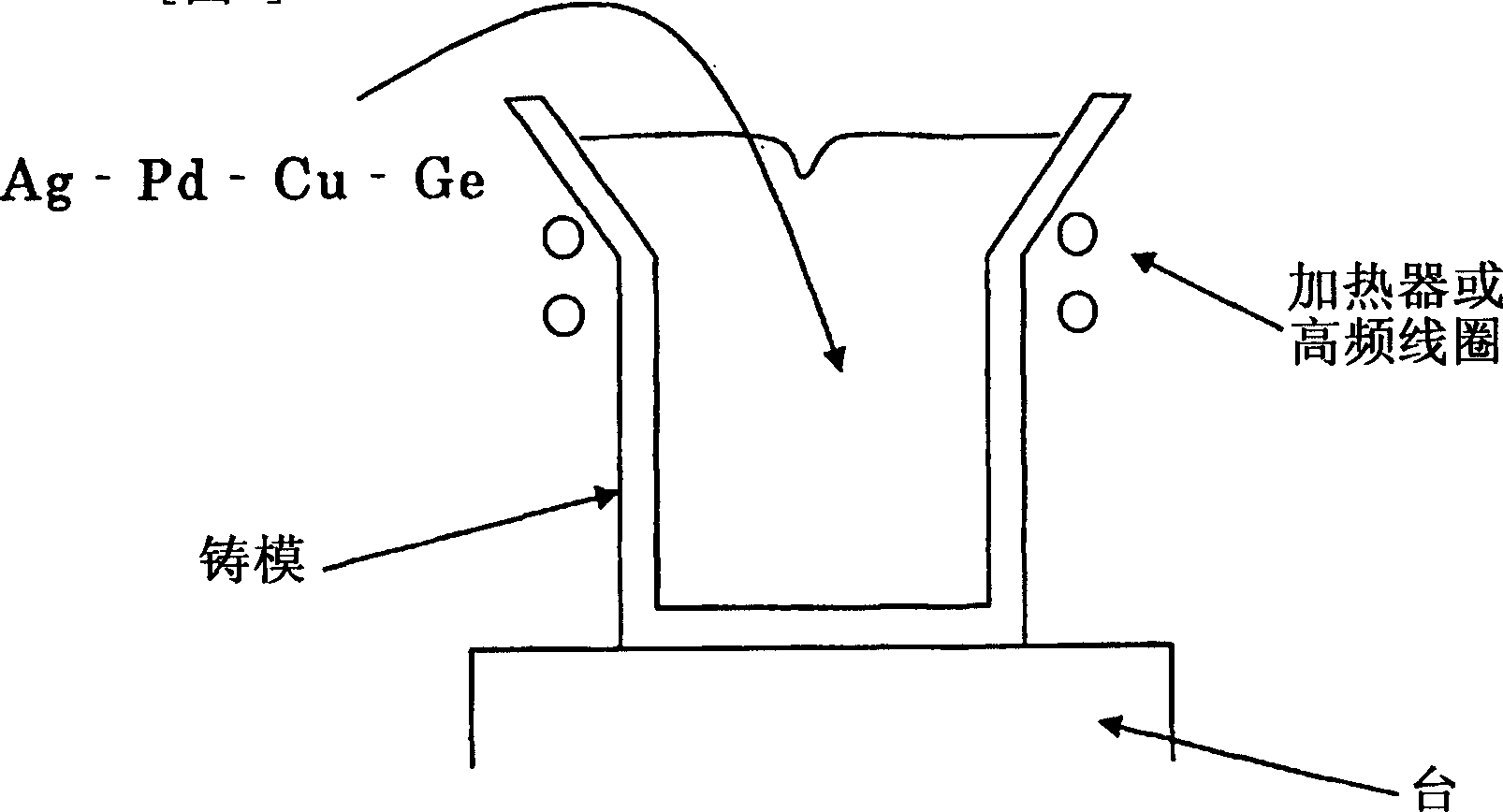

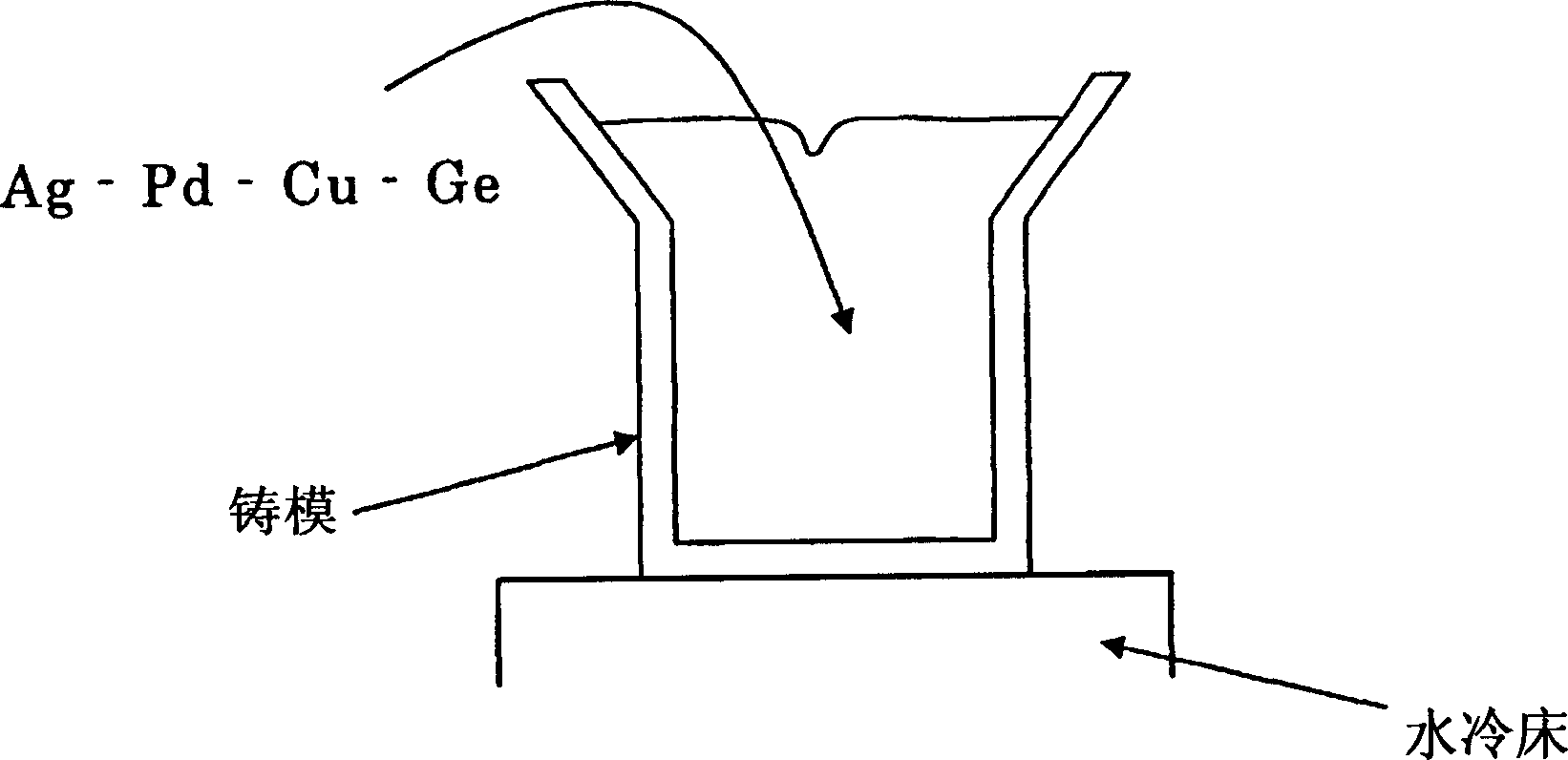

Method used

Image

Examples

Embodiment 1

[0055] Make 98.7Ag-0.8Pd-0.3Cu-0.2Ge (referring to Ag content: 98.7wt%, Pd content: 0.8wt%, Cu content: 0.3wt%, Ge content: 0.2wt%) with the method shown in embodiment .The following notation is used to indicate the composition of the silver alloy.) The silver alloy sputtering target material. Using this silver alloy sputtering target material, a silver alloy reflective film having the above composition was formed by sputtering on a quartz glass substrate with a smooth surface, as Example 1. The film thickness was 200 nm. The AFM (atomic force microscope, Atomic Force Microscope, manufactured by SII Corporation, model SPA300HV) image of the formed thin film is as follows Figure 4 (a) shown. At this time, surface roughness analysis was carried out, and Ra (nm) was 1.410, RMS (nm) was 1.785, and P-V (nm) was 14.07. Further, the reflectance of the silver alloy thin film of Example 1 was measured with a spectrophotometer (manufactured by Shimadzu Corporation, model UV-3100PC)....

Embodiment 2

