Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87results about How to "Effective partition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

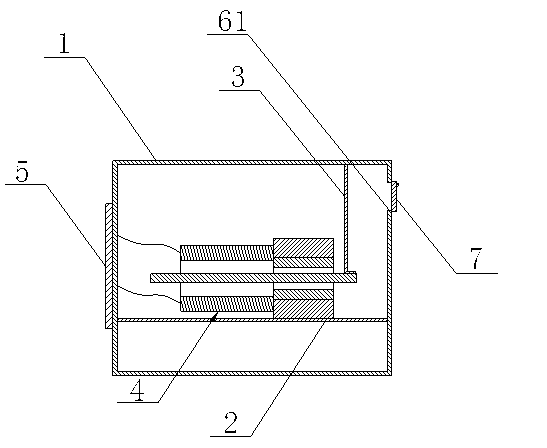

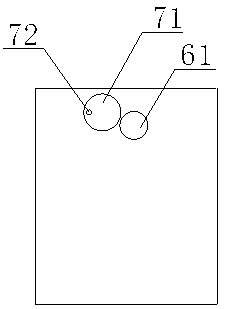

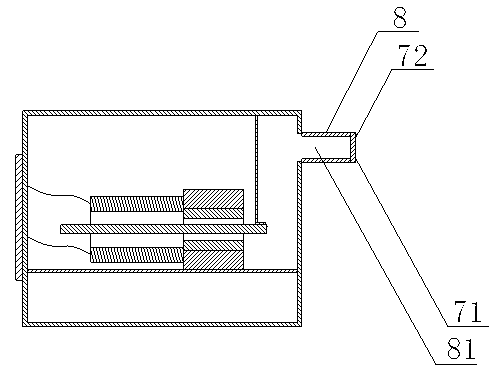

Bone conduction receiver with air conduction effect

ActiveCN103167390AReduce vibration amplitudeHigh outputEarpiece/earphone attachmentsDeaf-aid setsEngineeringBone conduction hearing

The invention discloses a bone conduction receiver with an air conduction effect. The bone conduction receiver comprises a shell, a vibrating diaphragm assembly, a conduction rod, an electromagnetic conversion device and a micro circuit board, wherein at least one through hole is formed on the shell; and at least one opening and closing device or a sound transmission tube of at least one sound transmission hole opening and closing device is arranged on the through hole. Moreover, the opening and closing device or the sound transmission hole opening and closing device comprises at least one cover plate, wherein the cover plate covers the through hole or a sound transmission hole of the sound transmission tube and is rotationally connected with the shell or the sound transmission tube. The application range of the bone conduction receiver can be enlarged, so that the listening of hearing handicapped is enriched, and the life of the hearing handicapped is also enriched; and the bone conduction receiver can be used for persons with normal hearing besides the hearing handicapped.

