Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Enable direct recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

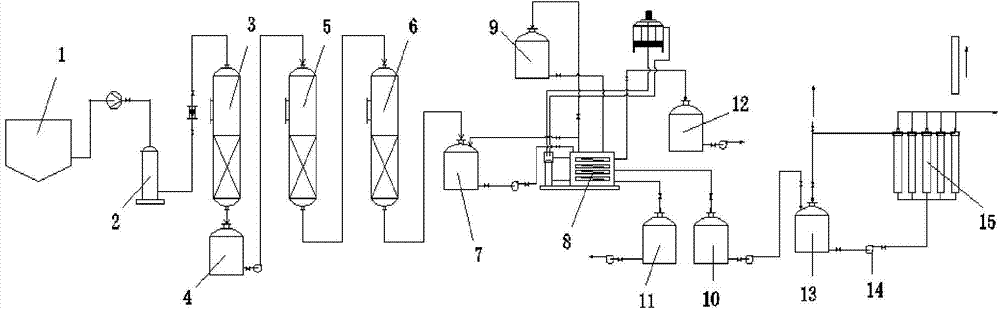

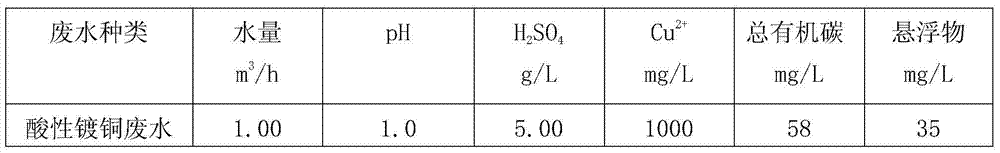

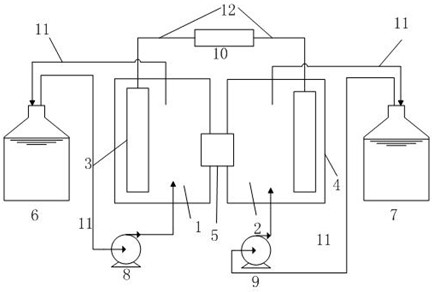

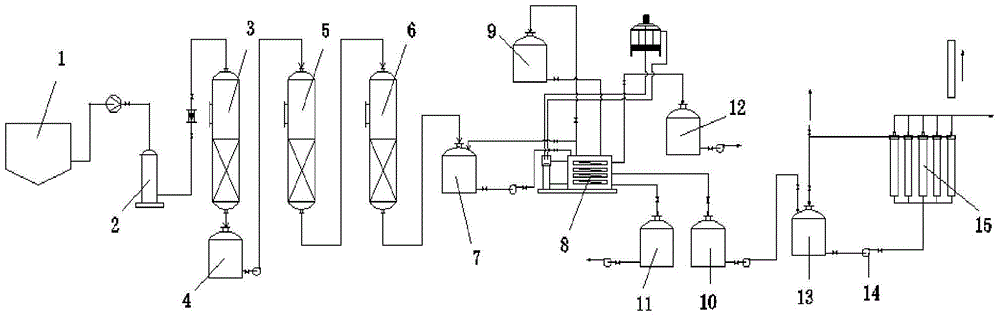

Process and device for recovering electrolytic copper from copper-containing wastewater

ActiveCN104773887AEnable direct recyclingReduce processing costsWater contaminantsWaste water treatment from metallurgical processElectrolysisAutomatic control

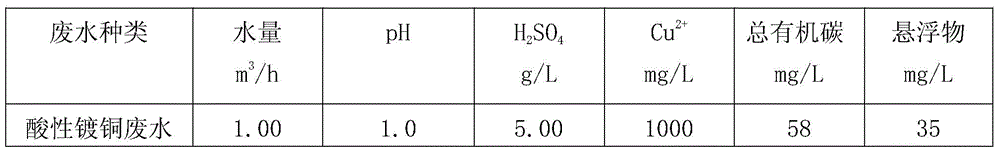

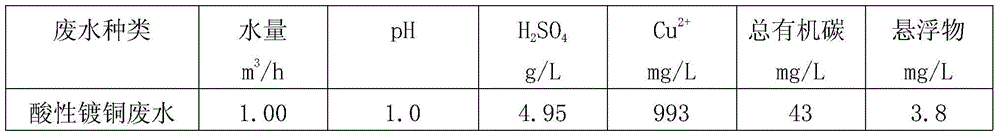

The invention relates to a process and device for recovering electrolytic copper from copper-containing wastewater. The electrolytic copper is produced by adopting the technological processes of removing suspended matters and part of organic matters through pretreatment, carrying out ultrafiltration treatment, retaining concentrated copper sulfate with a nanofiltration membrane, recovering wastewater and acids with a reverse osmosis membrane and carrying out cyclone electrolysis. The process and the device have the beneficial effects that the recovery rate of the electrolytic copper is 90% and the copper purity is more than 99.95%; meanwhile, the wastewater recovery rate is more than 90%; the recovery rate of free sulfuric acid in the wastewater is more than 90%; the resource recovery rate is high and the economic benefits are good; adopting the technological processes of combined adsorption resin, ultrafiltration membrane, acid stabilizing nanofiltration membrane and high desalting rate reverse osmosis membrane, compared with other membrane recovery systems, the process has the advantage that the properties and service lives of the membranes can be maintained for a long term; the process has the effects of achieving automatic control and ensuring stable operation of a wastewater treatment system and the quality of recovered matters; the process is suitable for recovering copper in the copper-containing wastewater in the electroplating industry, the electronic industry and the metallurgical industry and other copper-containing industrial wastewater and for wastewater treatment.

Owner:NANJING LINEHOME ENVIRONMENTAL TECH CO LTD

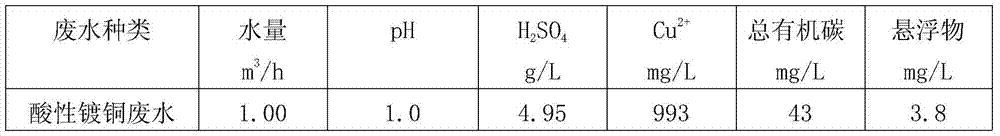

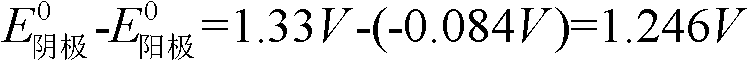

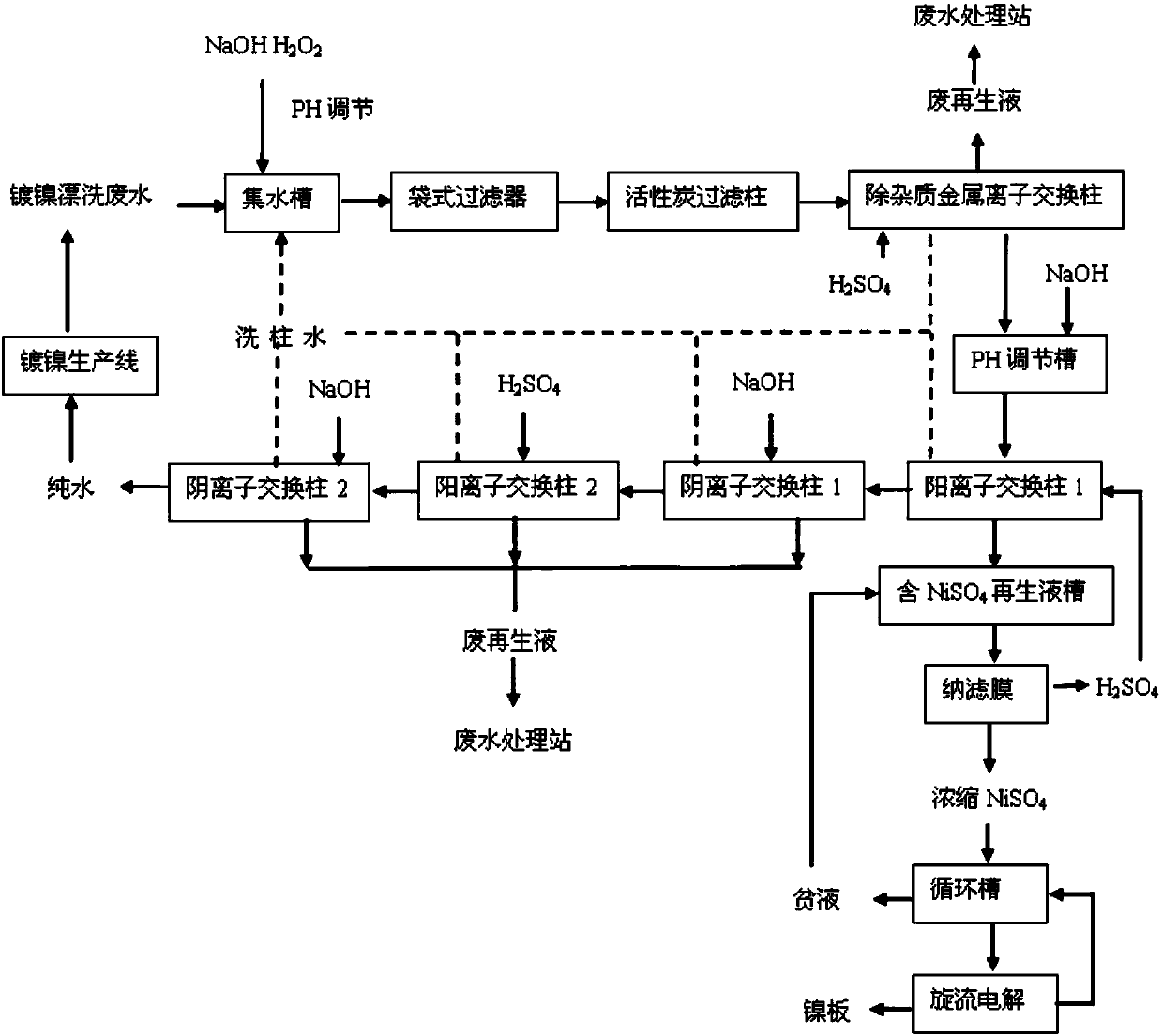

Recycling treatment process for recovering pure water and pure nickel from electro-nickelling rinsing wastewater

ActiveCN105858987AEnable direct recyclingReduce the amount addedPhotography auxillary processesTreatment involving filtrationCycloneElectrolysis

The invention relates to a recycling treatment process for recovering pure water and pure nickel from electro-nickelling rinsing wastewater. The recycling treatment process adopts a variety of ion exchange resin-acid stabilizing nanofiltration membrane-cyclone electrolysis combined processes and has the advantages that pure water and metal nickel can be directly recovered from the wastewater, the nickel recovery rate is greater than or equal to 90%, the electrolytic nickel purity is greater than or equal to 99.95%, the wastewater recovery rate is greater than or equal to 70%, and the electrical conductivity of the recovered water is smaller than or equal to 10 micro-seconds / cm. Compared with other methods, the recycling treatment process is high in resource recovery rate and good in economic benefit, can ensure stable operation of a wastewater treatment system and the quality of recovered substances and is suitable for nickel recovery from nickel-containing wastewater and other nickel-containing industrial wastewater and wastewater recycling treatment in the electroplating industry, electronic industry and metallurgical industry.

Owner:NANJING LINEHOME ENVIRONMENTAL TECH CO LTD

Method for directly recovering 7-ACA from 7-ACA crystal mother liquid

ActiveCN106117245AEnable direct recyclingAchieve high-quality recyclingOrganic chemistrySocial benefitsDesorption

The invention relates to a method for directly recovering 7-ACA from 7-ACA crystal mother liquid, and belongs to the technical field of medicines. A resin adsorption method is adopted for neutralizing the cooled crystal mother liquid, and then adsorption is directly performed through macroporous resin; concentration is performed, the absorption temperature is controlled to be 2-10 DEG C, the flow rate is controlled to be 0.2BV / h-3BV / h, and then a desorbing agent is used for desorption, wherein the desorption temperature is 2-10 DEG C; and then acidification crystallization is performed, sucking filtration is performed, and then drying is performed, so that the 7-ACA is obtained. The method disclosed by the invention can effectively reduce the production cost and the environmental pollution of the 7-ACA, green production of the 7-ACA can be realized, and the method has high economic and social benefits.

Owner:TIANJUSHI ENG TECH GROUP

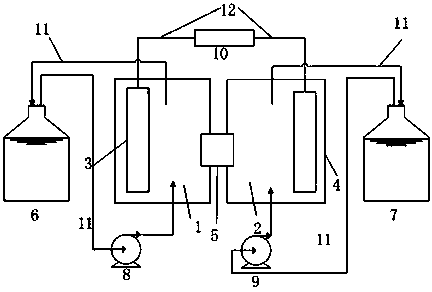

Device capable of generating electric energy and simultaneously removing metal ions and method of device

The invention discloses a device capable of generating electric energy and simultaneously removing metal ions and a method of the device. An anode chamber is connected with a cathode chamber by an immobilized electrolyte device, an anode is arranged in the anode chamber, a cathode is disposed in the cathode chamber, the anode and the cathode are respectively connected with two ends of an external load by leads, an outlet of an anode liquid storage chamber is sequentially connected with a first liquid delivery chamber and an inlet of the lower portion of the anode chamber via liquid delivery pipes, an inlet of the anode liquid storage chamber is connected with an outlet of the upper portion of the anode chamber, an outlet of a cathode liquid storage chamber is sequentially connected with a second liquid delivery pump and an inlet of the lower portion of the cathode chamber, and an inlet of the cathode liquid storage chamber is connected with an outlet of the upper portion of the cathode chamber. Electrons are outputted after oxidation reaction of electroactive substances of the anode, and are shifted to the cathode, metal ions of the cathode receive the electrons to realize reduction reaction so as to generate substances or simple substances with less toxicity, and electric energy is generated under the certain external load. When the method is applied to treating waste water containing metal ions, a large amount of chemical is omitted, high energy consumption is avoided, and the electric energy can be generated.

