Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Excellent cold formability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-cost non-quenched and tempered high-strength weathering steel with yield strength level of 700MPa and manufacturing method thereof

InactiveCN101921965AAdd corrosion resistant elementsLow costUltimate tensile strengthContinuous rolling

The invention provides low-cost non-quenched and tempered high-strength weathering steel with yield strength level of 700MPa for containers and a manufacturing method thereof. Based on the carbon manganese structural steel composition, the reinforcement effect is enhanced by adding a proper amount of micro-alloy elements such as Nb, Ti, Cu, Cr, Ni and the like, adopting a controlled rolling and controlled cooling technique, taking production characteristics of a normal hot continuous rolling machine into consideration and using a high-Ti component design. Meanwhile, Si content is reduced and high cold forming performance is ensured. The weathering steel for the containers comprises the following components in percentage by weight: 0.05 to 0.10 percent of C, less than or equal to 0.15 percent of Si, 1.5 to 2.0 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.01 percent of S, 0.3 to 0.8 percent o Cr, 0.2 to 0.4 percent of Cu, 0.15 to 0.4 percent of Ni, 0.09 to 0.15 percent of Ti, 0.02 to 0.08 percent of Nb, less than or equal to 0.005 percent of N, less than or equal to 0.002 percent of O and the balance of Fe and inevitable impurities. The yield strength is over 700MPa, the tensile strength is over 800MPa and the elongation is over 18 percent.

Owner:SHANDONG IRON & STEEL CO LTD

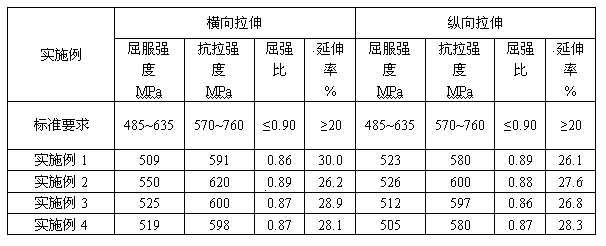

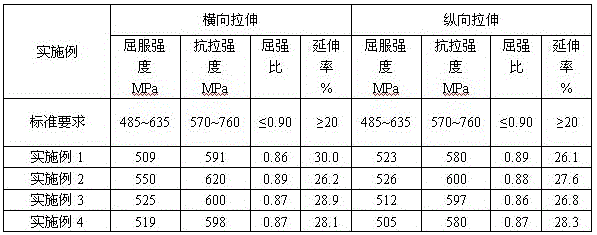

Pipeline steel plate with low yield ratio, fine grains and high strength and production method thereof

The invention discloses a pipeline steel plate with low yield ratio, fine grains and high strength and a manufacturing method thereof, and steel in the pipeline steel plate comprises the following chemical components by weight percent: 0.03-0.10% of C, 0.10-0.30% of Si, 1.20-1.80% of Mn, not more than 0.015% of P, not more than 0.005% of S, 0.040-0.060% of Nb, 0.006-0.020% of Ti, 0.10-0.40% of Cr, 0.10-0.30% of Ni, 0.010-0.050% of Al and the balance of Fe and inevitable impurities. The manufacturing method adopts a converter for smelting, adopts the TMCP (thermo mechanical control process) and the two-phase region subthermal quenching treatment at 720-750 DEG C, thereby obtaining the pipeline steel plate with low yield ratio, fine grains and high strength; and the manufacturing method has stable production process, strong operability, low cost and high performances.

Owner:NANJING IRON & STEEL CO LTD

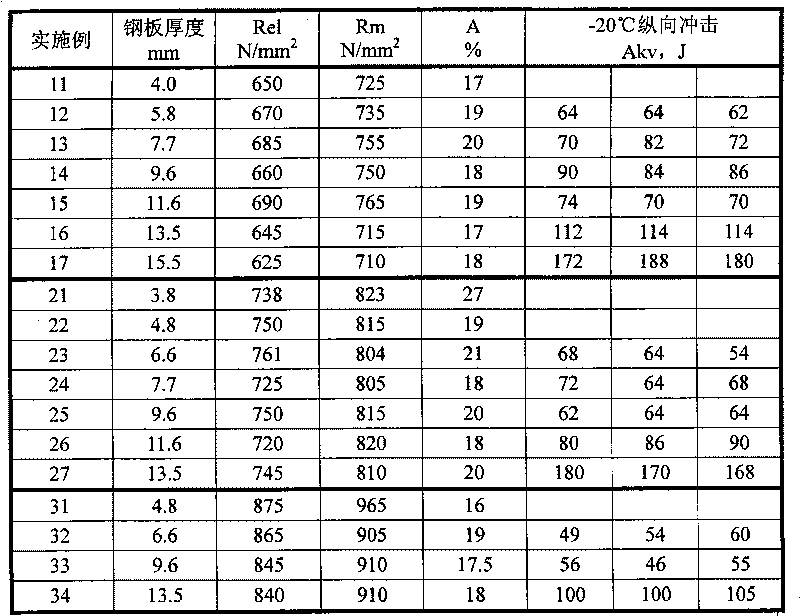

High tensile strength low carbon bainite thick steel plate and its production method

InactiveCN1786245AReduce carbon contentLow carbon content, low temperature toughnessOther manufacturing equipments/toolsChemical compositionHigh intensity

The invention offers a high tensile strength low carbon bainite coarse plate and its manufacturing method. Its compositions (Wt%) are C 0.052%-0.08%, Si 0.1%-0.5%, Mn1.65%-1.90%, Nb 0.015%-0.060%, Ti 0.005%-0.03%, B 0.0005%-0.003%, Mo 0.25%-0.50%, Cu 0.62%-0.85%, Ni 0.42%-0.80%, Al 0.015%-0.05%, and rest Fe and other inevitable impurity. The invention adopts low cost Mn element as the main additional element, fully applies the changing action of Cu, Mo, Ni, Nb, B to the bainite. The steel has low carbon, good low temperature toughness, welding performance, and forming performance. Its Nb and Ti element is low. And it is fit for large-scale industrialization continuous casting production. The TMCP+ RPC+T technique is adopted to make tensile strength over 900N / mm2 high intensity and tenacity steel. Adopting lower steel blank heating temperature can economize energy and improve steel low temperature toughness. The product can apply in engineering machinery, digging machinery, heavy-duty car, and marine facilities field, and etc.

Owner:UNIV OF SCI & TECH BEIJING +1

Super-thick X70 pipeline steel and manufacturing method thereof

The invention discloses super-thick X70 pipeline steel and a manufacturing method thereof, wherein the pipeline steel is 30-32mm thick, and the pipeline steel comprises the following chemical ingredients in percentage by mass: 0.03-0.06% of C, 0.1-0.30% of Si, 1.30-1.60% of Mn, less than or equal to 0.010% of P, less than or equal to 0.0050% of S, 0.030-0.050% of Nb, 0.008-0.020% of Ti, 0.10-0.30% of Ni, 0.l0-0.30% of Cr, 0.10-0.30% of Cu and the balance being Fe and inevitable impurity elements. smelting raw materials are sequentially subjected to KR molten iron pretreatment, converter smelting, LF refining and RH vacuum degassing to obtain molten steel which is relatively high in purity, and then the pipeline steel, which is high in thickness, high in strength, narrow in strength interval, excellent in low-temperature toughness, and excellent in both low-temperature resistant aging performance and HIC resistance, is obtained through a controlled rolling and controlled cooling process.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

