Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

118results about How to "Eliminate Uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

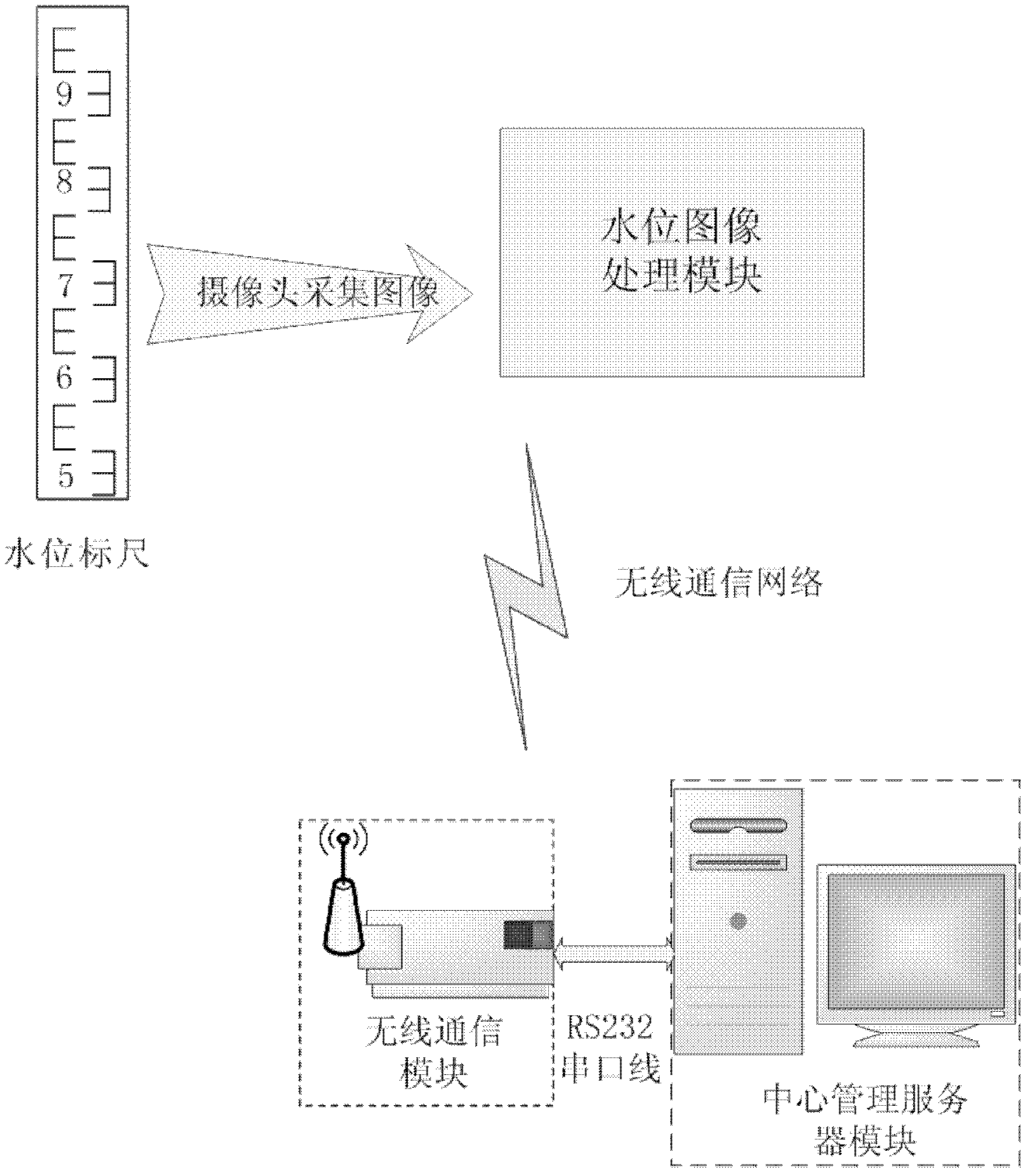

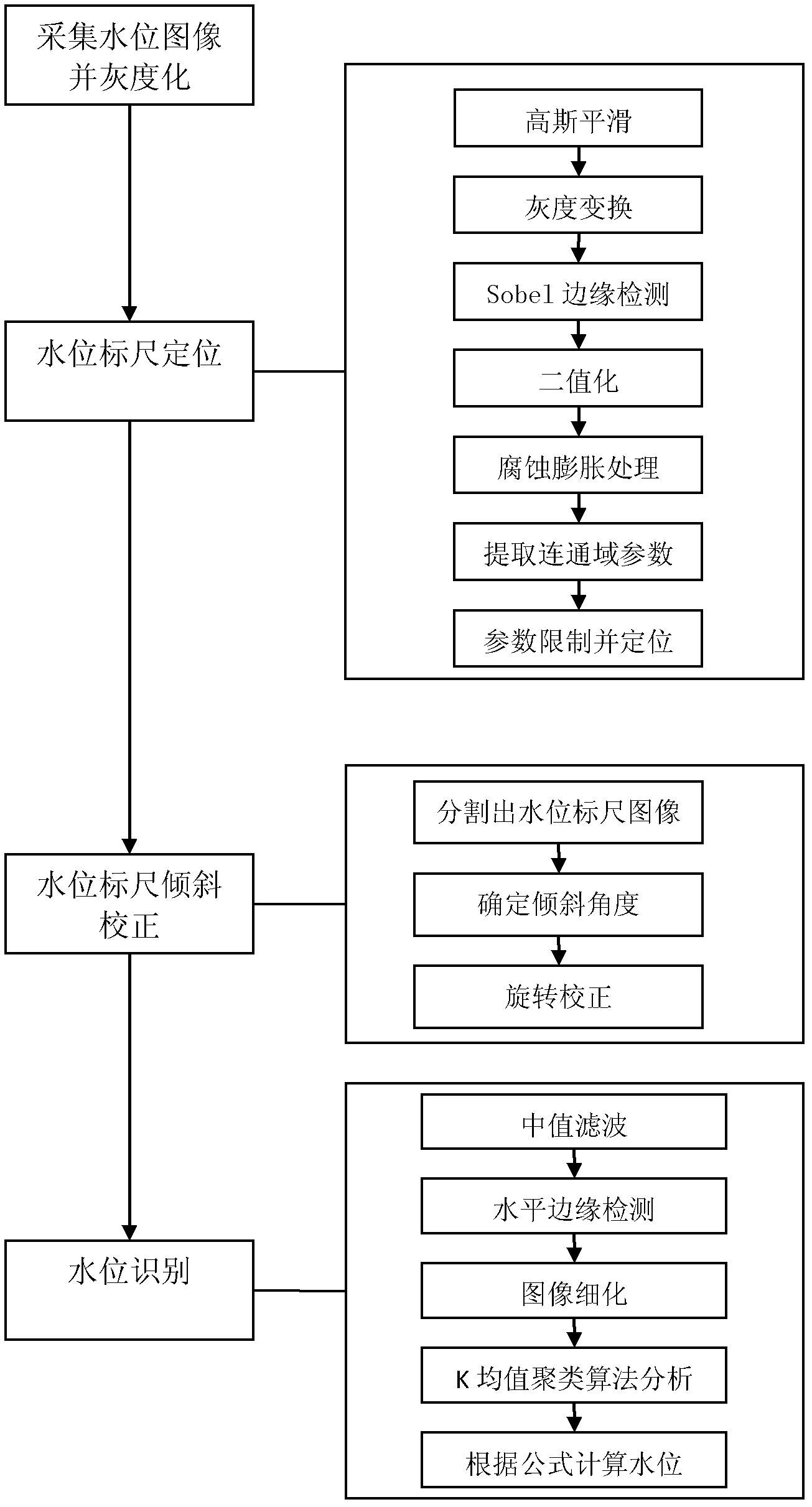

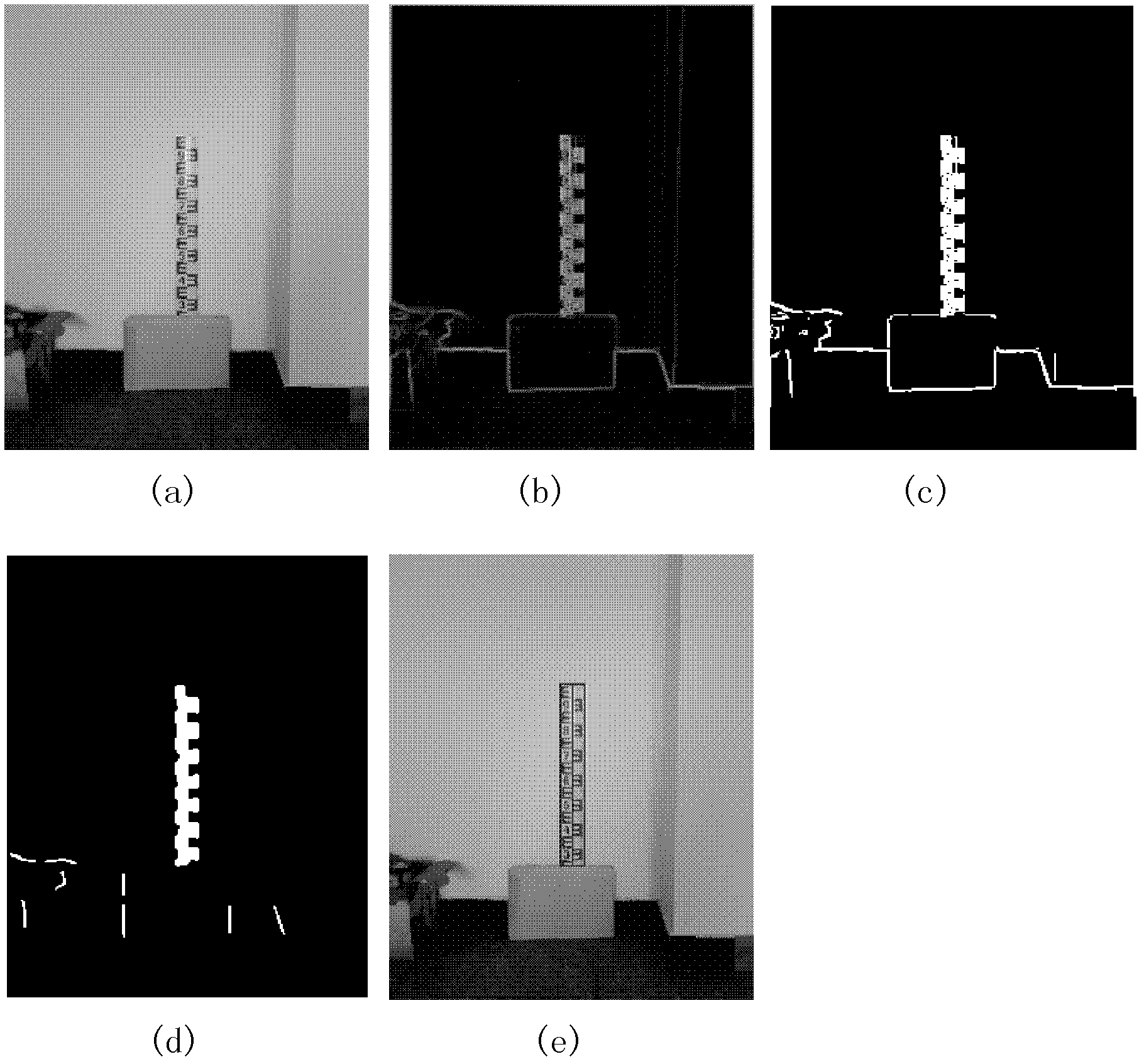

Water level monitoring system based on image processing and method

InactiveCN102494733AHigh speedHigh precisionImage enhancementLevel indicators by physical variable measurementImaging processingMonitoring system

The invention discloses a water level monitoring system based on image processing and a method, which mainly solve the problem that water level cannot be monitored automatically in the prior art. The water level monitoring system comprises a water level gauge, a water level image processing module, a wireless communication module and a central management server module. Working principle of the system is that: firstly the water level gauge is used for marking the water level, water level images marked by the water level gauge can be collected by a camera, the water level image processing module further performs automatic positioning, skew correcting and recognizing on the water level gauge in the water level images to obtain water level data and transmits the water level data to the wireless communication module through a wireless communication network, then the wireless communication module transmits the received water level data to the central management server module which stores the received water level data into a computer data base so as to draw current hydrograph in real time, when the current water level is higher than a preset water level, alarm information can be given out, and accordingly automatic monitoring of the water level can be achieved.

Owner:XIDIAN UNIV

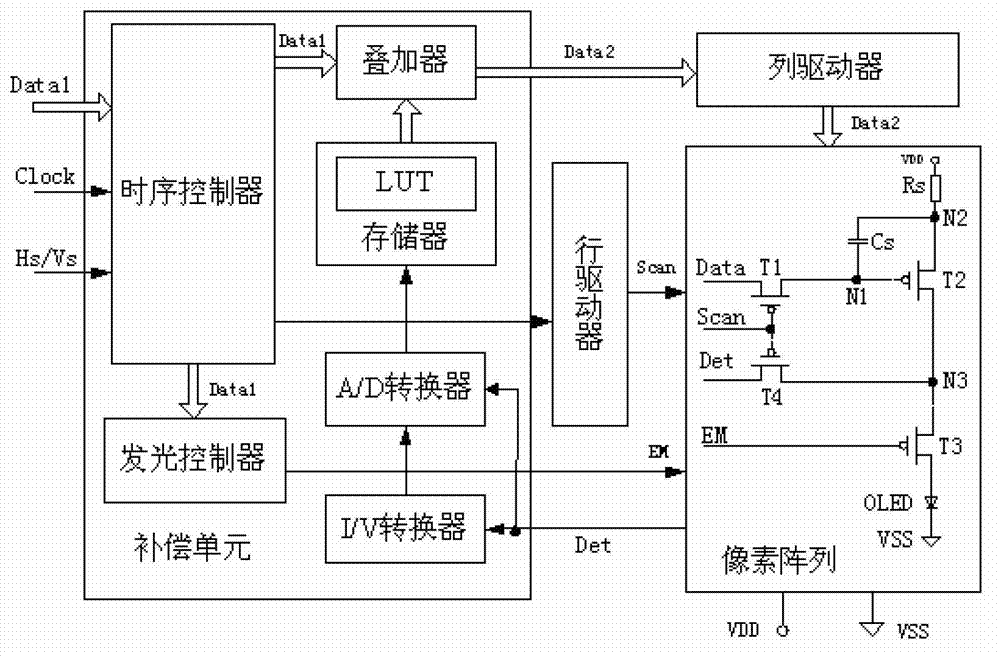

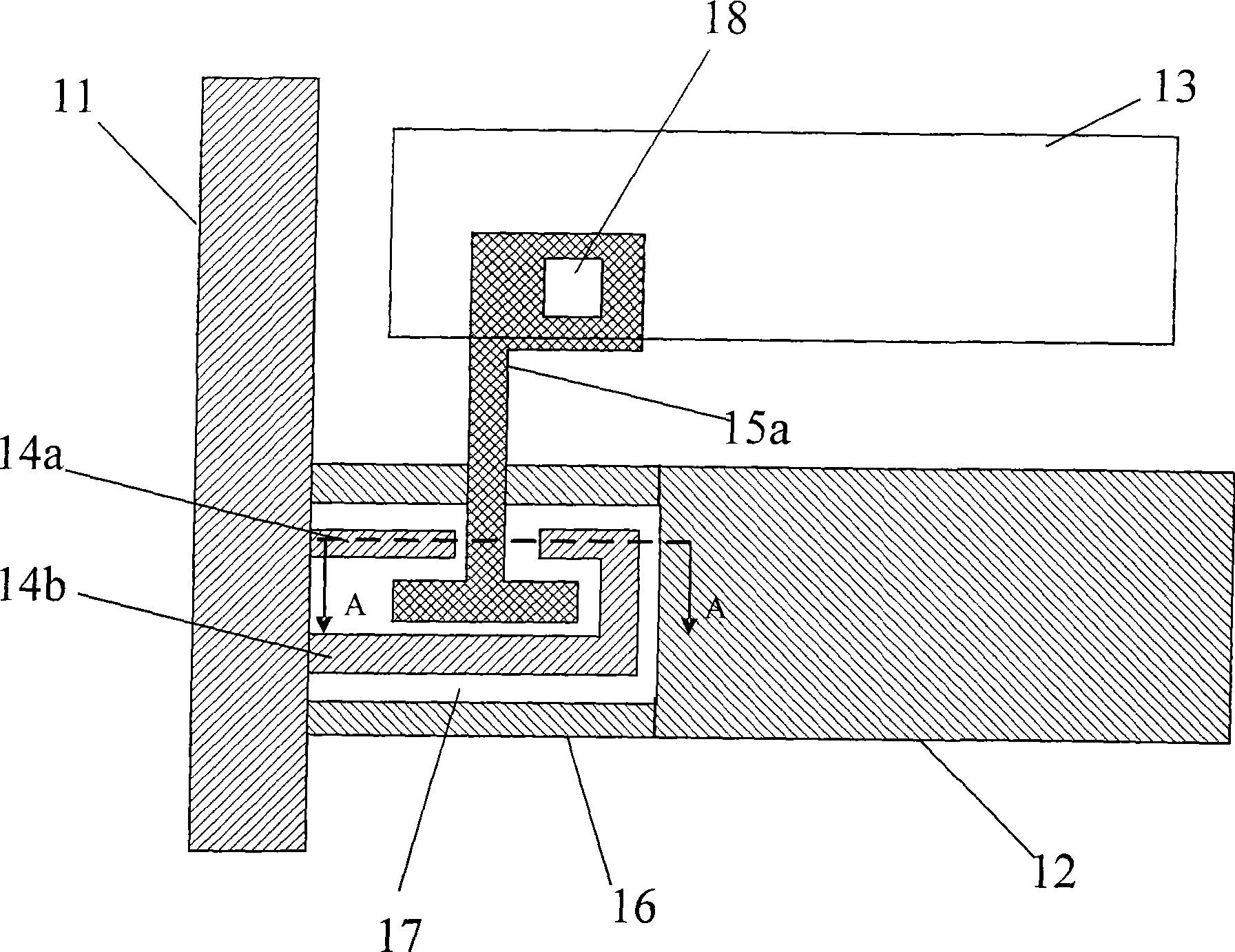

AMOLED (active matrix/organic light emitting diode) display and driving method of AMOLED display

InactiveCN102768821AEliminate UniformityEliminate image retention and other phenomenaStatic indicating devicesImage quality degradationEngineering

The invention relates to an AMOLED (active matrix / organic light emitting diode) display and a driving method of the AMOLED display. The AMOLED display is provided with a compensation unit as well as a row driver and a column driver which are connected with a pixel array, wherein the compensation unit is provided with an overlaying device connected with a time sequence controller, the time sequence controller is also connected with the row driver, and the overlaying device is connected with a memory, an A / D (Analog to Digital) converter, a I / V converter and the column driver; each pixel unit of the pixel array comprises a first switch conducting element and a second switch conducting element, wherein the data conducting pins of the first switch conducting element are connected with the control pins of the column driver and a drive conducting element respectively; a capacitor is arranged between the input pin and the control pin of the drive conducting element; the input pins and the output pins of the second switch conducting element are connected with the output pins of the drive conducting element, the I / V converter and the A / D converter respectively. According to the AMOLED display and the driving method, a plurality of factors causing the image quality degradation can be compensated, the image display quality of the AMOLED display is improved, and the AMOLED display is simple in circuit structure.