Owner:ZHEJIANG UNIV

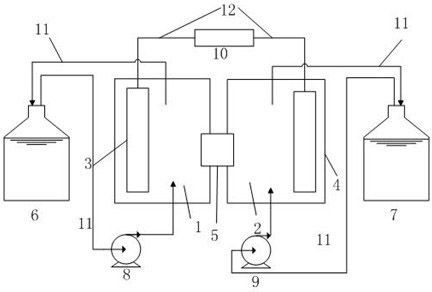

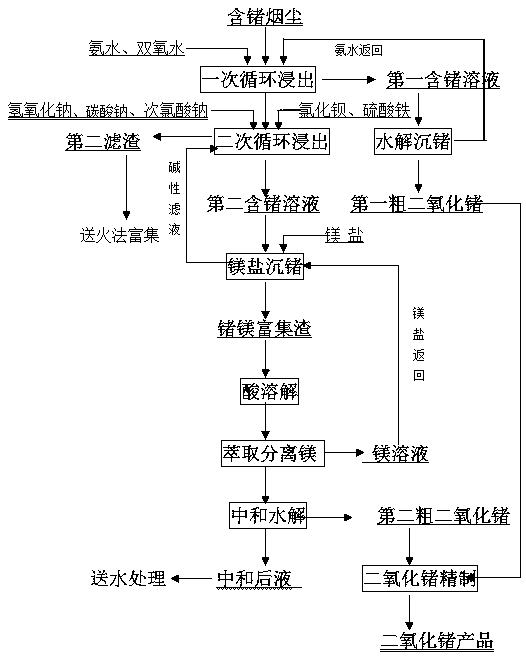

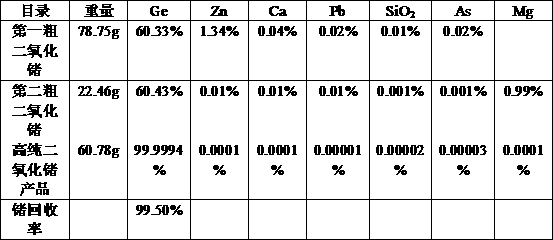

Method for recovering germanium dioxide from germanium-containing smoke dust

ActiveCN110819828AEnable direct recyclingAccelerated precipitationGermanium dioxideProcess efficiency improvementEnvironmental chemistryEnvironmental geology

The invention provides a method for recovering germanium dioxide from germanium-containing smoke dust and relates to the technical field of germanium metallurgy. After the germanium-containing smoke dust is leached by a two-stage alkali method, and the germanium dioxide is recovered by filtering, purification and precipitation methods. By the process method provided by the invention, the recoveryrate of the germanium can reach to more than 90 percent, and medicaments such as ammonia water, sodium hydroxide and magnesium salt can be recycled. The process has very positive significance in solving the problems of low germanium recovery rate, high consumption, high recovery cost, low resource utilization rate and serious environmental pollution in the traditional acid method treatment processof the smoke dust.

Owner:YANGZHOU NINGDA NOBLE METAL CO LTD

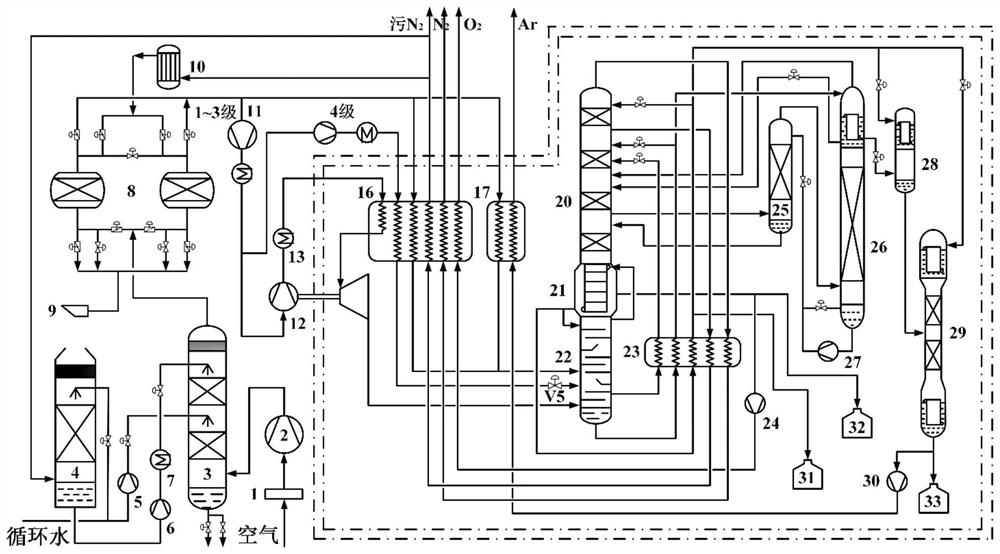

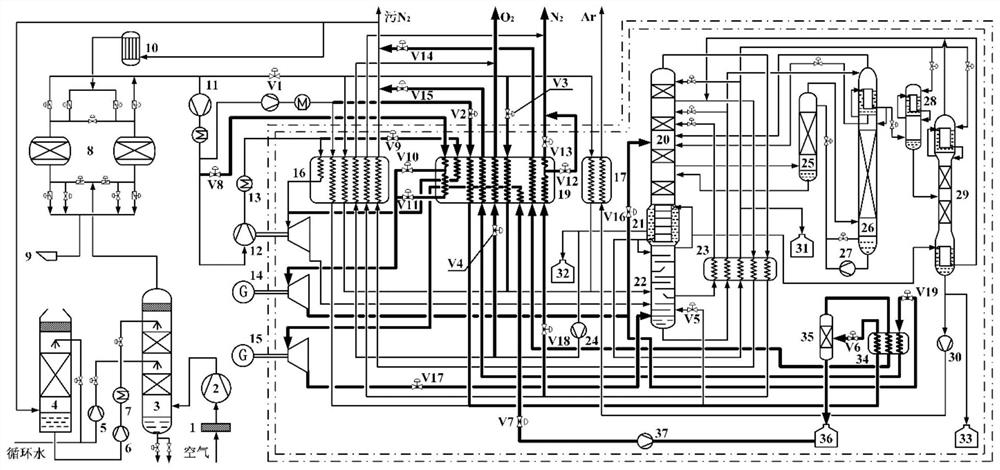

Internal compression air separation technological process with energy storage and efficient recovery of material energy resources

The invention provides an internal compression air separation technological process with energy storage and efficient recovery of material energy resources, and belongs to the technical field of air separation. According to the process, a low-temperature liquid-air storage and substance energy recovery system is arranged on the basis of a conventional air separation internal compression technological process, so that a novel air separation technological process integrating gas separation, liquid-air storage and substance energy resource recovery is formed, and the large-scale energy storage characteristic of air separation equipment and technology is realized. The technological process is a novel air separation technological process, and is also suitable for upgrading and updating transformation of an existing air separation internal compression technological process. According to the technological process, surplus electric energy can be stored in liquid air through cheap valley electricity resources, the demand of the system for electric energy in the peak electricity period is reduced by recycling stored substances and cold energy released in the gasification process in the energy release process, and the energy conversion efficiency and the operation economical efficiency of the air separation system are effectively improved.

Owner:UNIV OF SCI & TECH BEIJING

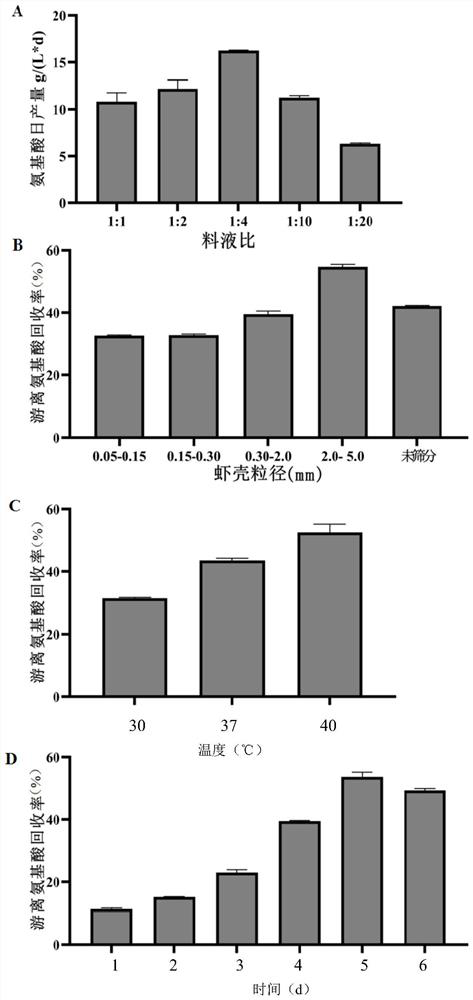

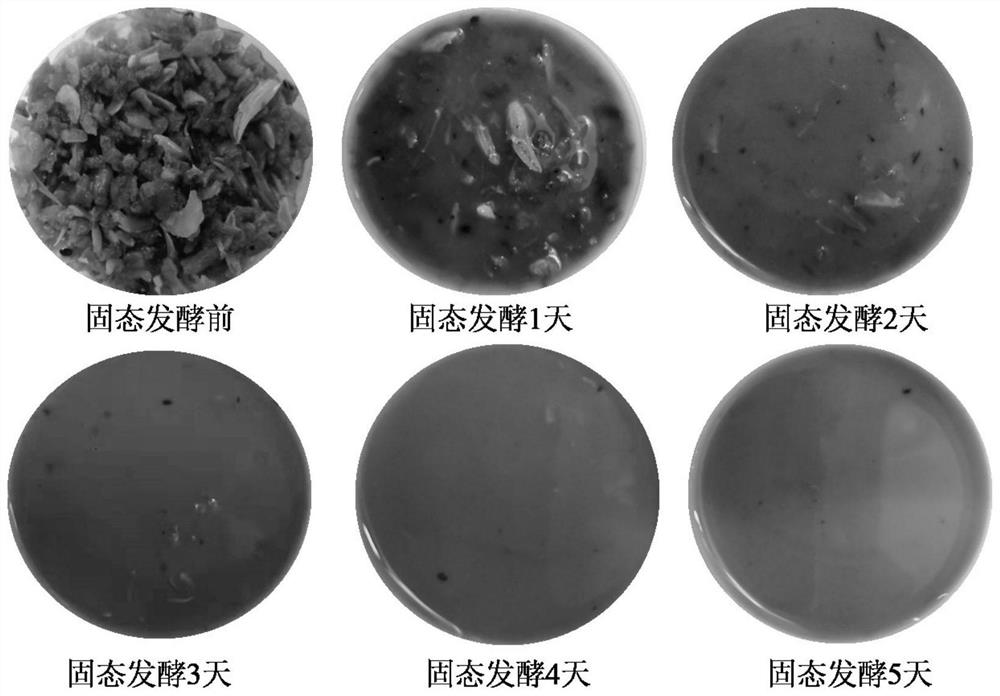

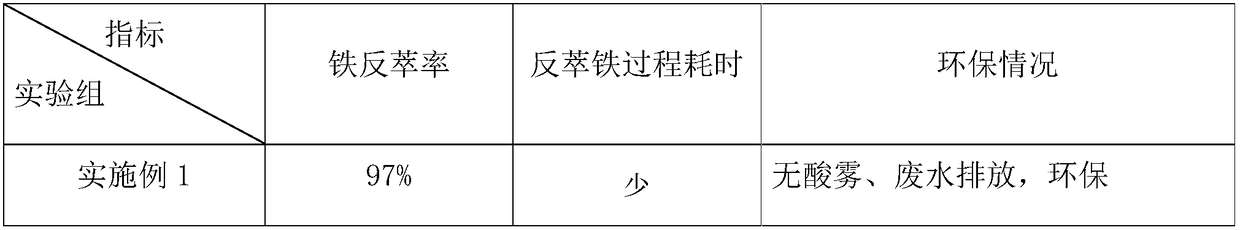

Method for producing amino acid, oligopeptide, calcium lactate and chitin by treating shrimp shell waste through solid-state fermentation of streptomyces and application of amino acid, oligopeptide, calcium lactate and chitin

ActiveCN114438144ARealize direct productionImprove cleanlinessOrganic active ingredientsPeptide/protein ingredientsNutritionCALCIUM LACTOBIONATE

The invention discloses a method for producing amino acid, oligopeptide, calcium lactate and chitin by treating shrimp shell waste through streptomyces solid state fermentation and application of the method, and belongs to the technical field of biological engineering. The invention relates to a method for producing amino acid, oligopeptide, calcium lactate and chitin by treating shrimp shell waste through streptomycete solid state fermentation, which comprises the following steps: inoculating streptomycete seed fermentation liquor into a fermentation culture medium containing the shrimp shell waste to obtain fermentation liquor, and separating to obtain first supernate and first precipitate; and preparing an amino acid product, membrane separation raffinate, an oligopeptide product, chitin and calcium lactate. According to the method, a large amount of amino acid is produced from shrimp shell waste for the first time, the recovery rate reaches 61.55%, the free amino acid concentration reaches 82.5 g / L, the amino acid productivity reaches 16.5 g / (L * d), the content of essential amino acid reaches 58.52%, and the shrimp shell waste is an excellent medicine and health care product raw material, a food nutrition additive and a feed additive.

Owner:SOUTH CHINA UNIV OF TECH

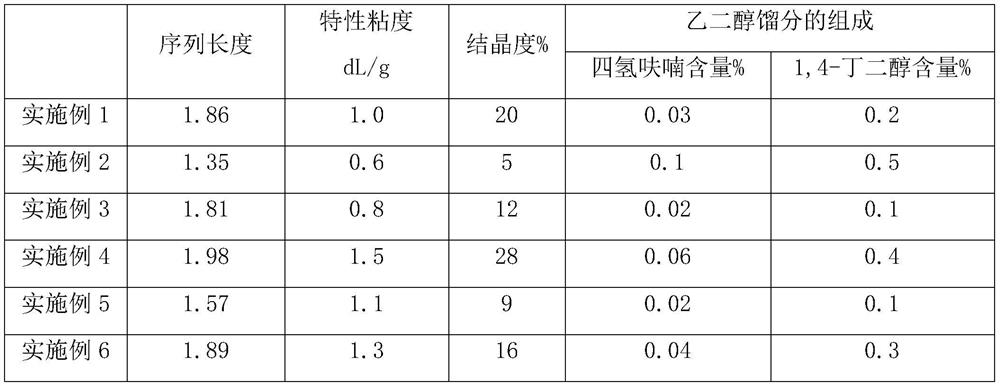

Continuous preparation method of biodegradable block co-polyester and biodegradable block co-polyester

The invention discloses a continuous preparation method of biodegradable block co-polyester and biodegradable block co-polyester. The preparation method comprises the following steps: preparing terephthalic acid, aliphatic dibasic acid and ethylene glycol into slurry, carrying out esterification and polycondensation to obtain a polyester prepolymer melt, melting poly(butylene succinate) and a transesterification catalyst to obtain a poly(butylene succinate) mixed melt, converging the polyester prepolymer melt and the poly(butylene succinate) mixed melt, conveying to a final polycondensation reaction system, and carrying out final polycondensation reaction to obtain a biodegradable block co-polyester melt; and subjecting the biodegradable block co-polyester melt to forming, crystallization and grain-sized dicing to obtain the biodegradable block co-polyester crystal slice. The preparation method disclosed by the invention can be continuously carried out, tetrahydrofuran is not generated in the preparation process, the recycling rate of ethylene glycol is improved, and the prepared co-polyester is good in thermal property and physical processing properties.

