Preparation method of large molybdenum rod blank

A molybdenum bar and large-scale technology, which is applied in the field of preparation of large-scale molybdenum bar billets, can solve the problems of uneven pressure on the billet, inability to manufacture large-scale molybdenum bar billets, and the molybdenum bar billet is small at the top and large at the bottom, so as to eliminate the uneven structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The first step, jet mill treatment

[0033] Put the molybdenum powder into the fluidized bed jet mill for jet mill treatment, and set the air source pressure to 0.4MPa, so that the average particle size of the treated molybdenum powder is 3.0um, and the loose ratio is 1.2g / cm 3 ;

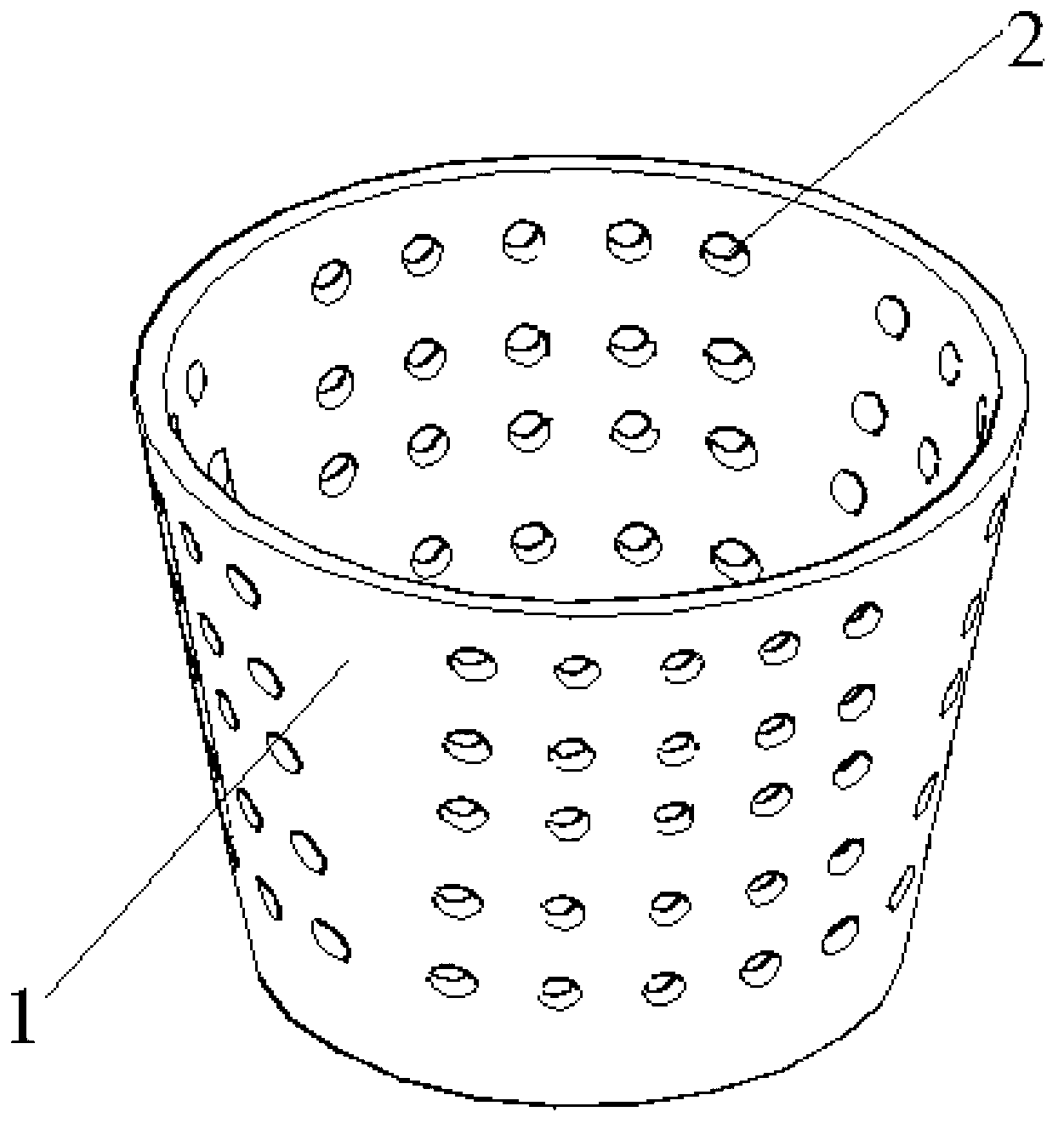

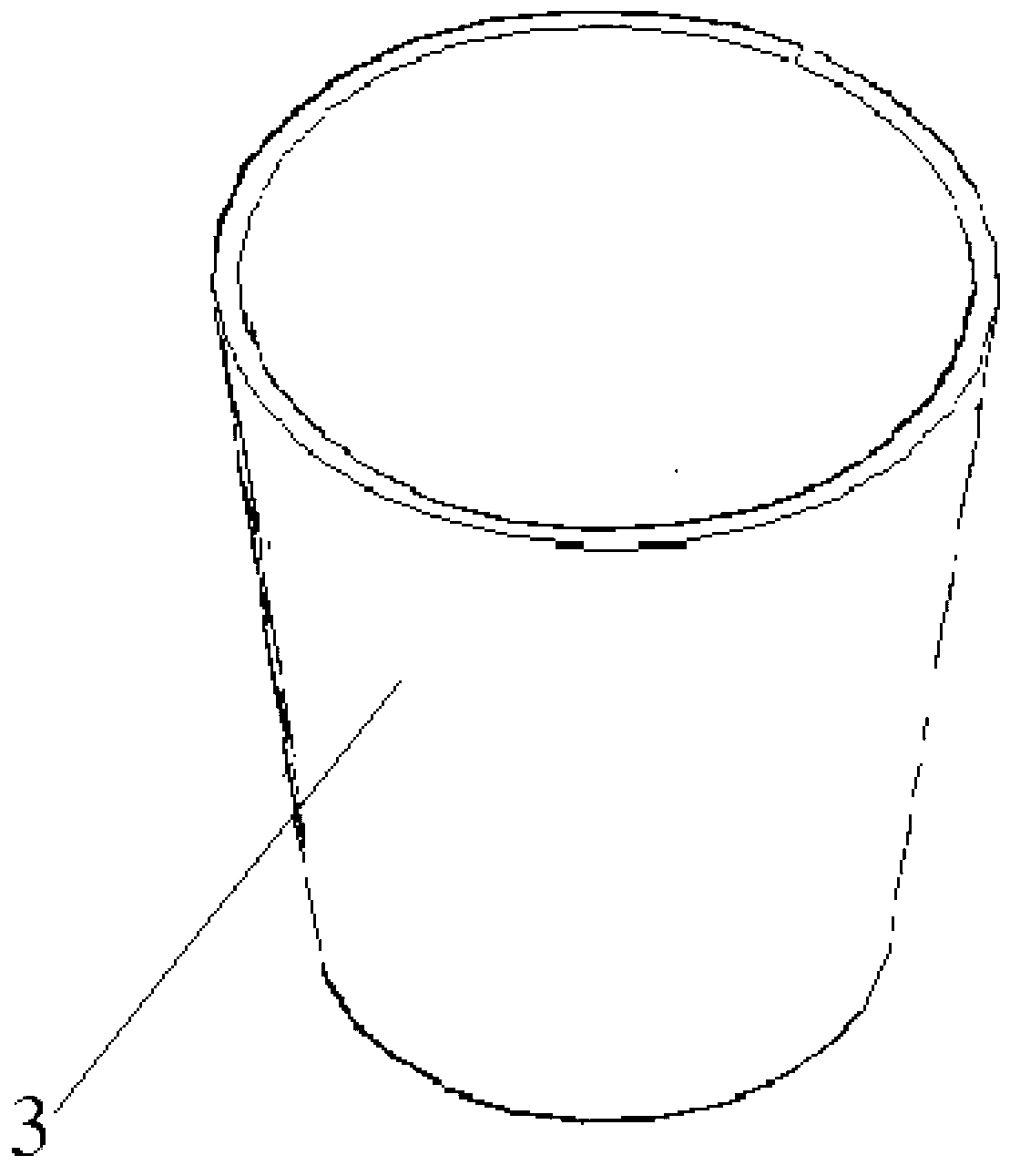

[0034] The second step, powder

[0035] Put the molybdenum powder treated in the first step into the mold, which is composed of a steel mold 1 and a latex rubber mold 3, the outer steel mold 1 and the inner latex rubber mold 3, and the latex rubber mold 3 is made of steel The mold 1 is fixed, wherein the inner diameter of the bottom of the steel mold 1 is 380mm, the inner diameter of the upper opening is 385mm, and the height is 1300mm; the inner diameter of the bottom of the latex rubber mold 3 is 360mm, the inner diameter of the upper opening is 365mm, and the height is 1500mm. Load 50kg of molybdenum powder each time, and after each powder loading, continuously vibrate and compact the mo...

Embodiment 2

[0043] The first step, jet mill treatment

[0044] Put the molybdenum powder into a fluidized bed jet mill for jet milling, and set the air source pressure to 0.45MPa, so that the average particle size of the treated molybdenum powder is 3.4um and the loose ratio is 1.75g / cm 3 ;

