Bottle cap glue-injection machine

A technology of glue injection machine and bottle cap, which is applied to other household appliances, household appliances, household components, etc., to improve the efficiency of glue injection, prevent secondary pollution, and reduce waste rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

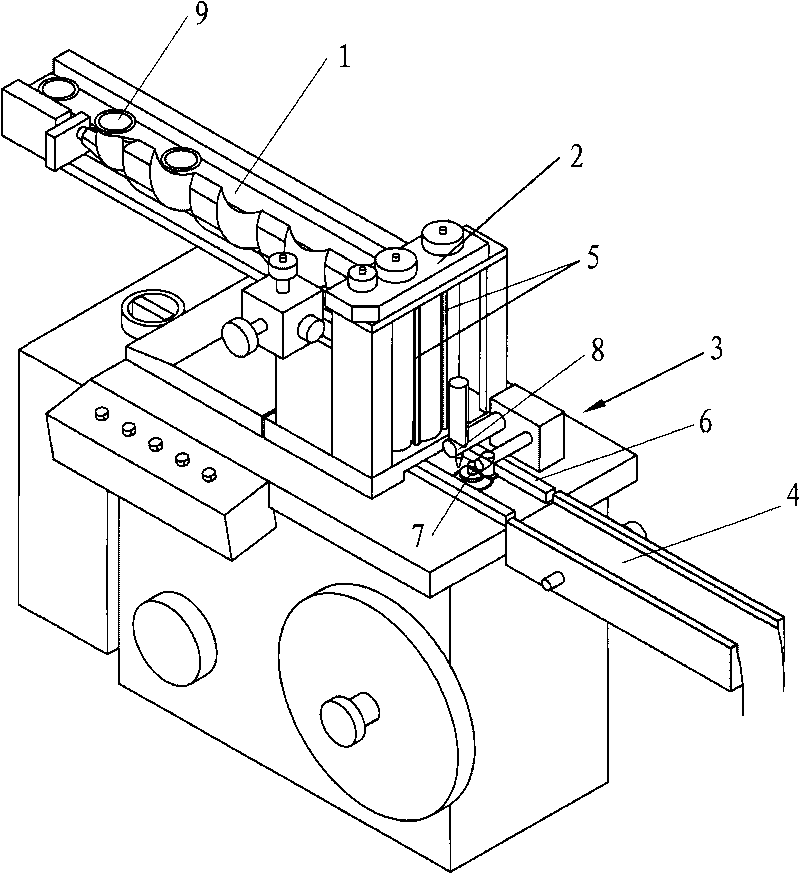

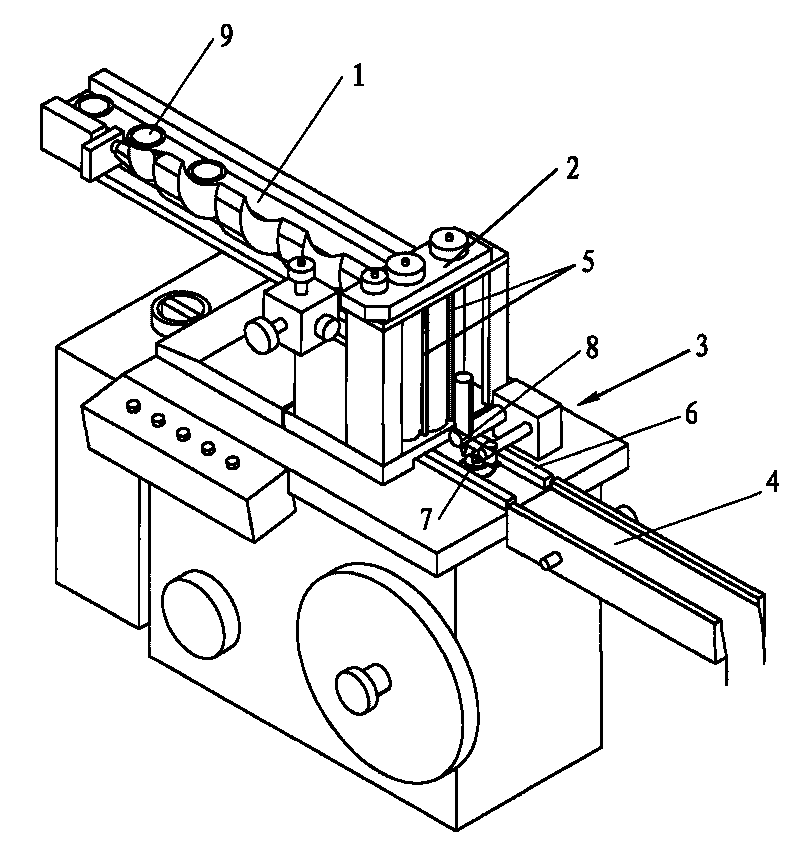

[0009] The bottle cap glue injection machine of the present invention will be further described below in conjunction with the accompanying drawings.

[0010] as attached figure 1 Shown, a kind of bottle cap injection machine, it comprises input assembly line 1, output assembly line 4, sub-cap device 2, injection device 3, described injection device 3 comprises the manipulator 6 for moving bottle cap, for The sensor 7 for detecting the position of the bottle cap and the injection mold 8 for injecting glue on the bottle cap, the sensor 7 is connected to the glue injection device 8 with a signal, and the upper end of the cap splitting device 2 is connected to the input The assembly line 1 is connected, and the lower end is connected with the glue injection device 3. The cover sub-device 2 includes two completely identical lead screws 5 vertically placed and parallel to each other. The two lead screws 5 are The direction of rotation and the speed of rotation are the same, the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com