Owner:CHINESE TEXTILE ACAD

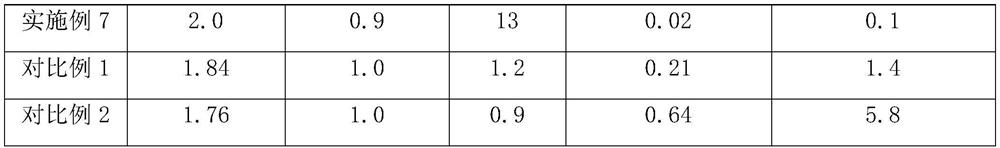

Method for reversely extracting iron by adopting solvent extraction

InactiveCN108179273AEnable direct recyclingSimple recycling processProcess efficiency improvementFerric hydroxidePhase separation process

The invention discloses a method for reversely extracting iron by adopting solvent extraction. The method comprises the following steps that (1) an organic phase is used to extract iron in iron-containing leachate; (2) the iron is reversely extracted by using an anti-iron solution, phase separation is carried out on the iron subjected to reverse extraction, and the iron flows out together with a water phase in the phase separation process; and (3) the water phase obtained in the step (2) is filtered to obtain a ferric hydroxide solid, wherein the anti-iron solution comprises an anti-iron agent, a nucleating accelerant and water, the anti-iron agent can be one or more kinds of NaOH, KOH, ammonia water, ammonium carbonate, Na2CO3 and Ca(OH)2, and the concentration of the OH<-> is 0.2-3 mol / L. The method for reversely extracting the iron by adopting solvent extraction has the advantages of being efficient, low in cost and environment-friendly.

Owner:CHONGQING KOOPPER CHEM IND

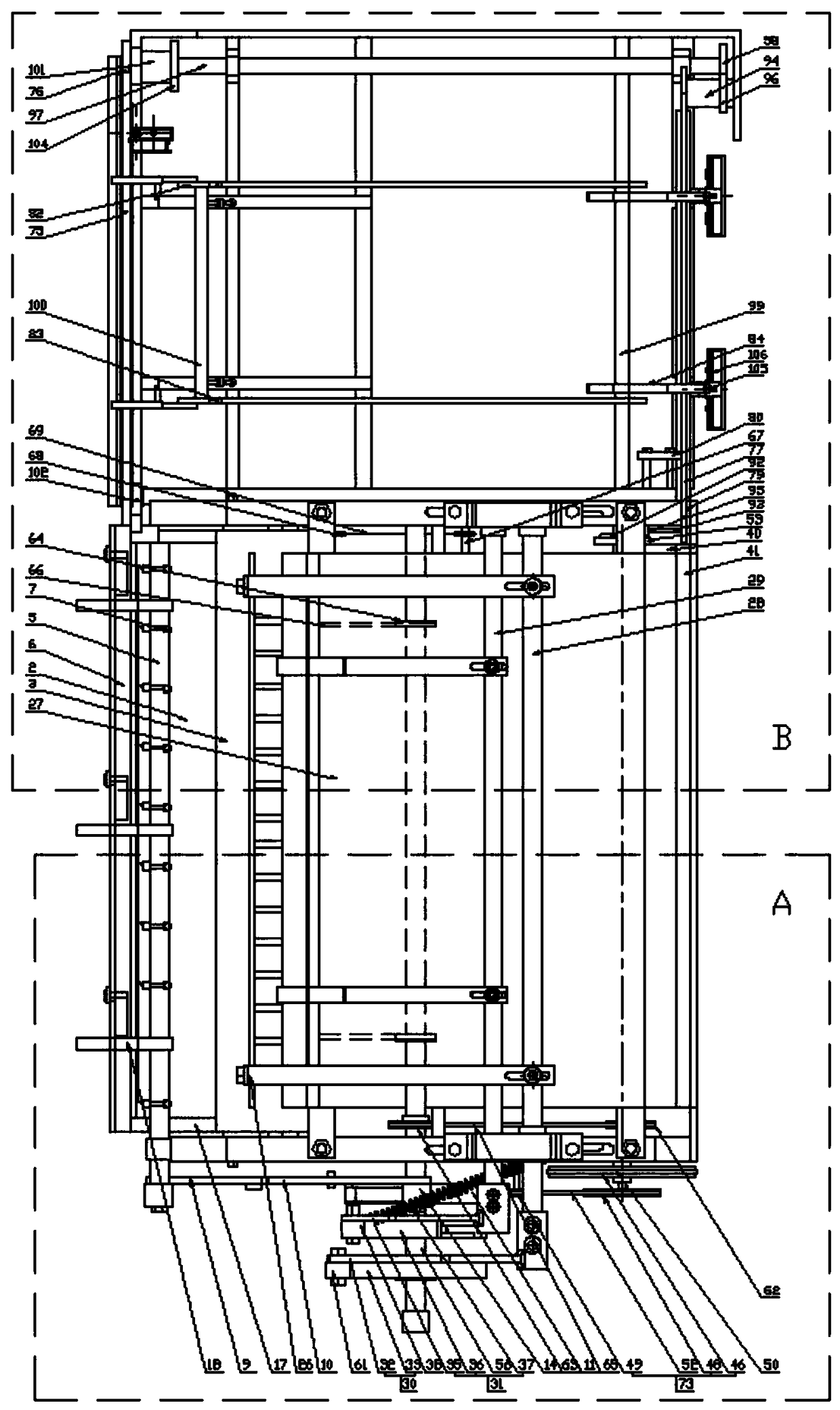

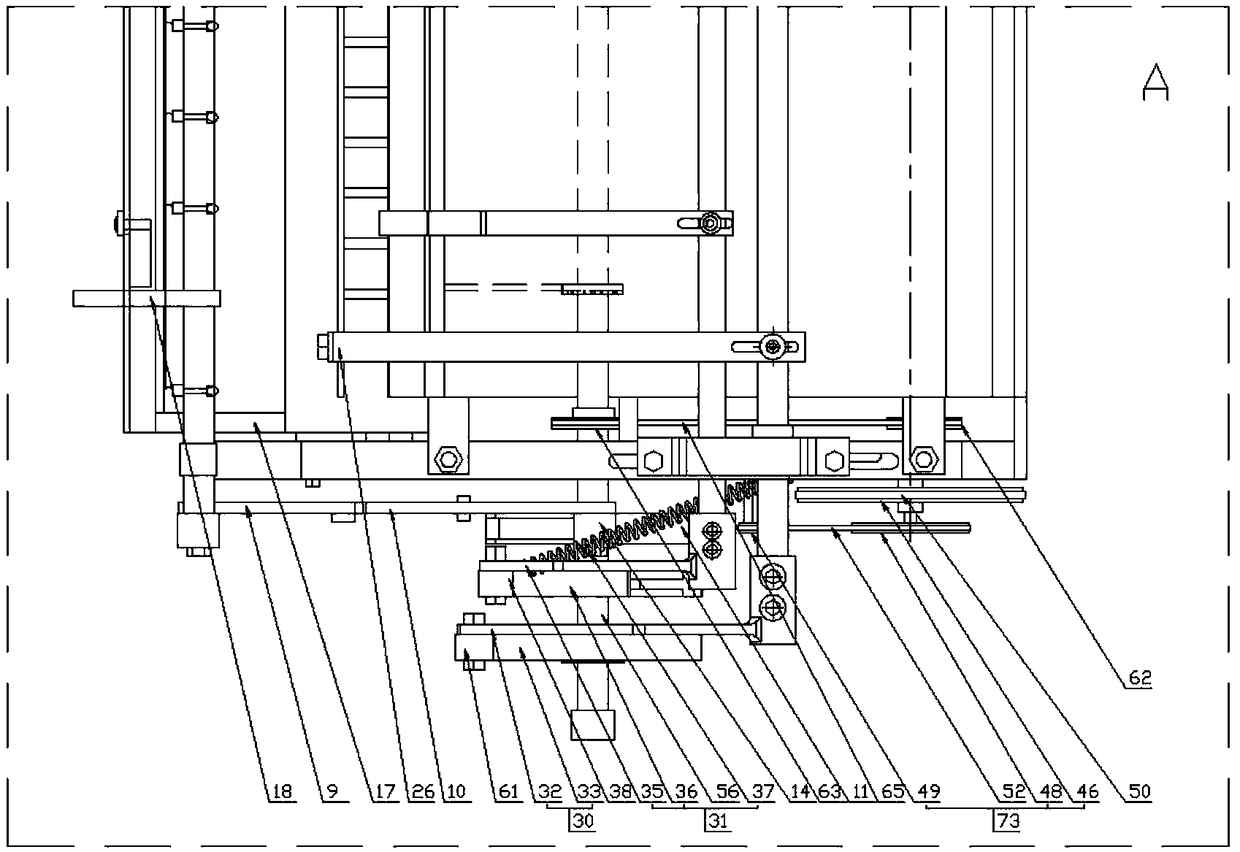

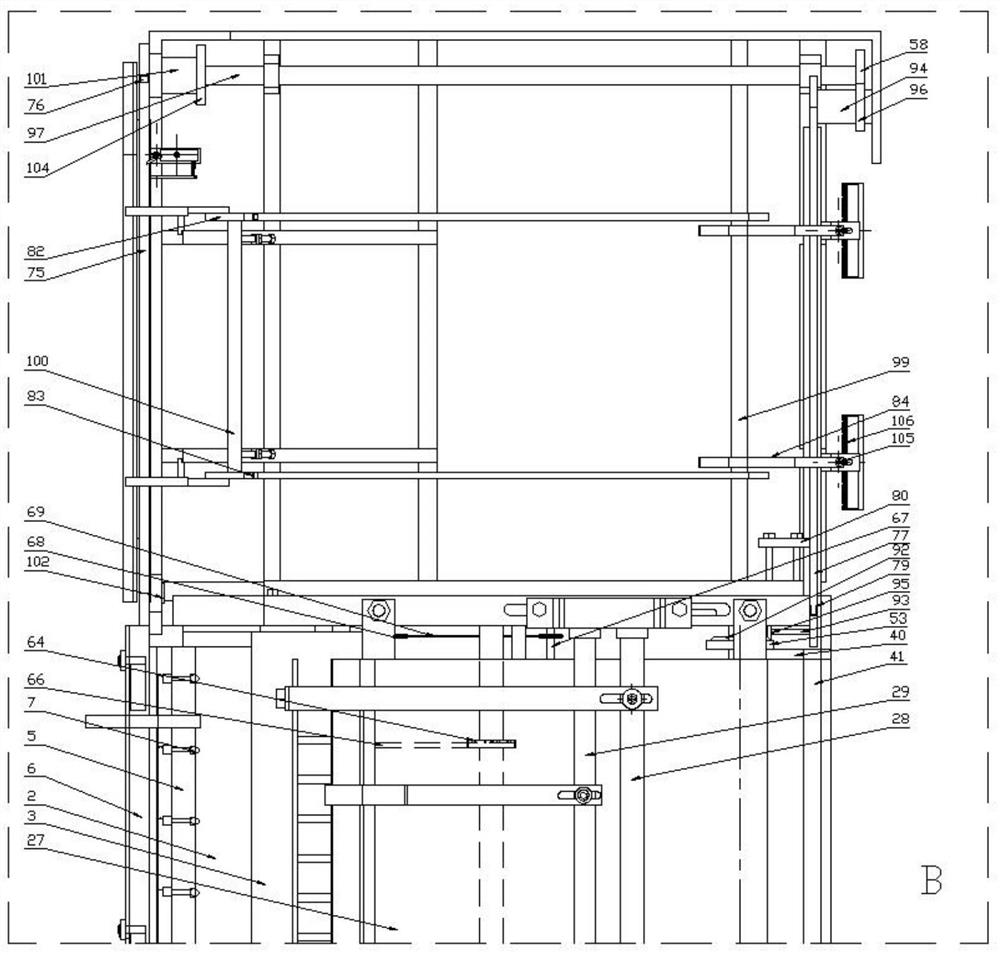

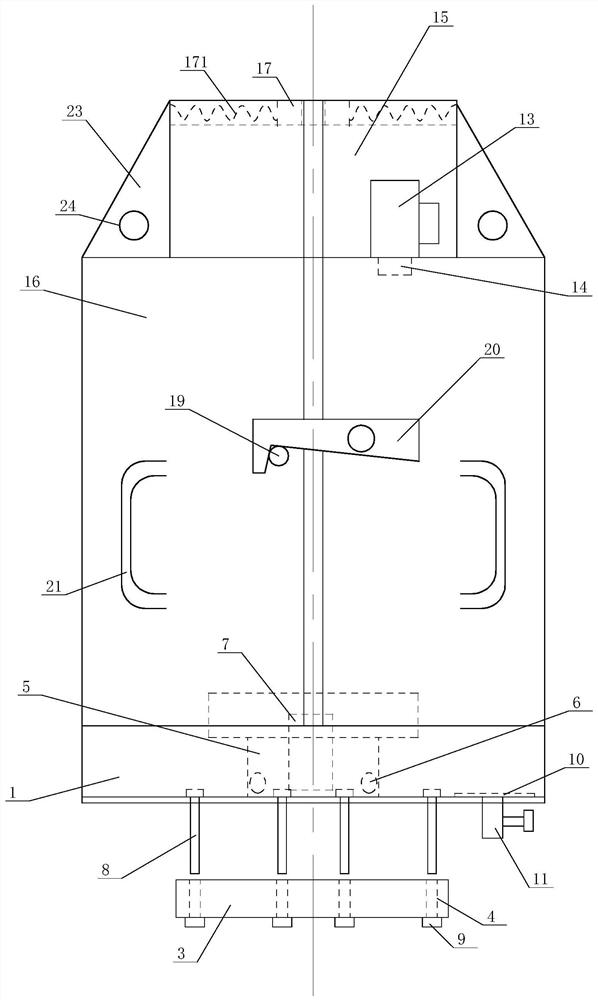

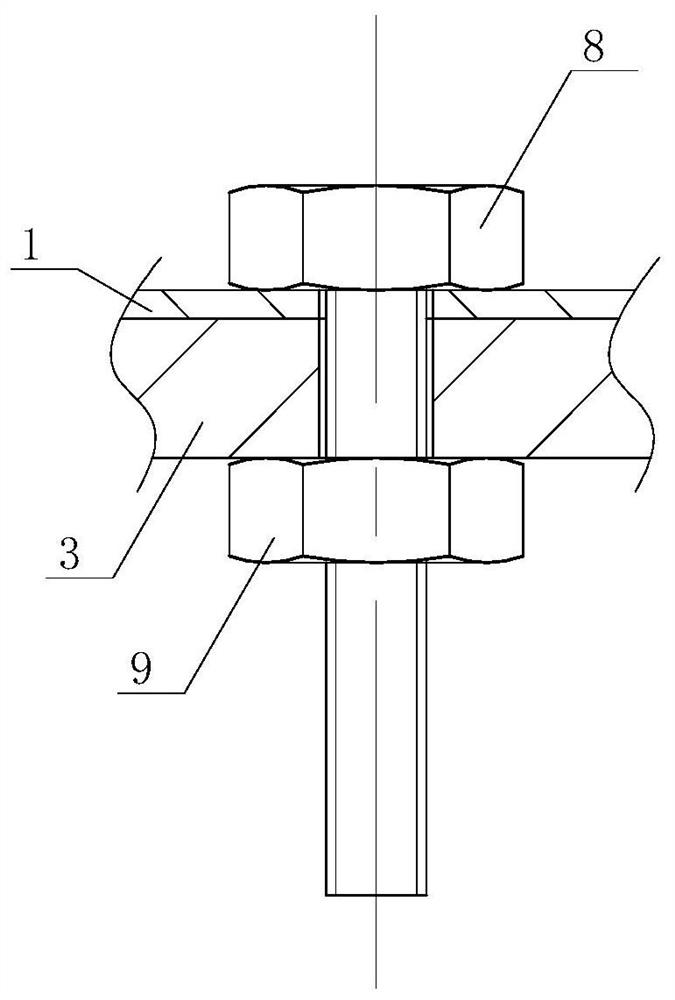

Electrical insulation paper wrinkle tube continuous processing device

ActiveCN109334113AReduce in quantityLow costPaper/cardboard wound articlesInsulatorsWrinkle skinElectrical insulation paper