Owner:SUZHOU YICHUAN TECH CO LTD

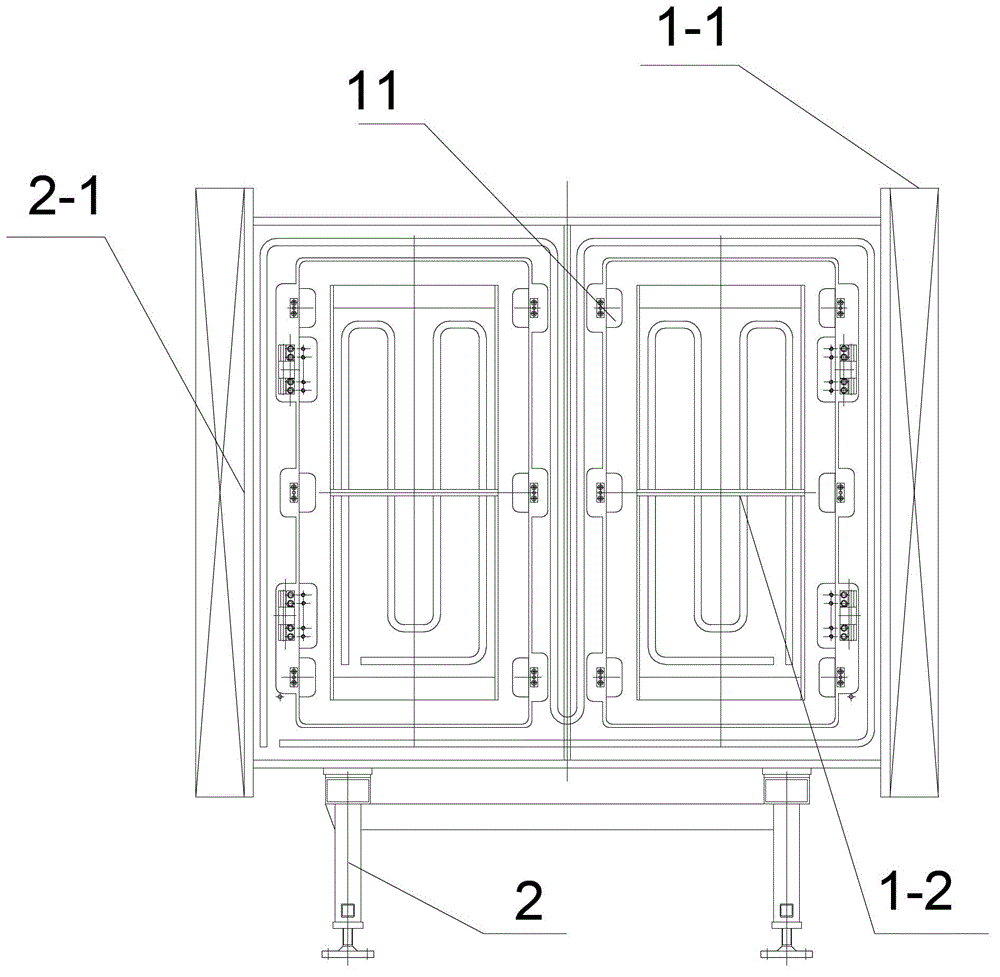

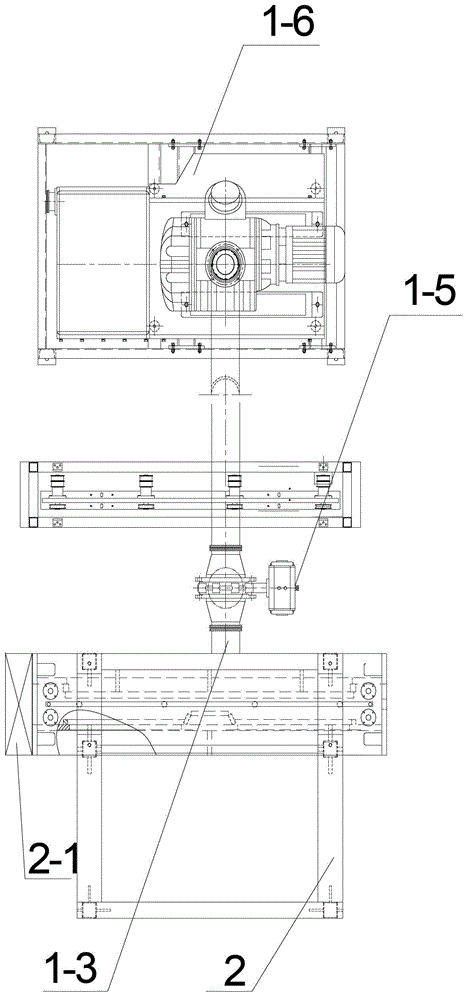

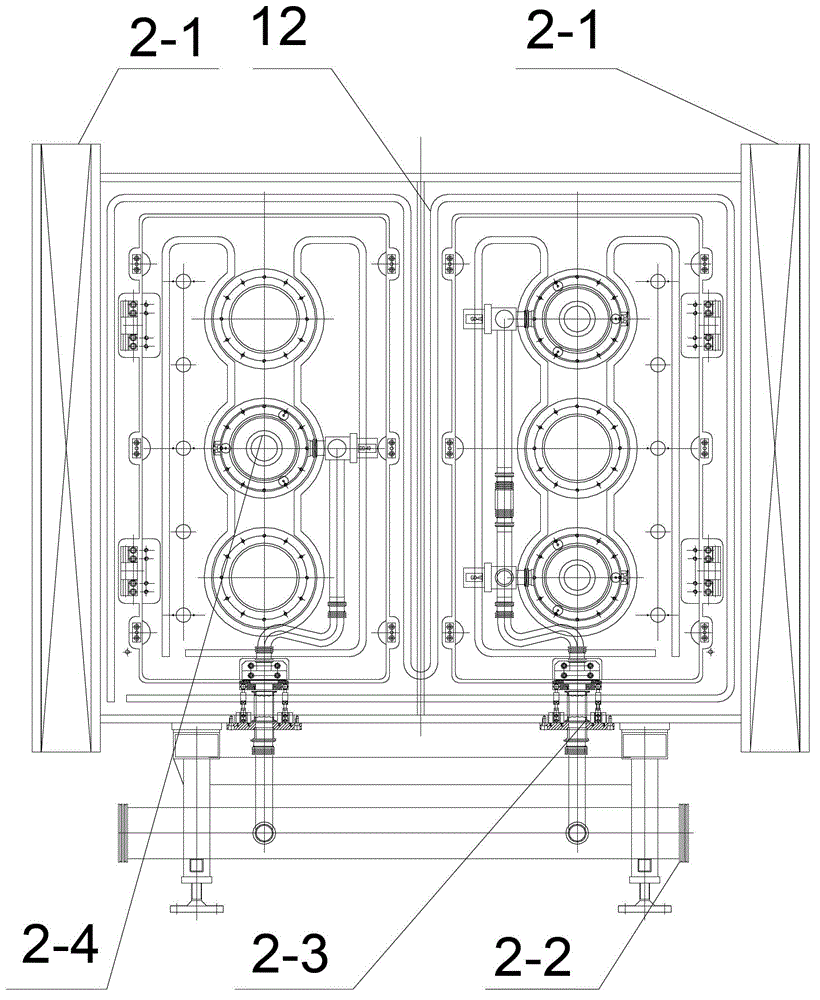

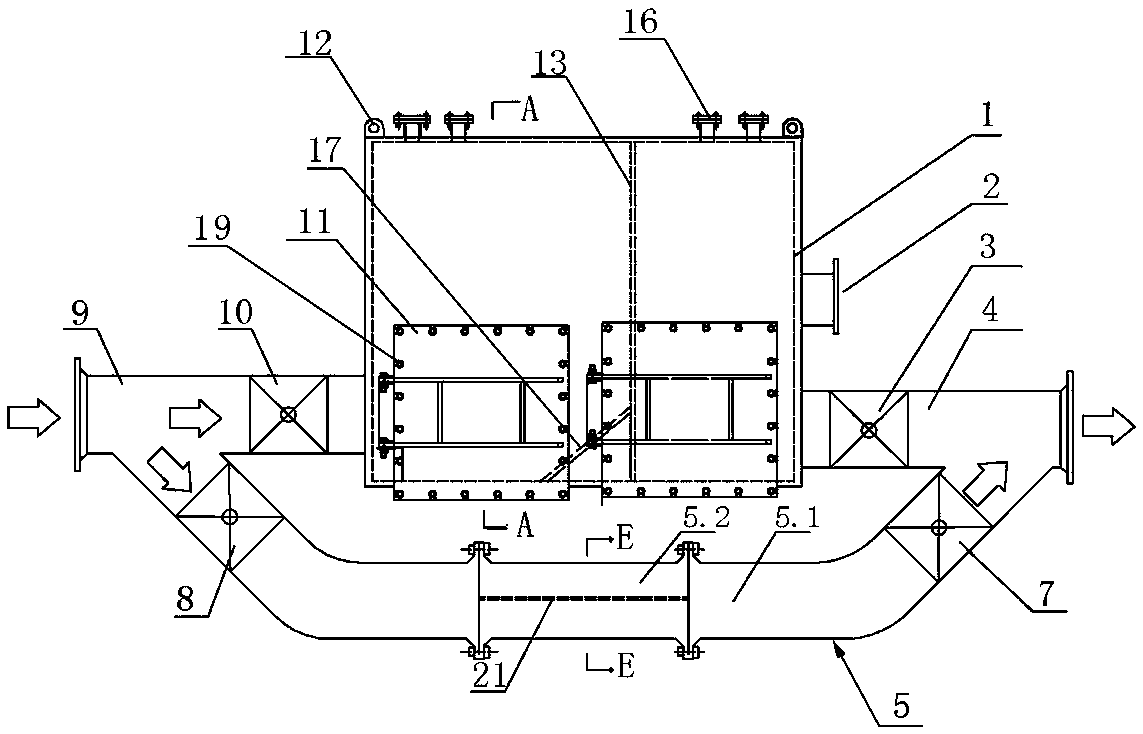

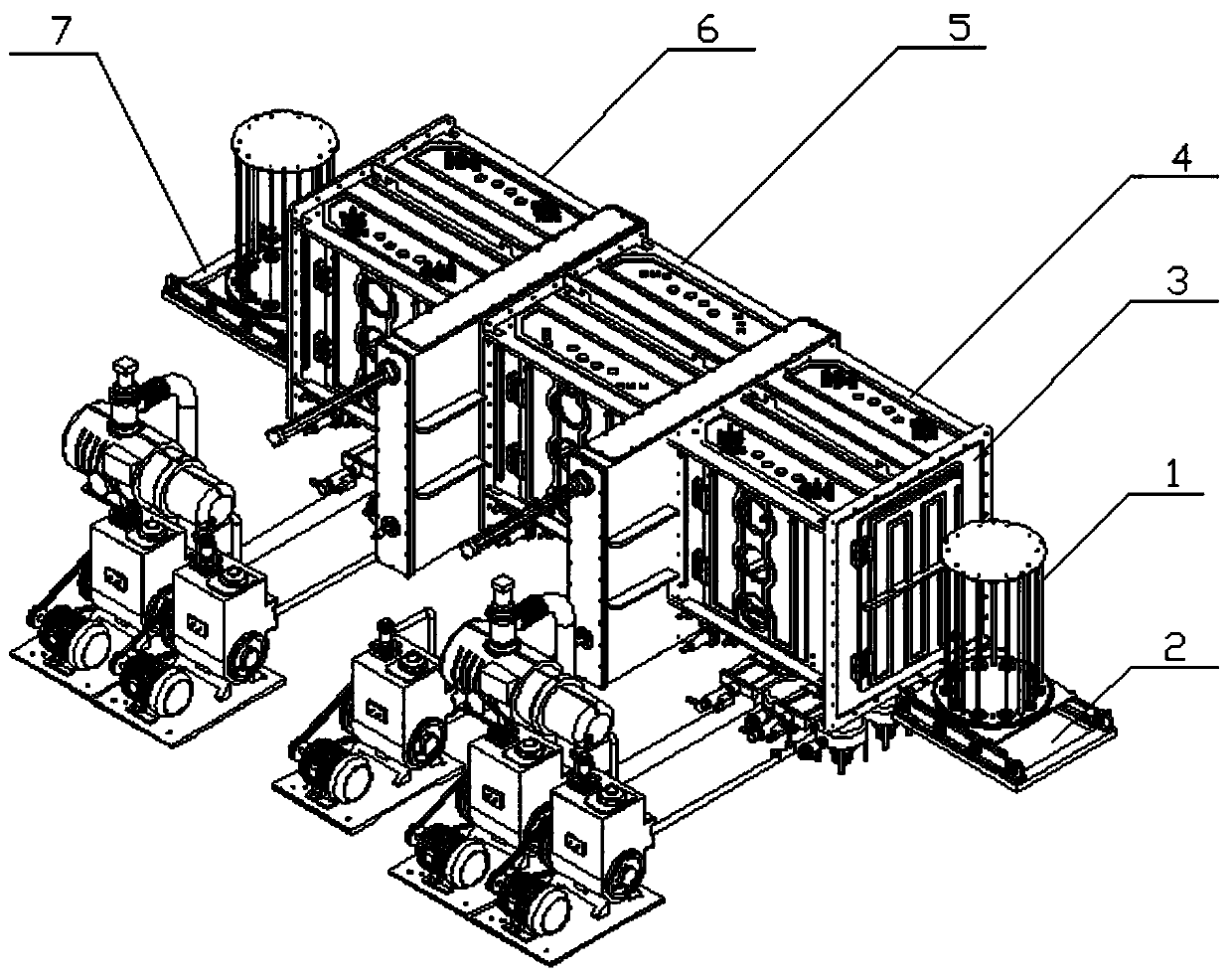

Magnetron sputtering coating production line for capacitive touch screens

ActiveCN102943243AImprove transmission stabilityEffective partitionVacuum evaporation coatingSputtering coatingProduction lineProcess engineering

The invention discloses a magnetron sputtering coating production line for capacitive touch screens. The magnetron sputtering coating production line comprises a vacuum coating cavity and a plurality of cavity supports, the vacuum coating cavity is arranged on the plurality of cavity supports, and an inner conveyer system is arranged inside the vacuum coating cavity. The vacuum coating cavity is sequentially divided into an inlet vacuum section, an inlet buffering vacuum section, an inlet transition vacuum section, a process coating vacuum section, an outlet transition vacuum section, an outlet buffering vacuum section and an outlet vacuum section. Each section is provided with an air sucking system respectively. The vacuum cavity is partitioned through gate valves, effective separation can be achieved, and process gas is stabilized. A conveying system adopts magnetic steering and is good in stability. The magnetron sputtering coating production line achieves continuous mass production of the capacitive touch screens and is high in production efficiency.