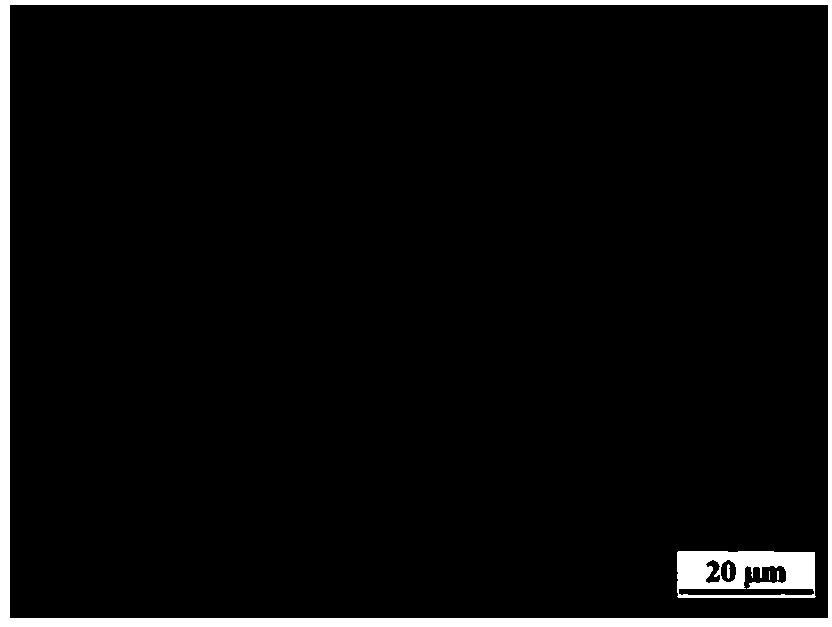

Hot rolling strip steel for high-strength cold forming welding structures and manufacturing method thereof

ActiveCN101736199AHigh strengthExcellent cold formabilityTemperature control deviceCold formedHigh intensity

The invention provides a hot rolling strip steel for high-strength cold forming welding structures and a manufacturing method thereof. The hot rolling strip steel comprises the following components: 0.055-0.09% of C, 0.05-0.50% of Si, 1.50-1.90% of Mn, 0.035-0.07% of Nb, 0.06-0.13% of Ti, 0.05-1.0% of Cr, 0.010-0.070% of Als and the balance of Fe and other unavoidable impurities. The manufacturing method comprises the steps of smelting, refining, continuous casting and rolling; heating up to 1150-1250 DEG C before rolling; rolling is controlled by two stages; rough rolling ending temperature is more than 1020 DEG C, finish rolling beginning temperature is less than 1040 DEG C, and finish rolling ending temperature is controlled to 820-920 DEG C; quick cooling is carried out after rolling; and reeling temperature is 520-620 DEG C. The hot rolling strip steel contains few C and more Ti and adds a proper amount of Cr and Nb; by the composite invigorating effect of elements, such as Cr, Nb and Ti, no noble elements, such as Mo, Ni, Cu, V and the like are added; steel types have favourable toughness, plasticity and welding property and convenient production operation and do not need heat treatment technology, such as tempering or conditioning and the like while improving strength.

Owner:ANGANG STEEL CO LTD

Thin gauge carriage body steel belt with yield strength of 600MPa, and manufacturing method of thin gauge carriage body steel belt

The invention discloses a thin gauge carriage body steel belt with a yield strength of 600MPa. The thin gauge carriage body steel belt is prepared from the following chemical components by weight percent: 0.06-0.08% of C, less than or equal to 0.20% of Si, 1.5-1.7% of Mn, less than or equal to 0.020% of P, less than or equal to 0.010% of S, 0.10-0.04% of Alt, 0.025-0.035% of Nb, 0.08-0.10% of Ti and the balance of Fe and unavoidable impurities. The invention also discloses a manufacturing method of the thin gauge carriage body steel belt with the yield strength of 600MPa. The manufacturing method comprises the steps of converter steel making, ladle furnace (LF) refining, continuous casting, slab heating, rack rough rolling, rack finish rolling, laminar cooling and reeling. By adopting a low-carbon microalloy composition design, the obtained steel belt has good cold roll forming performance.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

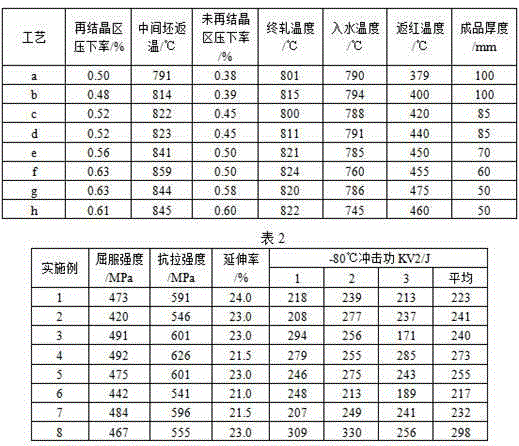

Manufacturing method for high-strength ship TMCP steel superior in minus-80 DEG C low-temperature toughness for polar region

The invention discloses a manufacturing method for high-strength ship TMCP steel superior in minus-80 DEG C low-temperature toughness for a polar region. Common continuous castings serve as raw materials, the low-sulfur smelting technology is utilized, and the TMCP technology is adopted for rolling. During rolling, the near surface of a middle blank is rapidly cooled to be below Ar3 in an acceleration manner, temperature re-rising of the near surface is achieved through the heat of a core part of the middle blank, and after the surface temperature of the middle blank is stabilized to the set initial rolling temperature, rolling of a non-recrystallization area is carried out; and after rolling, an ultra-fast cooling device is used for accelerated cooling, and then the high-strength ship TMCP steel superior in minus-80 DEG C low-temperature toughness is obtained. A steel plate is superior in mechanical performance, high in operability, low in cost and high in production efficiency.

Owner:NANJING IRON & STEEL CO LTD

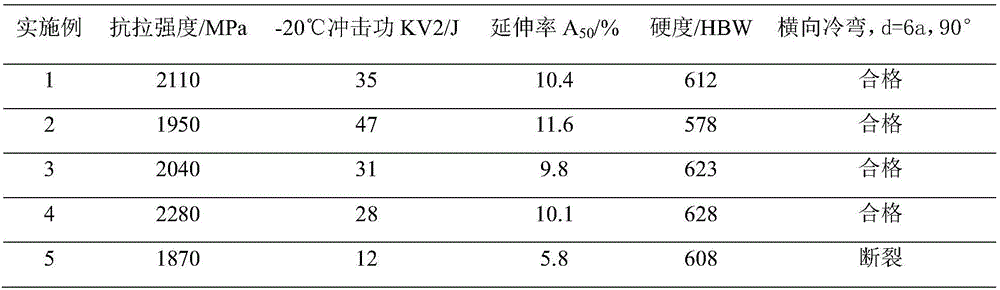

NM600 high-grade low-alloy wear-resistant steel and application thereof

The invention provides NM600 high-grade low-alloy wear-resistant steel and a manufacturing method thereof. The steel is prepared from, by weight, 0.38%-0.45% of C, 0.10%-0.40% of Si, 0.30%-0.80% of Mn, smaller than or equal to 0.012% of P, smaller than or equal to 0.003% of S, 0.30%-1.00% of Cr, 0.20%-0.60% of Mo, 1.50%-2.50% of Ni, 0.30%-0.60% of Cu, 0.008%-0.030% of Ti, 0.015%-0.050% of Nb, smaller than or equal to 0.010% of V, 0.0008%-0.0025% of B, smaller than or equal to 0.0035% of N and smaller than or equal to 0.0025% of O. The invention further provides a steel plate prepared from the NM600 high-grade low-alloy wear-resistant steel. The Brinell hardness of the steel plate ranges from 570 HBW to 630 HBW, and low temperature impact toughness at -20 DEG C is larger than or equal to 27.

Owner:NORTHEASTERN UNIV LIAONING +1

Low-cost non-quenched and tempered high-strength wear-resistant steal plate with yield strength of 780 MPa grade and manufacturing method thereof