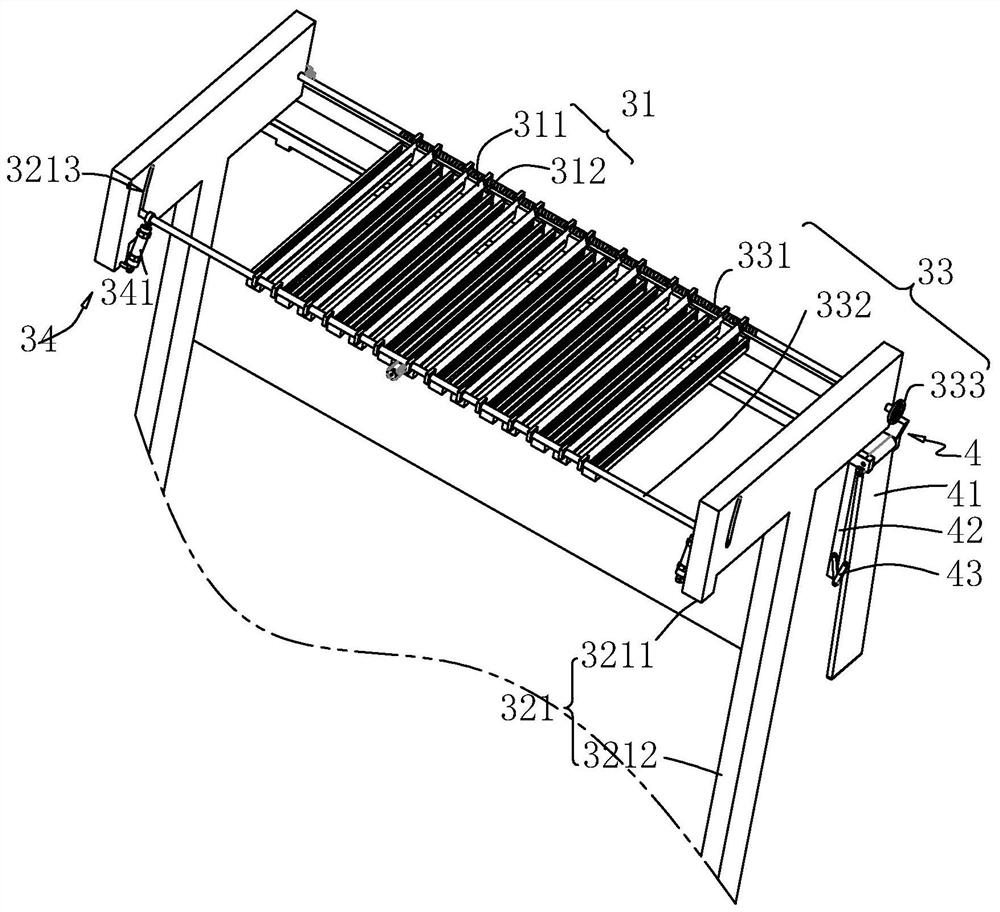

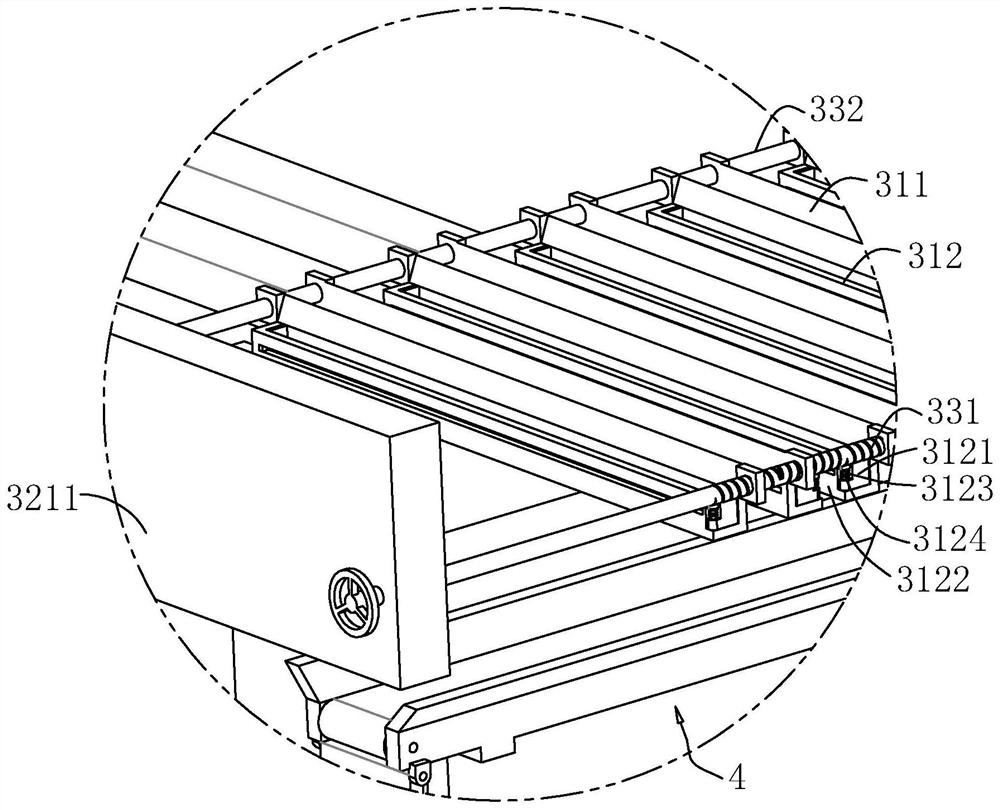

The invention relates to an electrical insulation paper wrinkle tube continuous processing device. The continuous processing device comprises a machine frame, a first baffle, a guide plate, a conveying belt and a driving mechanism are arranged on the machine frame, a first shaft body with a rubber brush and a brazing frame are arranged on the top of the side of the first baffle plate, a first deflection mechanism is arranged on the first shaft body, an upper brazing chain is arranged on one side of the brazing frame, a second deflection mechanism is arranged on a brazing claw of the brazing frame, a second shaft body of a pressing frame and a third shaft body of a pushing frame are provided with a third deflection mechanism and a fourth deflection mechanism respectively, a fifth deflectionmechanism is arranged on a material frame of a second arc-shaped plate, a brazing chain is arranged on one side of the material frame, at least two return brazing chains are arranged between the brazing chain and the upper brazing chain, and a transmission mechanism is arranged on a driving roller of the conveying belt. The continuous processing device is compact in structure, the energy consumption is low, the whole machine is linked, the operation is simple, automatic and rapid continuous brazing, gluing, twisting and forming, brazing circulation and discharging and machining can be realized, so that the equipment, the brazing and the labor cost can be remarkably reduced, the production efficiency and the yield of paper tubes are improved.

