Method for recycling steel ladle casting residual steel and casting residual slag

A casting slag and casting slag technology, which is applied in the manufacture of converters, etc., can solve the problems that casting slag and cast steel can not be effectively utilized, and achieve the effects of reducing lime consumption, increasing usage, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

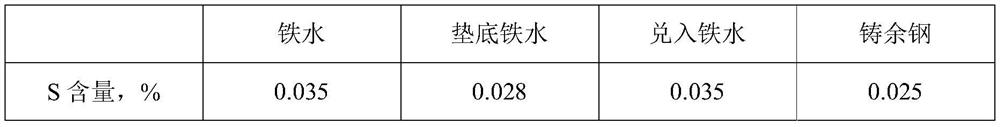

[0044] In this example, the tapping temperature is 1640°C, the cast steel temperature is 1550°C, the scrap steel temperature is 25°C, the ore temperature is 25°C, and the molten iron temperature is 1250°C. Therefore, the cooling energy of each component is shown in Table 2. , where the cooling energy refers to the ratio of the heat absorbed by the material to the scrap steel.

[0045] The starting temperature, tapping temperature, heat absorption and cooling energy of each component in Table 2

[0046] Material Cast steel molten iron ore scrap steel start temperature 1550 1250 25 25 Physical heat, kJ.kg -1

1342.53 1145.44 0 -1417.86 Element oxidation heat release, kJ.kg -1

986.47 Decomposition heat, kJ.kg -1

-4323.8 Heat energy, kJ.kg -1

1342.53 2131.91 -4323.8 -1417.86

[0047] Note: "+" means converter heat income, "-" means converter heat expenditure.

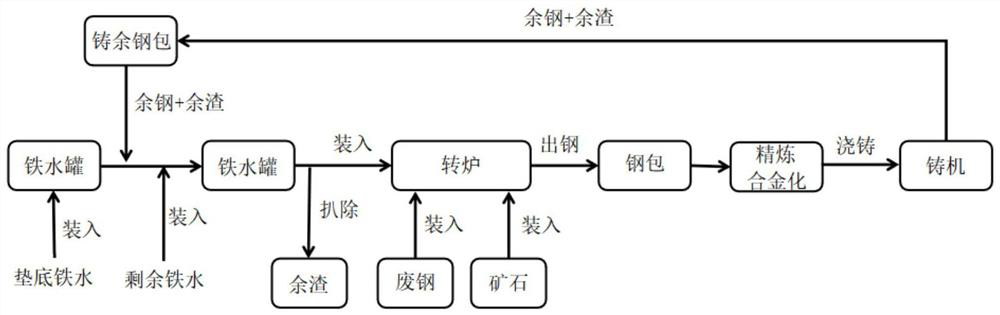

[0048] Such as figure 1 As show...

Embodiment 2

[0070] This embodiment provides a method for recycling ladle cast steel and cast slag, which is basically the same as that of Example 1, the difference being that the cast steel is used to replace scrap steel, since the scrap steel contains 8%- About 9% impurities, use 1 ton of cast steel, correspondingly reduce 1.10 to 1.15 tons of scrap steel. Since every 1 ton of excess cast steel is increased, 1.10t of scrap steel loading can be reduced correspondingly, and the corresponding heat can increase the ore amount by 0.67t (=(heat energy of cast excess steel-conversion ratio of cast excess steel*scrap heat energy) / ore Heat energy=(1342.53-(-1417.86)*1.1) / 4323.8=0.67). Since other conditions are almost unchanged, the removal rate of P and S in the bottom molten iron by casting slag is basically the same as that of Example 1, and the difference mainly lies in the amount of steel tapped in each furnace.

[0071] The charging method adopted in this embodiment is: total charging amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com