Reflective film laminate

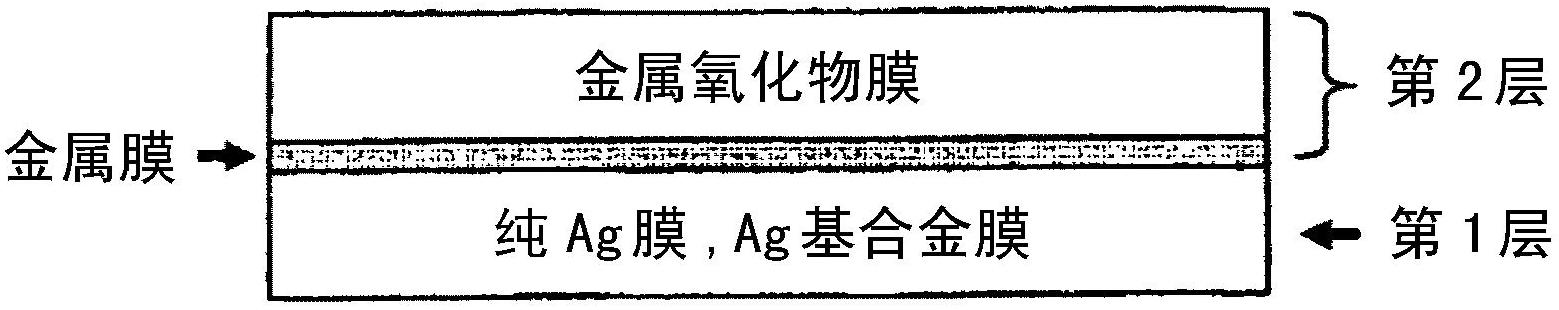

A technology of reflective film and laminated body, which is applied in the field of optical mirror bodies, vehicle lamps, and lighting appliances. It can solve the problems of high reflectivity reduction of Ag film, and achieve excellent vulcanization resistance, high reflectivity, and excellent heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1~41

[0089] The substrate uses polycarbonate (PC), and the sputtering target uses a pure Ag or Ag-based alloy sputtering target with a diameter of 101.6 mm×a thickness of 5 mm. First, according to the pressure in the sputtering chamber is 1.3×10 -3 The method below Pa is evacuated. Next, by introducing Ar gas into the sputtering chamber, the pressure in the sputtering chamber is 2.6×10 -1 In the method of Pa, DC (direct current) power of 200W is applied to the electrode to generate plasma, and the sputtering target is sputtered to form a film to form the first layer. The distance between the sputtering target and the PC base was 80 mm, and it was formed while the PC base was revolving. In addition, film formation was performed at normal temperature except that the film formation temperature in Production Example 41 was set to 150°C.

[0090] The method of measuring the average content of various additive elements in the Ag-based alloy film thus formed will be described later.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com