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

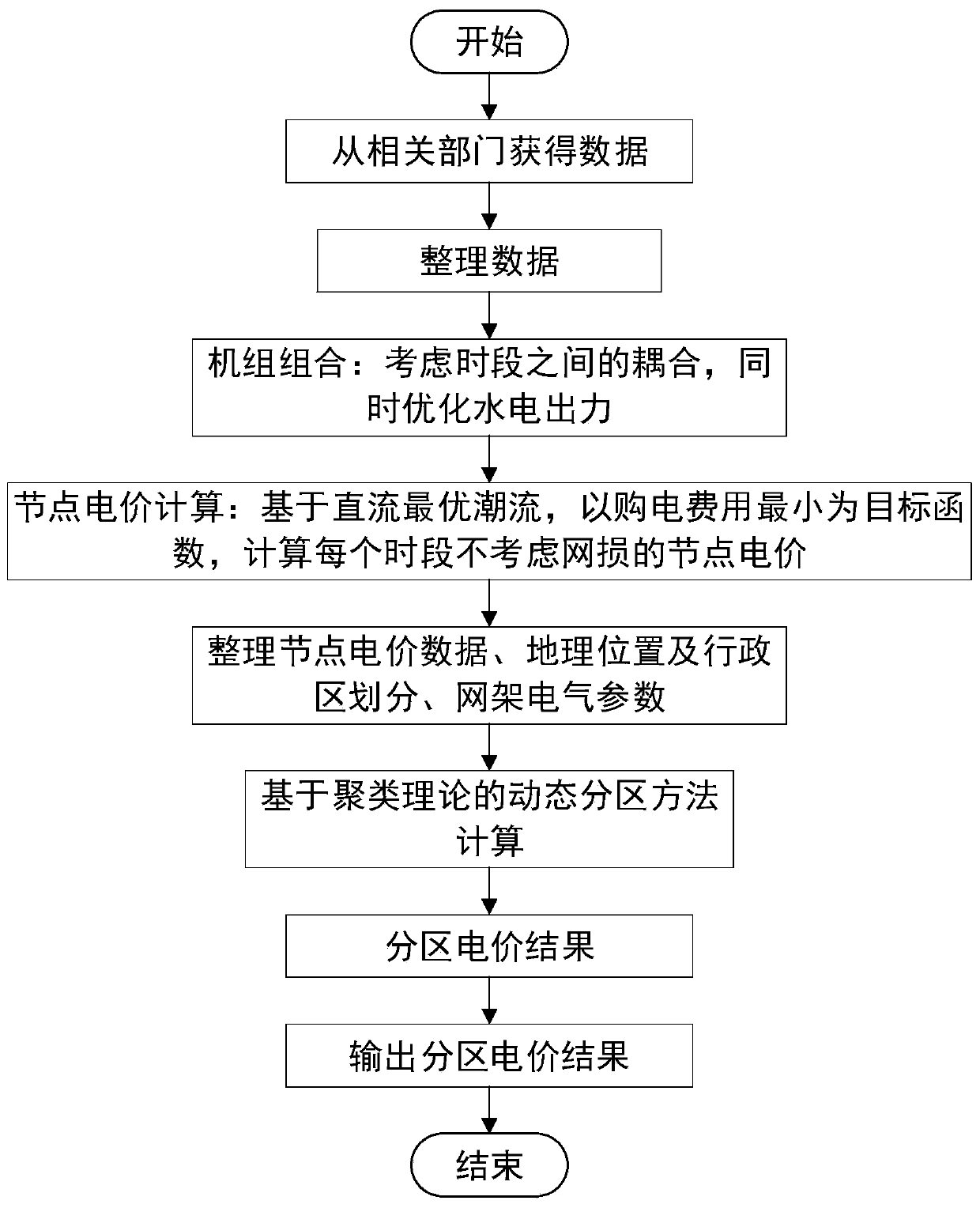

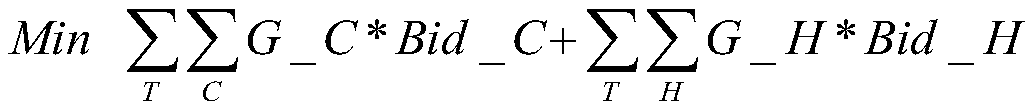

A dynamic partition electricity price calculation method based on partition clustering analysis

ActiveCN109886836AHigh transparencyImprove predictabilityData processing applicationsCharacter and pattern recognitionCluster algorithmElectricity price

The invention discloses a dynamic partition electricity price calculation method based on partition clustering analysis. The method comprises constructing a direct-current optimal power flow optimization target, determining a power system operation constraint condition, solving to obtain optimized hydroelectric output, and then solving node electricity price, conventional unit and new energy unitoutput, power flow data, an active dual factor and node injection power; generating an effective clustering attribute; determining an optimal clustering number; generating a dissimilarity matrix through standardization processing and a Euclidean distance method, and dividing a clustering algorithm to realize clustering; dividing each electricity price area according to the clustering result, and finally determining the unified pricing of each area; feeding back a calculation result of the regional electricity price, and carrying out settlement on market participants in each region according tothe regional electricity price. According to the invention, the electricity price of each subarea can be determined, and finally, each node in the same area is settled in a unified pricing manner, sothat the practical operability is improved, and the demand of obtaining relatively stable price by most users is met.