Owner:SICHUAN CCO DISPLAY TECH

Two-dimensional blur polymer based ultrasonic image division method

InactiveCN1924926ACorrect convergence guaranteeCancel noiseImage enhancementCharacter and pattern recognitionDiffusionSonification

This invention relates to one two-dimension fuzzy poly spot noise filter and brightness compensation B type of hypersonic cutting method, which comprises the following steps: extending the image brightness information to the update two-dimension poly fuzzy type near the pixel zone based on image brightness information; leading each heter diffusion spot noise filter to the fuzzy poly aim function to provide near information and to strengthening spot robust property; leading two-dimension fuzzy poly aim function with brightness compensation factor based on the noisy on uneven hypothesis and using image aim and background even to strengthen uneven noise robust.

Owner:FUDAN UNIV

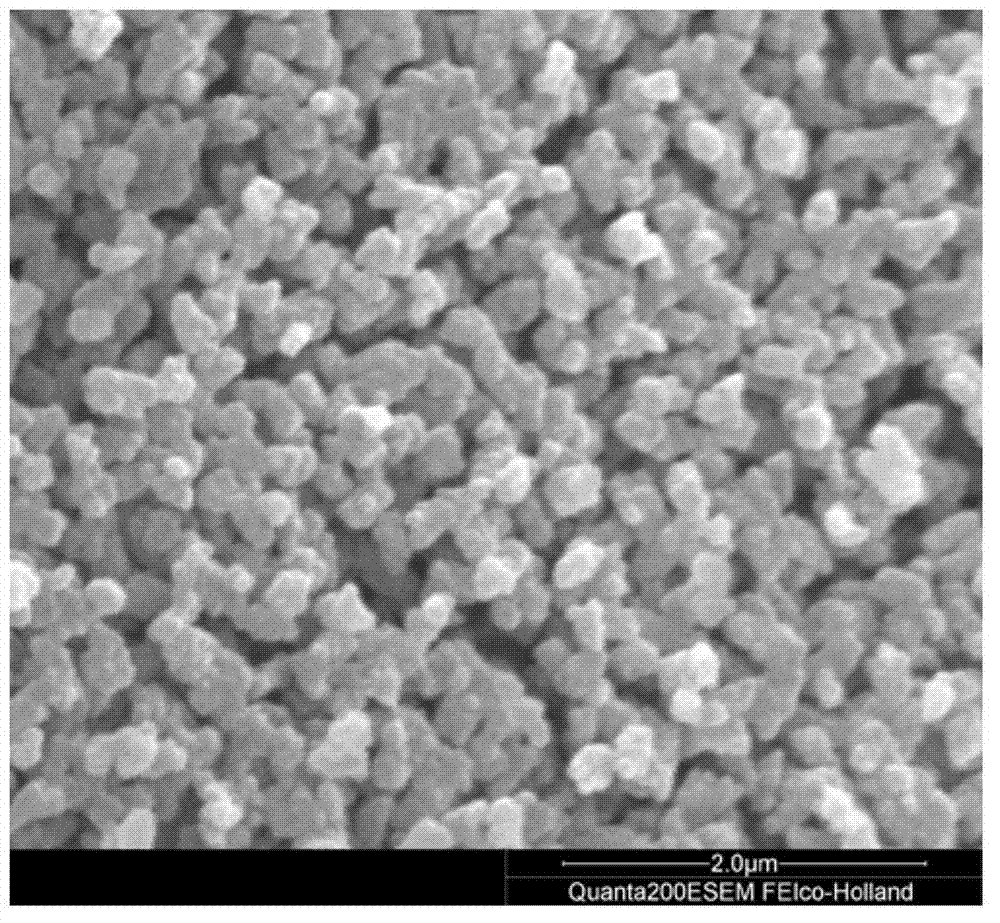

Anionic abrasive particles treated with positively charged polyelectrolytes for CMP

InactiveUS7306637B2Increase chanceReduce reunionPigmenting treatmentPolishing machinesPolyelectrolyteChemistry

The invention provides chemical-mechanical polishing systems, and methods of polishing a substrate using the polishing systems, comprising (a) an abrasive, (b) a liquid carrier, and (c) a positively charged polyelectrolyte with a molecular weight of about 15,000 or more, wherein the abrasive comprises particles that are electrostatically associated with the positively charged polyelectrolyte.

Owner:CMC MATERIALS INC

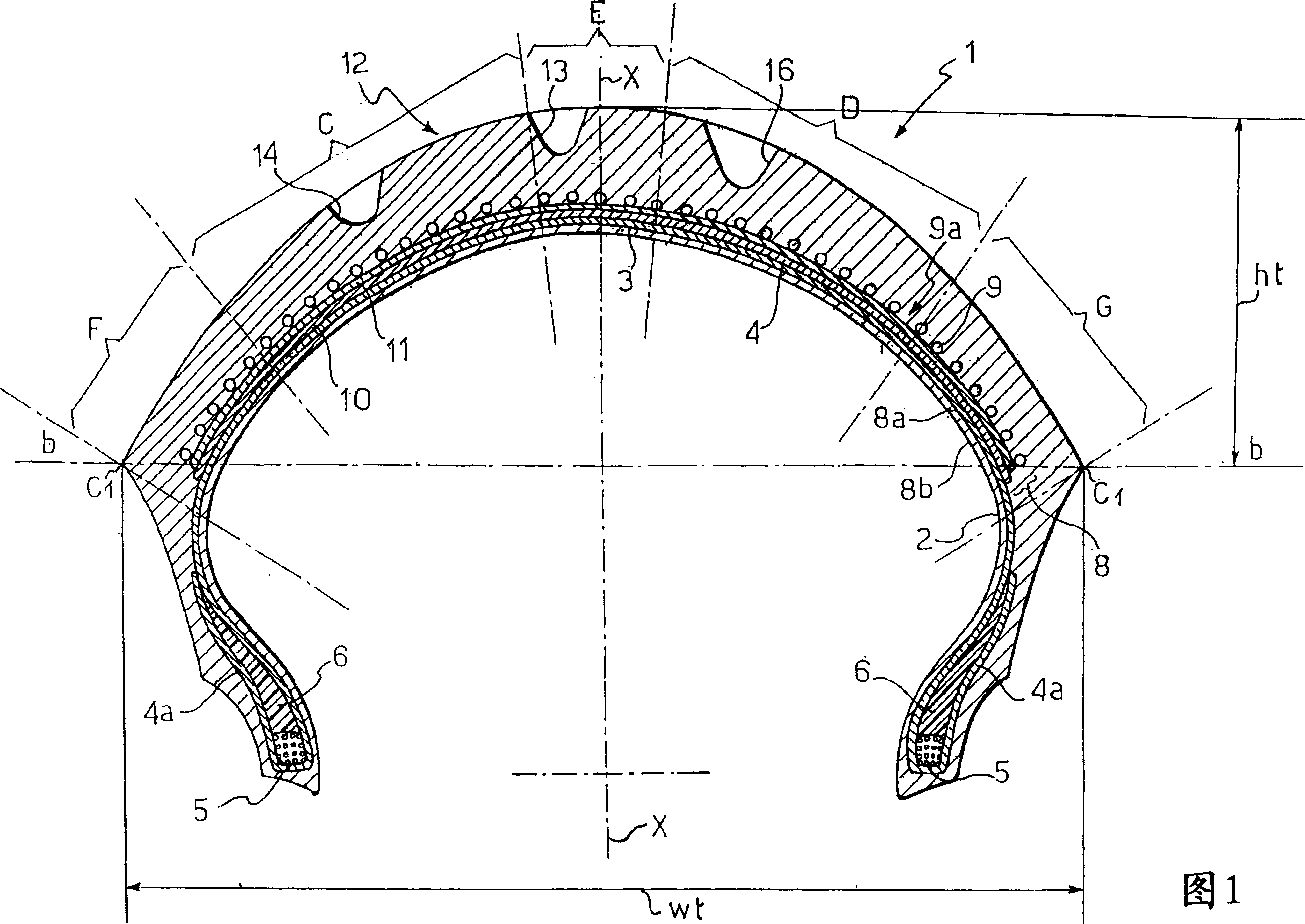

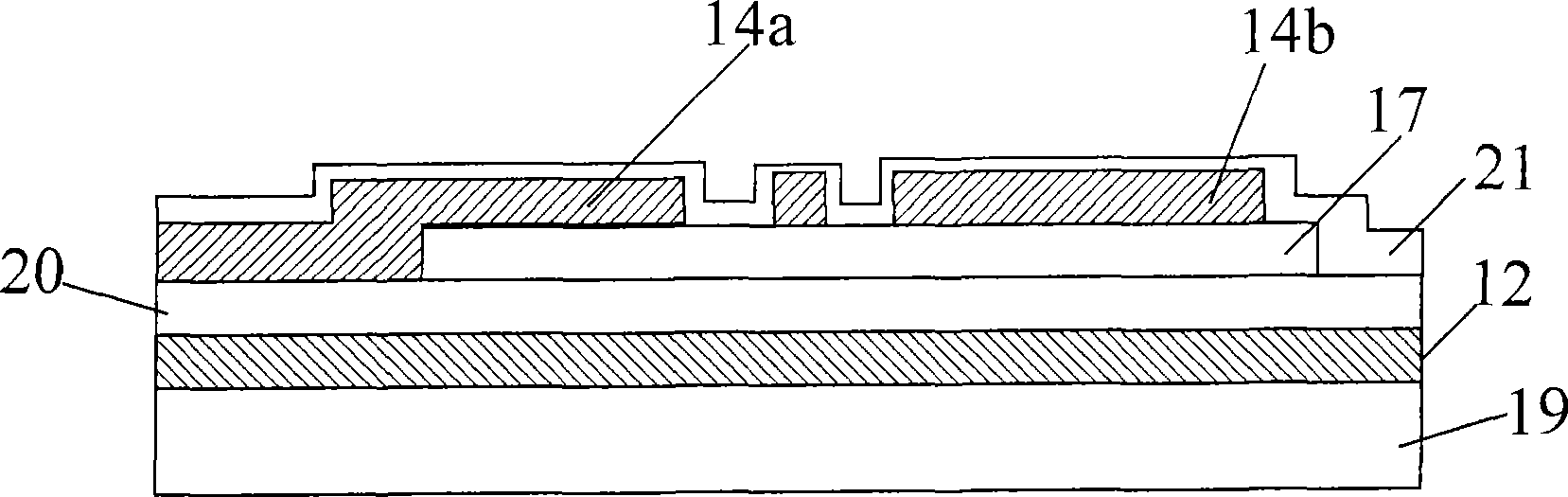

Front and rear pneumatic tires for motorcycles and method of improving the performance on both wet and dry ground of a motorcycle equipped with said pair

InactiveCN1802268AControl floating phenomenonImprove driving stabilityMotorcycle tyresTyre tread bands/patternsRoad surfaceTread

A pair of pneumatic tires (1, 101) comprises a front tire (1) and a rear tire (1 O 1) to be mounted, respectively, on a front wheel and on a rear wheel of a motorcycle, wherein the tread band (12) of the front tire (1) comprises: a) at least one circumferential groove (13) extending at the equatorial plane (X X) of the front tire (1) within a central zone (E) extending astride the equatorial plane (X-X); b) a plurality of transversal grooves (14) having an axially inner (14a) end lying within the central zone (E) of the tread band (12) and alternately extending from said central zone (E) towards axially opposite shoulder zones (F, G) of the tread band external to the central zone (E), at least some of the transversal grooves (14) being connected to the circumferential groove (13); and wherein the tread band (12) of the rear tire (101) comprises an area defining a substantially null sea / land ratio within a central zone (E) of the tread band (12) extending astride the equatorial plane (X-X) of the rear tire (101) and having a width of from about 5% to about 30% of the axial development of the tread band (12). Such a pair of pneumatic tires (1, 101) advantageously allows to improve both the performance on dry and wet ground and the kilometric yield and traction characteristics of the tires.

Owner:PIRELLI TYRE SPA

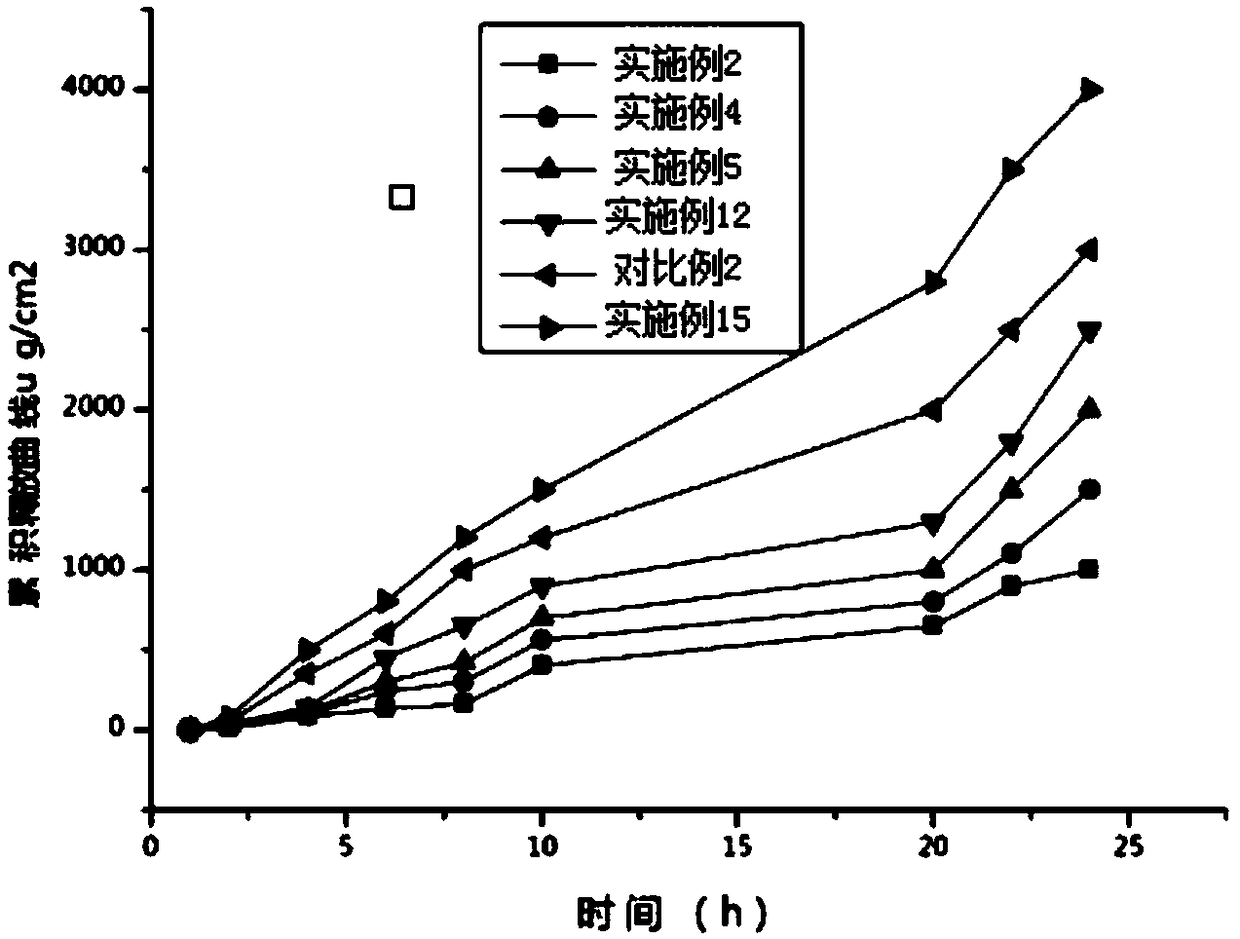

Whitening liquid crystal composition as well as preparation method and application thereof

ActiveCN108451837AImprove stabilityGood whitening effectCosmetic preparationsToilet preparationsHigh concentrationCrystallography

The invention relates to the field of cosmetics and provides a whitening liquid crystal composition. The whitening liquid crystal composition is prepared from whitening active ingredients and liquid crystal carriers, wherein the whitening active ingredients are prepared from at least two of an active ingredient for promoting exfoliation, a tyrosinase inhibitor, an active ingredient for inhibitingmelanosome migration, an antioxidant active ingredient, an anti-inflammation active ingredient and an anti-glycation active ingredient; the liquid crystal carriers are prepared from the following rawmaterials: a liquid crystal emulsifying agent, a co-emulsifier and an emulsification thickening agent; the whitening liquid crystal composition is also prepared from liquid-state lipide for dissolvingthe whitening active ingredients and the liquid carrier raw materials as well as water. According to the whitening liquid crystal composition, through compounding of different whitening mechanisms and load of the liquid crystal carriers, an obvious synergetic effect is achieved, the stability and the whitening effect of the whitening liquid crystal composition can be obviously improved, and meanwhile, the problem of skin irritation easily caused by the load of the whitening active ingredients with high concentration is solved.

