Continuous preparation method of biodegradable block co-polyester and biodegradable block co-polyester

A block copolyester, biological technology, applied in the field of biodegradable block copolyester, can solve the problem of poor thermal performance and physical processing performance of degradable polymers, difficulty in continuous production, and ethylene glycol recycling rate Bad question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

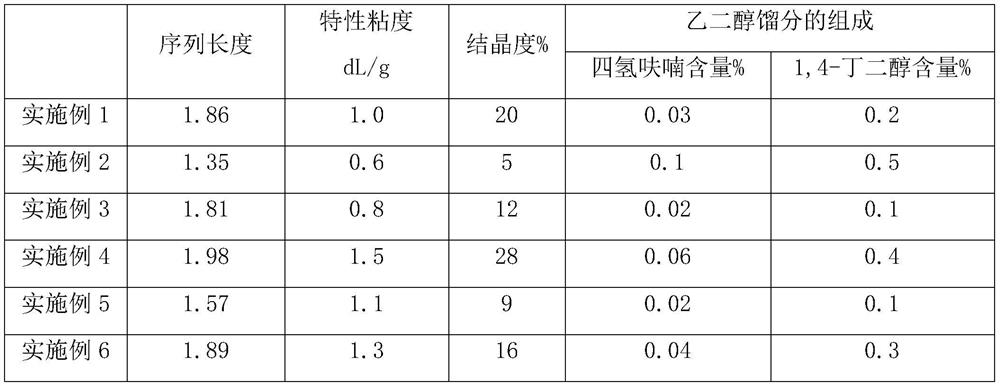

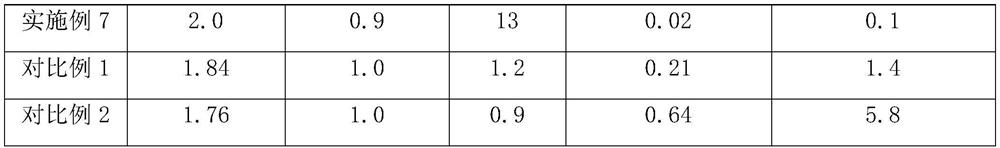

Examples

Embodiment 1

[0042] (1) Prepare terephthalic acid, succinic acid, and ethylene glycol into a slurry, and the molar ratio of terephthalic acid, succinic acid, and ethylene glycol in the slurry is: 1:0.2:1.5.

[0043] (2) The slurry prepared in the step (1) is continuously fed into an esterification tank, and esterified at a temperature of 220° C. to form a polyester prepolymer.

[0044] (3) Inject the polyester prepolymer into the precondensation system, and complete the polycondensation at 250°C to obtain a polyester prepolymer melt with an intrinsic viscosity of 0.3dL / g, which is measured by a melt metering gear pump from the precondensation system. The polycondensation system is delivered to the prepolymer melt pipeline.

[0045] (4) Melt polybutylene succinate with an intrinsic viscosity of 1.0dL / g and lanthanum acetate transesterification catalyst through a screw extruder to form a mixed melt of polybutylene succinate, polybutylene succinate The acid butylene glycol ester mixed melt is ...

Embodiment 2

[0049] (1) Prepare terephthalic acid, oxalic acid, and ethylene glycol into a slurry, and the molar ratio of terephthalic acid, oxalic acid, and ethylene glycol in the slurry is: 1:0.42:2.0.

[0050] (2) The slurry prepared in step (1) is continuously fed into an esterification tank, and esterified at a temperature of 200° C. to form a polyester prepolymer.

[0051] (3) Inject the polyester prepolymer into the precondensation system, and complete the polycondensation at 240°C to obtain a polyester prepolymer melt with an intrinsic viscosity of 0.1dL / g, which is measured by the melt metering gear pump from the precondensation system. The polycondensation system is delivered to the prepolymer melt pipeline.

[0052] (4) Melt the polybutylene succinate with an intrinsic viscosity of 0.5dL / g and the cerium propionate transesterification catalyst through a screw extruder to form a mixed melt of polybutylene succinate, polybutylene succinate The mixed melt of butanediol dioate is m...

Embodiment 3

[0056] (1) Prepare terephthalic acid, sebacic acid, and ethylene glycol into a slurry, and the molar ratio of terephthalic acid, sebacic acid, and ethylene glycol in the slurry is: 1:0.3:1.6.

[0057] (2) The slurry prepared in the step (1) is continuously fed into an esterification tank, and esterified at a temperature of 230° C. to form a polyester prepolymer.

[0058] (3) Inject the polyester prepolymer into the precondensation system, and complete the polycondensation at 260°C to obtain a polyester prepolymer melt with an intrinsic viscosity of 0.4dL / g, which is measured by a melt metering gear pump from the precondensation system. The polycondensation system is delivered to the prepolymer melt pipeline.

[0059] (4) Melt the polybutylene succinate with an intrinsic viscosity of 1.5dL / g and the lanthanum acetate transesterification catalyst through a screw extruder to form a mixed melt of polybutylene succinate, polybutylene succinate The acid butylene glycol ester mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com