[0045]The second step, powder

[0046] Put the molybdenum powder treated in the first step into the mold, which is composed of a steel mold 1 and a latex rubber mold 3, the outer steel mold 1 and the inner latex rubber mold 3, and the latex rubber mold 3 is made of steel The mold 1 is fixed, wherein the inner diameter of the bottom of the steel mold 1 is 385mm, the inner diameter of the upper opening is 390mm, and the height is 1200mm; the inner diameter of the bottom of the latex rubber mold 3 is 365mm, the inner diameter of the upper opening is 370mm, and the height is 1400mm. Load 80kg of molybdenum powder each time, and after each powder loading, continuously vibrate and compact the mold contai...

Embodiment 3

[0054] The first step, jet mill treatment

[0055] Put the molybdenum powder into a fluidized bed jet mill for jet milling, and set the air source pressure to 0.4MPa, so that the average particle size of the treated molybdenum powder is 3.1um and the loose ratio is 1.5g / cm 3 ;

[0056] The second step, powder

[0057] Put the molybdenum powder treated in the first step into the mold, which is composed of a steel mold 1 and a latex rubber mold 3, the outer steel mold 1 and the inner latex rubber mold 3, and the latex rubber mold 3 is made of steel The mold 1 is fixed, wherein the inner diameter of the bottom of the steel mold 1 is 380mm, the inner diameter of the upper opening is 385mm, and the height is 1100mm; the inner diameter of the bottom of the latex rubber mold 3 is 360mm, the inner diameter of the upper opening is 365mm, and the height is 1300mm. Load 60kg of molybdenum powder each time, and after each powder loading, continuously vibrate and compact the mold contain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com