Owner:WUHAN BEST CARRIER NANO TECH

Manufacturing method for colored fluorine-free imitation ceramic glaze

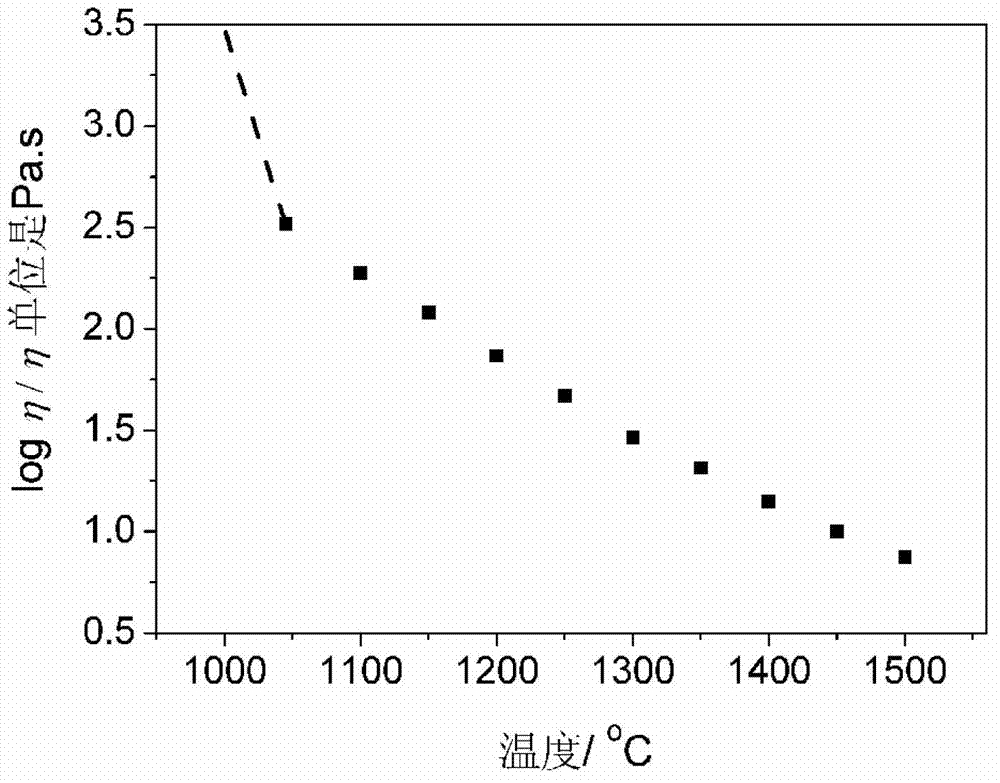

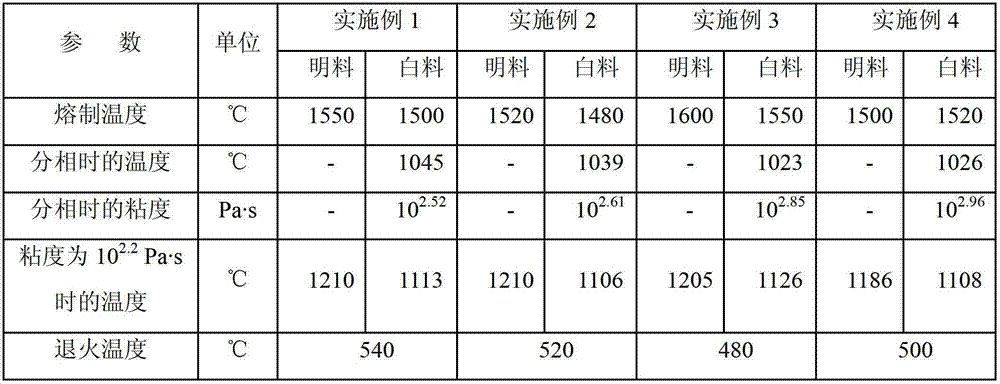

ActiveCN102786202AReduce cooling rateSlow coolingGlass blowing apparatusDevitrificationPhase splitting

A manufacturing method for colored fluorine-free imitation ceramic glaze belongs to the field of advanced glass materials. According to the manufacturing method, a melt jacking blowing method is adopted, and the five-layer colored fluorine-free imitation ceramic glaze is prepared by dip blowing according to the sequence of bright material, white material, bright material, pigment and bright material. The manufacturing method overcomes the defect that the traditional imitation ceramic glass production greatly depends on the initial temperature of glass melt phase-splitting or devitrification and the cooling speed during forming; and meanwhile, the manufacturing method realizes very good opacifying effect under the condition of lower phosphorous content, and the common defects of uneven opacifying degree, stripe and the like are not liable to occur.

Owner:淄博市宝泉轻工制品有限公司

Production method of aluminum alloy sheet

The invention provides a production method of an aluminum alloy sheet. The production method comprises the following steps in sequence: homogenizing and thermally treating aluminum alloy ingot with mass percentage of magnesium of 4.0 to 4.5%; heating; carrying out hot rolling while reserving deflection; cooling to obtain an intermediate aluminum alloy sheet; and rolling the intermediate aluminum alloy sheet to obtain the aluminum alloy sheet. Compared with 5083 alloy in the prior art, the aluminum alloy sheet produced by the production method provided by the invention has the advantages that firstly, the content of the magnesium element is controlled to 4.0 to 4.5%, thus the possibility that the second phase Beta is separated along the grain boundary and subgrain boundary can be reduced, and the corrosion sensitivity of the alloy can be reduced; secondly, the mechanical property and the corrosion resistance of the aluminum alloy sheet are improved under the coordination of the rolling deformation and twice-rolling technology; and thirdly, the internal organization of the alloy can be improved through the homogenizing and thermal treatment, the phenomenon that the structure and content of the aluminum alloy ingot cannot meet the uniformity can be eliminated, and the plastic deformation capacity of the alloy is improved.

Owner:SOUTHWEST ALUMINUM GRP

Device for testing slump of concrete mixture and use method thereof

The invention discloses a device for testing slump of a concrete mixture. The device comprises a lower electrical push rod mechanism, a middle electrical push rod mechanism, an upper electrical push rod mechanism, a slump cylinder and a spiral movement mechanism, wherein the lower electrical push rod mechanism comprises a lower base, the lower base is arranged on ground, and a lower electrical push rod is arranged on the lower base; the middle electrical push rod mechanism comprises a middle base, and a middle electrical push rod is arranged on the middle base; an extending rod of the middle electrical push rod is upwards connected with an upper base, and the slump cylinder is connected with the upper base; the upper electrical push rod is positioned just above the slump cylinder, and an extending rod of the upper electrical push rod is vertically and downwards connected with the spiral movement mechanism; the spiral movement mechanism is connected with a vertical vibration bar. The invention also discloses a use method of the device for testing the slump of the concrete mixture. The device has the advantage that the artificial vibration is not needed, so that the error due to theartificial vibration is avoided, and the stability and accuracy in testing are improved.

Owner:HENAN VOCATIONAL COLLEGE OF WATER CONSERVANCY ANDENVIRONMENT

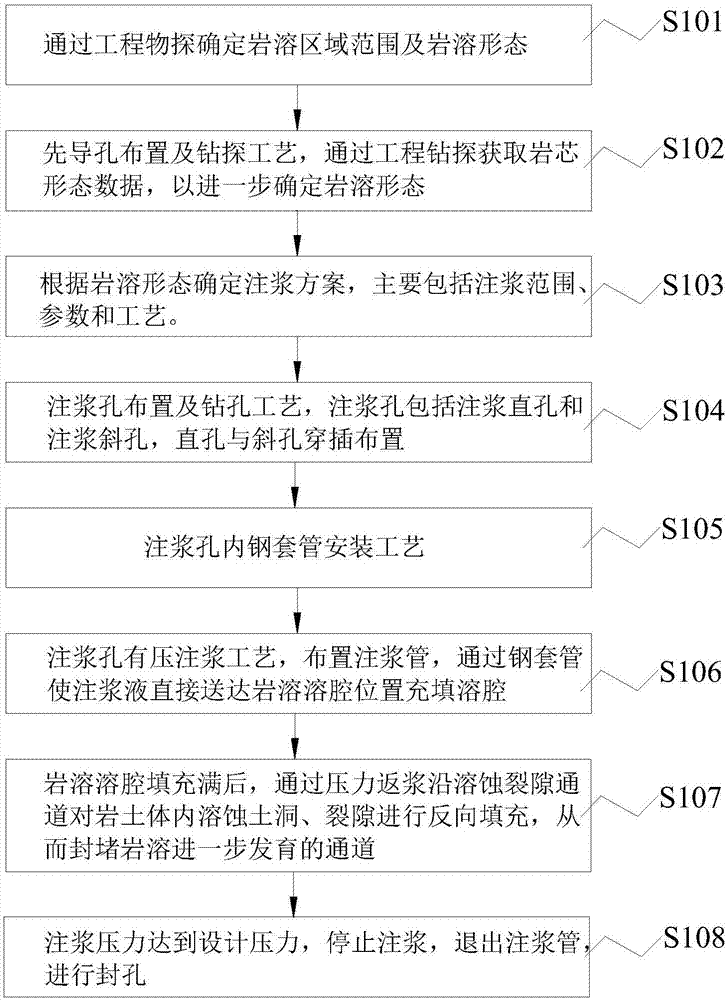

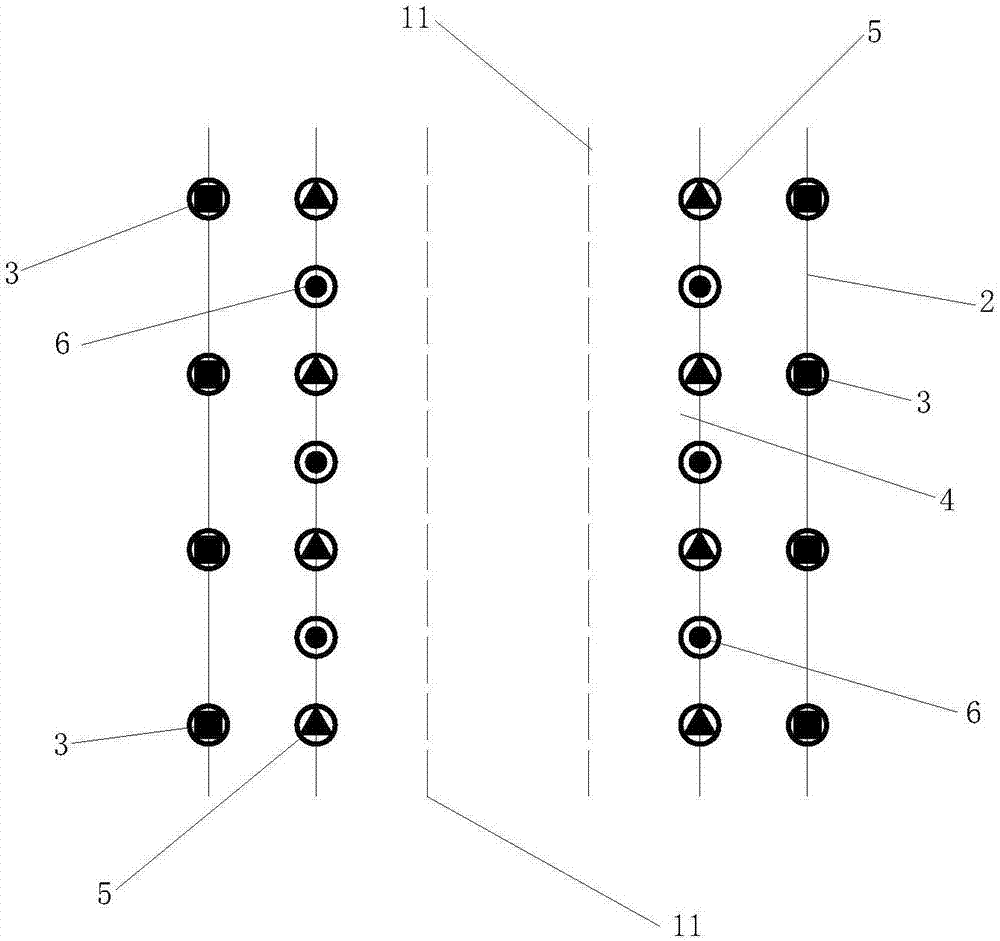

Pressurized returned grout reinforced covered karst embankment grouting method

PendingCN107151956AAvoid developmentSecure the foundationRoadwaysSoil preservationGeomorphologyPilot hole

The invention discloses a pressurized returned grout reinforced covered karst embankment grouting method. The method includes steps: determining a karst area range, depth and karst morphology through engineering geophysical exploration; determining a pilot hole arrangement range, spacing and depth according to the determined karst area range, depth and karst morphology; carrying on a hole forming process on each pilot hole according to reconnaissance standards, and acquiring stratum rock core morphological data in a pilot hole implementation process; determining a grouting scheme according to the karst area range, depth and karst morphology determined according to the acquired rock core morphological data. Aiming at existing railway lines with roadbeds in covered karst development areas, the pressurized returned grout reinforced covered karst embankment grouting method is provided for solving the problem of geological disasters such as roadbed differential settlement, instability and collapse caused by karst dissolution to provide a safety environment for normal operation of the existing railway lines.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

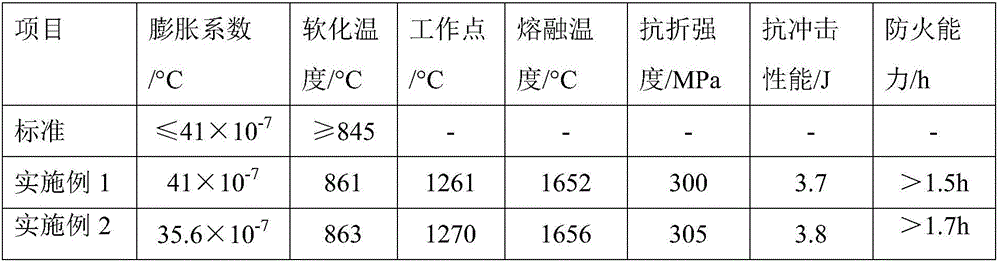

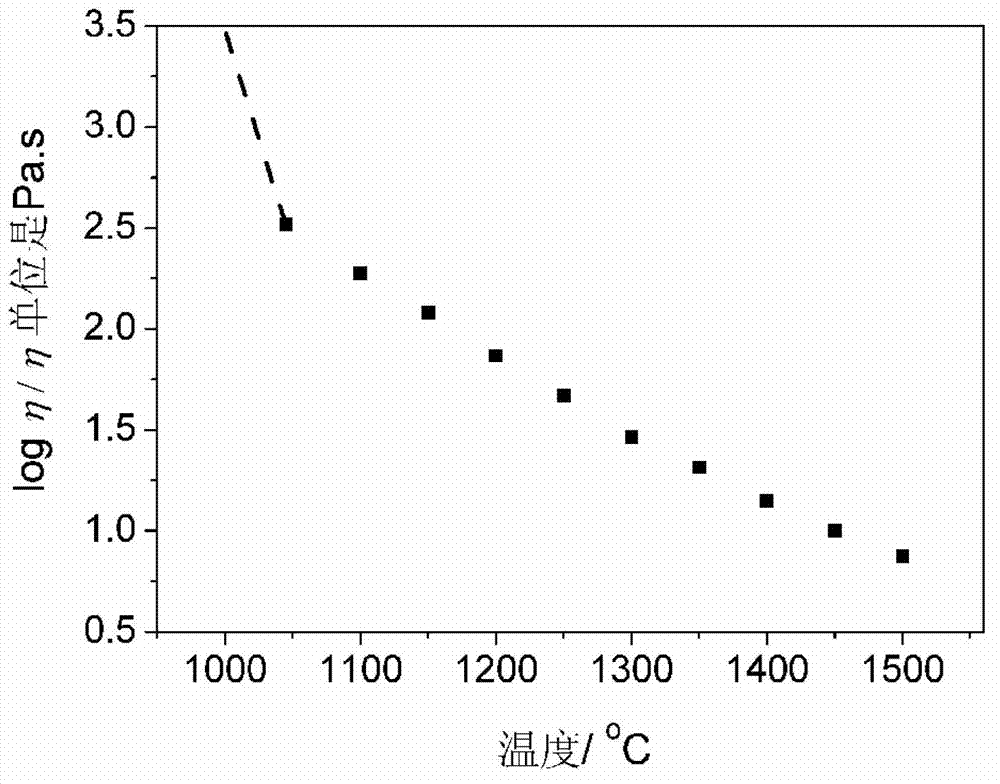

Heat-resistant borosilicate flat glass and preparation method thereof

ActiveCN106587604AEffective control of air bubblesEffective control of striaeFlat glassFire protection

The invention provides heat-resistant borosilicate flat glass and belongs to the technical field of fireproof glass. The heat-resistant borosilicate flat glass is prepared from, by weight, 78.1-82% of SiO2, 1-5% of Al2O3, 9-14% of B2O3, 3-6% of Na2O, 1-5% of CaO, 0.5-2% of K2O, 0.1-3% of ZrO2 and 0.01-2% of GeO2, wherein the total content of SiO2 and B2O3 accounts for 87.1-92% of the total content of all the materials, and the weight ratio of SiO2 to B2O3 is 5.5 to 8.6. The invention further provides a preparation method of the heat-resistant borosilicate flat glass; compared with current borosilicate flat glass in the market, the heat-resistant borosilicate flat glass has a higher glass softening point and a lower linear expansion coefficient, at the same time, the melting temperature and the molding temperature are relatively low; the glass is easy to manufacture and can serve as the fireproof glass applied in the fire protection field after being tempered.