Owner:镇江市鑫泰绝缘材料有限公司

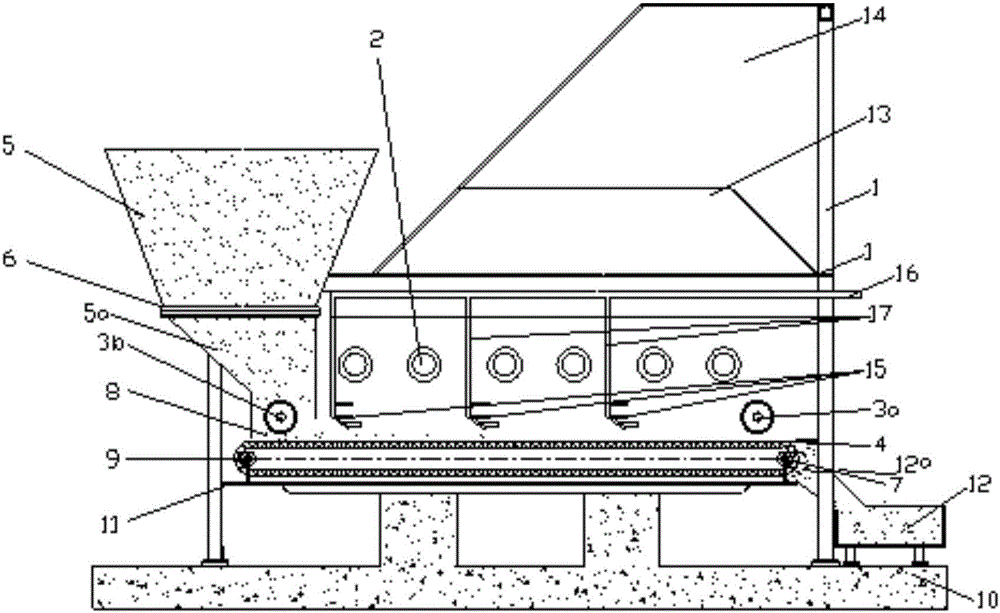

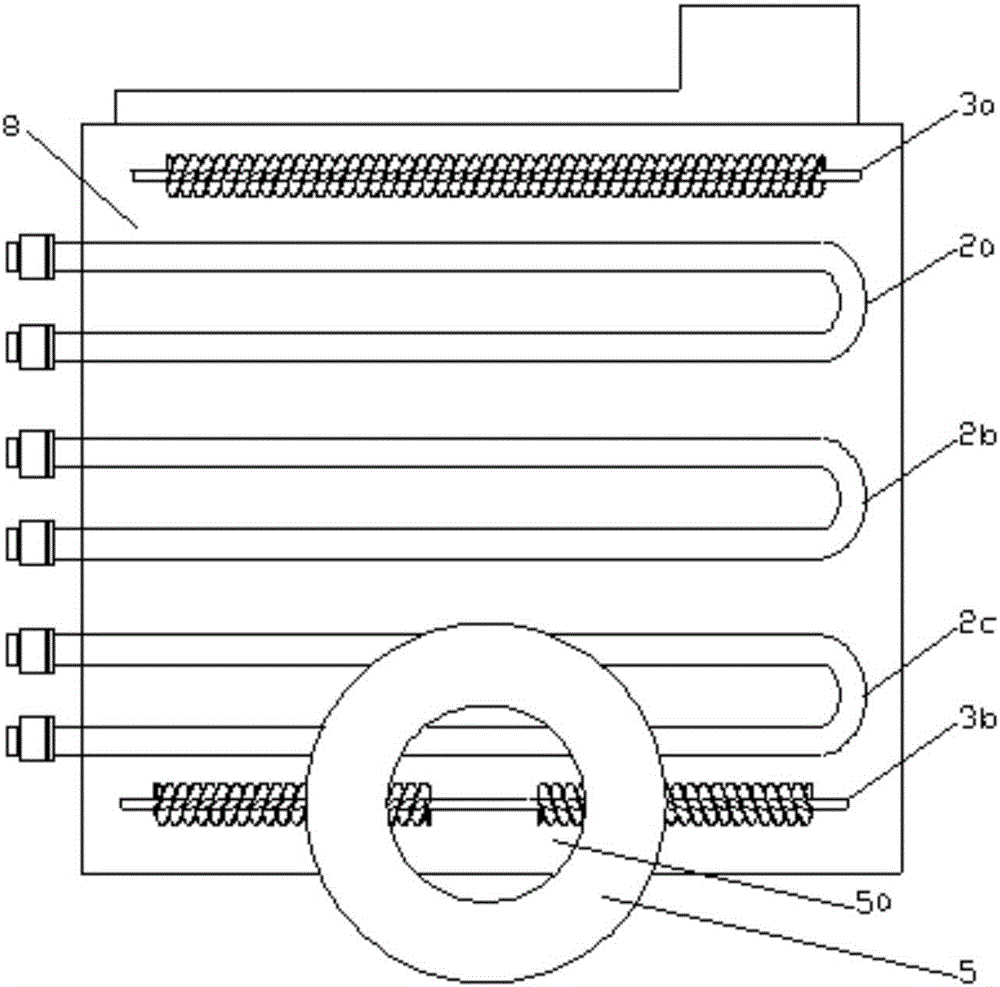

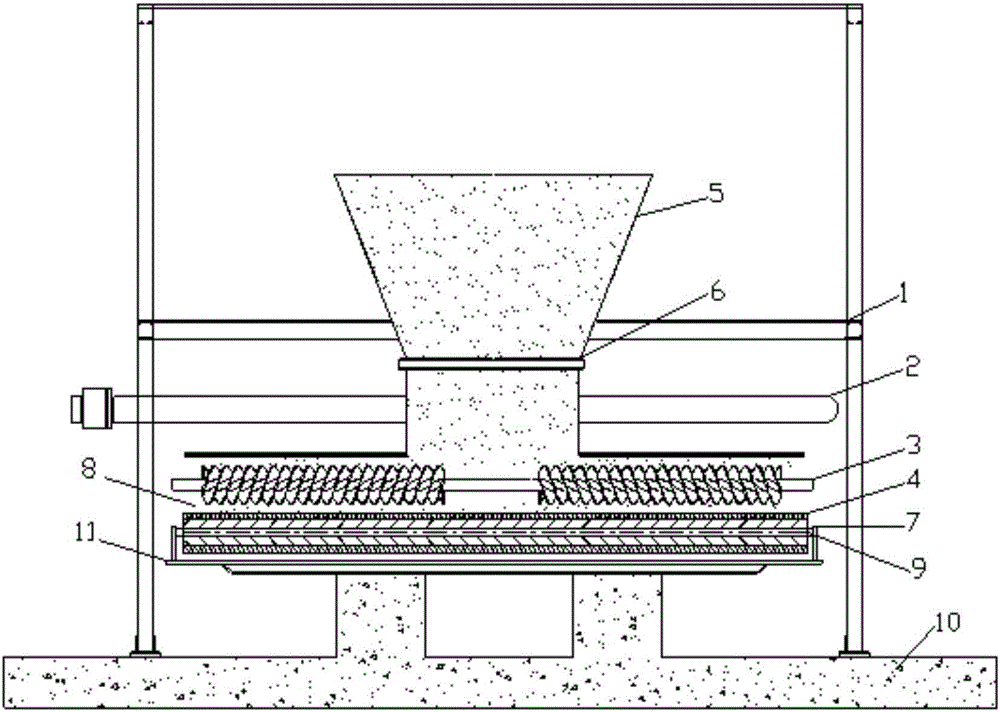

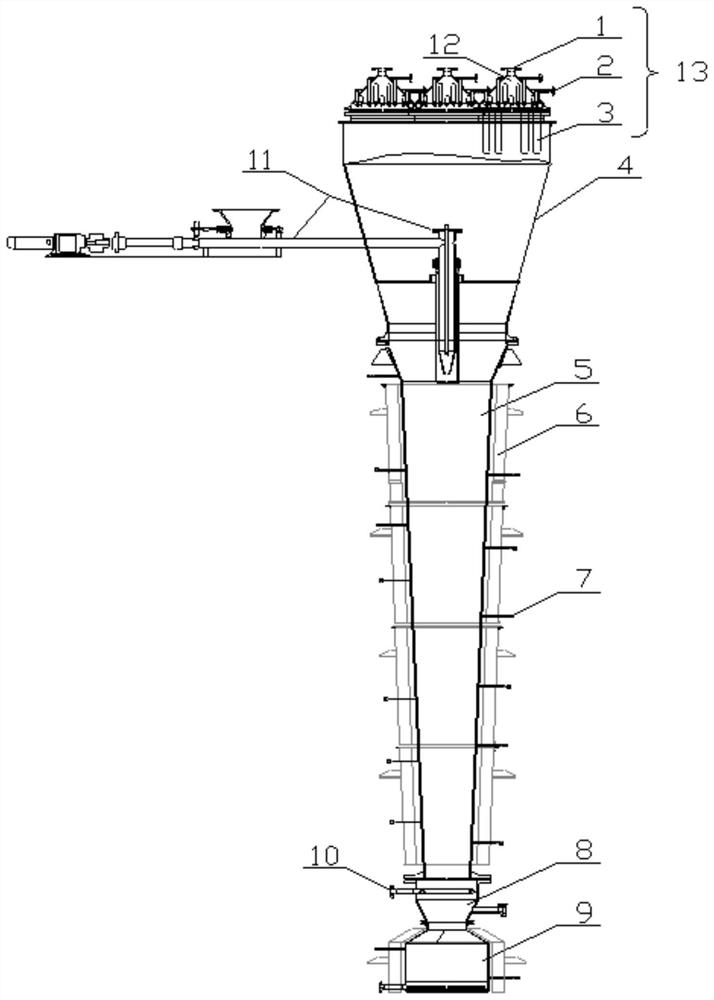

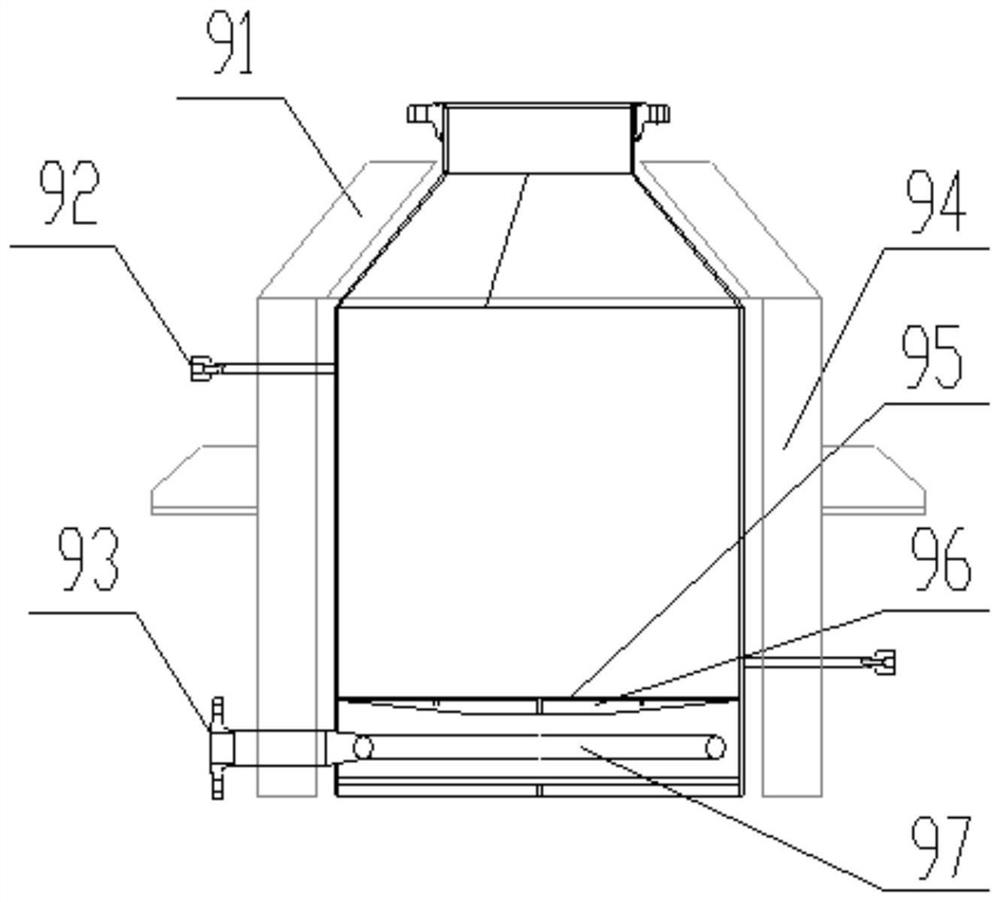

Fixed bed reactor and method for preparing activated carbon by continuously pyrolyzing biomass at low temperature

PendingCN106281375AReduce dust contentEnable direct recyclingProductsReagentsBiomassActivated carbon

The invention relates to a fixed bed reactor and a method for preparing activated carbon by continuously pyrolyzing biomass at low temperature. The reactor comprises a feeding hole, a reaction system and a discharge hole, wherein the feeding hole is formed above the discharge hole; the reaction system comprises a gas collecting chamber, a gas collecting region and a reaction chamber from top to bottom; a feeding screw, a discharge screw and a material plate are arranged in the reaction chamber; the material plate has a feed end and a discharge end; the feeding screw is arranged below the feeding hole and above the feed end; the discharge screw is arranged above the discharge end; the discharge end is above the discharge hole; the feeding screw comprises a central screw and left and right screw blades; the left and right screw blades are traversed by the central screw and are in axial symmetry by being vertical to the center line of the central screw; the distance between the left and right screw blades is 1 / 3-1 / 2 of the aperture of the feeding hole; reaction chamber clapboards are arranged in the reaction chamber; the two ends of the reaction chamber clapboards are respectively connected with a steam inlet and steam nozzles to spray steam to the reaction chamber. The reactor can achieve pyrolysis of biomass and preparation of activated carbon at the same time, can achieve continuous feeding and discharge and has obvious economic benefits.

Owner:SHENWU TECH GRP CO LTD

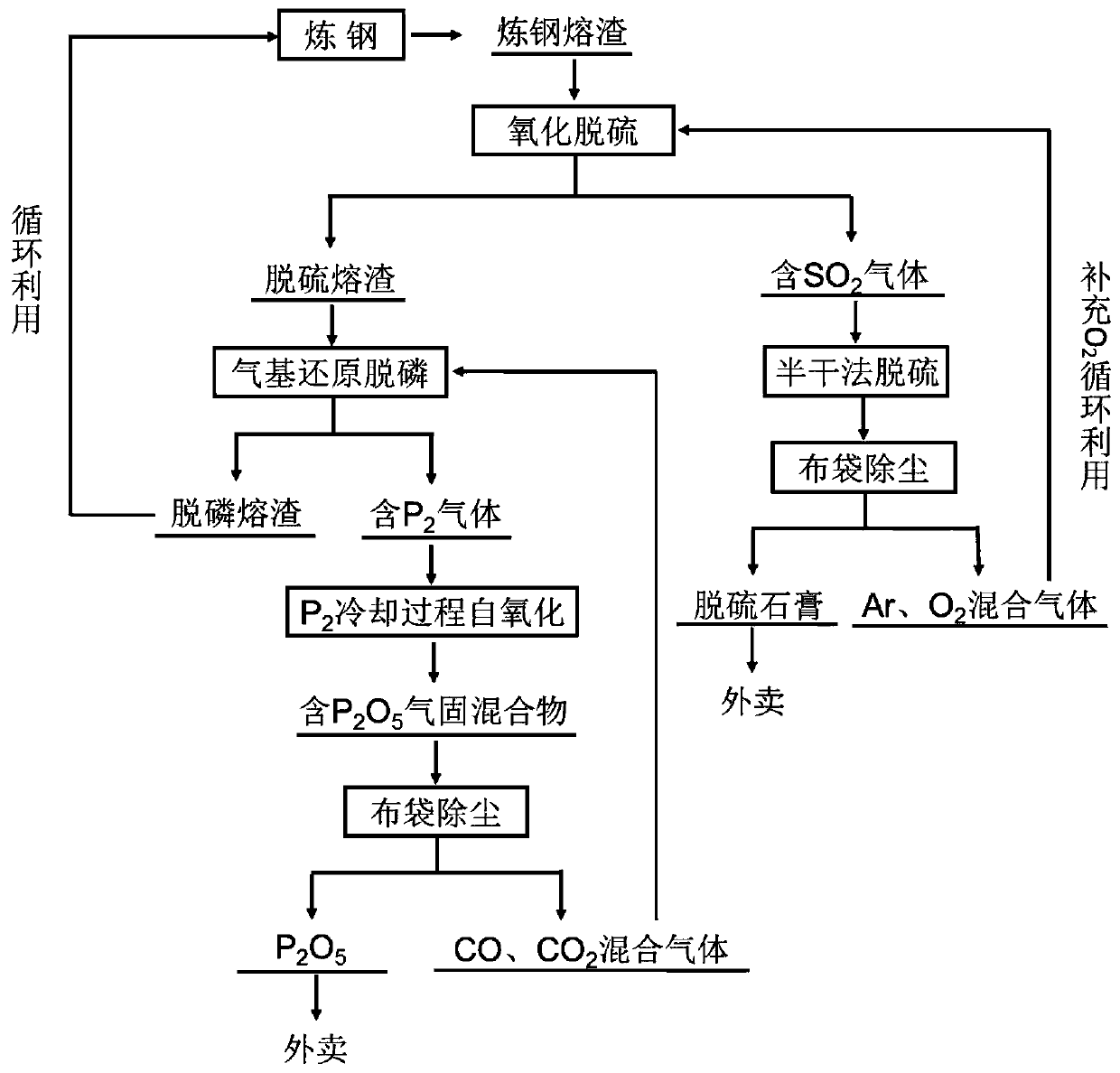

Two-step steel slag treatment method using oxidation desulfurization and reduction dephosphorization

ActiveCN110184399AComposition is stableReduce the reductive dephosphorization temperatureRecycling and recovery technologiesProcess efficiency improvementResource utilizationSulfur

The invention relates to a two-step steel slag treatment method using oxidation desulfurization and reduction dephosphorization, and belongs to the technical field of iron and steel metallurgy and resource utilization. According to the steel slag treatment method, the problem of S and P enrichment in the prior art of steel slag recycling is solved. The two-step steel slag treatment method using oxidation desulfurization and reduction dephosphorization comprises the following steps of 1, carrying out oxidation desulfurization of steel slags, specifically, a mixture of Ar and O2 is introduced into the molten steel slag, oxidized SO2 is removed from slag phase, and the removal rate of the S is 82%-97%; and 2, carrying out gas-based reduction dephosphorization of the desulfurized steel slag obtained in step 1, specifically, the reducing gas is a mixture of CO and CO2, the removal rate of the P is up to 80% or above, and reduced P2 is removed from the slag. According to the two-step steel slag treatment method using oxidation desulfurization and reduction dephosphorization, the problem of removing the S and the P from the steel slag is thoroughly solved, the recycling utilization ratioof the steel slag is greatly improved, and the full utilization of the steel slag, the S and the P is achieved, so that the cost of steel-making is reduced, the utilization values of the S and the P are improved, and the two-step steel slag treatment method has a broad application prospect.

Owner:钢研晟华科技股份有限公司

Process and device for recovering electrolytic copper from copper-containing wastewater

ActiveCN104773887BEnable direct recyclingReduce processing costsWater contaminantsWaste water treatment from metallurgical processAutomatic controlElectrolysis

The invention relates to a process and device for recovering electrolytic copper from copper-containing wastewater. The electrolytic copper is produced by adopting the technological processes of removing suspended matters and part of organic matters through pretreatment, carrying out ultrafiltration treatment, retaining concentrated copper sulfate with a nanofiltration membrane, recovering wastewater and acids with a reverse osmosis membrane and carrying out cyclone electrolysis. The process and the device have the beneficial effects that the recovery rate of the electrolytic copper is 90% and the copper purity is more than 99.95%; meanwhile, the wastewater recovery rate is more than 90%; the recovery rate of free sulfuric acid in the wastewater is more than 90%; the resource recovery rate is high and the economic benefits are good; adopting the technological processes of combined adsorption resin, ultrafiltration membrane, acid stabilizing nanofiltration membrane and high desalting rate reverse osmosis membrane, compared with other membrane recovery systems, the process has the advantage that the properties and service lives of the membranes can be maintained for a long term; the process has the effects of achieving automatic control and ensuring stable operation of a wastewater treatment system and the quality of recovered matters; the process is suitable for recovering copper in the copper-containing wastewater in the electroplating industry, the electronic industry and the metallurgical industry and other copper-containing industrial wastewater and for wastewater treatment.

