Electrolytically silver plated and/or electrolytically silver alloy plated article having oxide layer on surface

A technology of electroplating silver and oxide layer, applied in the plating of superimposed layers, electrical components, coatings, etc., can solve the problem of not carrying out effective technical development, and achieve high productivity, high reflectivity, and excellent sulfidation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1

[0045] Silver plating was performed on copper substrates under the following silver plating baths and plating conditions.

[0046] silver plating bath

[0047] Ag: 2.5g / L (using potassium silver cyanide as Ag)

[0048] KCN: 5g / L

[0049] Plating temperature: 25°C

[0050] Plating area: 0.1dm 2 (25mm×20mm)

[0051] Parts to be plated: copper plate

[0052] Current density: 2A / dm 2

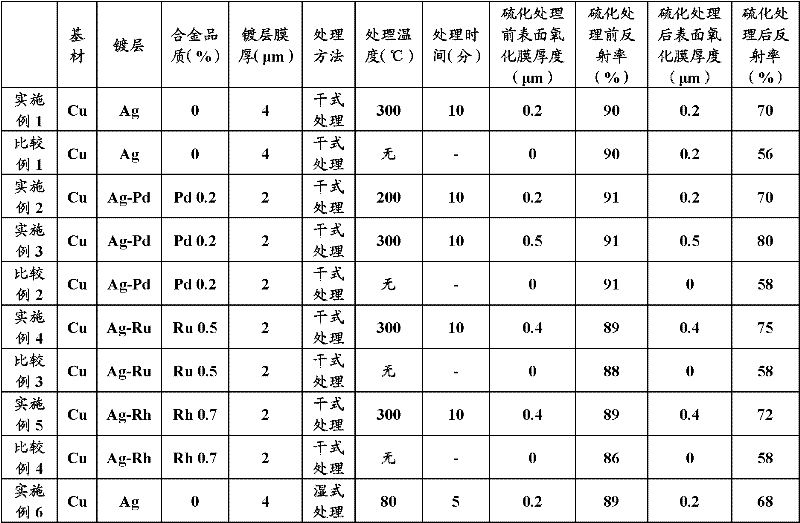

[0053] Next, in Example 1, oxidation treatment was performed under the conditions described in Table 1 as follows, and after the oxidation treatment, the film thickness and reflectance of the oxide layer were measured before and after sulfur treatment. In addition, in Comparative Example 1, oxidation treatment was not performed, and the film thickness and reflectance of the oxide layer were measured before and after sulfur treatment.

[0054] In addition, the film thickness of the silver plating film and / or silver alloy plating film is obtained by fluorescent X-ray analysis.

[0055] The re...

Embodiment 2~3、 comparative example 2

[0067] On the basis of Example 1, instead of electroplating silver, the following silver alloy plating bath and plating conditions were used, and the oxidation treatment temperature was set to the temperature listed in Table 1, except that it was plated in the same manner as in Example 1 to obtain The plated materials of Example 2 and Example 3 were evaluated in the same manner as in Example 1.

[0068] In addition, on the basis of comparative example 1, instead of electroplating silver, utilize the following silver alloy plating bath and plating conditions to carry out silver plating alloy, obtain the plated part of comparative example 2 in the same way as comparative example 1 except this, and comparative example 1 Evaluate in the same way.

[0069] Silver-Palladium Plating Bath

[0070] Ag: 2.5g / L (using potassium silver cyanide as Ag)

[0071] Pd: 5.0g / L (using potassium palladium cyanide)

[0072] KCN: 5g / L

[0073] Plating temperature: 25°C

[0074] Plating area: 0....

Embodiment 4、 comparative example 3

[0079] On the basis of Example 1, instead of electroplating silver, the following silver alloy plating bath and plating conditions were used, and the oxidation treatment temperature was set to the temperature listed in Table 1, except that it was plated in the same manner as in Example 1 to obtain The plated material of Example 4 was evaluated in the same manner as in Example 1.

[0080] In addition, on the basis of comparative example 1, instead of electroplating silver, utilize the following silver alloy plating bath and plating conditions to carry out silver alloy plating, obtain the plated part of comparative example 3 in the same way as comparative example 1 except this, and comparative example 1 was evaluated in the same manner.

[0081] Silver-ruthenium plating bath

[0082] Ag: 2.5g / L (using potassium silver cyanide as Ag)

[0083] Ru: 5.0g / L (using potassium ruthenium cyanide)

[0084] KCN: 5g / L

[0085] Plating temperature: 25°C

[0086] Plating area: 0.1dm 2 (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com