Method for carrying out continuous cold roll forming on asymmetric plates of bottom side beams for container

A cold-formed, symmetrical technology, applied to the direction of beams, long-strip structural members for load-bearing, structural elements, etc., can solve the problems of difficult processing, high energy consumption, slow production efficiency, etc., and achieve the elimination of uneven material thickness Even or wrinkled effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

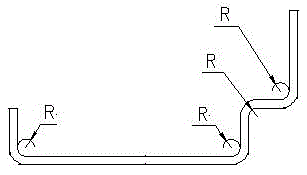

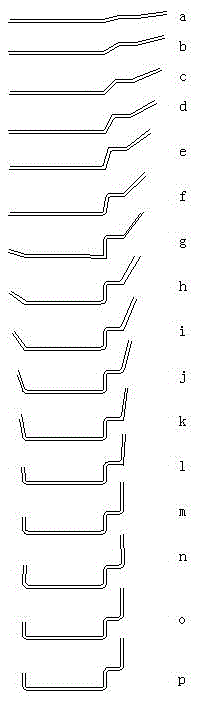

[0021] like Figure 1-5 As shown in the present invention, a method for continuous cold-bending of container bottom side girder asymmetric plate, specifically includes the following steps:

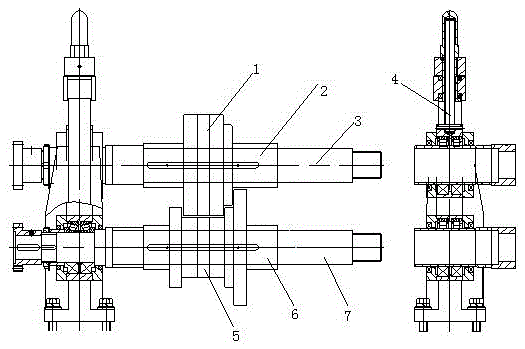

[0022] a. Cold roll forming unit preparation: such as image 3 As shown, first remove the movable archway 4 on the right side of the first roller in the cold roll forming unit, put the upper roller ring 1 and the sleeve 2 of the first roller on the upper roller shaft 3, and put the lower roller of the first roller The roll ring 5 and the shaft sleeve 6 are put on the lower roll shaft 7, and then the movable archway 4 is installed and fixed to ensure that the gap between the roll ring of the upper roll and the roll ring of the lower roll is consistent with the thickness of the sheet, repeat the above The steps are to complete the installation of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com