Owner:NANJING LINEHOME ENVIRONMENTAL TECH CO LTD

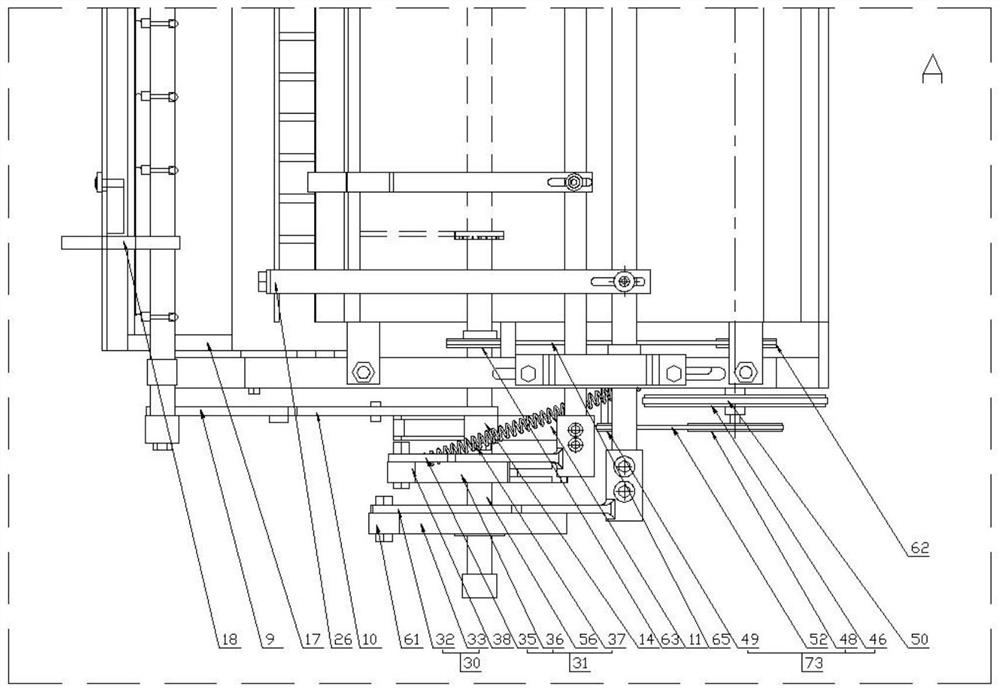

Automatic powder scraping device for electrolytic copper powder

ActiveCN113502509AImprove qualityIncrease productivityElectrolysis componentsPhotography auxillary processesMetallurgyElectrolytic cell

The invention provides an automatic powder scraping device for electrolytic copper powder, and relates to the technical field of electrolytic copper powder. The automatic powder scraping device for the electrolytic copper powder is used for scraping off the copper powder on a negative plate, and comprises a lifting mechanism and a powder scraping mechanism, wherein the negative plate is arranged on the lifting mechanism, and the lifting mechanism is used for driving the negative plate to rise from an electrolytic cell; the powder scraping mechanism comprises a plurality of groups of powder scraping assemblies, and each group of powder scraping assemblies comprises two powder scraping parts which are parallel to each other and are arranged at intervals; and the powder scraping mechanism further comprises a moving assembly, the powder scraping assemblies are installed on the moving assembly, the moving assembly enables the powder scraping assemblies to horizontally move to the lower side of the negative plate, and the lifting mechanism drives the negative plate to move downwards and penetrate through a gap between each group of powder scraping parts. According to the automatic powder scraping device for the electrolytic copper powder, the multiple negative plates can be scraped off at the same time, the production efficiency is improved, and the quality of the copper powder is improved.

Owner:CHONGQING YOUYAN ZHONGYE NEW MATERIAL +1

Converter steelmaking slagging agent prepared from aluminum ash dolomite and preparation method

PendingCN114737013AAvoid lossReduce occupancyManufacturing convertersProcess efficiency improvementSteelmakingMetallic aluminum

The invention provides a converter steelmaking slagging agent prepared from aluminum ash dolomite and a preparation method. The converter steelmaking slagging agent comprises aluminum ash and dolomite powder. According to the converter steelmaking slagging agent, the aluminum ash and the light-burned dolomite powder in a proper proportion are mixed and homogenized in the uniform mixing container for blocking air circulation to form the dry mixture, and the dry mixture is subjected to dry pressing to form the ellipsoidal converter steelmaking slagging agent, so that the loss of various effective components with high reaction activity, such as metal aluminum, in the aluminum ash is avoided. The composite slagging material (agent) which is produced by taking the aluminum ash and the light-burned dolomite powder as raw materials and contains magnesium oxide and aluminum oxide components not only can improve the steelmaking slagging operation of a converter, but also can overcome the defects of high resource consumption and high cost caused by taking aluminum vanadium soil blocks and light-burned dolomite blocks as slagging raw materials; the effect of directly recycling the light-burned dolomite fine powder is achieved, the aluminum ash can be efficiently utilized in a full-value mode, and the method has economic, environment-friendly and social positive significance in the aspects of reduction of aluminum ash stockpiling land occupation, reduction of other environment-friendly negative effects and comprehensive utilization of resources.

Owner:HENAN MECHANICAL & ELECTRICAL VOCATIONAL COLLEGE

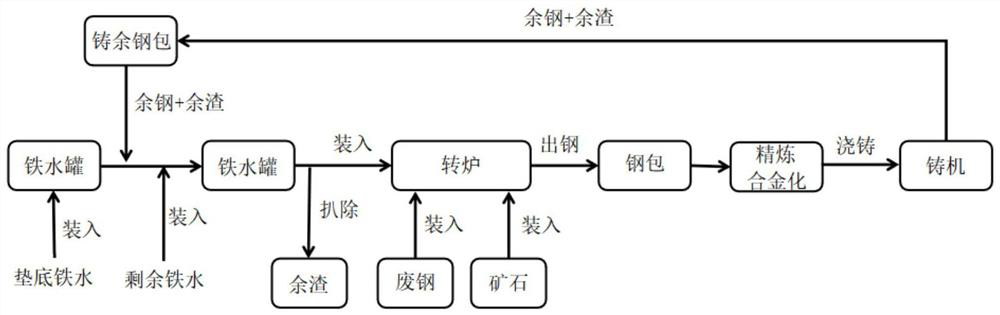

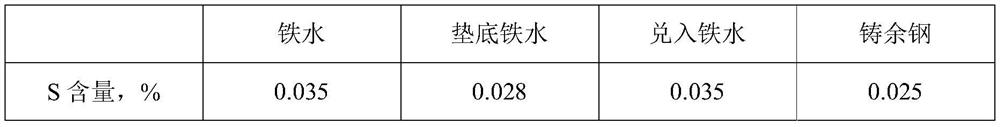

Method for recycling steel ladle casting residual steel and casting residual slag

The invention discloses a method for recycling steel ladle casting residual steel and casting residual slag, and belongs to the technical field of steel and iron smelting. The method comprises the following steps that casting residual steel and casting residual slag are loaded into a molten iron tank containing bottom molten iron; and a temperature of the casting residual steel and the casting residual slag is not lower than 1500 DEG C, and in the bottom molten iron, a content of P ranges from 0.100 wt% to 0.150 wt% and a content of S ranges from 0.020 wt% to 0.060 wt%. According to the method, direct recycling of heat of the casting residual steel and the casting residual slag can be achieved, meanwhile, when the bottom molten iron makes contact with the casting residual steel, the casting residual slag also enters the bottom molten iron, harmful elements S and P in part of the molten iron can be removed by means of the high-alkalinity casting residual slag under a stirring effect, and lime consumption for converter smelting is reduced.

Owner:南京宝希智能技术有限公司

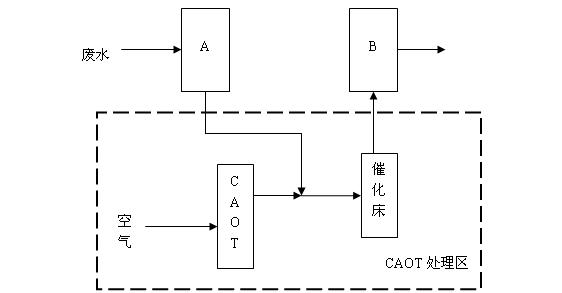

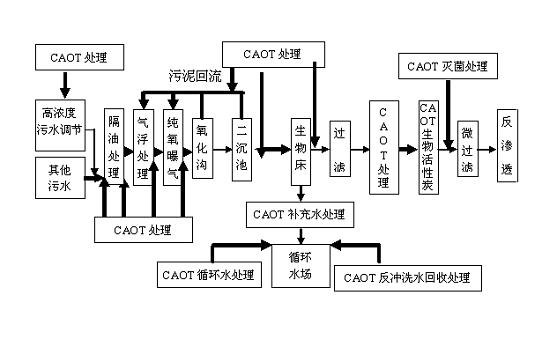

Oily wastewater treatment method

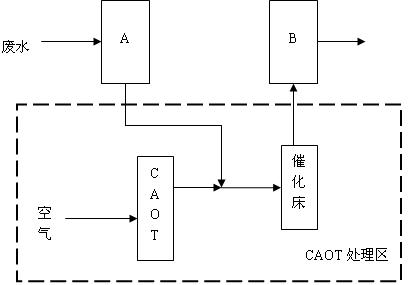

InactiveCN102583691AImprove purification effectReduce consumptionWater/sewage treatment by oxidationEmission standardOxidative treatment

The invention relates to an oily wastewater treatment method which is characterized by comprising the following steps of: adding one advanced oxidation treatment device (CAOT) capable of generating activated gas containing OH- between any two treatment apparatuses in the conventional wastewater treatment technology, mixing the wastewater flowing out of the first treatment apparatus with air of activated gas containing OH- generated by the advanced oxidation treatment device (CAOT), generating CAOT activated water in the wastewater, leading the wastewater containing the CAOT activated water into a catalytic bed to perform a catalytic reaction with a catalyst, leading the products into the second treatment apparatus to improve the purification and separation capability of the second treatment apparatus, controlling the volume ratio of the OH- activated gas to the wastewater between 1% and 20%, and controlling the residence time of the wastewater on the catalytic bed between 2 s and 1500 s. The oily wastewater treatment method has the advantages of low investment and low cost, and the emission standards and the treatment efficiency are improved.

Owner:杨政宏 +4

A continuous processing device for electrical insulation paper corrugated tube

ActiveCN109334113BReduce in quantityLow costPaper/cardboard wound articlesInsulatorsElectrical insulation paperBrush

The invention relates to an electrical insulation paper wrinkle tube continuous processing device. The continuous processing device comprises a machine frame, a first baffle, a guide plate, a conveying belt and a driving mechanism are arranged on the machine frame, a first shaft body with a rubber brush and a brazing frame are arranged on the top of the side of the first baffle plate, a first deflection mechanism is arranged on the first shaft body, an upper brazing chain is arranged on one side of the brazing frame, a second deflection mechanism is arranged on a brazing claw of the brazing frame, a second shaft body of a pressing frame and a third shaft body of a pushing frame are provided with a third deflection mechanism and a fourth deflection mechanism respectively, a fifth deflectionmechanism is arranged on a material frame of a second arc-shaped plate, a brazing chain is arranged on one side of the material frame, at least two return brazing chains are arranged between the brazing chain and the upper brazing chain, and a transmission mechanism is arranged on a driving roller of the conveying belt. The continuous processing device is compact in structure, the energy consumption is low, the whole machine is linked, the operation is simple, automatic and rapid continuous brazing, gluing, twisting and forming, brazing circulation and discharging and machining can be realized, so that the equipment, the brazing and the labor cost can be remarkably reduced, the production efficiency and the yield of paper tubes are improved.

Owner:镇江市鑫泰绝缘材料有限公司

Device capable of generating electric energy and simultaneously removing metal ions and method of device

ActiveCN102502925BAvoid it happening againNo energy input requiredWater/sewage treatmentHigh energyWastewater

Owner:ZHEJIANG UNIV

Recycling process of recovering pure water and pure nickel from electroplating nickel rinsing wastewater

ActiveCN105858987BEnable direct recyclingReduce the amount addedPhotography auxillary processesTreatment involving filtrationCycloneElectrolysis

The invention relates to a recycling treatment process for recovering pure water and pure nickel from electro-nickelling rinsing wastewater. The recycling treatment process adopts a variety of ion exchange resin-acid stabilizing nanofiltration membrane-cyclone electrolysis combined processes and has the advantages that pure water and metal nickel can be directly recovered from the wastewater, the nickel recovery rate is greater than or equal to 90%, the electrolytic nickel purity is greater than or equal to 99.95%, the wastewater recovery rate is greater than or equal to 70%, and the electrical conductivity of the recovered water is smaller than or equal to 10 micro-seconds / cm. Compared with other methods, the recycling treatment process is high in resource recovery rate and good in economic benefit, can ensure stable operation of a wastewater treatment system and the quality of recovered substances and is suitable for nickel recovery from nickel-containing wastewater and other nickel-containing industrial wastewater and wastewater recycling treatment in the electroplating industry, electronic industry and metallurgical industry.

