An oil well wellhead blowout preventer and system

A technology for blowout prevention devices and oil wells, which is applied in wellbore/well components, measurement, sealing/isolation, etc., and can solve problems such as low recovery rate of ground oil, high rate of industrial waste generation, and high cost of special vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

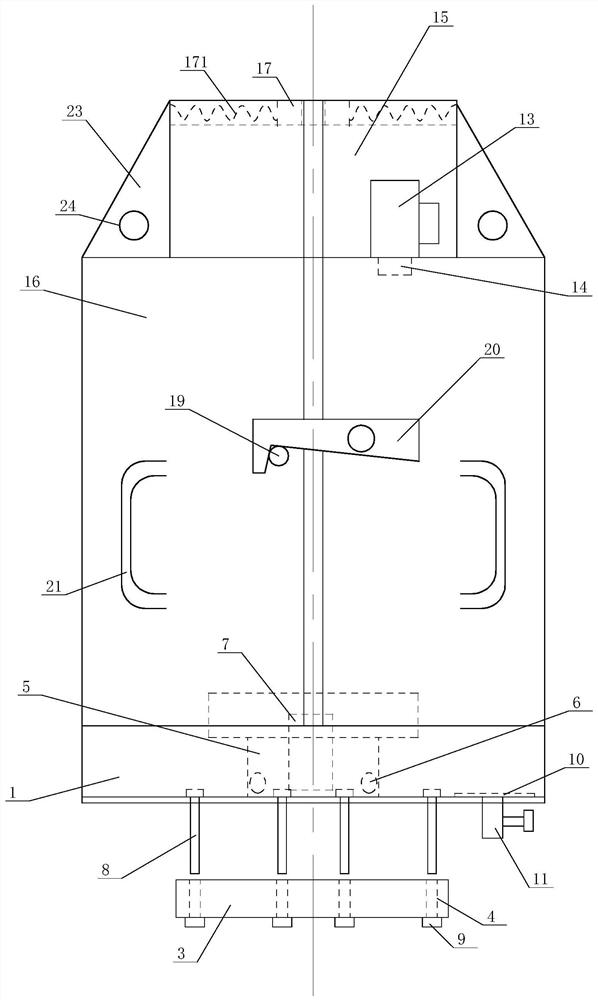

[0039] like Figure 1-Figure 5As shown, this embodiment provides a wellhead blowout prevention device and system for an oil well, including a wellhead blowout prevention device for an oil well, a warning system and a comprehensive monitoring system. In the spraying device, the bottom of the housing part is provided with a first through hole, and the top of the housing part is provided with a second through hole, and the first through hole and the second through hole are used to allow the oil pipe connected to the wellhead blowout preventer to pass through;

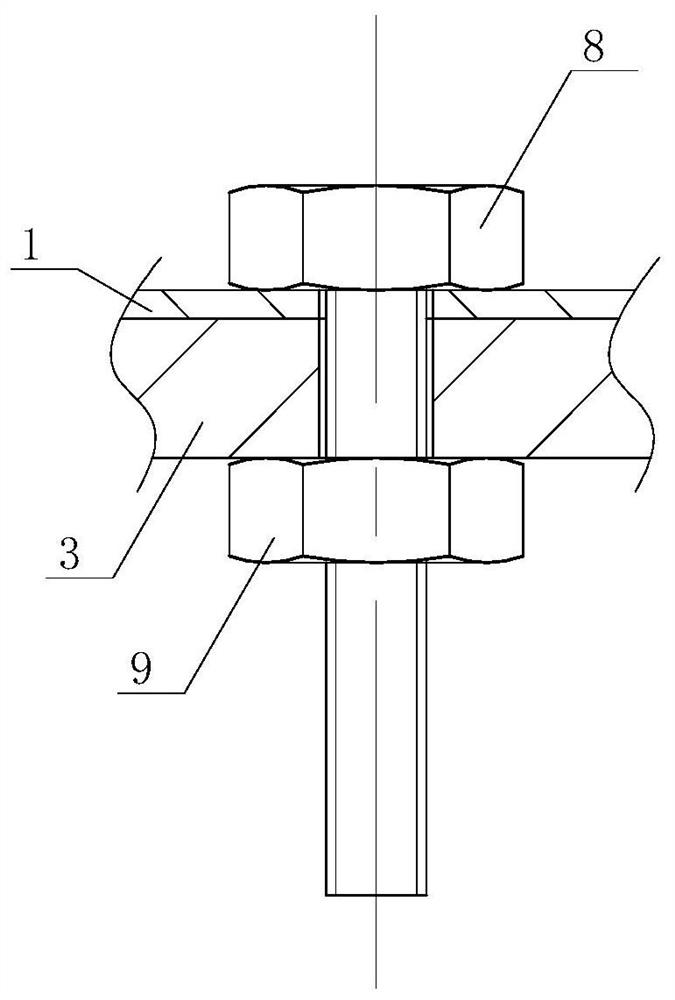

[0040] A first sleeve portion 5 is formed inside the first through hole at the bottom of the housing portion, and a return hole 6 is provided on the first sleeve portion 5 through the sleeve wall of the first sleeve portion 5 in a radial direction.

[0041] The warning system includes a control device and a prompting device. The monitoring device is used to monitor the change of gas and liquid in the casing and feeds back ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com