Owner:XI AN JIAOTONG UNIV

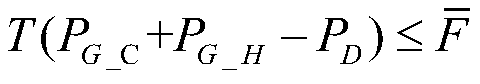

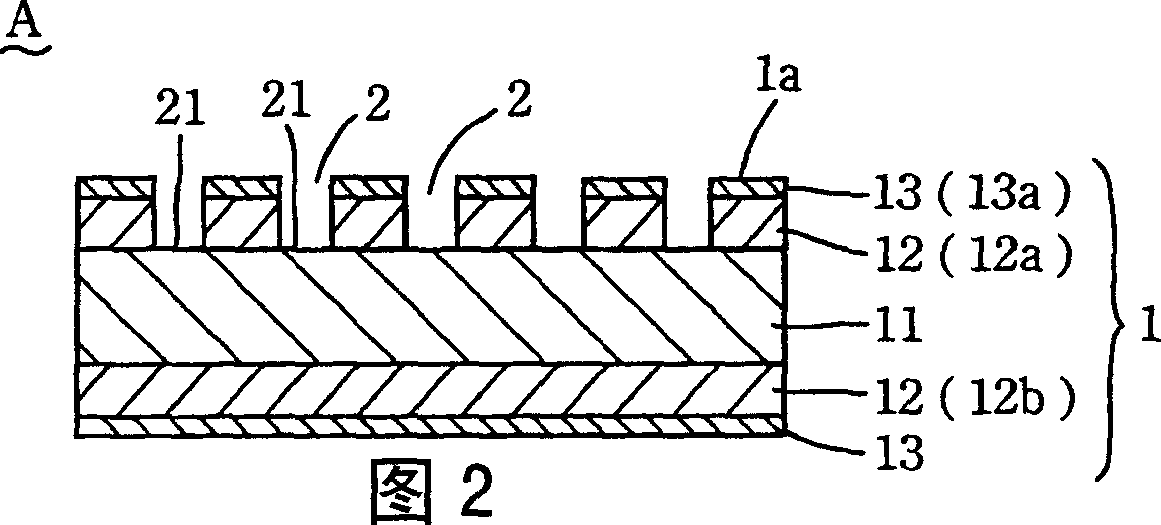

Foam sheet for interior material of automobile and interior material of automobile

InactiveCN1833272AImprove sound absorptionValid conversionSound producing devicesThermal energyEther

A foam sheet for an interior material of an automobile formable in a specified shape while maintaining excellent sound absorbing performance, characterized in that hole parts opening to the surface thereof are formed in one surface of a denatured polyphenylene ether-based resin foam sheet with a continuous bubble fraction of 50% or higher. Thus, the foam sheet can develop excellent sound absorbing performance by smoothly guiding sound vibration energy to the continuous bubbles in the foam sheet (1) through the hole parts to vibrate the bubble walls of the continuous bubbles so as to transform the vibration energy into thermal energy.

Owner:SEKISUI PLASTICS CO LTD +1

Bone conduction receiver with air conduction

ActiveCN103167390BReduce vibration amplitudeHigh outputEarpiece/earphone attachmentsDeaf-aid setsSound transmission classEngineering

The invention discloses a bone conduction receiver with an air conduction effect. The bone conduction receiver comprises a shell, a vibrating diaphragm assembly, a conduction rod, an electromagnetic conversion device and a micro circuit board, wherein at least one through hole is formed on the shell; and at least one opening and closing device or a sound transmission tube of at least one sound transmission hole opening and closing device is arranged on the through hole. Moreover, the opening and closing device or the sound transmission hole opening and closing device comprises at least one cover plate, wherein the cover plate covers the through hole or a sound transmission hole of the sound transmission tube and is rotationally connected with the shell or the sound transmission tube. The application range of the bone conduction receiver can be enlarged, so that the listening of hearing handicapped is enriched, and the life of the hearing handicapped is also enriched; and the bone conduction receiver can be used for persons with normal hearing besides the hearing handicapped.