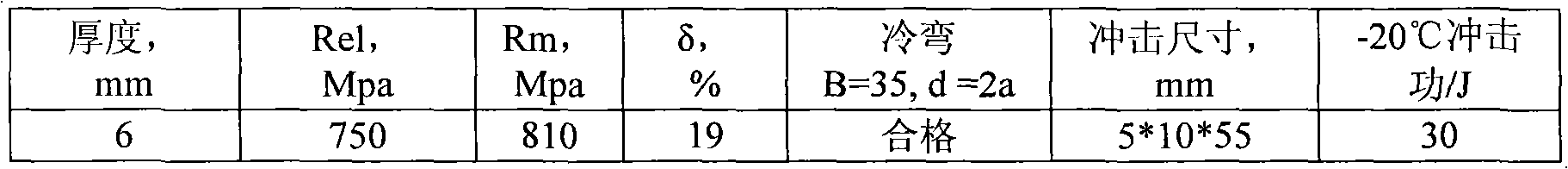

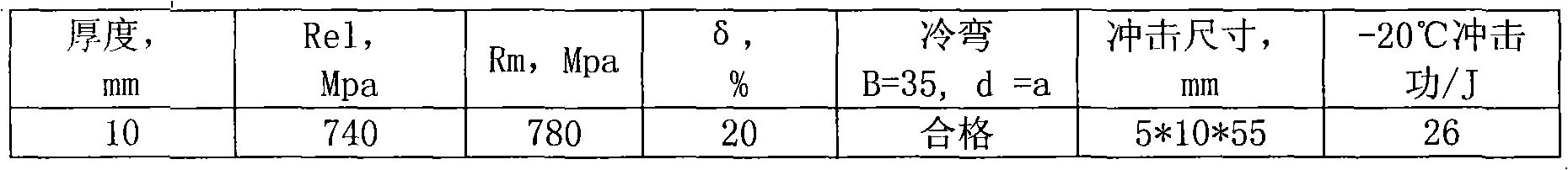

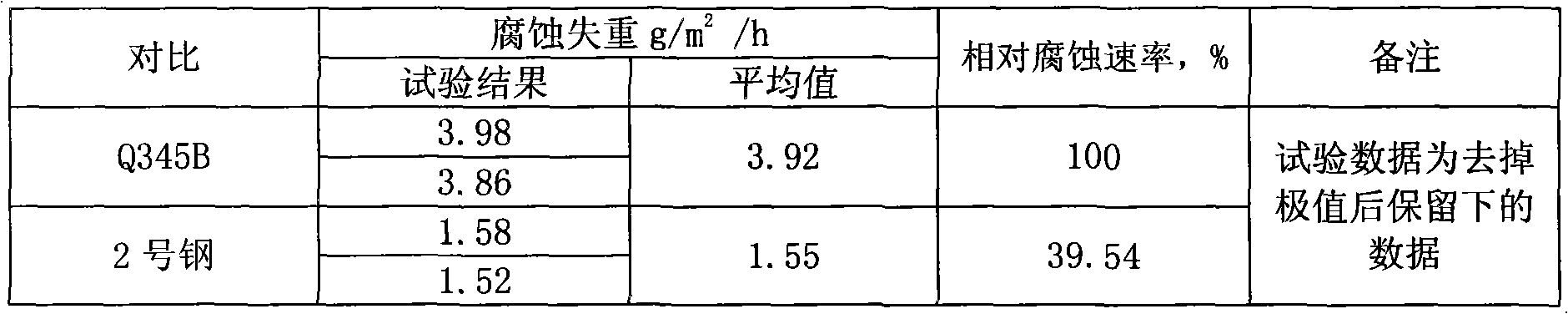

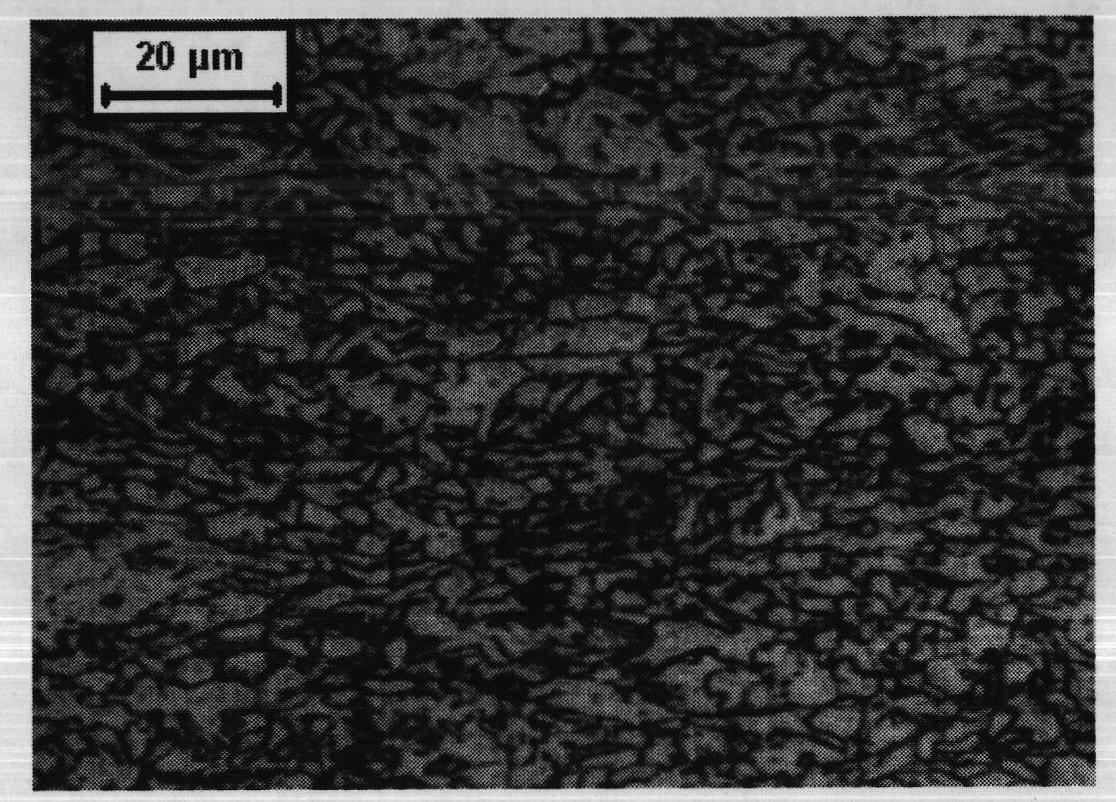

The invention discloses a low-cost non-quenched and tempered high-strength wear-resistant steal plate with a yield strength of 780 MPa grade, which comprises the following chemical components in percentage by weight: 0.08 to 0.13 percent of C, less than or equal to 0.5 percent of Si, 1.6 to 1.9 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.01 percent of S, 0.6 to 1.0 percent of Cr, 0.1 to 0.15 percent of Ti, 0.02 to 0.06 percent of Nb, less than or equal to 0.005 percent of N, less than or equal to 0.002 percent of O, and the balance of iron (Fe) and inevitable impurities. A manufacturing method of wear-resistant steel comprises the steps of electric furnace or converter smelting, refining, continuous casting, continuous casting bloom heating, hot continuous rolling, laminar flow cooling, coiling, decoiling and cutting to obtain a finished plate. A high-strength steel strip of the invention can achieve the following combination properties that: the ReL is 780 to 840 MPa, the Rm is 850 to 930 MPa, delta is more than or equal to 16 percent, the high-strength steel strip meets high wear resistance, and compared with Q345B, the wear resistance is improved by more than 2 times.

Owner:SHANDONG IRON & STEEL CO LTD

High-strength cold-roll-forming structural steel and method for producing same

InactiveCN1970811AInhibition of segregationFast solidificationTemperature control deviceMetal rolling arrangementsMolten steelHeating furnace

The invention discloses a high-strength cool-bent moulding structural steel and manufacturing method, which comprises the following parts: 0.03-0.12% C,0.08-0.50% Si,1.20-1.95% Mn,not more than 0.02% P,not more than 0.006% S, 0.05%-0.15% Mo,0.005-0.055% Als,0.03-0.07% Nb,0.08-0.15% Ti,0.01-0.05% V ,0.0008-0.004% Ca and Fe and inevitable impurity with Ceq not more than 0.42%. The making method is characterized by the following: controlling the fusing point of smolten steel over 15-30 deg.c; casting continuously; setting drawing speed of casting bland at 1.5-4.0m / min and blank thickness between 100 and 200mm; heating in the furnace directly; setting the even heating temperature at 1100-1250 deg.c, fine-rolling temperature at 940-1070 deg.c and outlet temperature at 840-920 deg.c; freezing rapidly after 0-7s; setting the coiling temperature at 500-610 deg.c with yielding strength of steel board over 700Mpa and drawing-proof strength between 750 and 950Mpa and extending rate over 17%.

