Resin Composition For Encapsulating Optical Semiconductor Element And Light Emitting Device

A technology for optical semiconductor components and resin compositions, which is applied to semiconductor devices, semiconductor/solid-state device parts, electrical components, etc., can solve the problems of resin cracking, failure to pass the reliability test, and high gas permeability, and achieves high resistance to Excellent vulcanization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

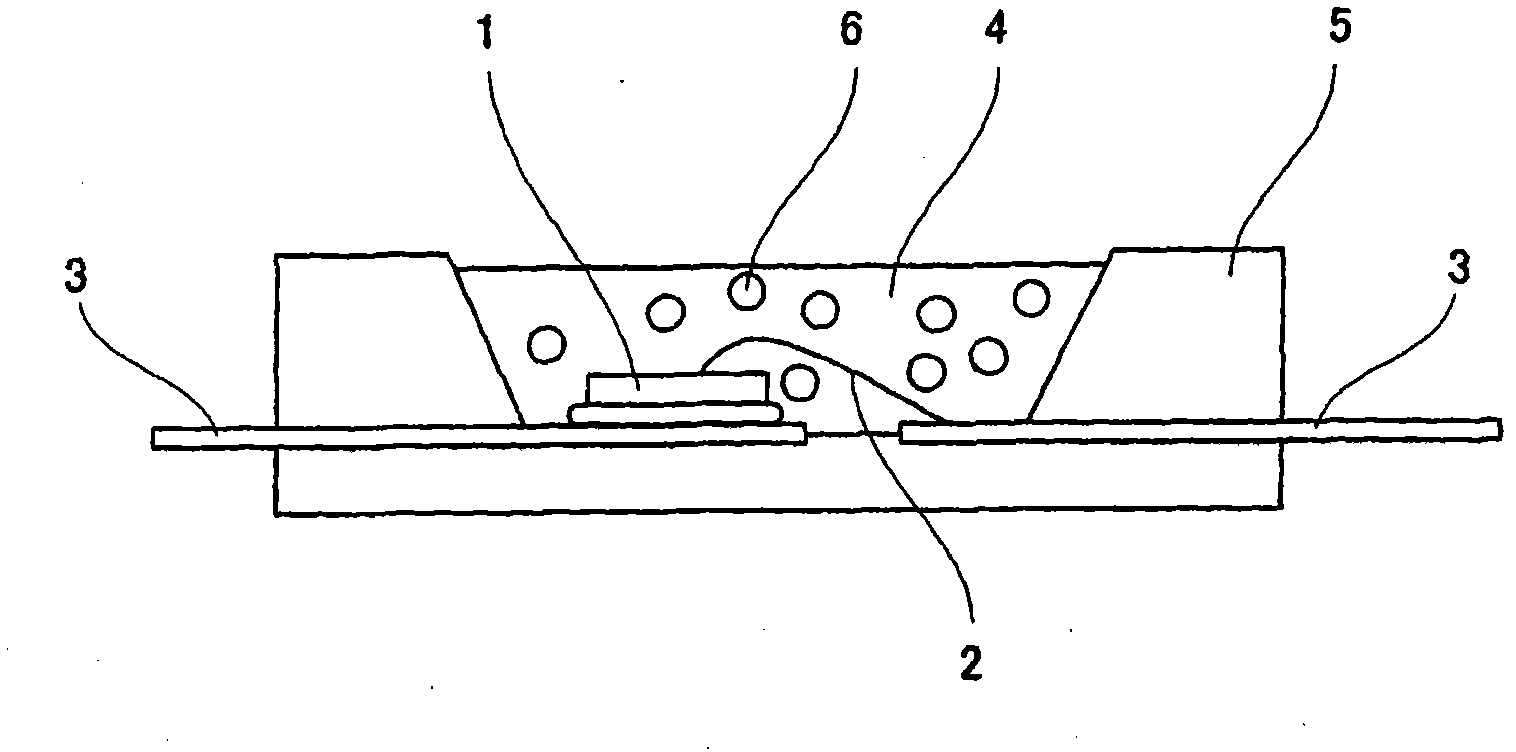

[0108] In the above-mentioned basic compound, disperse Glasflex (registered trademark) (product number: REP-015, average particle diameter) manufactured by Nippon Sheet Glass Co., Ltd., which has a refractive index of 1.51 as the (D) component, at a concentration of 10% by mass. : 15 μm, aspect ratio: 3-10) The resulting substance was filled into an unsealed light-emitting diode (LED), and the main curing was performed at 150° C. for 4 hours to manufacture a light-emitting diode for evaluation.

Embodiment 2

[0110] In the above-mentioned basic compound, disperse as a concentration of 50% by mass of Galas Flue (registered trademark) (product number: REP-015, average particle size : 15 μm, aspect ratio: 3-10) The resulting substance was filled into an unsealed light-emitting diode (LED), and the main curing was performed at 150° C. for 4 hours to manufacture a light-emitting diode for evaluation.

Embodiment 3

[0112] In the above-mentioned basic compound, disperse Mildford (registered trademark) (product number: PFE-301, fine powder) manufactured by Nitto Industries Co., Ltd. with a refractive index of 1.51 as the (D) component at a concentration of 10% by mass. Shaped glass fiber, average particle size: 10 μm, aspect ratio: 1.1 to 10) The resulting material is filled into an unsealed light-emitting diode (LED), and the main curing is carried out at 150°C for 4 hours to manufacture a luminescent light-emitting diode for evaluation. diode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com