Owner:NANJING LINEHOME ENVIRONMENTAL TECH CO LTD

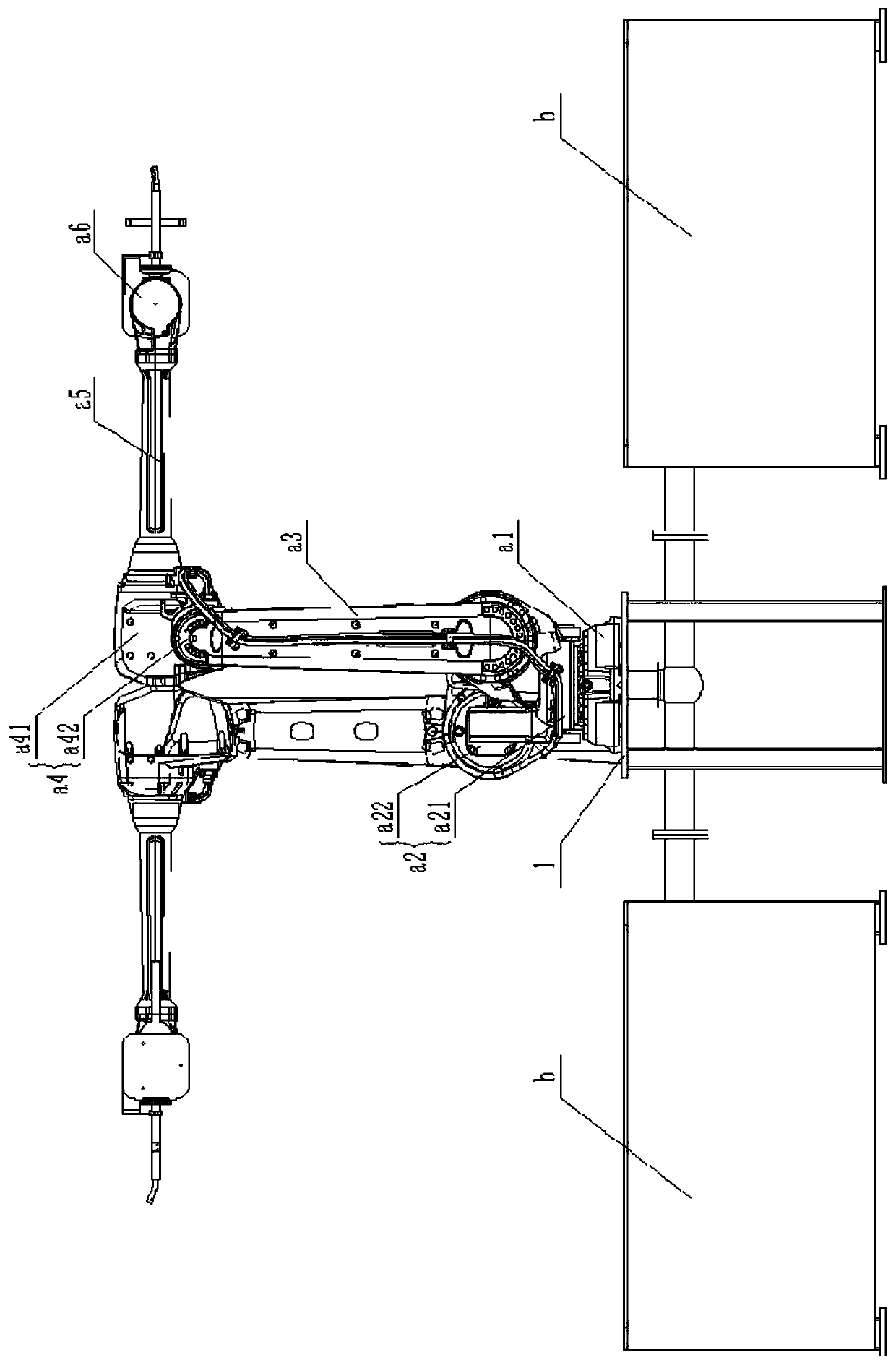

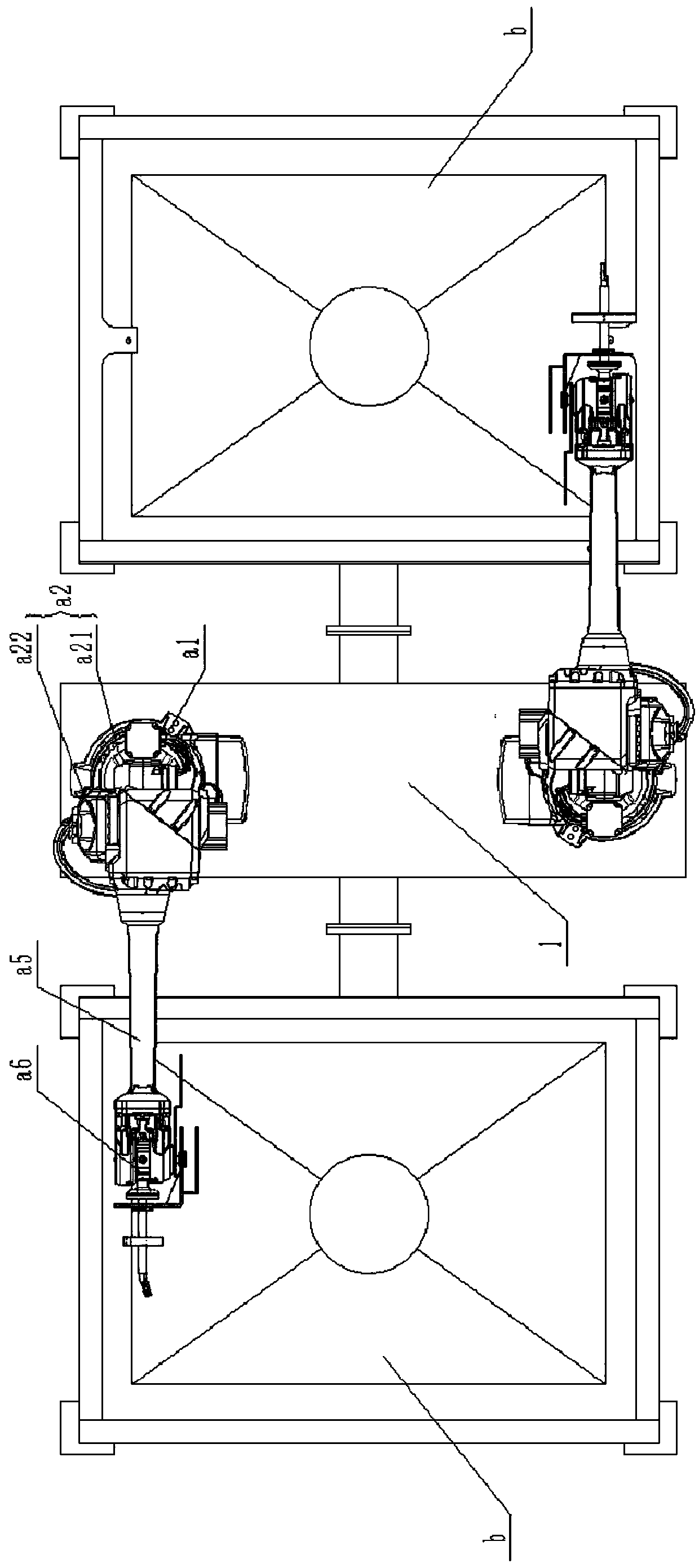

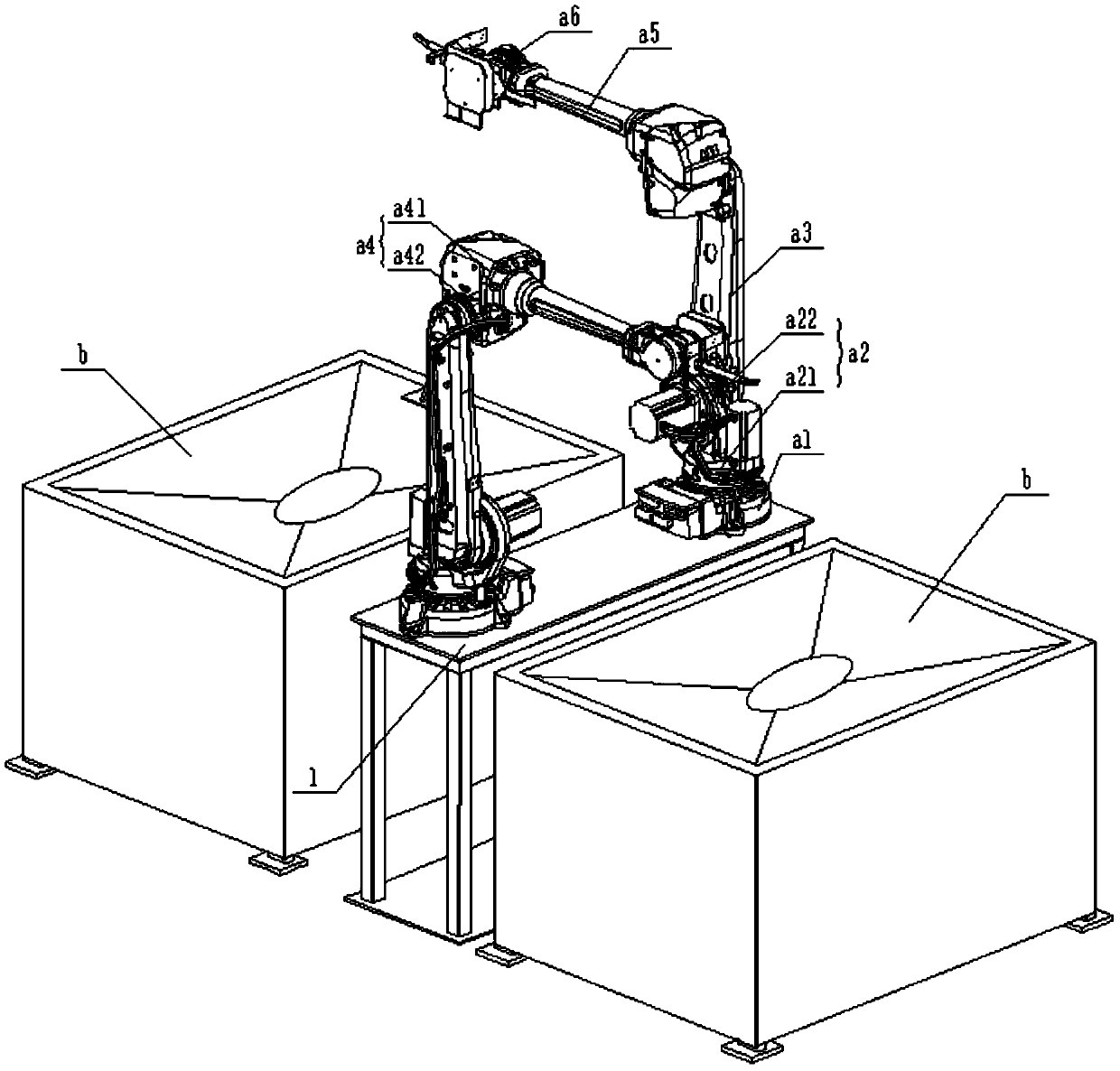

Efficient low-energy-consumption anti-blocking water cutting jet

InactiveCN110893631AEnable direct recyclingImprove filter qualityMetal working apparatusFiltration circuitsWater resourcesEnvironmental engineering

The invention discloses an efficient low-energy-consumption anti-blocking water cutting jet. The efficient low-energy-consumption anti-blocking water cutting jet comprises water cutting robots which are arranged in a directly-facing mode, the two water cutting robots are mounted on the same base, water cutting machine tools are arranged on the two sides of the base in a directly-facing mode and comprise platform bodies, water collecting hoppers are arranged at the tops of the platform bodies, separation seats are horizontally arranged in the platform bodies and isolate the platform bodies intoupper muddy liquid areas and lower clean liquid areas, debris separation assemblies are arranged in the upper muddy liquid areas, and centrifugal separation devices are arranged in the lower clean liquid areas and communicate with the upper muddy liquid areas. Compared with the prior art, the efficient low-energy-consumption anti-blocking water cutting jet is compact in structure, high in practicability and good in filtering effect, by dually filtering discharged water of the water cutting jet, residue in the water can be effectively removed, thus the water is recovered and utilized, the water in the water cutting machine tools is recycled, the discharged water can be directly recycled, the effective working time is prolonged, water resource waste is also avoided, and thus the productioncost is lowered.

Owner:重庆环纽信息科技有限公司

Oxidized graphene aftertreatment work procedure acid-containing wastewater cyclic utilization method

The invention discloses an oxidized graphene aftertreatment work procedure acid-containing wastewater cyclic utilization method which comprises the following steps: (1) preparing oxidized graphene slurry; (2) diluting the oxidized graphene slurry; (3) adding hydrogen peroxide and diluted hydrochloric acid into the diluted slurry and stirring to obtain oxidized graphene slurry to be treated; (4) repeatedly washing the oxidized graphene slurry to be treated and filtering acid-containing wastewater out after every time of washing; (5) dividing the acid-containing wastewater into high, middle andlow electric conduction sections according to conductivity and collecting the acid-containing wastewater in the middle and low electric conduction sections; (6) applying the acid-containing wastewaterin the middle and low electric conduction sections to washing the oxidized graphene slurry in the high and middle electric conduction sections. According to the oxidized graphene aftertreatment workprocedure acid-containing wastewater cyclic utilization method disclosed by the invention, the acid-containing wastewater discharged in a purifying work procedure is divided according to the conductivity; the acid-containing wastewater in the middle and low electric conduction section is respectively applied to washing the oxidized graphene slurry in the high and middle electric conduction sections; thus, the method achieves cyclic utilization of acid-containing wastewater.

Owner:新疆烯金石墨烯科技有限公司

Method for preparing expanded graphite by using mixed reaction liquid of graphene oxide

PendingCN114455580AReduce the cost of industrial preparationLow industrial preparation costCarbon compoundsStrong acidsOxidizing agent

The invention provides a method for preparing expanded graphite by using a mixed reaction solution of graphene oxide, which comprises the following steps: taking the mixed reaction solution containing strong acid (such as sulfuric acid) and strong oxidant (such as potassium permanganate) in the production of graphene oxide as a raw material for preparing the expanded graphite, and regulating the ratio of the mixed reaction solution to the graphite raw material to prepare the expanded graphite. And setting the temperature and the reaction time suitable for the raw material ratio to prepare the expanded graphite product. According to the method, the strong acid and the strong oxidant in the graphene oxide preparation process are recycled and used for preparing the expanded graphite, purification and impurity removal treatment is not needed in the recycling process, direct recycling of the strong acid and the strong oxidant can be achieved, and the discharge amount of the strong acid and the strong oxidant is reduced; the industrial preparation cost of two graphite deep processing products, namely the graphene oxide and the expanded graphite, can be reduced at the same time, and the method is widely applicable to low-cost industrial production of the graphene oxide and the expanded graphite.