Owner:ANGANG STEEL CO LTD

High toughness low carbon bainite thick steel plate and its production method

InactiveCN1786247AReduce carbon contentImprove low temperature toughnessOther manufacturing equipments/toolsChemical compositionUltimate tensile strength

The invention offers a high tensile strength low carbon bainite coarse plate and its manufacturing method. Its compositions (Wt%) are C 0.04%-0.08%, Si 0.1%-0.5%, Mn 1.4%-1.85%, Nb 0.015%-0.060%, Ti 0.005%-0.03%, B 0.0005%-0.0030%, Cu 0.10%-0.60%, Ni 0.05%-0.6%, Al 0.015%-0.05%, rest Fe and other inevitable impurity. The invention adopts low cost Mn element as the main additional element, fully applies the changing action of Cu, Ni, Nb, B to the bainite. The steel has low carbon content, good low temperature toughness. The turning temperature is under ¿C80 centigrade degree. Welding performance is good and simple. Forming is good. TMCP+RPC technique is adopted to improve steel tensile strength, reduced cost. The product can widely apply in engineering machinery, digging machinery, heavy-duty car, and marine facilities field, and etc.

Owner:UNIV OF SCI & TECH BEIJING +1

High-strength weather-resistant steel with yield strength of 700 MPa and production method thereof

InactiveCN109898032AReliable corrosion resistanceGood weather resistanceChemical compositionWeather resistance

The invention discloses high-strength weather-resistant steel with yield strength of 700 MPa and a production method thereof, and belongs to the technical field of steel and iron production. The high-strength weather-resistant steel with the yield strength of 700 MPa is prepared from the following chemical components in percentage by mass: 0.05 to 0.09 percent of C, 0.25 to 0.35 percent of Si, 1.50 to 1.60 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.005 percent of S, 0.25 to 0.30 percent of Cu, 0.30 to 0.40 percent of Cr, 0.05 to 0.15 percent of Ni, 0.040 to 0.050 percent of Nb 0.10 to 0.15 percent of Ti, less than or equal to 0.006 percent of N, less than or equal to 0.005 percent of O, and the balance of Fe and unavoidable impurities. Compared with the prior art, a final product is reliable in corrosion resistance and has good weather resistance.

Owner:RIZHAO STEEL HLDG GROUP

Atmospheric corrosion resisting steel with yield strength more than 400MPa

InactiveCN101235468AGood mechanical propertiesGood welding performanceMetallurgyAtmospheric corrosion

The invention provides atmospheric corrosion resistant steel whose yield strength is more than 400MPa grade aiming at the defects that the yield strength of existing atmospheric corrosion resistant steel is comparatively low and the producing cost is over high, which is composed of components with following weight percent: C 0.06-0.12 %, Si 0.25-0.55%, Mn 0.30-0.80%, P 0.07-0.12%, S<=0.020%, Cu 0.25-0.55%, Cr 0.30-0.80% and Ni 0.30-0.6%, and allowance is Fe and unavoidable impurity. The mechanical ability of the steel of the invention is excellent, the atmospheric corrosion resistant performance is comparatively strong, and the producing cost is low, which is beneficial for extending and applying.

Owner:武钢集团有限公司

Method for treating inclusions in hot-rolled steel plates for welded gas cylinder

The invention discloses a method for treating inclusions in hot-rolled steel plates for a welded gas cylinder. The method includes the following steps: the content of S in molten steel entering a furnace is controlled to be less than or equal to 0.015 percent by weight when steel production; the molten steel is calcium-treated in the process of steel production, that is, Ca-Fe core-spun yarn with a different amount is fed in to carry out Ca treatment on the molten steel according to different S contents in the molten steel so that sulfide in steel is spheroidized. Sulfide inclusions of the hot-rolled steel plates after the Ca treatment are spherically distributed in small sizes so that the hot-rolled steel plates for the welded gas cylinder has good cold roll forming performance.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +3

Low alloy structural steel with low cost and thick specification and production method thereof

The invention discloses low alloy structural steel with low cost and thick specification. The low alloy structural steel comprises the following components by weight percent: 0.17%-0.20% of C, 0.15%-0.30% of Si, 0.35%-0.55% of Mn, less than or equal to 0.025% of P, less than or equal to 0.01% of S, less than or equal to 0.008% of N, and the rest of Fe and inevitable impurities. A production method of the structural steel comprises the following steps: (1) continuous casting to obtain billet; (2) soaking the cast billet; (3) high-pressure descaling, and finish rolling, wherein the sum of reduction rates of F1 and F2 is greater than or equal to 98% and is less than or equal to 105%, and F1 and F2 cooling water amount is 70%-80% of normal water amount, F3 or F4 is nominal, and the outlet temperature is 840-870 DEG C; (4) setting the laminar flow cooling speed to be 40-83 DEG C / s, the coiling temperature to be 540-570 DEG C, and the head coiling temperature to be 580-600 DEG C; (5) cooling. The production method disclosed by the invention basically eliminates phenomena such as mixed crystal and cold bending cracking, has good coiling shape, and is suitable for being widely applied to the field of steel production.

Owner:武汉钢铁有限公司

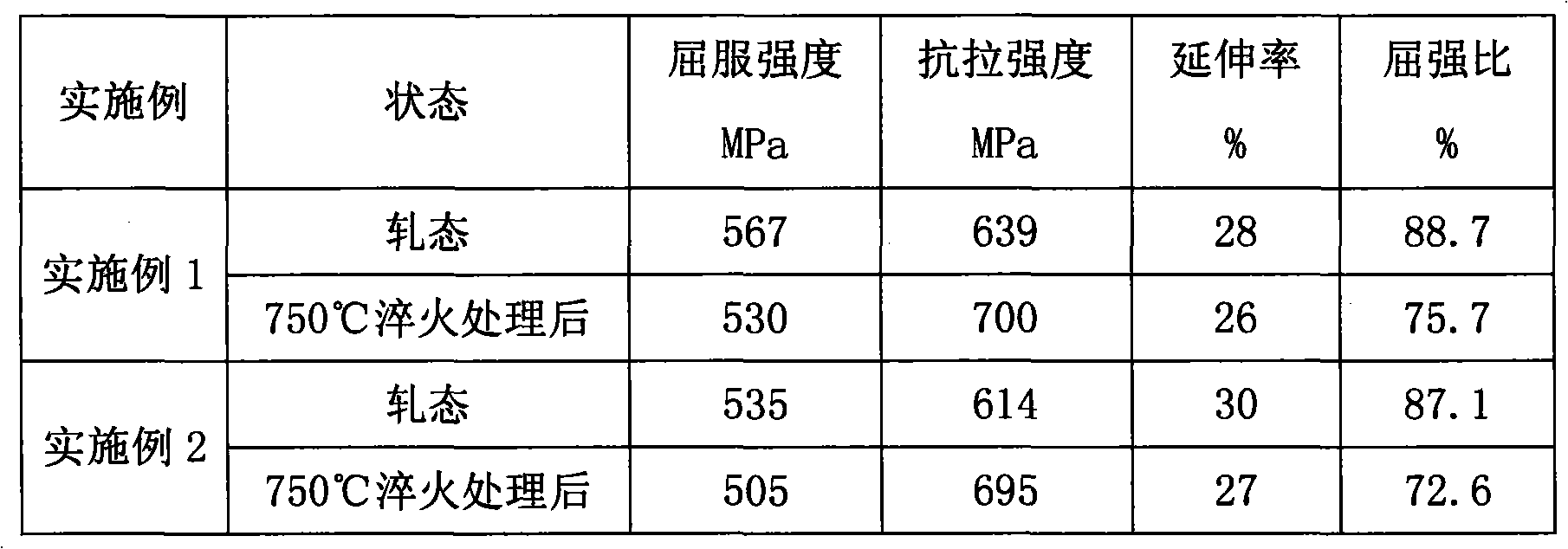

Martensite-ferrite-austenite complex-phase abrasion-resistant steel plate with low yield ratio and manufacturing method thereof

The invention provides a martensite-ferrite-austenite complex-phase abrasion-resistant steel plate with a low yield ratio and a manufacturing method thereof. The manufacturing method of the steel plate comprises the steps of smelting different alloy components; manufacturing a steel billet through continuous casting; and carrying out heating, controlled rolling, controlled cooling, thermal treatment, and the like. The martensite-ferrite-austenite complex-phase abrasion-resistant steel plate is characterized in that (1) the manufactured steel plate is of a martensite-ferrite-austenite multi-phase composite structure; (2) the yield ratio of the manufactured steel plate is greatly decreased compared with that of a traditional abrasion-resistant steel plate, the yield ratio is smaller than orequal to 0.75, and the manufactured steel plate has excellent formability; (3) the hardness of the manufactured steel plate is 300 HB to 420 HB, and acquisition of good abrasion resistance is guaranteed; and (4) the abrasion resistance is excellent, and the abrasion resistance of the obtained abrasion-resistant steel plate is doubled or above compared with that of a single-martensite abrasion-resistant steel plate with the same hardness. The martensite-ferrite-austenite complex-phase abrasion-resistant steel plate has good welding performance and higher low-temperature impact toughness, and isparticularly applicable to manufacturing of devices or parts like concrete stirring tank rollers, dump truck carriages and pipelines for channel dredging.