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE

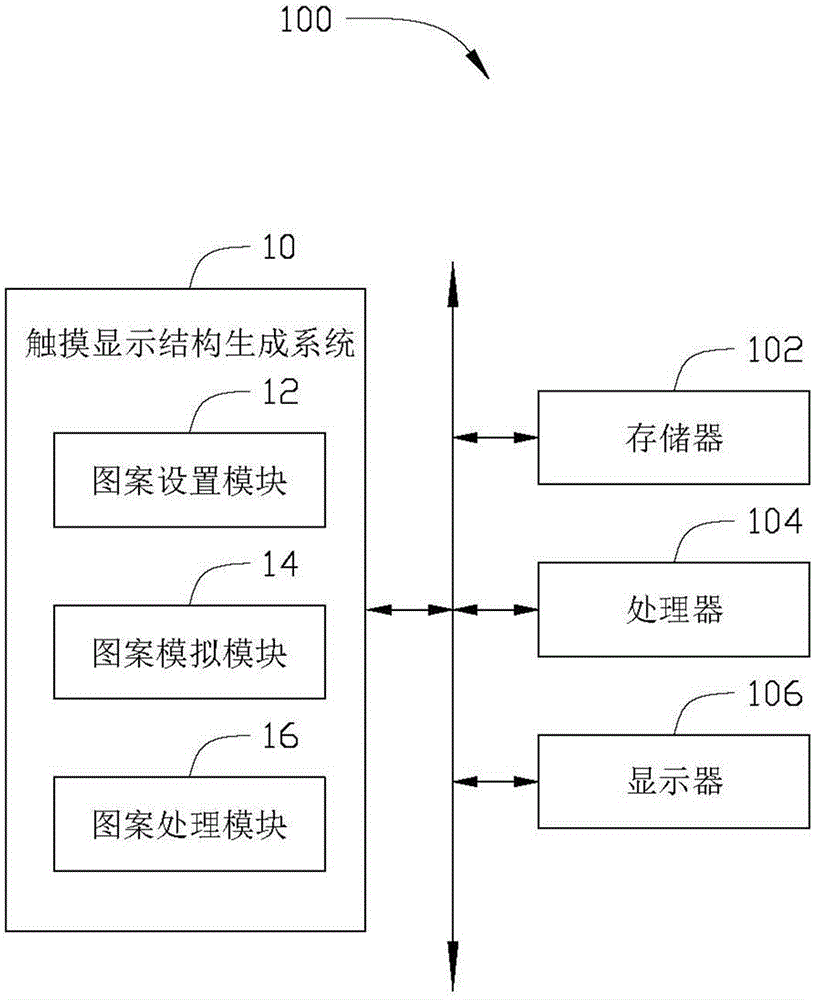

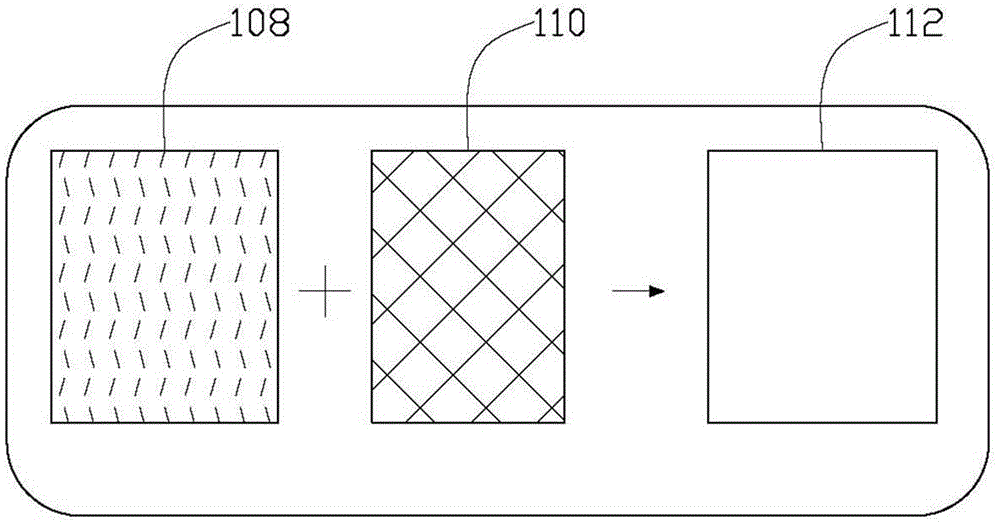

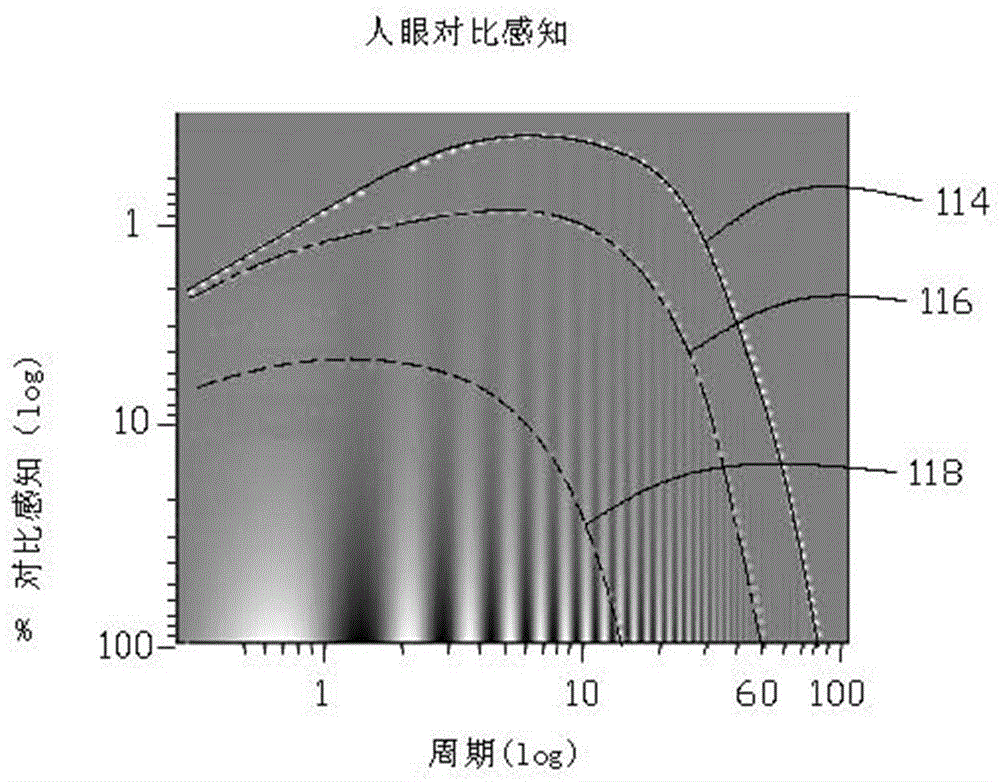

System and method for generating touch display structure

InactiveCN104656975AEliminate moiréEliminate UniformityInput/output processes for data processingImaging processingTouch Senses

The invention discloses a system and a method for generating a touch display structure used for a display of a touch screen to be laminated, so as to generate a touch sensing structure matched with the display. The system comprises a pattern setting module, an image simulation module and an image processing module, wherein the pattern setting module is used for setting parameters of a metal grid pattern of the touch sensing structure, the image simulation module is used for simulating an overlapped image between a display device of the touch screen to be laminated with the metal grid pattern, and the image processing module is used for judging whether the asymmetry of moire fringes or punctiform of the overlapped image is visible. When asymmetry of moire fringes or punctiform of the overlapped image is visible, the relevant parameters of the metal grid patterns are adjusted to obtain an optimal metal grid pattern when the asymmetry of moire fringes or punctiform of the overlapped image is invisible.

Owner:INTERFACE OPTOELECTRONICS SHENZHEN +1

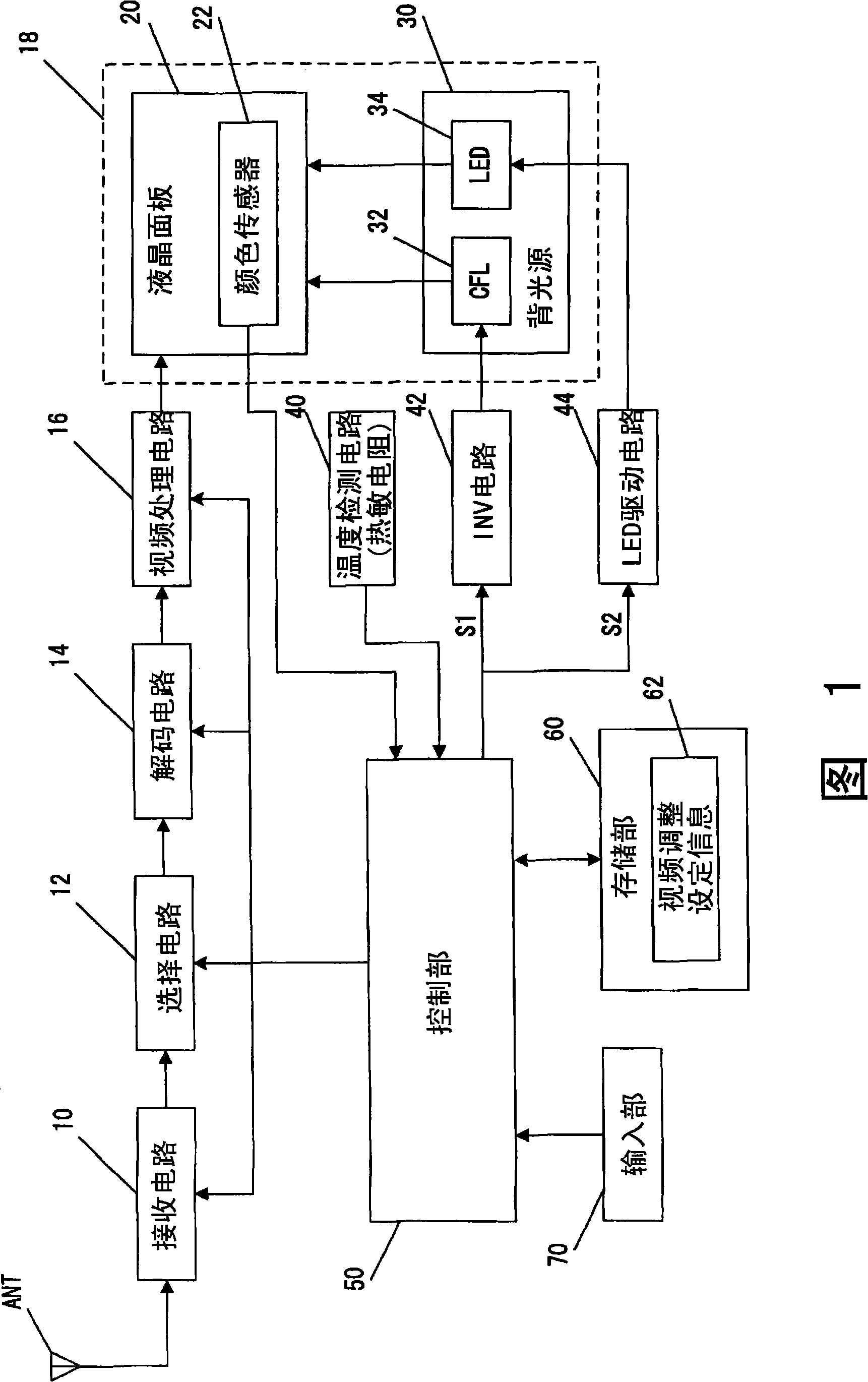

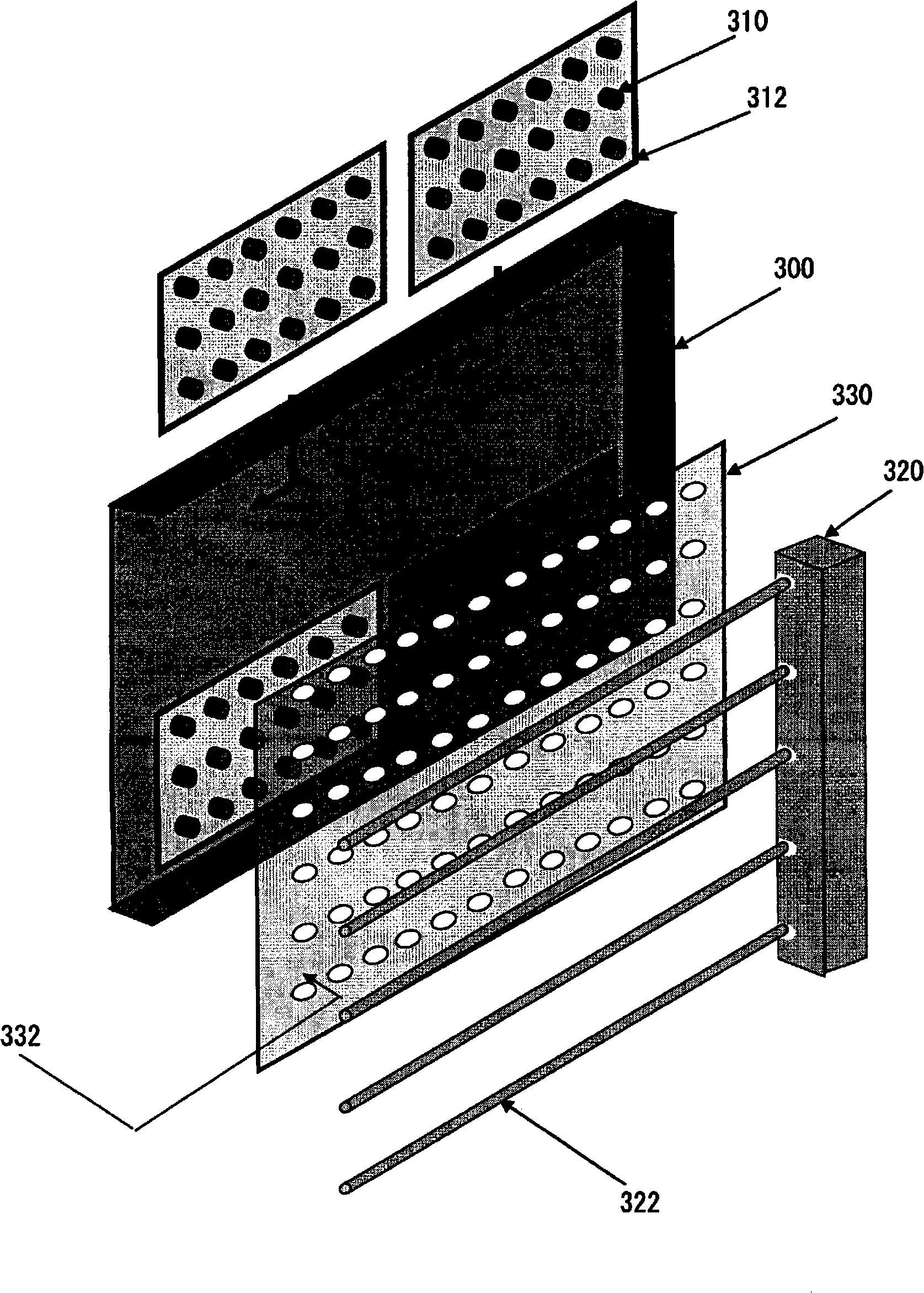

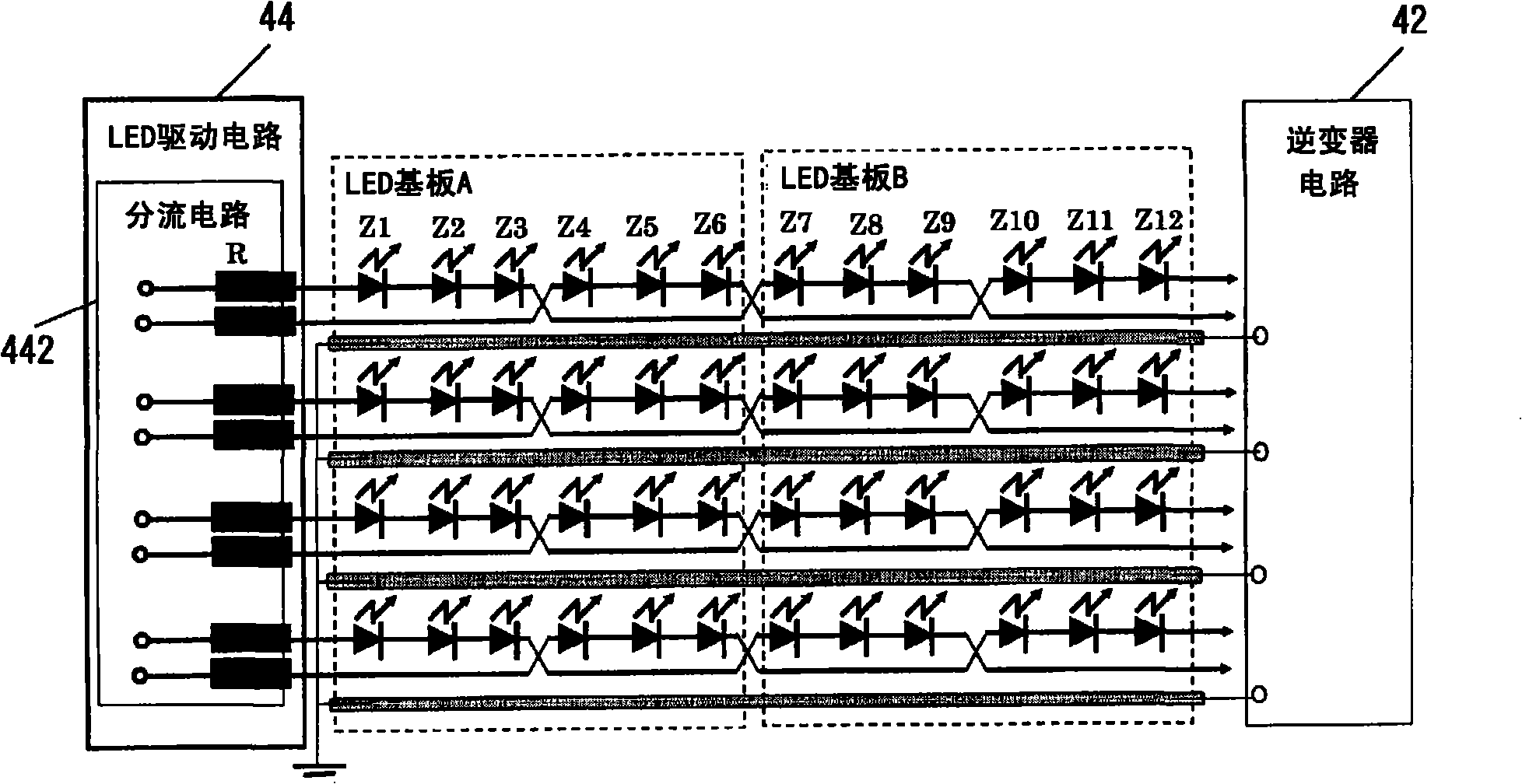

Backlight device and liquid crystal display device

InactiveCN101317035AEliminate UniformitySuppress uneven brightnessElectroluminescent light sourcesElectric lightingLiquid-crystal displayLed array

A substantially constant current is supplied from a shunt circuit to each line in order to control light emission of light emitting diodes. A predetermined number of light emitting diodes are arranged in series as a set. Sets of the light emitting diodes to be connected to a first line and the light emitting diodes to be connected to a second line are arranged in a line on the same straight line on a substrate. The substrates are connected adjacently in the row direction, so that the sets of the light emitting diodes to be connected to the first line and the light emitting diodes to be connected to the second line are alternately arranged. Thus, it is possible to provide a backlight device having a plurality of LED arrays capable of uniformly emitting light over the entire screen.