Owner:ZHANJIANG JUXIN NEW ENERGY +1

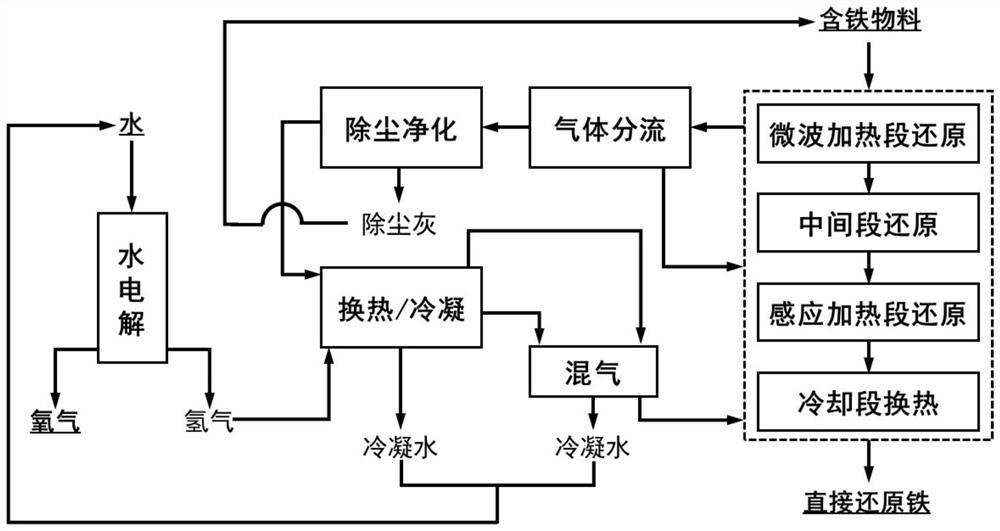

A hydrogen shaft furnace ironmaking system and method using electric energy heating

ActiveCN112899427BGuaranteed temperatureReduce recirculation air volumeExhaust gas handlingShaft furnaceElectrolysisShaft furnace

A hydrogen shaft furnace ironmaking system and method using electric energy heating, the system includes a water electrolyzer, a hydrogen storage tank, an electric energy heating hydrogen shaft furnace, a heat exchanger, and a gas mixing tank; the furnace body is provided with a microwave heating section, a middle section, The induction heating section, the cooling section and the screw discharger, the air inlet pier is below the cooling section, and the water electrolyzer, hydrogen storage tank, heat exchanger, gas mixing tank are connected with the air inlet of the air inlet pier in sequence. The method is as follows: (1) The hydrogen gas generated by the electrolysis of the water electrolyzer is passed into the hydrogen storage tank; (2) The hydrogen gas is passed into the coil in the heat exchanger, discharged into the gas mixing tank, and passed into the furnace body through the air inlet pier; (3) Turn on the microwave radiation source and the induction coil; (4) Put the iron-containing material into the furnace body to exchange heat with the gas and undergo a reduction reaction; (5) After the iron-containing material passes through each section of the furnace body, it will generate direct reduced iron and discharge it. The method of the present invention avoids oxygen blowing at the upper part, can realize the direct recovery and utilization of part of the high-temperature tail gas on the top of the furnace, reduces energy consumption and operation cost, and can avoid pipeline material failure and other related safety accidents caused by hydrogen diffusion.

Owner:NORTHEASTERN UNIV LIAONING

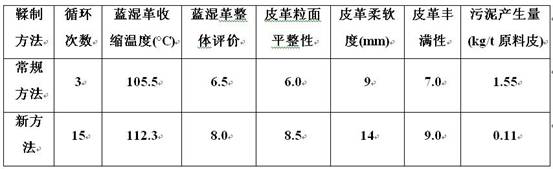

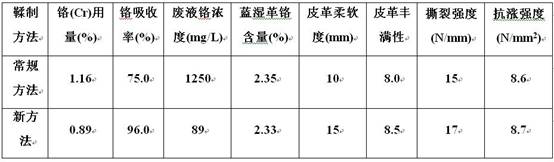

A salt-free and pickling-free animal skin chrome tanning method based on the synergistic effect of complex ligands

ActiveCN109880943BModulation of Chromium Crosslink StrengthGood flexibilityTanning treatmentSalt freeCollagen fiber

The invention provides a salt-free and non-pickling animal skin chrome tanning method based on the synergistic effect of complex chromium ligands. The feature of this method is to use a variety of ligands with gradient differences in coordination ability with hydrated chromium ions to treat and soften animal skins, effectively control the hydrolysis and polymerization rate of chromium complexes during the chrome tanning process, without pickling operation, and without using Chrome tanning is carried out under the condition of neutral salt and masking agent to realize salt-free and high absorption chrome tanning. The invention solves the problem that under the condition of high pH value, it is difficult to balance the rapid penetration and high-efficiency combination of chromium in animal skin and the degree of chromium crosslinking between collagen fibers is difficult to control, which affects the performance of leather; compared with conventional chrome tanning methods, it can The process operation is simplified, the chromium absorption rate is increased to over 95%, the chromium concentration in the waste liquid is reduced to below 100mg / L, the chrome tanning waste liquid can be efficiently and directly recycled, the generation of chromium-containing sludge is reduced by more than 80%, and the leather has better Softness and fullness. The invention significantly improves the leather-forming performance of salt-free high-absorption chrome tanning.

Owner:SICHUAN UNIV

Fluorine double-inlet vertical fluorination reactor and use method thereof

PendingCN114558526AReduce productionGood economic benefitsReactors manufactureChemical/physical/physico-chemical processesNitrogen gasFluoridation reaction

A fluorine double-inlet vertical fluorination reactor comprises a fluorination reactor body, a fluorination reactor expansion section and a fluorination reactor feeding device are connected to the upper portion of the fluorination reactor body, a filter is connected to the upper portion of the fluorination reactor expansion section, a filter pipe and a nitrogen back flushing device are arranged in the filter, and a nitrogen inlet is formed in the nitrogen back flushing device. The nitrogen inlet is communicated with the filter pipe, a uranium hexafluoride gas outlet is further formed above the nitrogen back flushing device, and the uranium hexafluoride gas outlet is communicated with the filter pipe; the lower part of the fluorination reactor body is connected with a fluorination reactor gas chamber; a fluorine gas inlet pipe a is arranged on the fluorination reactor gas chamber; and a slag tank is arranged below the fluorination reactor gas chamber. The use method of the fluorine gas double-inlet vertical fluorination reactor comprises the following steps: heating the fluorination reactor body, enabling fluorine gas to enter the fluorination reactor gas chamber and the slag tank, reacting to generate uranium hexafluoride gas, and enabling the filtered uranium hexafluoride gas to flow out of the fluorine gas double-inlet vertical fluorination reactor from the uranium hexafluoride gas outlet.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

A method for smelting lead-containing plaster of waste lead storage battery

The invention discloses a method for smelting lead paste of a waste lead storage battery. The method comprises the following steps: mixing the lead paste of the waste lead storage battery with a reducer-coke or powdered coal, copper residues, iron ores, quartz sand and limestone, wherein the additive amount of the coke or the powdered coal is 10%-25% by weight of the lead paste of the waste lead storage battery, the weight of the copper residues is 5-10 times that of sulfur in the lead paste of the waste lead storage battery, the added limestone, quartz sand and iron ores meet the smelting slag requirements that the weight ratio of FeO to SiO2 is 1.2 to 1.75 and the weight ratio of CaO to SiO2 is (0.4-0.9) to 1; adding a mixture into a cylinder or a disk granulator for granulating; conveying granulated materials into a smelting furnace; filling the smelting furnace with oxygen-rich air for reduction smelting. According to the method, a reducing atmosphere is controlled, so that copper-sulfur concentrates are obtained by reacting the copper residues with sulfur in the waste lead storage battery while crude copper is produced, and lead, copper and sulfur are directly recovered; the recovery rate of crude copper is more than 98% and the comprehensive recovery rate of copper and sulfur is more than 95%.

Owner:YONGZHOU FUJIA NON FERROUS METALS

An oil well wellhead blowout preventer and system

ActiveCN111058791BEnable direct recyclingAvoid it happening againSurveySealing/packingData informationOil field

The invention relates to the field of oil field production equipment, in particular to an oil well wellhead blowout preventer and an oil well wellhead blowout preventer system. The wellhead blowout preventer of the oil well includes a shell part and monitoring equipment. The bottom of the shell part is provided with a first through hole, and the top is provided with a second through hole, which are used for the passage of the pipeline connected with the wellhead blowout preventer of the oil well; The bottom of the part forms a first sleeve part with a return hole inside the first through hole; the monitoring equipment is arranged in the wellhead blowout preventer of the oil well, and is used to monitor the change of the fluid in the shell part and feed it back to the control device. The invention can fully ensure that no landing oil is generated within its effective load range, and control the mis-emission of harmful gases. It not only reduces the loss of landing oil and improves the overall oil production, but also avoids the generation of landing oil, and controls the overall monitoring and processing capabilities of harmful gas emissions, significantly improving the comprehensive pre-control of potential safety hazards. The operation data information of each oil well is collected in real time during operation. Provide rich data detail support for optimization operations.

Owner:西安狮龙石油设备监理技术有限公司

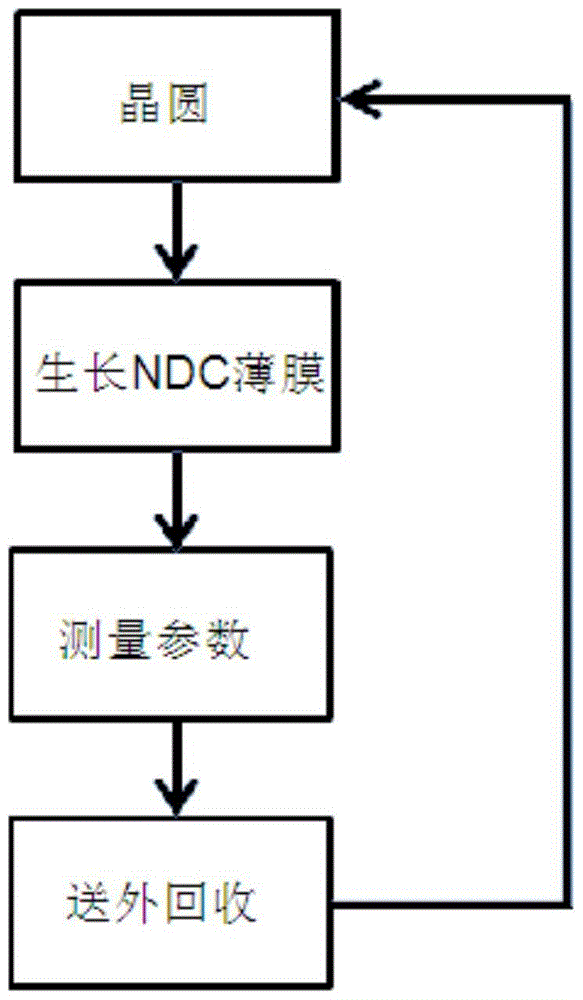

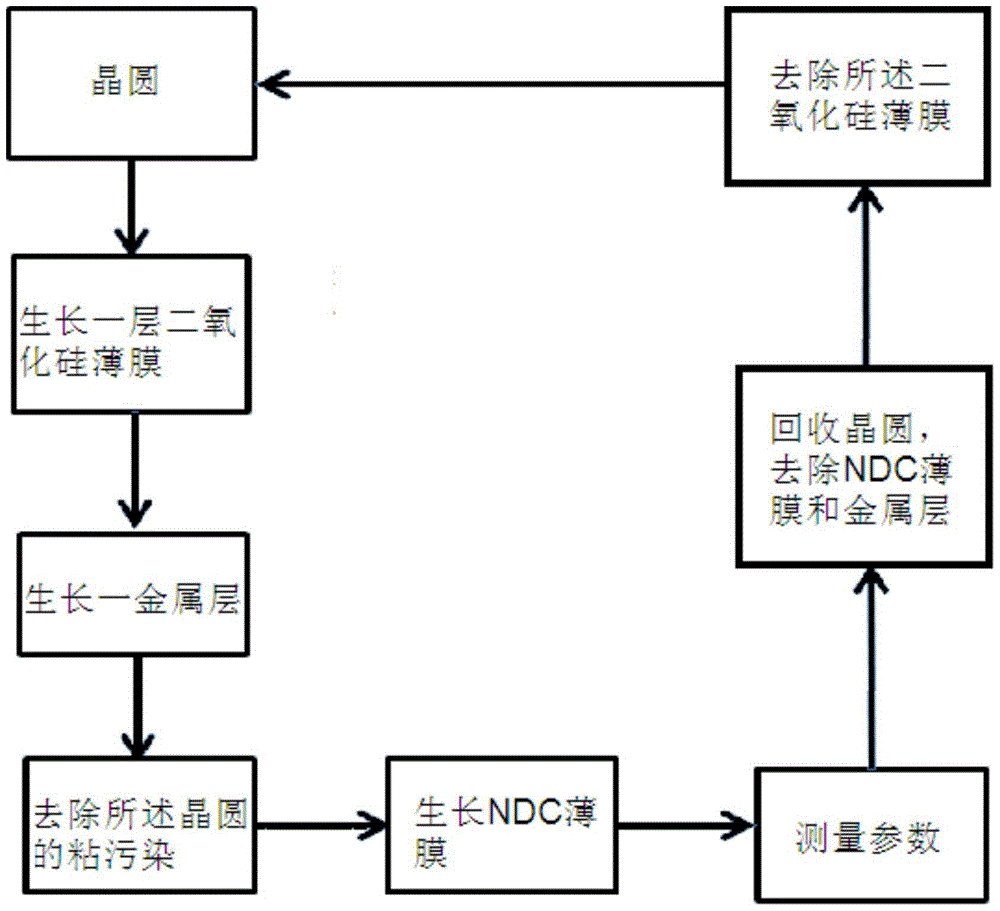

An off-line monitoring method for nitrogen-doped silicon carbide thin films

ActiveCN103904001BEnable direct recyclingReduce recycling costsSemiconductor/solid-state device testing/measurementIntegrated circuit manufacturingSilicon dioxide

The invention provides an off-line monitoring method for a nitrogen-doped silicon carbide film, and relates to the field of semiconductor integrated circuit manufacturing, in particular to the off-line monitoring method for the nitrogen-doped silicon carbide film. The method includes the following steps that a bare wafer is provided; a layer of silicon dioxide film grows on the bare wafer; a metal layer grows on the silicon dioxide film; sticky pollution on the surface of the metal layer is removed; the nitrogen-doped silicon carbide film is manufactured on the metal layer to form a monitoring wafer; parameters are measured; the monitoring wafer is recovered, and the nitrogen-doped silicon carbide film and the metal layer are removed; the silicon dioxide film is removed to form a bare wafer again; the preceding steps are repeated. By means of the method, direct recovery and use of the off-line monitoring wafer of the nitrogen-doped silicon carbide film on a semiconductor production line can be achieved, recovery cost of the off-line monitoring wafer of the nitrogen-doped silicon carbide film is saved, and a large quantity of standby bare wafers do not need to be stored.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

A method for directly recovering 7-aca from 7-aca crystallization mother liquor

ActiveCN106117245BEnable direct recyclingAchieve high-quality recyclingOrganic chemistrySocial benefitsDesorption

The invention relates to a method for directly recovering 7-ACA from 7-ACA crystal mother liquid, and belongs to the technical field of medicines. A resin adsorption method is adopted for neutralizing the cooled crystal mother liquid, and then adsorption is directly performed through macroporous resin; concentration is performed, the absorption temperature is controlled to be 2-10 DEG C, the flow rate is controlled to be 0.2BV / h-3BV / h, and then a desorbing agent is used for desorption, wherein the desorption temperature is 2-10 DEG C; and then acidification crystallization is performed, sucking filtration is performed, and then drying is performed, so that the 7-ACA is obtained. The method disclosed by the invention can effectively reduce the production cost and the environmental pollution of the 7-ACA, green production of the 7-ACA can be realized, and the method has high economic and social benefits.

Owner:TIANJUSHI ENG TECH GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com