Owner:NORTHEASTERN UNIV

A kind of extra-thick specification x70 pipeline steel and its manufacturing method

ActiveCN104264069BImprove low temperature toughnessImprove corrosion resistanceChemical compositionHigh intensity

The invention discloses an extra-thick specification X70 pipeline steel and a manufacturing method thereof. The thickness of the pipeline steel is 30-32 mm, and its chemical components are C: 0.03-0.06%, Si: 0.1-0.30%, Mn in terms of mass percentage. : 1.30~1.60%, P: ≤0.010%, S: ≤0.0050%, Nb: 0.030~0.050%, Ti: 0.008~0.020%, Ni: 0.10~0.30%, Cr: 0.10~0.30%, Cu: 0.10~ 0.30%, the balance is Fe and inevitable impurity elements. The smelting raw materials are sequentially subjected to KR molten iron pretreatment, converter smelting, LF refining, and RH vacuum degassing to obtain molten steel with high purity. Pipeline steel with excellent toughness, low temperature aging resistance and HIC resistance.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

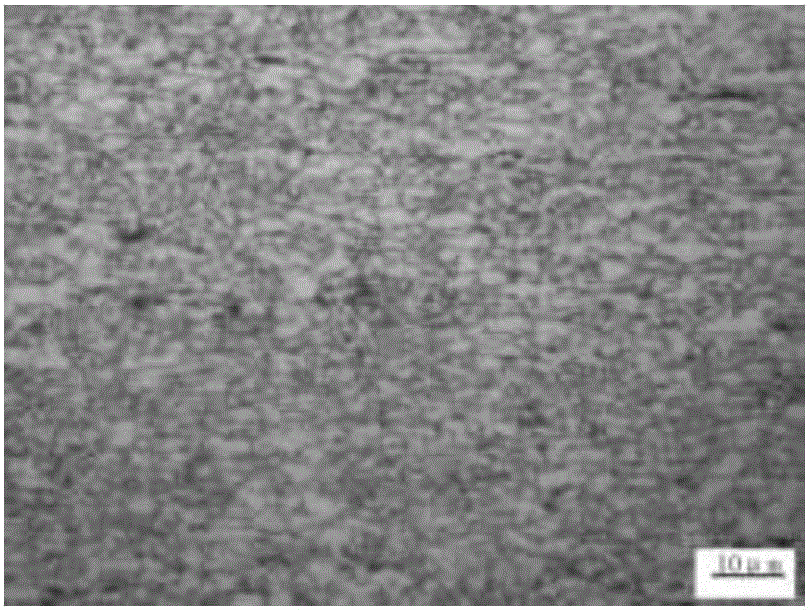

Steel sheet and method for production thereof

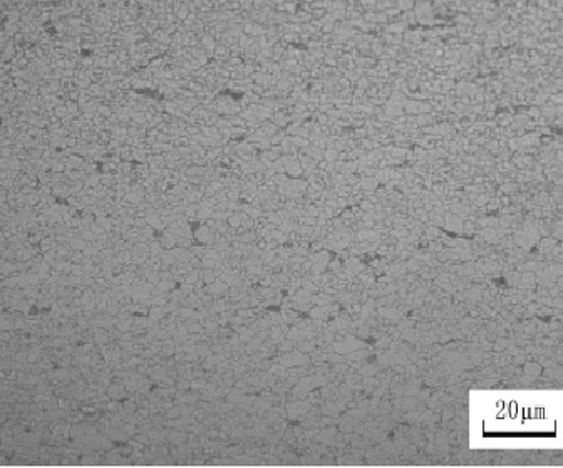

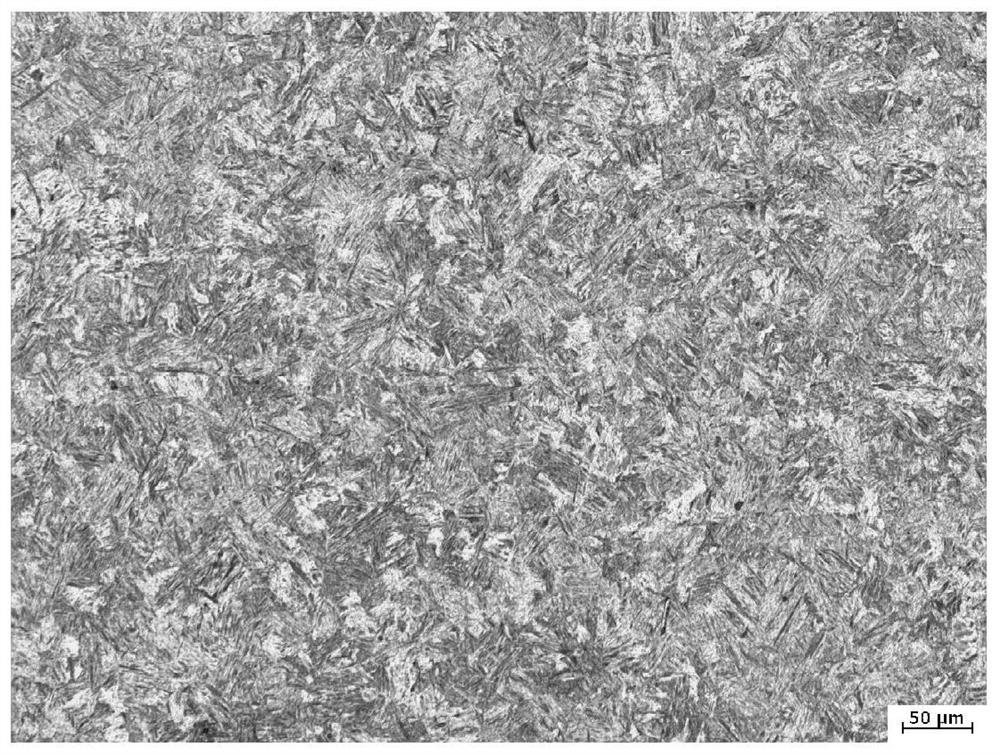

ActiveUS20180127848A1Excellent cold formabilityImprove ductilityFurnace typesHeat treatment furnacesDuctilityCrystallite

The present invention provides steel sheet excellent in cold formability and ductility after heat treatment and a method for production thereof. The steel sheet of the present invention is steel sheet which has a chemical composition containing, by mass %, C: 0.10 to 0.40%, Si: 0.30 to 1.00%, Mn: 0.30 to 1.00%, Al: 0.001 to 0.10%, P: 0.0001 to 0.02%, and S: 0.0001 to 0.01% and having a balance of Fe and impurities, which steel sheet characterized in that a ratio (B / A) of the number of carbides at the ferrite grain boundaries (B) to the number of carbides inside the ferrite grains (A) is over 1, a ferrite grain size is 5 μm to 50 μm, an average grain size of carbides is 0.4 μm to 2.0 μm, a pearlite area ratio is 6% or less, and a Vicker's hardness is 120 HV to 170 HV.

Owner:NIPPON STEEL CORP

Iron-based pre-alloyed powder prepared through recycled nickel and cobalt and preparing method

The invention discloses iron-based pre-alloyed powder prepared through recycled nickel and cobalt and a preparing method. The powder is composed of iron, nickel, copper, cobalt and chromium according to a certain proportion. The method comprises the steps of firstly, component detection, wherein an artificial diamond wastewater chemical electrolytic recovery waste nickel and cobalt plate is analyzed, and the content of nickel and cobalt is determined; secondly, material preparing, wherein according to the detected nickel and cobalt content result, iron, nickel, copper, cobalt and chromium are calculated, and according to the total weight of graphite powder : metal, graphite powder is prepared; thirdly, water atomization powder making, wherein the prepared metal is placed in an intermediate frequency furnace, nitrogen is used for forming a gas curtain, air is isolated, after the mixed metal is molten, the graphite powder is added, and liquid metal is crushed and atomized into alloy powder through high-pressure water; fourthly, screening blending, wherein the prepared alloy powder is sieved, and is sufficiently blended in a mixing machine, and the pre-alloyed powder is obtained. The method is reasonable in formula, simple in production technology, low in powder oxygen content, uniform in granularity and good in cold pressing molding, and has the wide application prospect in diamond cutters and tool structural parts.

