Steel with tensile strength not lower than 1100MPa for engineering machinery and production method thereof

A technology for engineering machinery and tensile strength, applied in the field of alloy steel production, can solve problems such as poor economy, and achieve the effects of low production cost, simple alloy composition and good hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is further described below:

[0037] The chemical composition of the embodiments of the present invention is shown in Table 1;

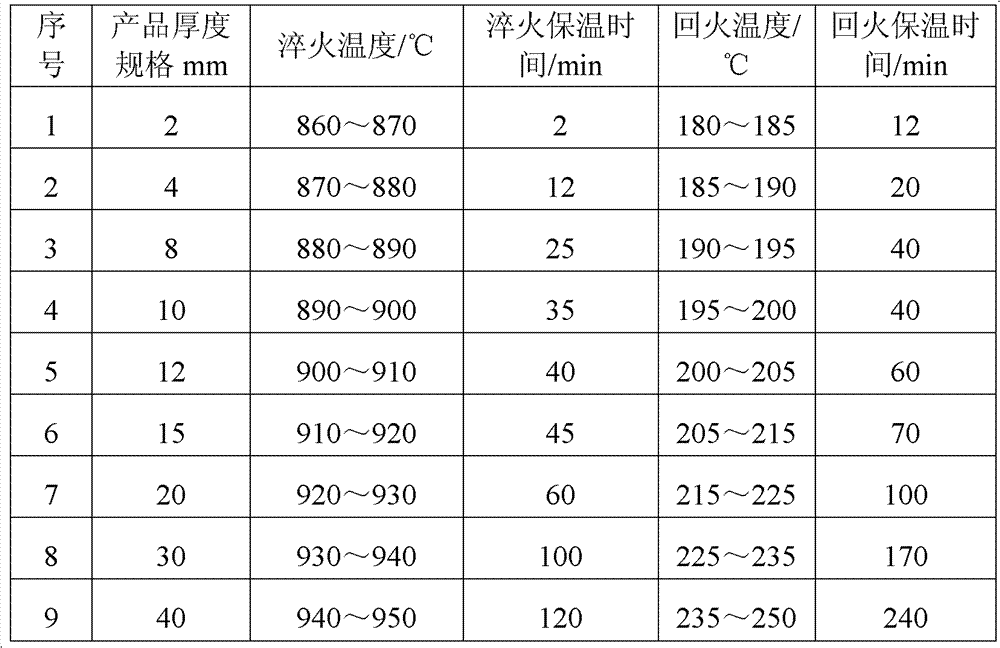

[0038] Its production process is carried out according to the following steps:

[0039] 1) Using hot metal desulfurization technology, double blowing at the top and bottom of the converter, RH vacuum treatment and fine-tuning of components, the whole process is protected and poured into billets;

[0040] 2) Heating the slab: when the product specifications are steel plates with a thickness of 2-15mm, the heating temperature is controlled at 1250-1280°C and fully austenitized;

[0041] When the thickness of the product specification is greater than 15-40mm, the slab is cleaned and cut before heating, the heating temperature is controlled at 1240-1280°C, and the heating rate is controlled at 8-10min / cm;

[0042] 3) Rough rolling: when the product specifications are steel plates with a thickness of 2 to 15 mm, continuous r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com