Blade inner reinforcement method and wind generating set blade

An inner-blade reinforcement technology, applied in blade inner reinforcement, wind turbine blade field, can solve problems such as sag and smooth resin surface, strength reduction of reinforcement cloth layer, detachment of reinforcement layer and shell, etc. Eliminate the effect of reinforcing glass fiber cloth slipping, reducing the generation of air bubbles, and avoiding the expansion of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

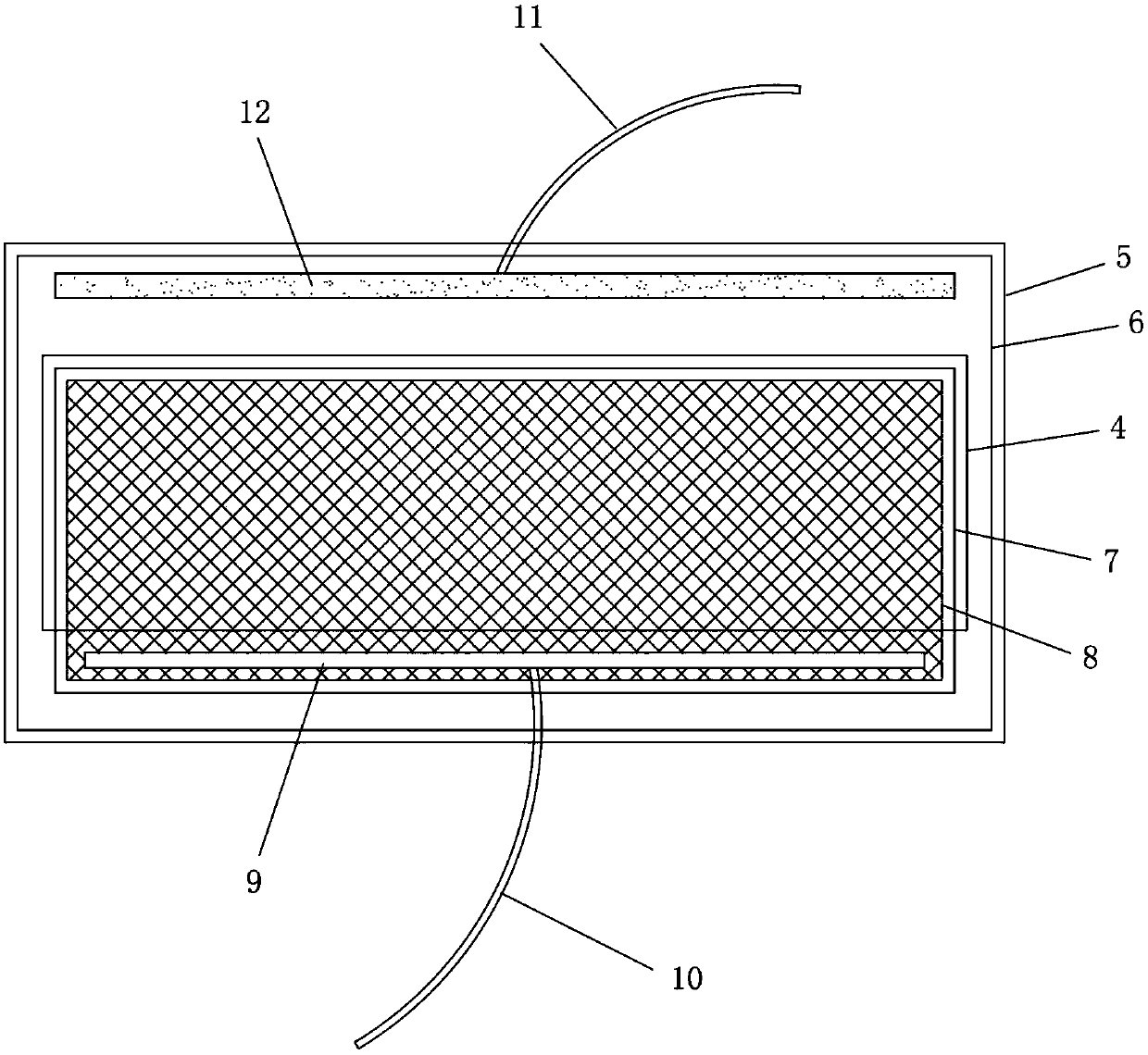

[0027] In order to enable those skilled in the art to better understand the present invention, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] When the blade 1 of the wind power generating set is manufactured, it is usually necessary to carry out internal reinforcement at the front and rear edges after the mold is closed, so as to improve the structural strength of the blade here and avoid cracking at the front and rear edge structures of the blade root. The internal reinforcement area 3 for internal reinforcement at the front and rear edges of the blade is located around the mold joint 2, such as figure 1 As shown, the inner reinforcing area 3 can be several meters long, and the specific length and width can be determined according to the size of the blade and the model of the wind power generating set.

[0029] Because when the blade is manufactured, there may be small holes in the struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com