Owner:SHARP KK

Colored fluoride-free ceramic imitation azure stone

ActiveCN102806727AReduce cooling rateIncrease the degree of phase separationGlass/slag layered productsSecondary layerColourant

The invention discloses a colored fluoride-free ceramic imitation azure stone, and belongs to the field of new materials of glass. The colored fluoride-free ceramic imitation azure stone is characterized by having a laminated structure and is divided into fiver layers from inside to outside, wherein a first layer is a first bright material layer; a second layer is a white material layer; a third layer is a second bright material layer; a fourth layer is a pigment layer; a fifth layer is a third bright material layer; the thickness of the white material layer is 0.7 to 0.95mm; and the thickness of the pigment layer is 0.6 to 0.85mm. According to the ceramic imitation azure stone, the defect of high dependence degree of the conventional ceramic imitation azure stone on the starting temperature of a glass melt in the phase-splitting or crystallizing process and the cooling speed of the temperature melt in the forming process is overcome; and simultaneously, common defects of non-uniform opacification degrees, stripes and the like are overcome through the ceramic imitation azure stone.

Owner:淄博市宝泉轻工制品有限公司

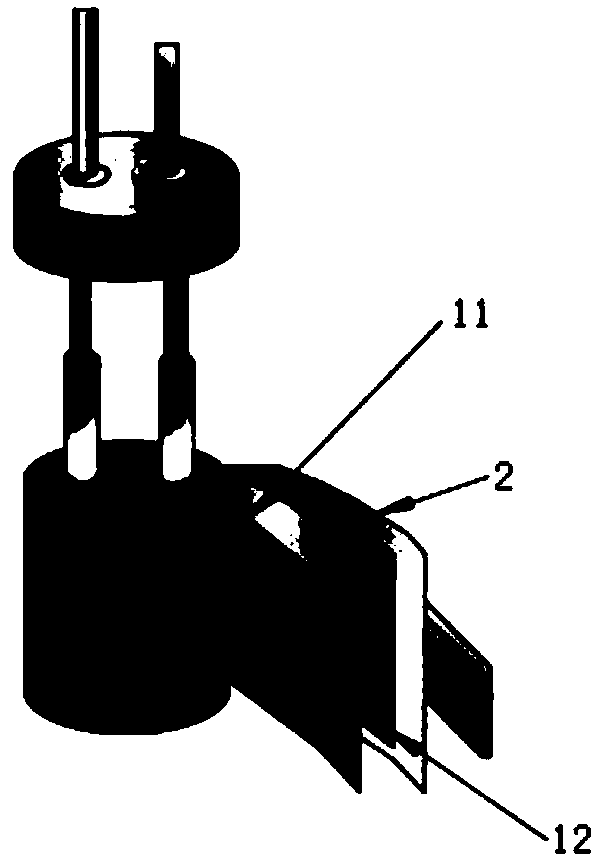

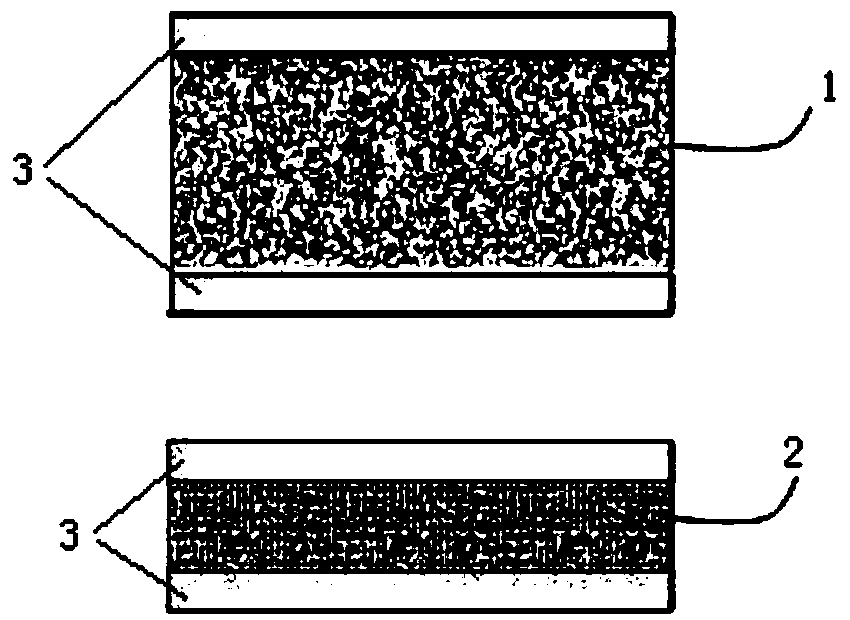

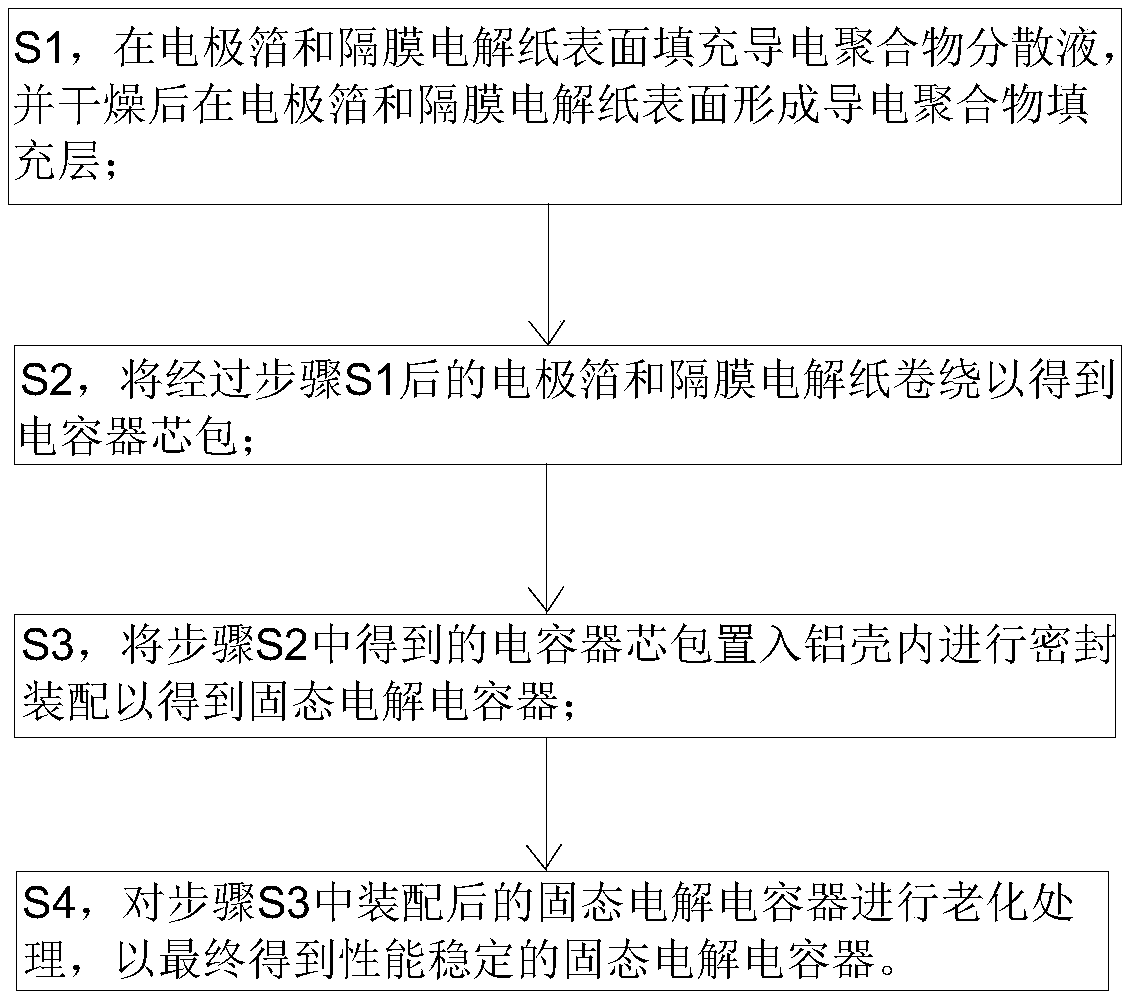

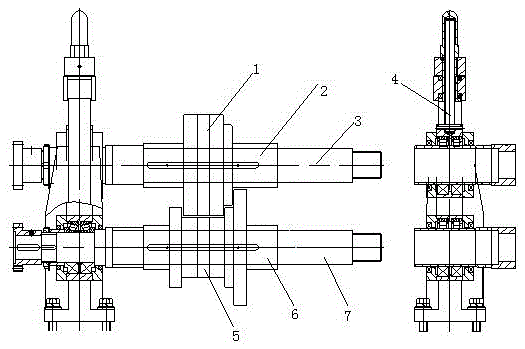

Solid electrolytic capacitor and preparation method thereof

PendingCN109659139AHigh Enabling PropertiesSave operating timeSolid electrolytic capacitorsCapacitor electrolytes/absorbentsCapacitanceState of art

The invention relates to the technical field of capacitors, and specifically relates to a solid electrolytic capacitor and a preparation method thereof. The solid electrolytic capacitor is characterized in that the surface of an electrode foil and the surface of a piece of diaphragm electrolytic paper are each filled with a conductive polymer filling layer, so that the electrode foil and the diaphragm electrolytic paper have high energizing properties; and the voltage of the solid aluminum electrolytic capacitor is effectively improved, and can reach 450 V and above. The preparation method ofthe solid electrolytic capacitor eliminates the impregnation process in the prior art, eliminates the impregnation unevenness or non-intensive impregnation caused by the impregnation process by filling or covering the surface of the electrode foil and the surface of the diaphragm electrolytic paper in all directions, and can prepare a solid electrolytic capacitors with the voltage of 450V and above. As the capacitor core package does not need an impregnation process in the preparation method, and does not need a chemical conversion pretreatment process of the core package, the preparation method of the solid electrolytic capacitor has greater advantages in production efficiency and environmental protection and energy saving aspects.

Owner:SHENZHEN JIANGHAO ELECTRON

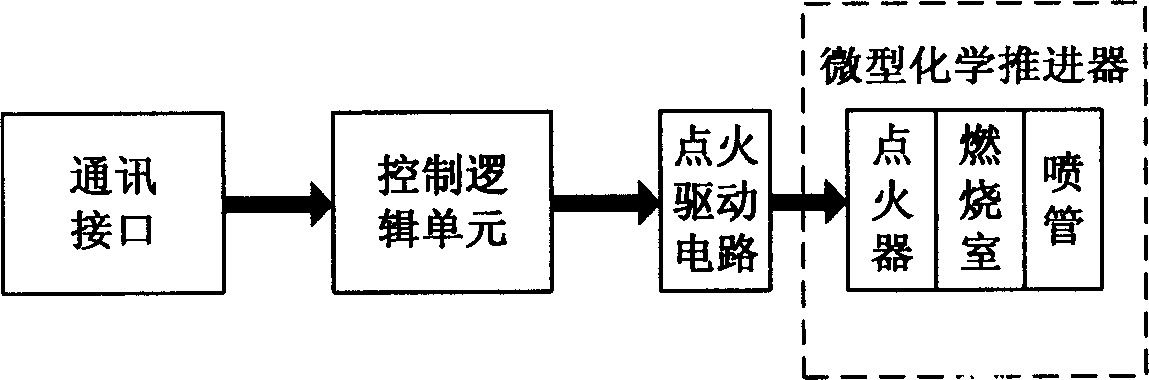

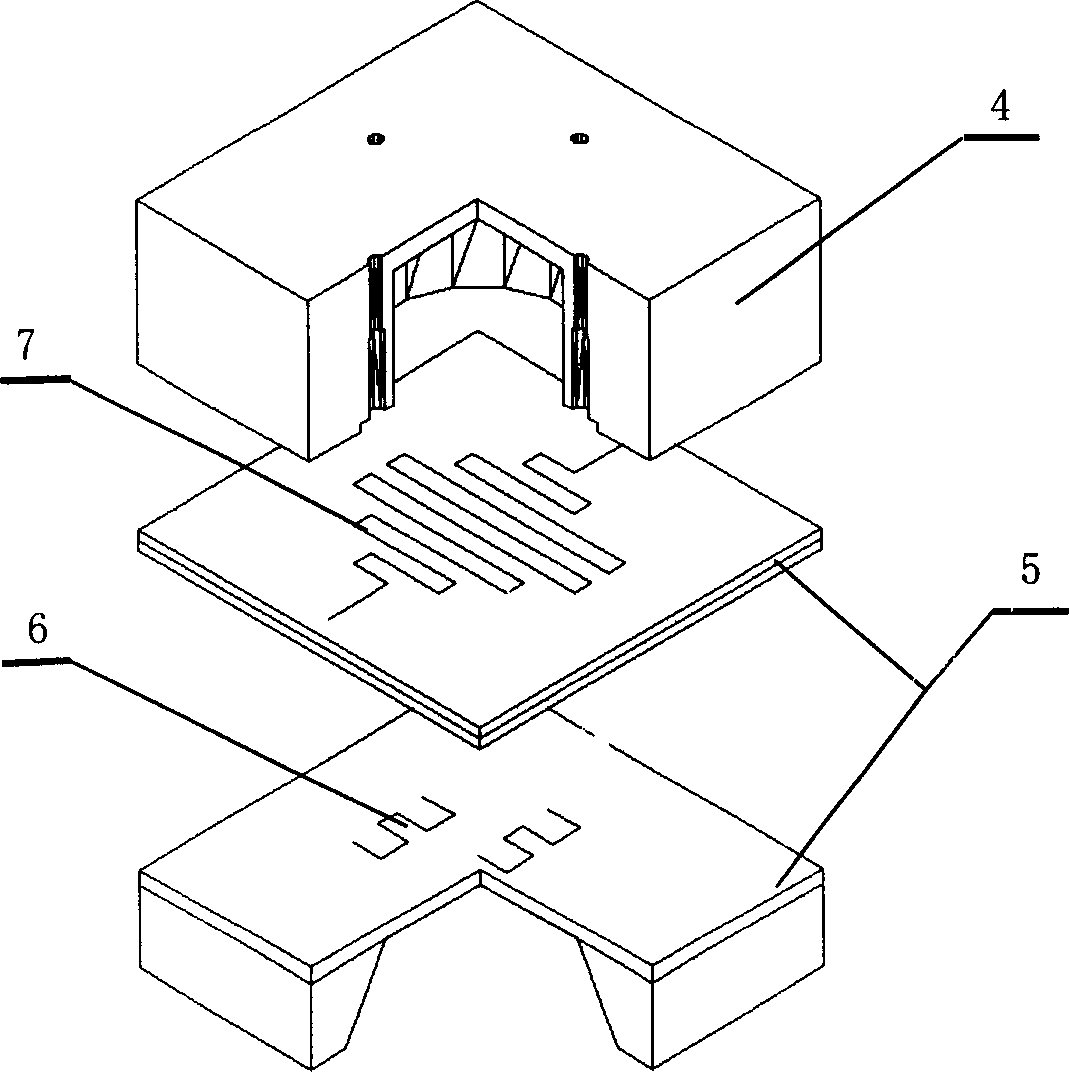

Minisize chemical propeller with pressure sensor

InactiveCN1603599AShort ignition delayLow ignition powerCosmonautic power supply systemsRocket engine plantsPropellerCombustion chamber

The belt pressure transmitter miniature chemistry propeller, belongs to the micro advancement technology and the MEMS area of technology. In order to solve the existing MEMS chemistry propeller to be unable the reaction control question, this invention discloses a kind of belt pressure transmitter miniature chemistry propeller, he becomes by the upper formation silicon chip and the lower level silicon chip two parts of caking, and is a series of basic advancements unit periodic array; Each basic advancement unit upper formation partially integrated the combustion chamber, the bomb igniter cavity and the nozzle, the nozzle plate and the combustion chamber base initial point gunpowder cavity unites passes; Each basic advancement unit lower level partially integrated the pressure transmitter and the igniter, its base for in concave frustum structure, the crown for the pressure sensitive thin film, the pressure transmitter inlays in the pressure sensitive thin film, the igniter is located the pressure sensitive thin film the top.The invention causes in the combustion chamber to implement the pressure to survey into possibly, simultaneously has omitted the craft step which the combustion chamber and the nozzle healthily gathers, has avoided because healthily gathers causes aims at the error.