Owner:HUBEI EXIN DIAMOND TECH

Method for preparing copper-tin alloy powder through diffusion

PendingCN113976896ADiffusion is fastInhibition of segregationTransportation and packagingMetal-working apparatusGunmetalGadolinium

The invention provides a method for preparing copper-tin alloy powder through diffusion. The method comprises the following steps that 1, weighing and mixing 49%-95% of copper powder, 4%-50% of tin powder and 0.1%-1% of copper-gadolinium alloy powder; 2, carrying out ball milling, wherein the mass ratio of milling balls to the mixed powder is 7: 3-3: 2, the ball milling time is 3-8 h, and the ball milling rotating speed is 50-80 r / min; 3, carrying out diffusion, wherein the protective atmosphere is hydrogen and nitrogen mixed gas, and the diffusion temperature of a reduction furnace is 200-500 DEG C; 4, crushing; and 5, after screening and anti-oxidation treatment, obtaining diffused copper-tin alloy powder. The obtained copper-tin alloy powder is uniform and stable in particle size, wide in sintering process window, fine and smooth in structure and good in cold press formability, the use proportion of the copper-tin alloy powder in diamond tools is increased, the problem of composition segregation of the copper-tin alloy powder is solved, the problem can be effectively solved, and the copper-tin alloy powder is widely applied to the diamond tools.

Owner:HENAN HUANGHE WHIRLWIND CO LTD

High tensile strength low carbon bainite thick steel plate and its production method

InactiveCN100350065CLow temperature toughnessLow heating temperatureOther manufacturing equipments/toolsChemical compositionHigh intensity

The invention offers a high tensile strength low carbon bainite coarse plate and its manufacturing method. Its compositions (Wt%) are C 0.052%-0.08%, Si 0.1%-0.5%, Mn1.65%-1.90%, Nb 0.015%-0.060%, Ti 0.005%-0.03%, B 0.0005%-0.003%, Mo 0.25%-0.50%, Cu 0.62%-0.85%, Ni 0.42%-0.80%, Al 0.015%-0.05%, and rest Fe and other inevitable impurity. The invention adopts low cost Mn element as the main additional element, fully applies the changing action of Cu, Mo, Ni, Nb, B to the bainite. The steel has low carbon, good low temperature toughness, welding performance, and forming performance. Its Nb and Ti element is low. And it is fit for large-scale industrialization continuous casting production. The TMCP+ RPC+T technique is adopted to make tensile strength over 900N / mm2 high intensity and tenacity steel. Adopting lower steel blank heating temperature can economize energy and improve steel low temperature toughness. The product can apply in engineering machinery, digging machinery, heavy-duty car, and marine facilities field, and etc.

Owner:UNIV OF SCI & TECH BEIJING +1

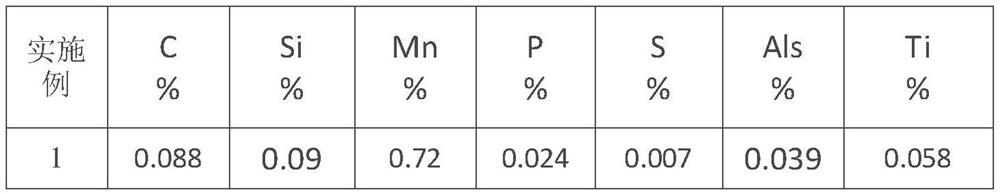

High-plasticity cold roll forming steel with tensile strength of 500 MPa and production method

The invention relates to high-plasticity cold roll forming steel with tensile strength of 500 MPa. The steel comprises the following chemical components, in percentage by weight, of 0.085% to 0.18% of C, less than or equal to 0.10% of Si, 0.50% to 0.90% of Mn, less than or equal to 0.025% of P, less than or equal to 0.020% of S, 0.010% to 0.040% of Al, and 0.020% to 0.060% of Ti. The production method comprises the following steps of conducting, after smelting in a converter, argon blowing treatment in a tundish; continuously casting to form a blank; heating the casting blank; conducting rough rolling; conducting finish rolling; and coiling. According to the steel, on the premise that the tensile strength is 500 MPa to 570 MPa, the yield strength is 370 MPa to 420 MPa, the elongation is larger than or equal to 30%, KV2 at a temperature of -20 DEG C is larger than or equal to 82 J, a bending center diameter d in a cold bending test is a thickness a of a sample, and cracks cannot be generated when a cold bending angle is 180 degrees.

Owner:武汉钢铁有限公司

Spring steel for suspension and method for producing same

InactiveUS20180230566A1High tensile strengthImprove cold forming propertiesSpringsFurnace typesAlloy elementArea fraction

Provided is spring steel for suspension suppressing or not requiring addition of expensive alloy elements, having a large tensile strength, and excellent in cold formability and delay fracture resistance, wherein at a cross-section parallel to a rolling direction, 90% or more of the metal microstructures by area fraction is tempered martensite, and at a cross-section parallel to the rolling direction, in a range of 10% of diameter or thickness from the surface, a ratio of a length in a long axis direction of prior austenite grains and a length in a direction perpendicular to the long axis direction of the prior austenite grains is 1.5 or more and a ratio of <011> fraction / <111> fraction of martensite texture as seen from the rolling direction is 3.0 or more.

Owner:NIPPON STEEL CORP +1

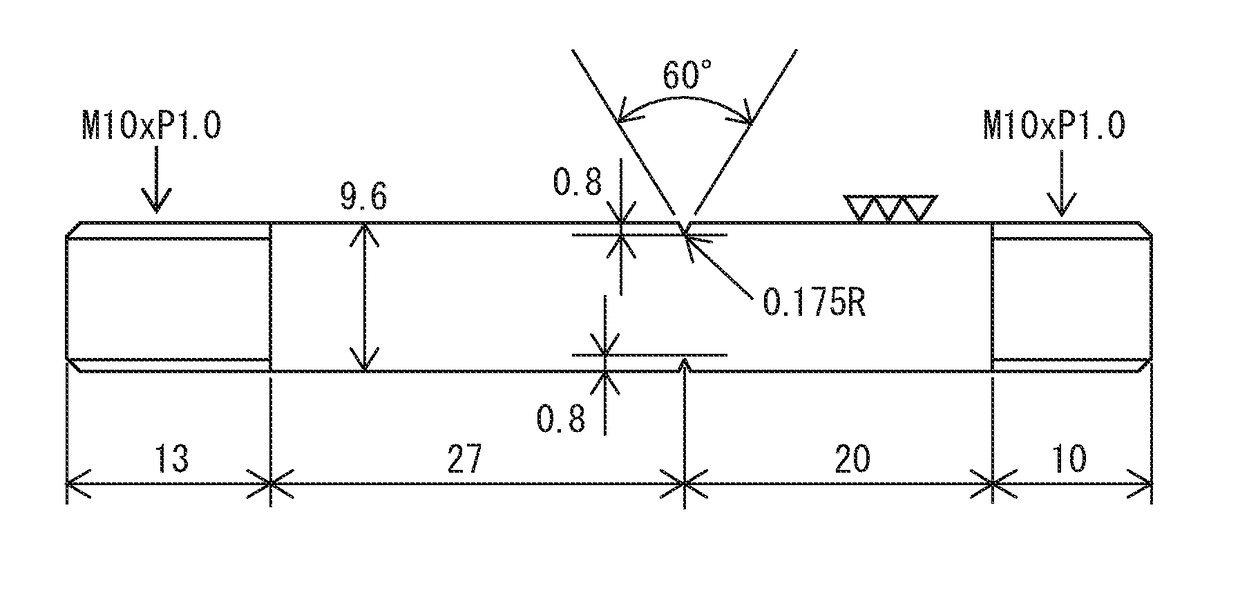

Steel with tensile strength not lower than 1100MPa for engineering machinery and production method thereof