[0057] The silver alloy thin film of Example 1 was heat-treated in air at 250° C. for 1 hour. Take this as Example 2. For the silver alloy film of Example 2, AFM observation is also carried out in the same manner as in Example 1, and the AFM image is shown in Figure 6 (a). At this time, surface roughness analysis was carried out, and Ra (nm) was 1.693, RMS (nm) was 2.203, and P-V (nm) was 24.55. Furthermore, the reflectance of the silver alloy thin film of Example 2 was measured similarly to Example 1. The results are shown in Figure 7 middle.

Embodiment 3

[0075] A silver alloy sputtering target material of 98.4Ag-0.8Pd-0.3Cu-0.5Ge was produced by the method shown in the embodiment. Using this silver alloy sputtering target material, a silver alloy reflective film of the above composition was formed on a quartz glass substrate with a smooth surface by sputtering. The film thickness was 200 nm. The silver alloy thin film was heat-treated at 250° C. for 1 hour in air. Take this as Example 3. Also carry out AFM observation to the silver alloy thin film of embodiment 3 in the same manner as embodiment 1, and the AFM image is shown in Figure 8 (a). At this time, surface roughness analysis was carried out, and Ra (nm) was 1.727, RMS (nm) was 2.314, and P-V (nm) was 28.06. Furthermore, the reflectance of the silver alloy thin film of Example 3 was measured similarly to Example 1. The results are shown in Figure 9 middle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com