Owner:TSINGHUA UNIV

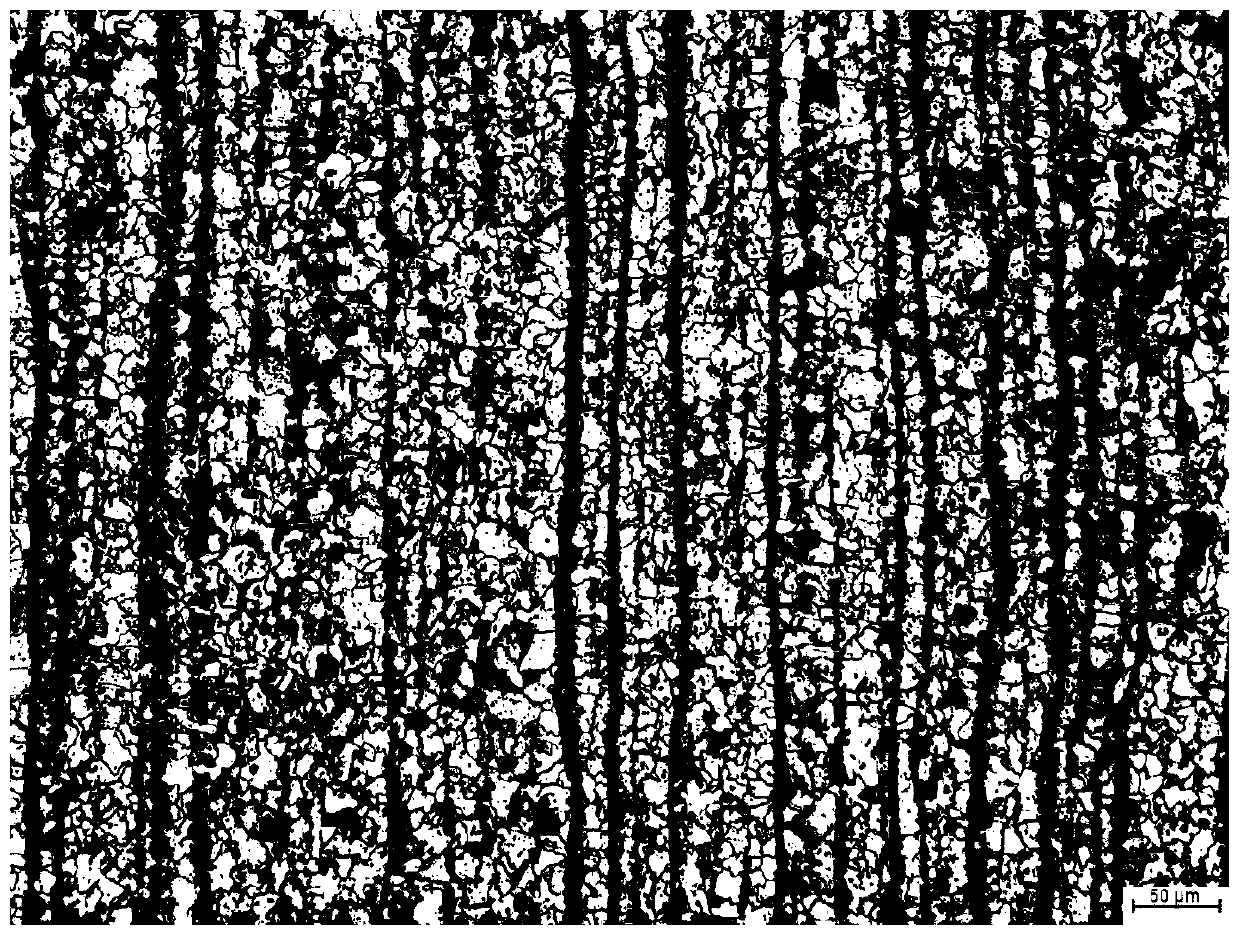

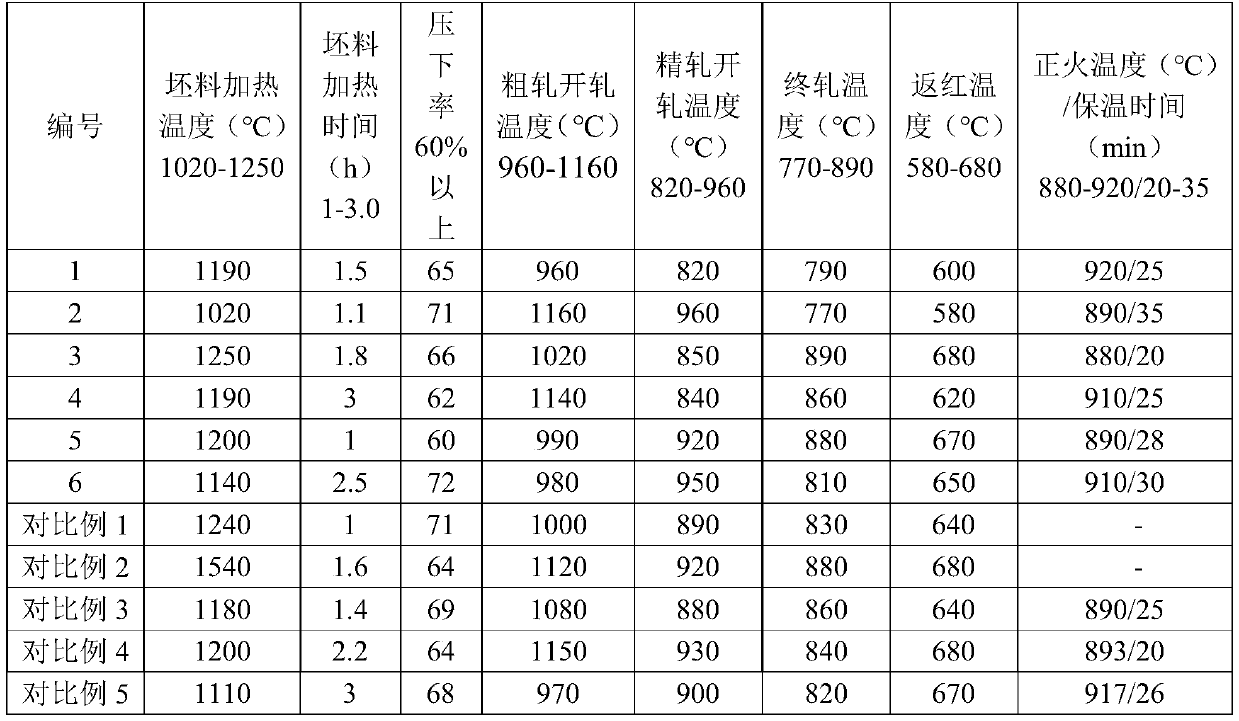

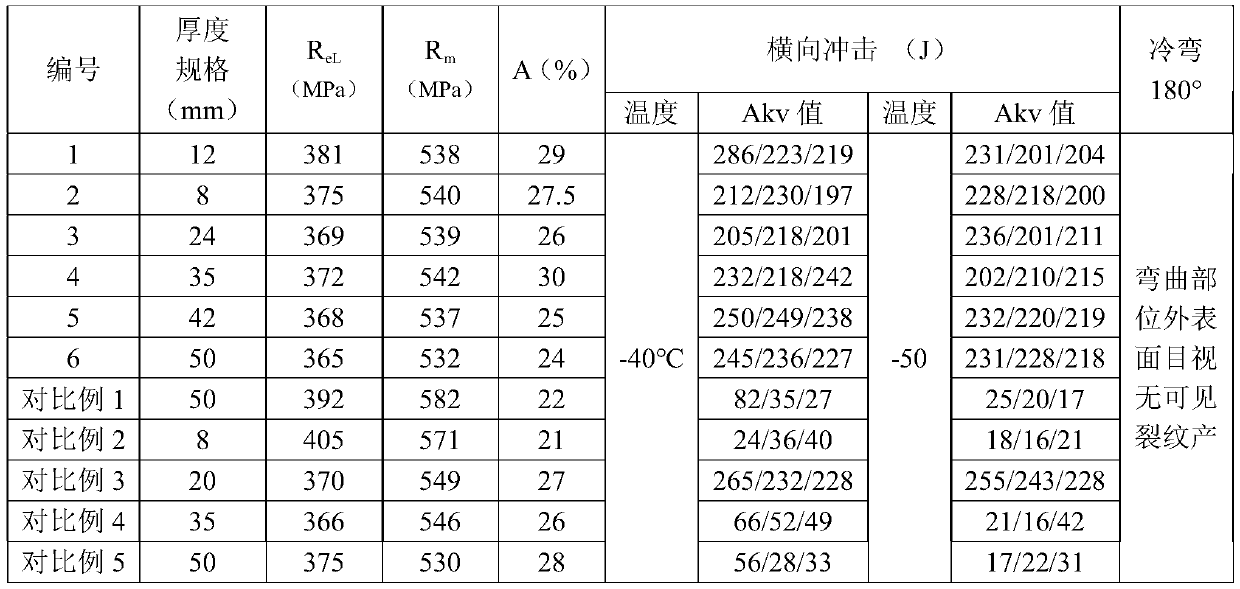

Method of Q345R steel for ultra-low temperature and manufacturing method thereof

The invention provides a method of Q345R steel for ultra-low temperature and a manufacturing method thereof, and belongs to the technical field of steel manufacturing. According to the Q345R steel forultra-low temperature, scheme matching is conducted by optimizing the alloy elements, the low-cost alloy elements are adopted, the adding amount of the more expensive alloy elements is cancelled, thecontent of harmful impurities elements P and S is appropriately reduced, the purity of molten steel is ensured, and the influence of inducing of the impact toughness due to the harmful impurity elements is reduced; and on the one hand, the low temperature impact toughness of a steel plate is effectively reduced, and on the other hand, the production cost is also successfully reduced. By means ofthe manufacturing method, a rolling and cooling controlling + normalizing heat treatment process technology is adopted, the defects such as grain coarseness and uneven structure produced in the rolling process through the normalizing heat treatment process are eliminated, the carbide is fully dissolved, the pearlitic structure is refined, and the uniform ferrite + small pearlitic structure + carbide precipitation structure is obtained, so that the steel plate has the high strength and toughness performance, and the requirements of use in ultra-low temperature environments are met.

Owner:NANJING IRON & STEEL CO LTD

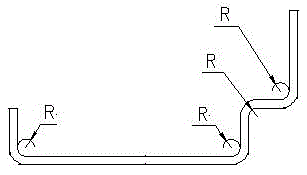

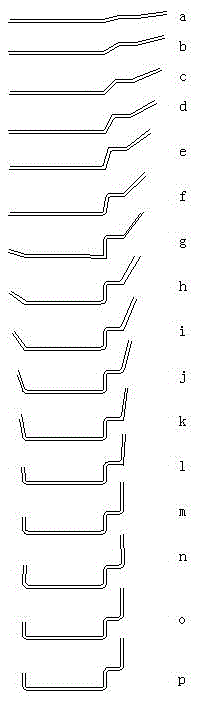

Method for carrying out continuous cold roll forming on asymmetric plates of bottom side beams for container

ActiveCN105562478AEliminates uneven material thickness or wrinklesEliminate UniformityLoad-supporting pillarsEngineeringRoll forming

The invention discloses a method for carrying out continuous cold roll forming on asymmetric plates of bottom side beams for a container. The method comprises the following concrete processing steps: preparing a cold roll forming unit, and sequentially loading first to sixteenth rollers into the cold roll forming unit; and carrying out cold roll forming on the plates: carrying out continuous bending on the right sides of the plates by the first to sixth rollers, flattening the left sides of the plates, shaping the right sides of the plates by the right sides of the seventh to twelfth rollers, carrying out cold bending on the left sides of the plates by left rollers, carrying out continuous bending on the left and right sides of the plates by the thirteenth roller, shaping the outermost edges of the left and right sides of the plates by the fourteenth to fifteenth profile steel, and correcting the shape of each edge of the plates by the sixteenth roller, thereby achieving the specified shape and size. According the cold roll forming method disclosed by the invention, by firstly carrying out cold bending treatment on the right sides and then carrying out cold bending treatment on the left sides, materials can freely extend from the right sides to the left sides without being restrained, thereby preventing the materials from stacking or wrinkling.

Owner:南通军盛机械模具有限公司

Blade inner reinforcement method and wind generating set blade

InactiveCN107618177AStop slippingEliminate wrinklesFinal product manufactureMachines/enginesGlass fiberEngineering

The invention discloses a blade inner reinforcement method and a wind generating set blade. The method comprises the steps that a plurality of glass fiber cloths are pre-laid and sewed together; the sewed glass fiber cloth layers are laid on the inner reinforcement area and fixed; and the inner reinforcement area is vacuumized, then resin permeates into the glass fiber cloth layers through vacuumfilling and is solidified into the glass fiber cloth layers, and during resin filling and resin solidification, the pressure of the inner reinforcement area is maintained. Through the inner reinforcement method, generation of hand layup bubbles is reduced, the inner reinforcement strength is improved, and the operation time in a reinforcement station in blade manufacturing is shortened.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

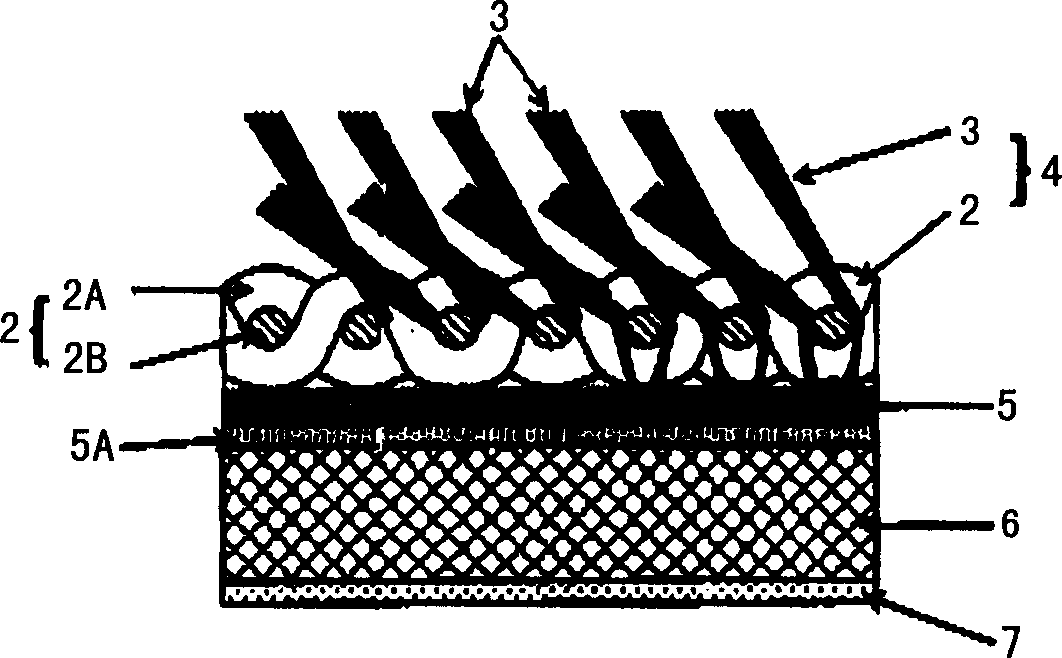

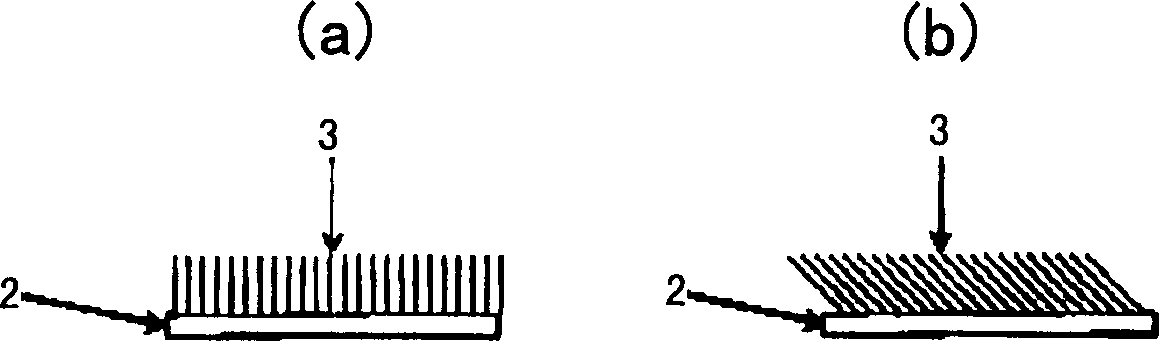

Sealing material with excellent sliding property and wear resistance and for prventing fine powder leakage

InactiveCN1417652ASoftPrevent pulling outOther chemical processesSynthetic resin layered productsVolumetric Mass DensityHigh intensity

A sealing member for preventing escape of micro particles, sealing a predetermined gap between a movable unit in contact with the micro particles and a housing of the movable unit, and adhered to the face of the movable unit or housing without impeding movement of the movable unit, based on a pile fabric configured with a pile yarn forming a sliding flock and a base cloth of plain woven tissue supporting the pile yarn, the pile yarn of the flock being formed of a high strength polyethylene fiber having a filament fineness of 0.1-6.0 dTex, a fiber cross section oblateness of at least 1.1, and an average tensile strength of at least 22 cN / dTex, and the flock having a height of 1.5-4.0 mm, a pile density of 13,000-346,000 filament / cm<2> at the pile yarn portion, and a pile yarn cross section area of 0.02-0.2 cm<2> per 1cm<2> of the base cloth, the inner surface of the base cloth has coat to prevent the emrging of flock.

Owner:TOYO TOYOBO CO LTD

Preparation method of large molybdenum rod blank

The invention discloses a preparation method of a large molybdenum rod blank. The preparation method of the large molybdenum rod blank comprises airflow grinding treatment, powder loading, molybdenum pressed rod blank preparation and molybdenum rod blank preparation. Piece weight of produced molybdenum rod blank reaches more than 500kg, and dimensions of finished products are that the molybdenum rod blank is 250-1200mm in diameter and 200-1500mm in length. The preparation method of the large molybdenum rod blank eliminates the defects of nonuniform texture and interior crack.

Owner:JINDUICHENG MOLYBDENUM CO LTD

2-series aluminum alloy

The invention provides 2-series aluminum alloy which consists of 0.06-0.5wt% of Fe, 0.12-0.5wt% of Si, 1.2-1.8wt% of Mg, 3.8-4.9wt% of Cu, 0.3-0.9wt% of Mn and the balance of aluminum. The 2-series aluminum alloy provided by the invention is applicable to the preparation of 2xxx aviation aluminum alloy; and the aluminum alloy provided by the invention is relatively low in crack propagation rate and relatively good in fatigue property and mechanical property.

Owner:SOUTHWEST ALUMINUM GRP

Automatic correcting belt conveyor

InactiveCN102180376AEliminate UniformityEliminate defects such as poor product finishArticle deliveryLens plateEngineering

The invention discloses an automatic correcting belt conveyor, comprising a main shaft, a workbench and a vacuum pull rod, wherein the vacuum pull rod is coaxially arranged in the main shaft, the lower end of the main shaft and the workbench are respectively and correspondingly provided with a suction head used for adsorbing an upper die sheet and a lower die sheet of a lens die, and the suction head comprises a suction head sleeve, a die sheet correcting locating rod, a locating rod limiting sleeve, a locating rod locking block, a locking block extrusion head and an elastic suction disc; andthe locking block extrusion head is fixedly arranged at the lower end of the vacuum pull rod, the locating rod locking block is sleeved outside the locking block extrusion head, the locating rod limiting sleeve is sleeved outside the locating rod locking block, and the suction head sleeve is fixedly sleeved outside the locating rod limiting sleeve. The automatic correcting belt conveyor can be used for automatically correcting the lens die cavity deviation caused by an uneven nonworking plane of the upper die sheet and the lower die sheet of the lens die, and after the lens die cavity deviation is corrected by a die sheet correcting locating rod, the defects, such as nonuniform product thicknesses, poor product smooth finish and the like caused by the uneven thickness of the nonworking plane of the lens die can be eliminated.