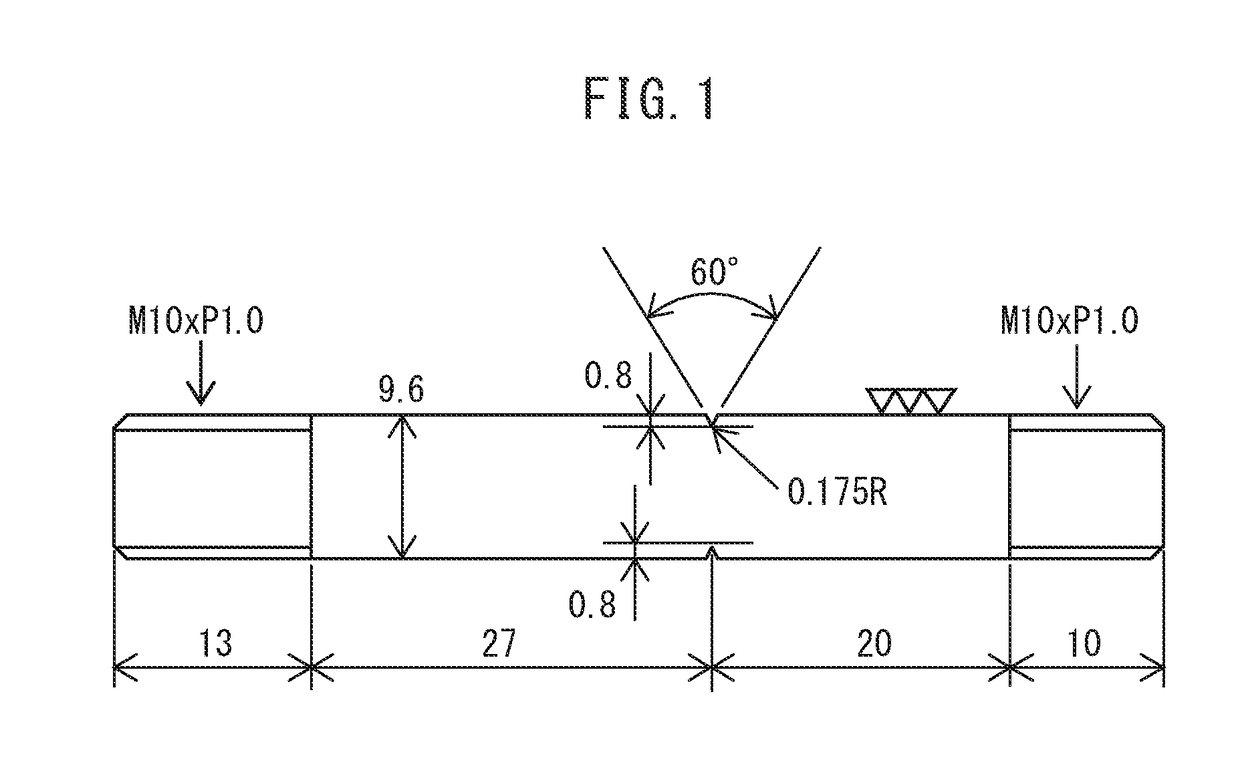

The invention relates to steel with tensile strength larger than 1100MPa for engineering machinery and a production method thereof. The steel comprises the following chemical components in percentage by weight: 0.09-0.12% of C, 0.50-0.75% of Si, 1.20-1.60% of Mn, not more than 0.025% of P, not more than 0.025% of S, 0.01-0.03% of Nb, 0.030-0.060% of Ti, 0.0010-0.0050% of B, and the balance of Fe and inevitable impurities, wherein Nb+Ti is not more than 0.08% and Ti / B is 6-35. The production method comprises the following steps of: pouring into a blank through molten iron desulfurization, converter top and bottom blowing, RH vacuum treatment and component micro-adjustment, and full-flow protection; heating the cast blank; and carrying our rough rolling, finish rolling and heat treatment. The steel has the advantages that: the components are simple, the process is simple, and the yield and performance qualification rate are high; after heat treatment, the steel board has Rm not lower than 1100MPa and (-20) DEG C KV2 not lower than 30 J, thereby completely meeting the use requirements; and the steel board has good cold bending shaping property, wherein b=2a, d=3a, and the steel boardis qualified after bending 180 degrees.

Owner:武钢集团有限公司

Low-cost thick-gauge low-alloy structural steel and production method thereof

The invention discloses low alloy structural steel with low cost and thick specification. The low alloy structural steel comprises the following components by weight percent: 0.17%-0.20% of C, 0.15%-0.30% of Si, 0.35%-0.55% of Mn, less than or equal to 0.025% of P, less than or equal to 0.01% of S, less than or equal to 0.008% of N, and the rest of Fe and inevitable impurities. A production method of the structural steel comprises the following steps: (1) continuous casting to obtain billet; (2) soaking the cast billet; (3) high-pressure descaling, and finish rolling, wherein the sum of reduction rates of F1 and F2 is greater than or equal to 98% and is less than or equal to 105%, and F1 and F2 cooling water amount is 70%-80% of normal water amount, F3 or F4 is nominal, and the outlet temperature is 840-870 DEG C; (4) setting the laminar flow cooling speed to be 40-83 DEG C / s, the coiling temperature to be 540-570 DEG C, and the head coiling temperature to be 580-600 DEG C; (5) cooling. The production method disclosed by the invention basically eliminates phenomena such as mixed crystal and cold bending cracking, has good coiling shape, and is suitable for being widely applied to the field of steel production.

Owner:武汉钢铁有限公司

A kind of ATM automatic teller machine high-strength steel plate and manufacturing method thereof

The invention provides a high-strength steel plate for an ATM automatic teller machine and a manufacturing method thereof. The composition of the steel plate is as follows by weight percentage: C: 0.03%-0.08%, Si: 0.1%-0.40%, Mn: 0.8%-1.7% , Cr: 0.20% ~ 0.60%, Nb: 0.030% ~ 0.065%, Ti: 0.080% ~ 0.160%, Mo: 0.10% ~ 0.50%, Als: 0.33% ~ 0.49%, N≤0.0070%, impurity elements P≤ 0.018% and S≤0.003%, Ceq<0.4; the balance is Fe and unavoidable impurities; the manufacturing method includes smelting, continuous casting, slab heating, rolling and cooling processes; the steel plate manufactured by the technical solution of the present invention has good Excellent low temperature toughness, able to serve in the severe cold environment in the north, strong weldability of the steel plate, good cold bending formability, excellent flatness, flatness less than or equal to 2mm / m, small internal stress of the steel plate, After shearing, there is no obvious warpage, camber, twist and other poor shape.

Owner:ANGANG STEEL CO LTD

A kind of 80mm large-thickness high-toughness low-alloy wear-resistant steel plate and its manufacturing method

The present invention is a kind of 80mm large thickness high toughness low alloy wear-resistant steel plate and its manufacturing method. S≤0.002%, Cr0.90‑1.20%, Mo0.20‑0.40%, Ni0.50‑0.80%, Ti0.008‑0.030%, Nb0.01‑0.050%, V≤0.030%, B0.0008‑0.0025 %, Alt: 0.02‑0.06%, N≤0.0040%, H≤0.0002%, and the rest are Fe and unavoidable impurities. Manufacturing methods include: hot metal desulfurization pretreatment-converter smelting-LF+RH refining-continuous casting-slab stacking slow cooling-slab inspection-slab judgment-slab acceptance-slab heating-phosphorus removal-rolling-air cooling ‑Flaw detection‑Shot blasting‑Quenching‑Tempering‑Straightening‑Cutting, sampling‑Spray printing marks‑Inspection‑Storage. According to the invention, the surface Brinell hardness of the steel plate is greater than 400HB, the core part Brinell hardness is greater than 330HB, and the low-temperature impact energy at -40°C is greater than or equal to 20J.

