Atmospheric corrosion resisting steel with yield strength more than 400MPa

A technology of atmospheric corrosion-resistant steel and yield strength, which is applied in the field of low-alloy steel manufacturing, can solve the problems of high production cost and low yield strength, and achieve the effects of easy production process, excellent mechanical properties and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] According to the above production process, steel 1 was produced, wherein the chemical composition of steel 1 is shown in 1 in Table 1, the mechanical properties of steel 1 are shown in 1 in Table 2, and the atmospheric corrosion resistance results of steel 1 are shown in 1 in Table 3.

Embodiment 2

[0024] According to the above production process, steel 2 is produced, wherein the chemical composition of steel 2 is shown in 2 in Table 1, the mechanical properties of steel 2 are shown in 2 in Table 2, and the atmospheric corrosion resistance results of steel 2 are shown in 2 in Table 3.

Embodiment 3

[0026] According to the above production process, steel 3 is produced, wherein the chemical composition of steel 3 is shown in 3 in Table 1, the mechanical properties of steel 3 are shown in 3 in Table 2, and the atmospheric corrosion resistance results of steel 3 are shown in 3 in Table 3.

[0027] In order to better reflect the advantages of the atmospheric corrosion resistance of the steel of the present invention, a group of comparative steel atmospheric corrosion resistance results are provided in this embodiment, see comparison 1 in Table 3.

[0028] Table 1 Chemical composition (Wt%) of steel of embodiment of the present invention

[0029]

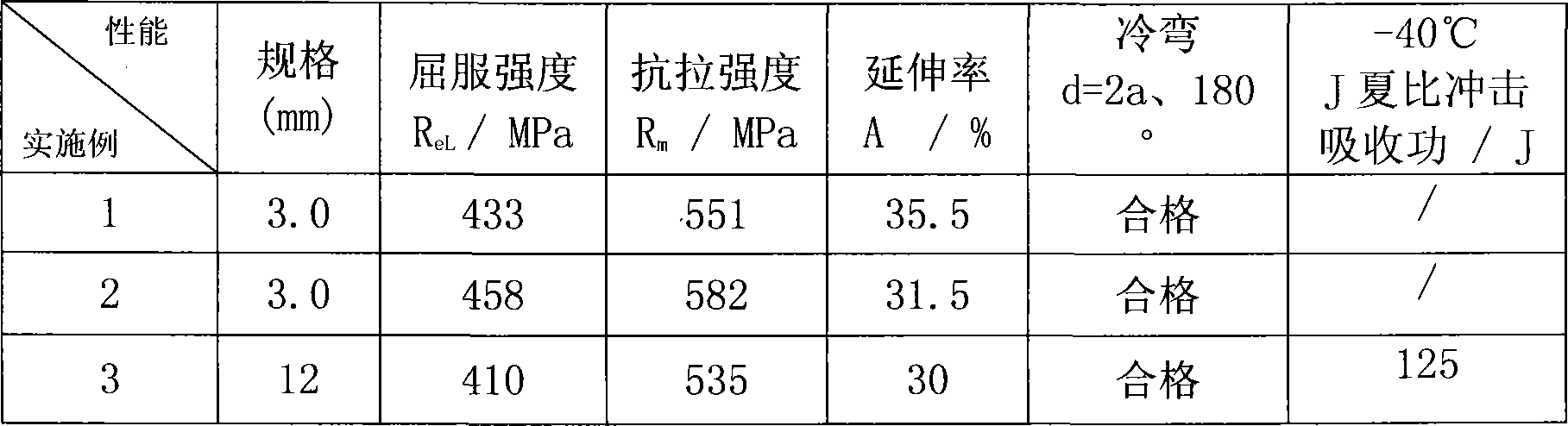

[0030] The mechanical property of table 2 embodiment steel of the present invention

[0031]

[0032] Table 3 Atmospheric corrosion resistance results of the embodiment steel of the present invention and comparative steel

[0033]

[0034] Table 1 is the chemical composition of the steel of the embodiment of the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com