Owner:LINHAI JINZHENG MACHINERY

Thin-film transistor and LCD device

InactiveCN101425542ASmall footprintReduce unused areaTransistorSolid-state devicesLiquid-crystal displayParasitic capacitance

The invention relates to a thin-film transistor and a liquid crystal display device using the thin-film transistor. The thin film transistor comprises a first drain electrode, a second drain electrode, a source electrode and a grid electrode, wherein a semi-close area is formed by the first drain electrode and the second drain electrode, and one end of the source electrode is positioned in the semi-close area. The thin-film transistor can reduce the parasitic capacitance generated between the source electrode and the grid electrode and improve the display quality of images.

Owner:SHANGHAI SVA LIQUID CRYSTAL DISPLAY

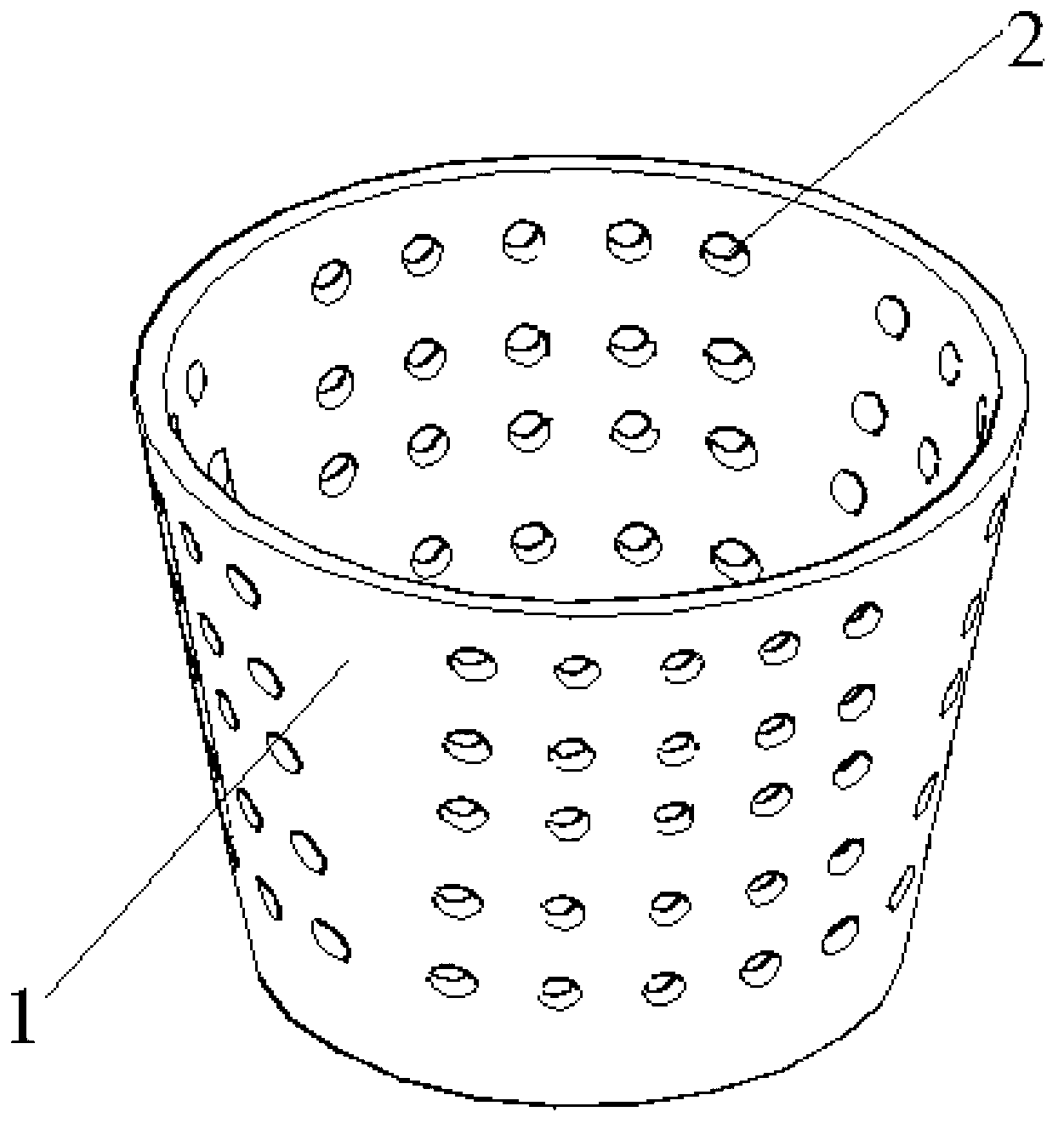

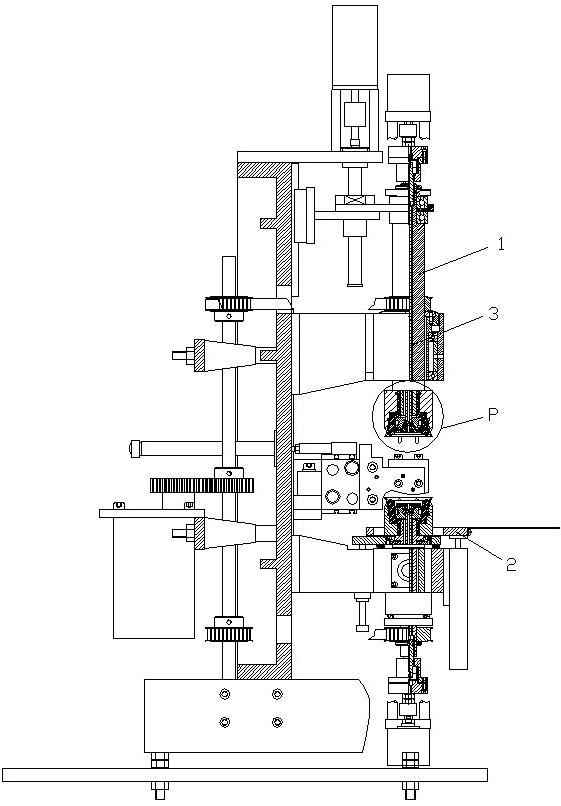

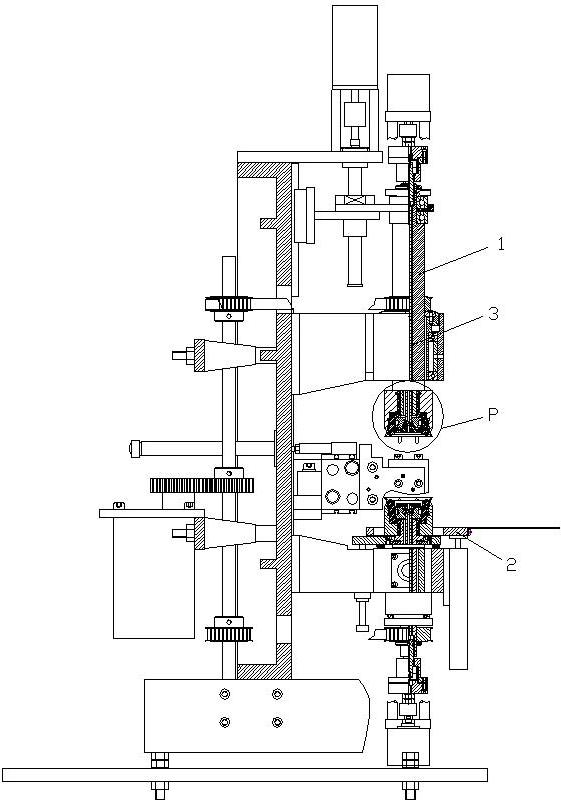

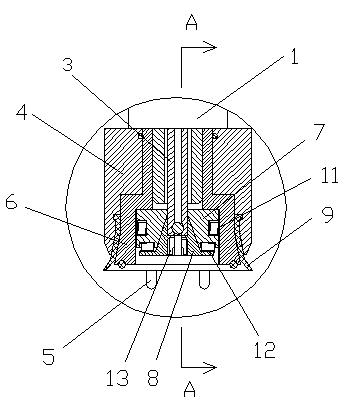

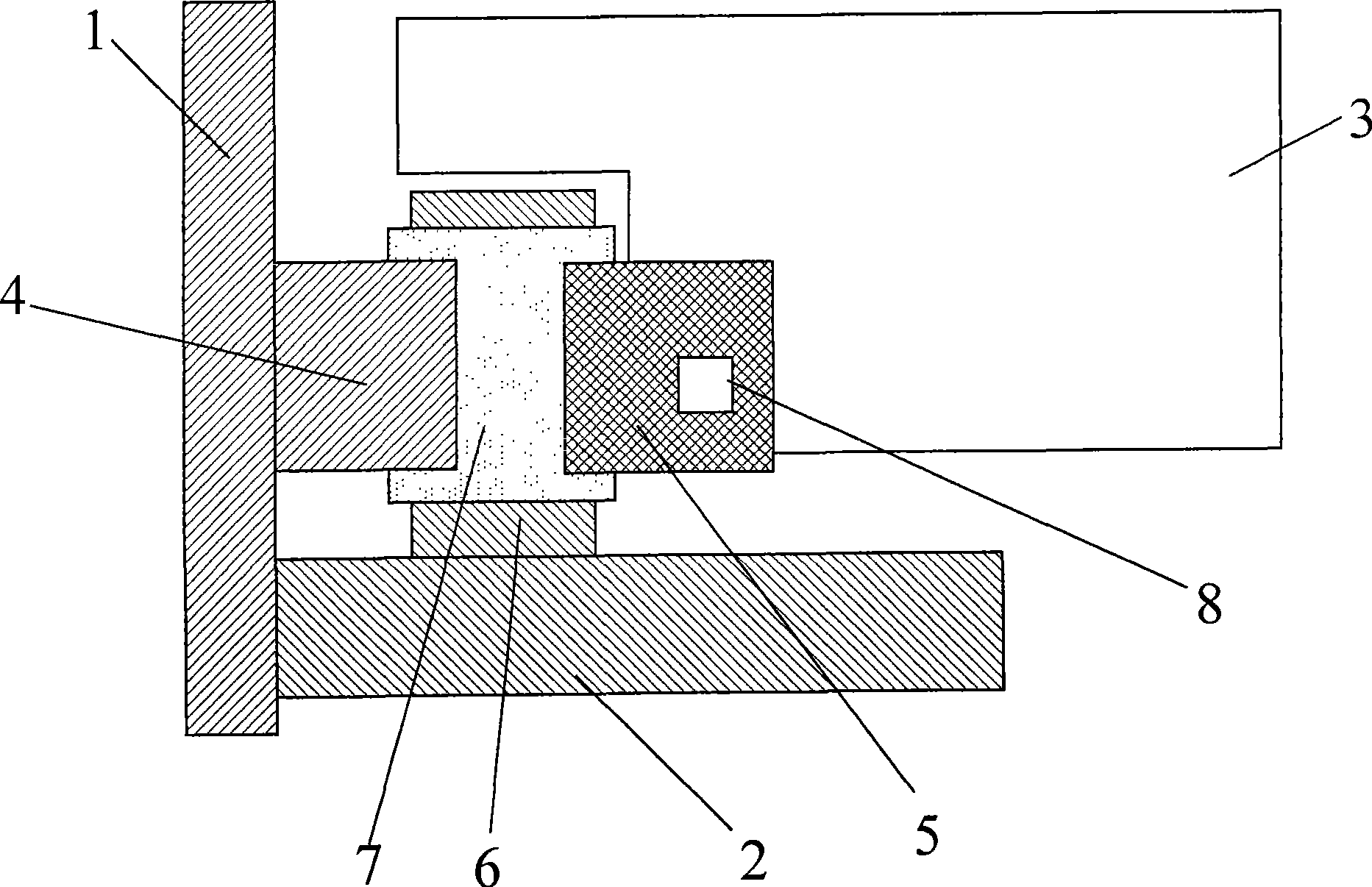

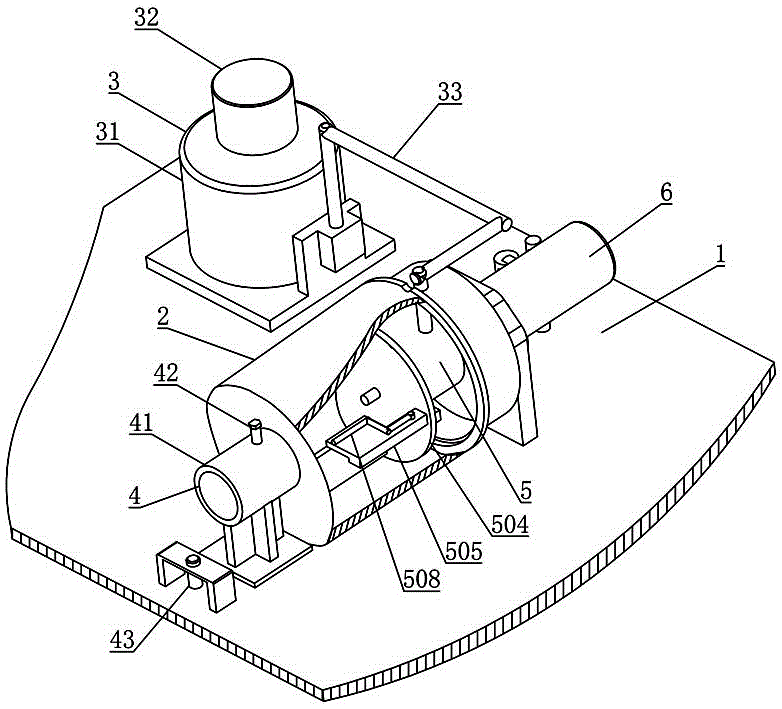

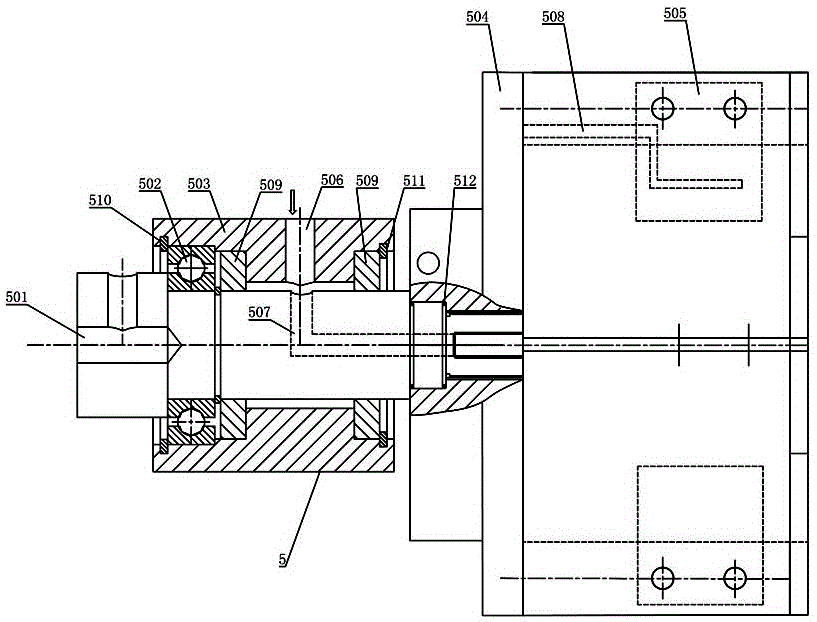

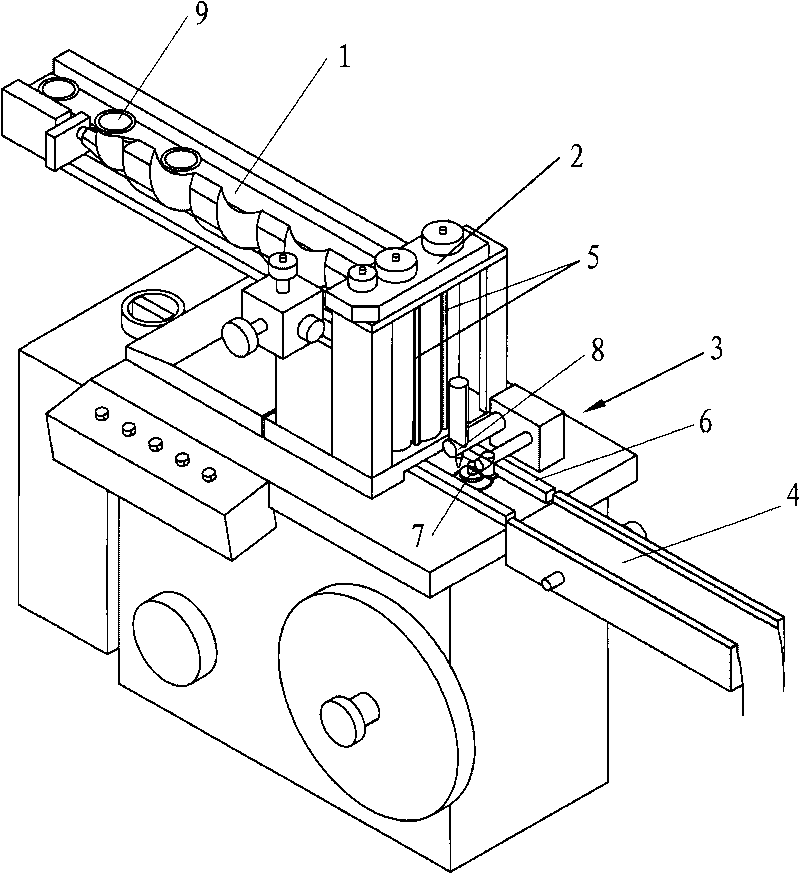

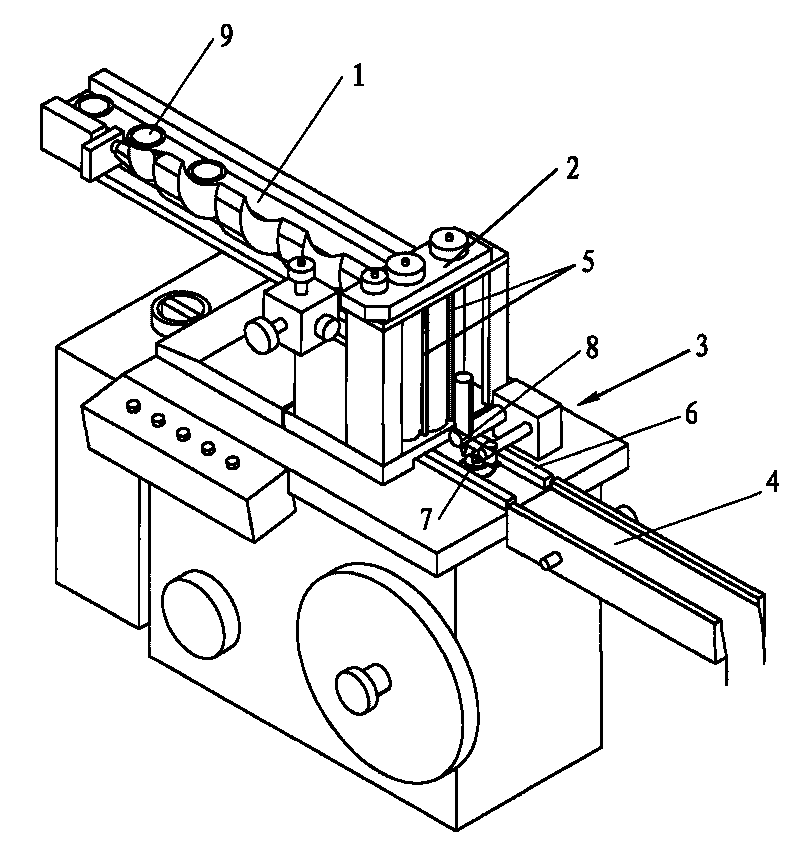

Smearing device for bolt lubricating grease

ActiveCN106238269AEliminate UniformityEliminate issues such as wasteLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a smearing device for bolt lubricating grease. The smearing device comprises a sealing barrel and a grease injection assembly. A positioning assembly used for positioning a bolt to be smeared with the lubricating grease is arranged at one end of the sealing barrel. A smearing assembly and a driving assembly are arranged at the other end of the sealing barrel. The smearing assembly is installed inside the sealing barrel and is connected with the driving assembly outside the sealing barrel. The smearing assembly is driven by the driving assembly to rotate so as to perform smearing operation on the bolt located on the positioning assembly. The grease injection assembly is connected with the smearing assembly and used for supplying the lubricating grease with adjustable flow to the smearing assembly. The smearing device for the bolt lubricating grease has the advantages of being simple in structure, high in smearing efficiency, sealed in smearing operation environment and the like.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