Owner:NANJING IRON & STEEL CO LTD

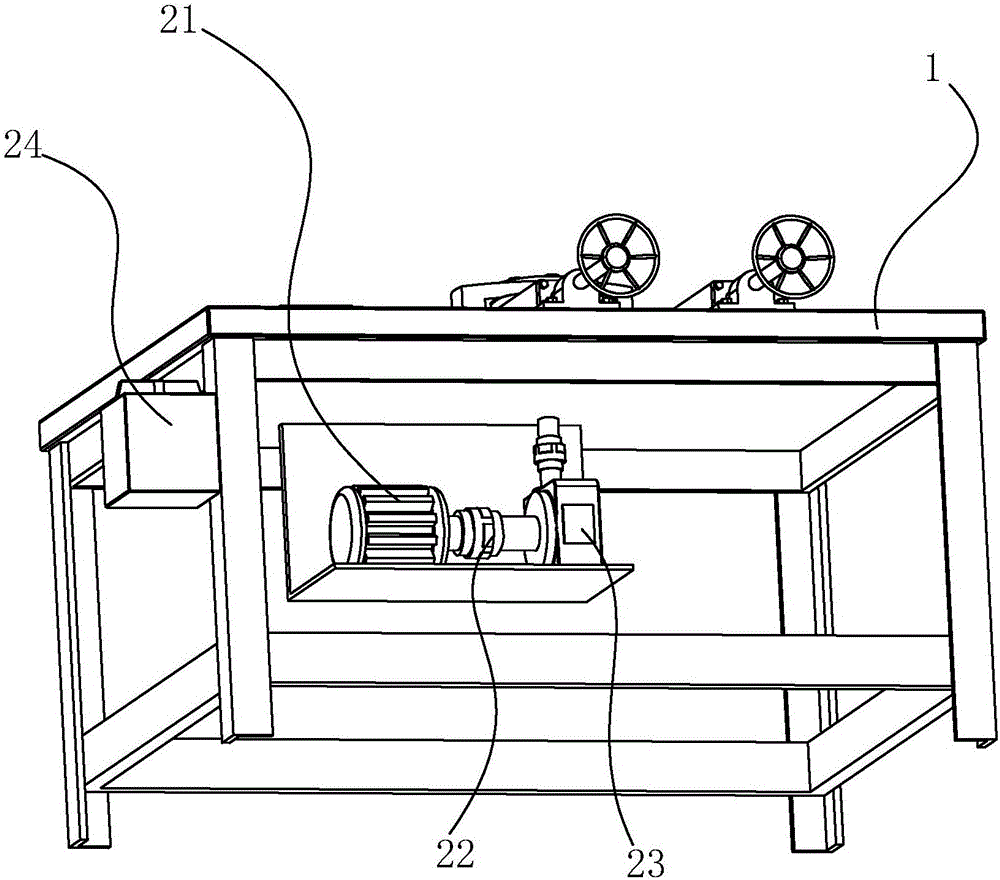

A rib cold bending forming machine

ActiveCN106216495BAvoid indentationAvoid wrinklesMetal-working feeding devicesShaping safety devicesEngineeringGrinding wheel

The invention discloses a cold bending forming machine for a rib. The technical scheme is characterized in that the cold bending forming machine comprises a working table, wherein limiting devices are mounted on the working table; a bending device is opposite to the limiting devices; a space for placing the rib is formed between the bending device and the limiting devices; the bending device comprises an eccentric grinding wheel and a driving mechanism for driving the eccentric grinding wheel to rotate; and the side wall of the eccentric grinding wheel presses against the rib in an intermittent manner. According to the cold bending forming machine for the rib, creases generated by bending of the rib is avoided, so that after being formed, the rib is linearly smooth and free of the creases and breakage.

Owner:PINGHU HUAHAI SHIPBUILDING CO LTD

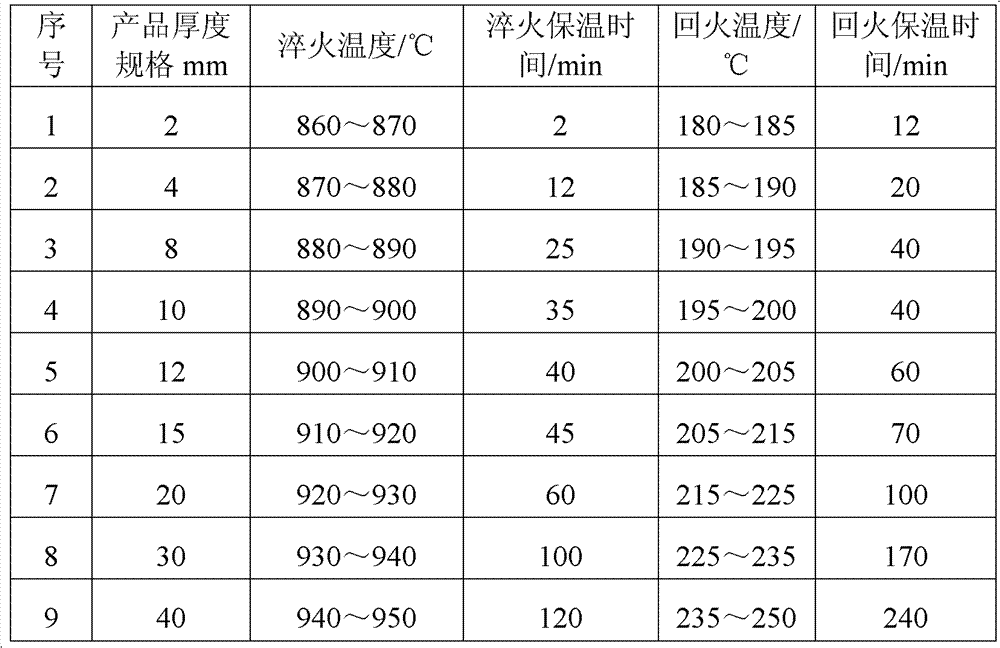

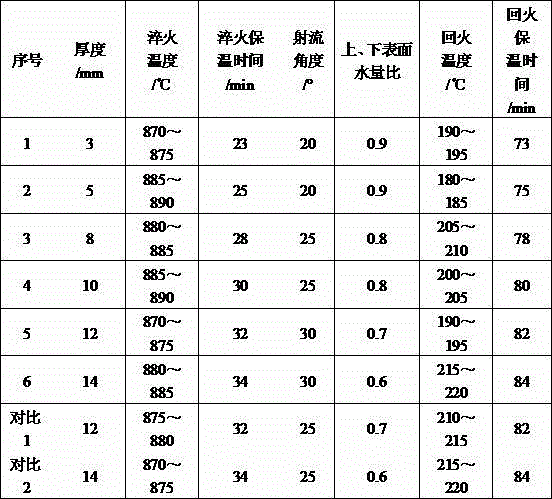

HB500 grade hot continuous rolling high strength wear-resisting steel and production method thereof

The invention relates to HB500 grade hot continuous rolling high strength wear-resisting steel which comprises the components in percentage: 0.21-0.30% of C, less than or equal to 0.20% of Si, 0.8-1.60% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.10-0.40% of Mo, 0.050-0.20% of Ti, 0.0005-0.0030% of B and less than or equal to 0.0050% of N, wherein the condition is met that Ti / N is greater than or equal to 10, and Mo / Ti is greater than or equal to 2. The preparation method comprises the following steps: smelting and continuously casting to blanks; directly heating the blanks; continuously rolling; batching; finishing and cutting; heating and insulating by a thermal treatment furnace; quenching by a roller type quenching machine; performing water cooling to reach room temperature; and annealing at low temperature and air-cooling to room temperature. According to the invention, the production cost is lower, and the Brinell Hardness of the steel plate after thermal treatment reaches 480-520 and KV2 at minus 40 DEG C is greater than or equal to 30J. The steel plate is excellent in shape, and the inequality in the length direction is less than or equal to 13mm / 1000mm. The steel plate is good in cold roll forming performance.

Owner:武汉钢铁有限公司

Cold bending forming machine for rib

ActiveCN106216495ASmooth moldingPrevents severe wear and tearMetal-working feeding devicesShaping safety devicesEngineeringRib cage

The invention discloses a cold bending forming machine for a rib. The technical scheme is characterized in that the cold bending forming machine comprises a working table, wherein limiting devices are mounted on the working table; a bending device is opposite to the limiting devices; a space for placing the rib is formed between the bending device and the limiting devices; the bending device comprises an eccentric grinding wheel and a driving mechanism for driving the eccentric grinding wheel to rotate; and the side wall of the eccentric grinding wheel presses against the rib in an intermittent manner. According to the cold bending forming machine for the rib, creases generated by bending of the rib is avoided, so that after being formed, the rib is linearly smooth and free of the creases and breakage.

Owner:PINGHU HUAHAI SHIPBUILDING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com