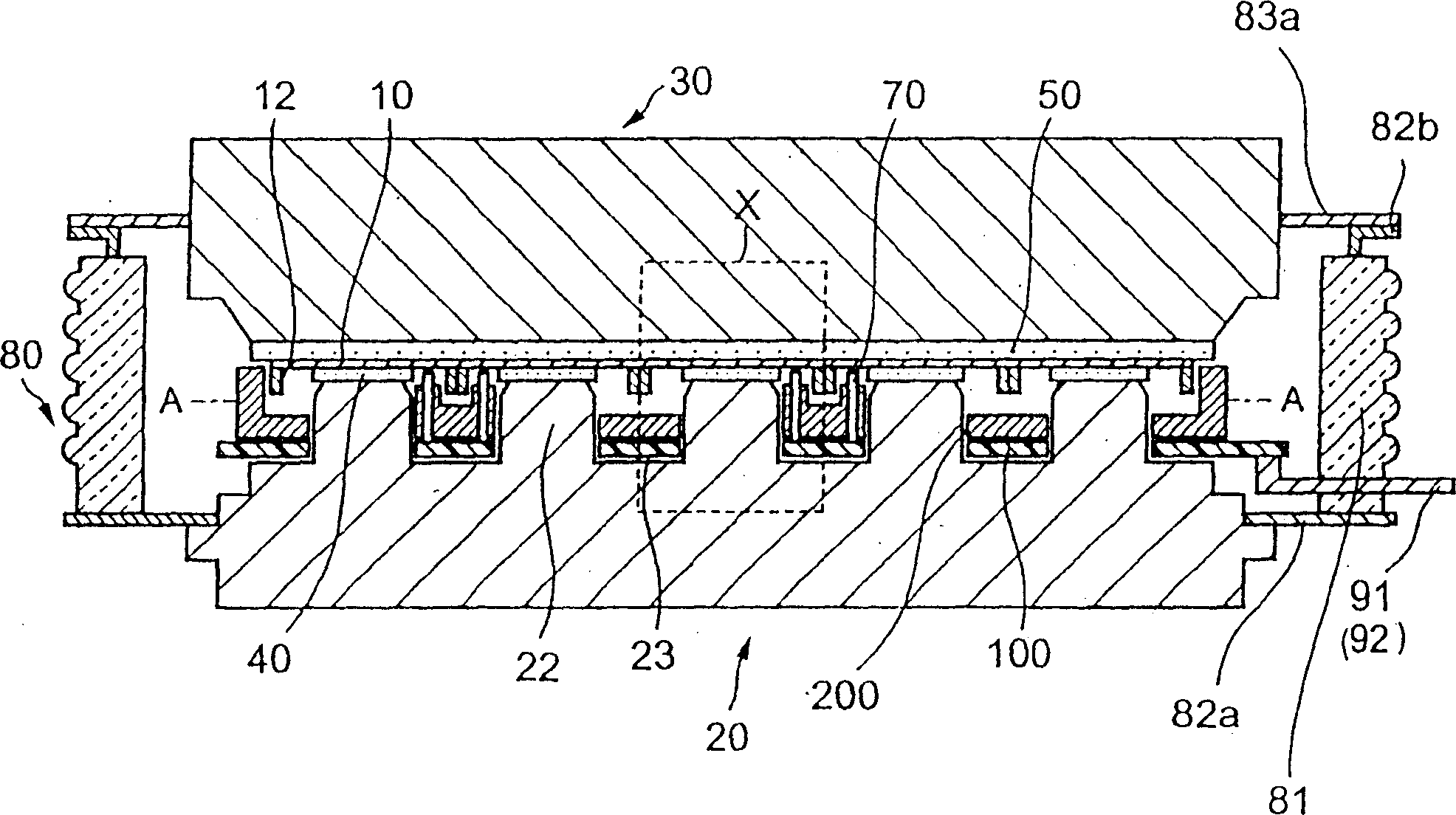

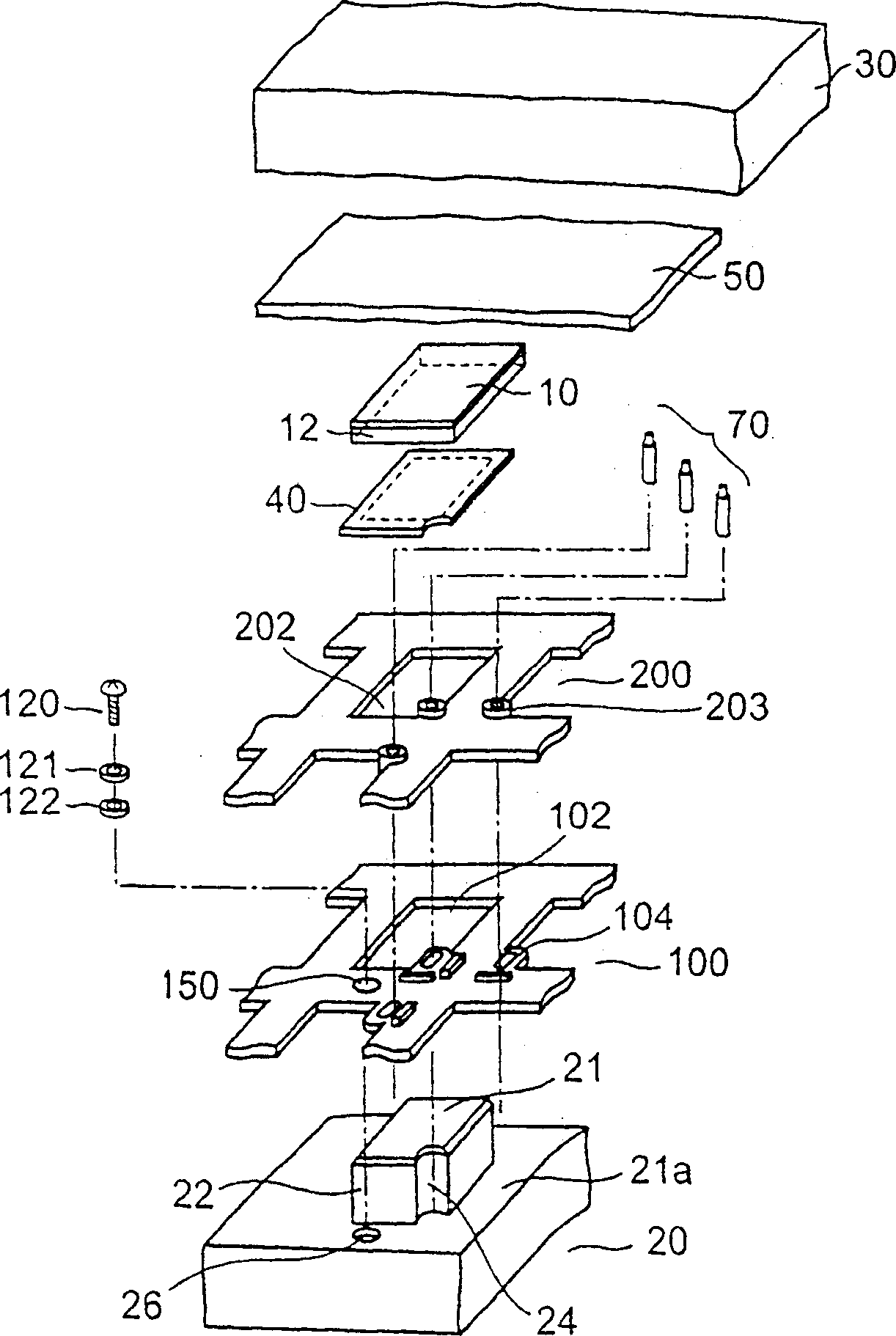

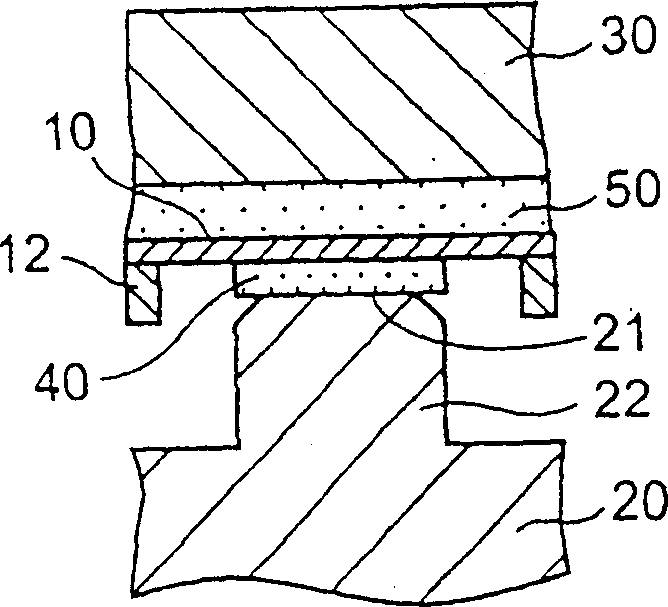

Semiconductor device

InactiveCN1434505AEliminate fluctuationsEliminate UniformitySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorDevice material

The present invention provides a semiconductor device which has a high maximum breaking current and hard to be broken. In the semiconductor device, a semiconductor chip 10 is pressue- welded to a part between a flat surface of a first main electrode member 30 and an upper surface 21a of a pillar 22 of a second main electrode member 20 via buffer plates 40, 50, and a gate electrode of the chip 10 is electrically connected with a gate signal wiring pattern of a circuit wiring board by using a gate connection conductor. One of a contact region between the pillar 22 of the second main electrode member 20 and the buffer plate 40 and a contact region between a part of the first main electrode member 30 facing the pillar 22 and the buffer plate 40 is formed small compared with a contact region between the buffer plate 40 on the second main electrode member 20 side and the semiconductor chip 10.

Owner:KK TOSHIBA

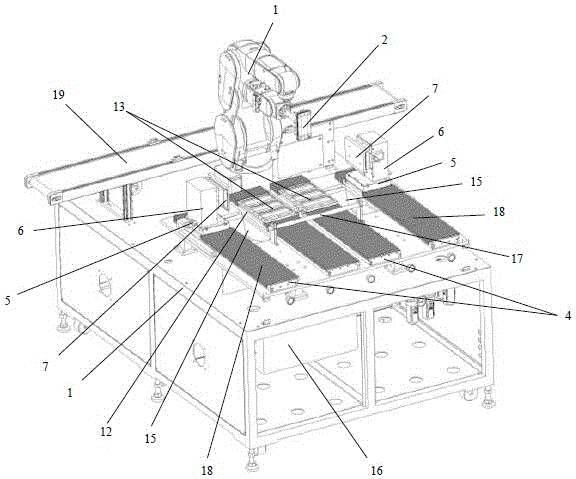

Full-automatic curve polishing and grinding device and process

PendingCN106466804APrecisely control the movement trajectoryControl motion trajectoryGrinding carriagesGrinding feed controlMechanical engineeringPoor quality

The invention provides a full-automatic curve polishing and grinding device and process. The device comprises a six-axis mechanical arm, a clamp, grinding mechanisms, a machine table mechanism, feeding mechanism, and a protection cover and is characterized in that the six-axis mechanical arm is arranged on the machine table mechanism; the tail end of the machine table mechanism is connected with the clamp; two sides of the right surface of the six-axis mechanical arm are provided with the grinding mechanisms and the feeding mechanism corresponding to the grinding mechanisms; the two feeding mechanisms are arranged between the two grinding mechanisms; the back side of the six-axis mechanical arm is provided with a conveyor belt used for automatically conveying mobile phone shells; a dust collection port is arranged between one grinding mechanism and one feeding mechanism; and the two dust collection ports communicate with a dust collection box below a table surface of the machine table mechanism.The full-automatic curve polishing and grinding device and process have following beneficial effects: problems such as poor quality of polishing and grinding and inefficiency are solved; dust generated by grinding is prevented from causing occupational diseases by carrying out manual and remote operation; and efficient and cost-effective full-automatic polishing and grinding operation for plastic injection parts is achieved.

Owner:东莞市卓安精机自动化设备有限公司

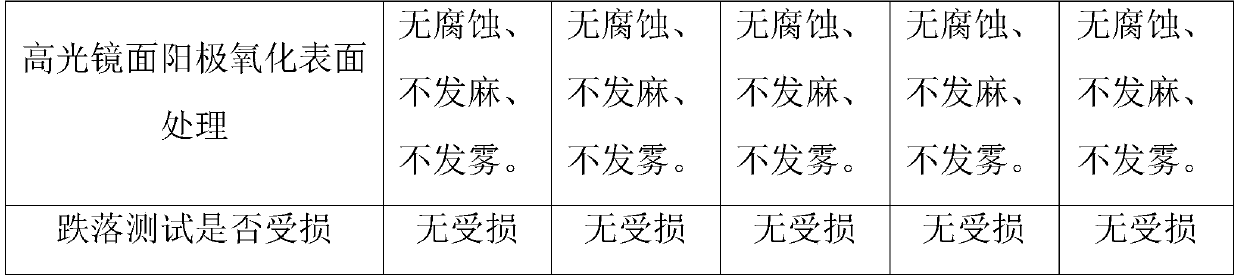

Aluminum alloy material for mobile phone structural part and preparation method of aluminum alloy material

The invention relates to the technical field of aluminum alloy machining, in particular to an aluminum alloy material for a mobile phone structural part and a preparation method of the aluminum alloymaterial. The aluminum alloy material is prepared from the components in percent by mass: 0.80-0.95% of Mg, 0.52-0.66% of Si, 0.52-0.66% of Cu, 0.12-0.28% of Mn, 0.05-0.18% of Zr, smaller than or equal to 0.1% of Fe, smaller than or equal to 0.10% of the sum of other impurities and the balance Al. The aluminum alloy material for the mobile phone structural part has high strength, toughness, surface treatment adaptability, tensile strength, yield strength, corrosion resistance and other performance, the strength is improved by one time or above, the tensile strength is larger than or equal to 380 MPa, the yield strength is larger than or equal to 340 MPa, the drop test does not affect the quality and performance of alloy, corrosion sensitivity or numbing or fogging is not generated during highlight mirror anode oxidized surface treatment, and the aluminum alloy material is high in corrosion resistance and suitable for mobile phone structural part materials treated with highlight mirrors.

Owner:LVMEI ALUMINUM

Preparation method of titanium alloy TA7 titanium alloy powder

InactiveCN107866564AReduce composition segregationHigh purityTransportation and packagingMetal-working apparatusShielding gasCentrifugal force

The invention discloses a preparation method of titanium alloy TA7 titanium alloy powder. The preparation method comprises the steps that step 1, smelting of a TA7 master alloy bar is carried out; step 2, the diameter of an electrode bar processed through the TA7 alloy bar is 10 mm to 90 mm, and the length of the electrode bar is 100 mm to 1000 mm; step 3, the electrode bar is placed in a reactionchamber with an inert gas and is rotated at a high speed, the end part of the electrode bar is heated through a plasma gun with the power of 100 kW to 300 kW, and the end part of the electrode bar ismolten; and step 4, after atomization, a molten metal flies out under the action of centrifugal force, fine liquid drops are formed, the liquid drops form spherical particles after being quickly cooled in a protective gas, the spherical particles fall into a collector at the bottom of an atomization chamber, and the TA7 alloy spherical powder is obtained. The TA7 alloy spherical powder prepared through the method has the characteristic that the oxygen enrichment amount is extremely low.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

Bottle cap glue-injection machine

ActiveCN101716825AGood effectImprove injection efficiencyDomestic articlesProduction linePulp and paper industry

The invention relates to a bottle cup glue-injection machine, comprising an input production line, an output production line, a cap separating device and a glue-injection device, the upper end of the cap separating device is connected with the input production line, and the lower end thereof is connected with the glue-injection device, the cap separating device comprises two same leading screws which are vertically arranged and are parallel, the rotating direction and the rotating speed of two leading screws are the same, the distance between top parts of screw threads of two leading screws is less than the diameter of a bottle cap to be processed, and the distance between the bottom parts of screw threads of two leading screws is greater than the diameter of the bottle cap to be processed. The application of the bottle cap glue-injection machine greatly increases the glue-injection efficiency, the reject rate of the product is reduced, and the secondary pollution of the product and the phenomena of uneven and non-flat glue surface of a product are basically eradicated.

Owner:SUZHOU HYCAN HLDG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com