Owner:SUZHOU YICHUAN TECH CO LTD

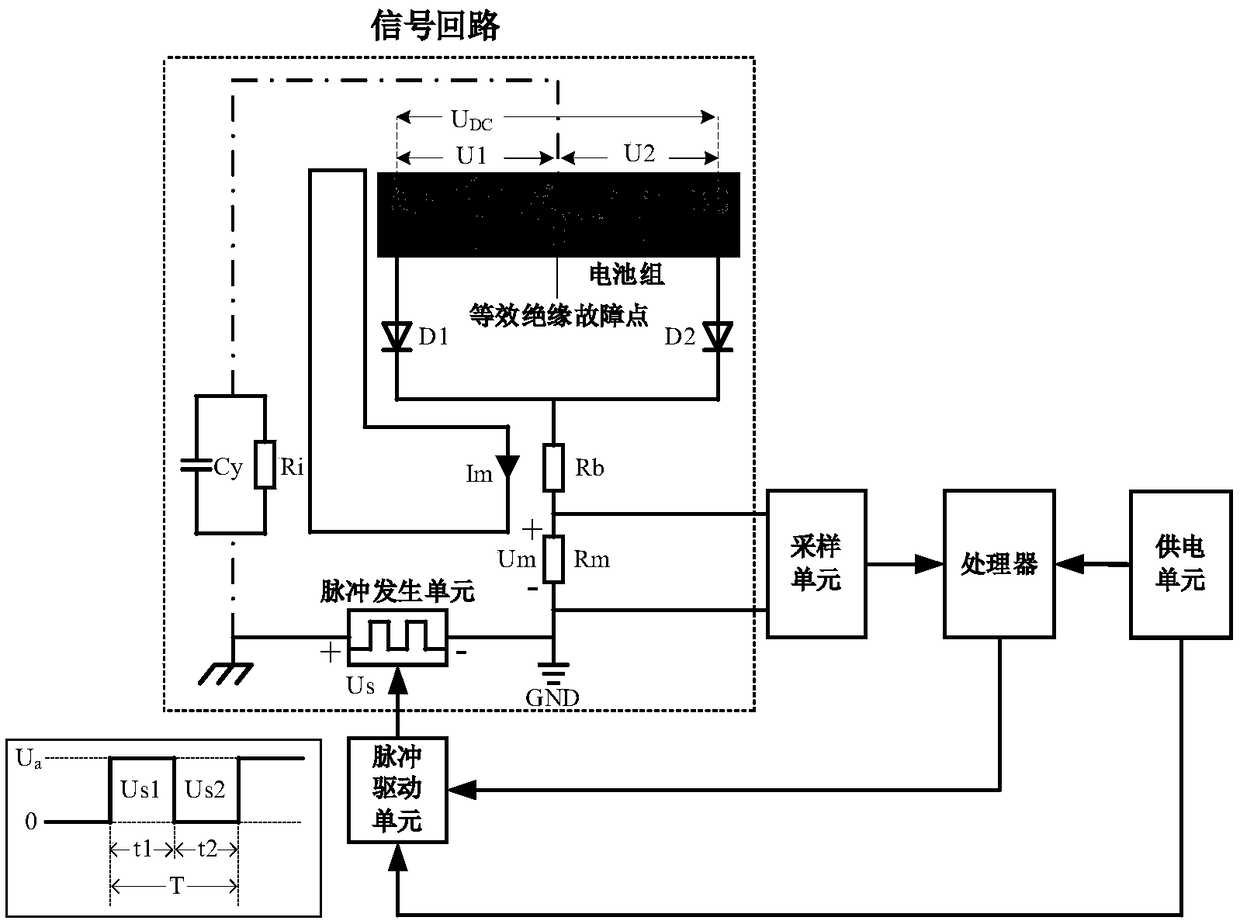

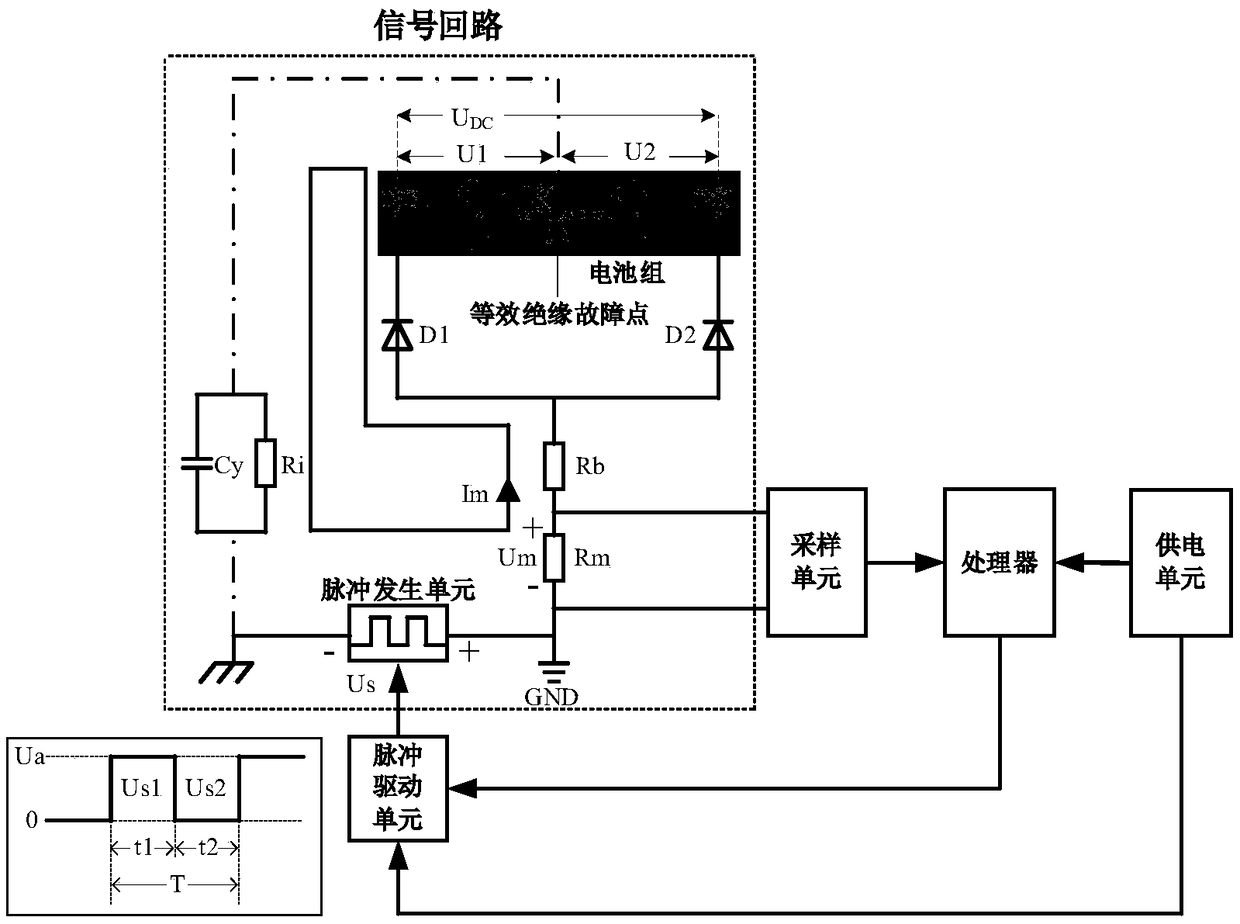

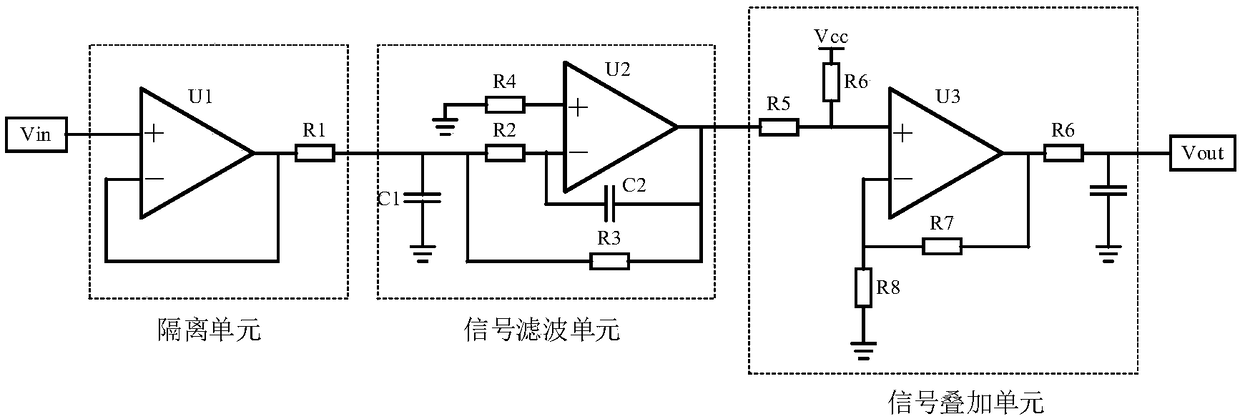

Electric-vehicle battery pack direct-current ground-insulation resistance detection device and method

InactiveCN109324231AGuaranteed safe operationImprove detection accuracyImpedence measurementsAutomotive batteryEngineering

The invention discloses an electric-vehicle battery pack direct-current ground-insulation resistance detection device and method, which are used for detection of a ground-insulation resistance value of an electric-vehicle high-voltage system. The device and the method include a signal loop, a pulse generation unit, a drive unit, a sampling unit, a processor and the like. The pulse generation unitgenerates a current, the current flows through a measured insulation resistor into a battery pack, and then flows through diodes, a current limiting resistor and a sampling resistor to return to the pulse generation unit, and a current loop is constructed. The sampling unit collects a voltage value on the sampling resistor, and carries out signal processing. The processor outputs a pulse drive signal, and the pulse signal is formed by chopping on a driving power source; and at the same time, the processor receives a voltage signal of the sampling unit for analog / digital conversion, and finallycalculates equivalent resistance of the battery pack to the ground through the voltage value of sampling. The method and the device can realize detection of a ground-insulation resistance value of any position inside the battery pack and fault position locking without impacts on a vehicle body system.

Owner:苏州共元自控技术有限公司

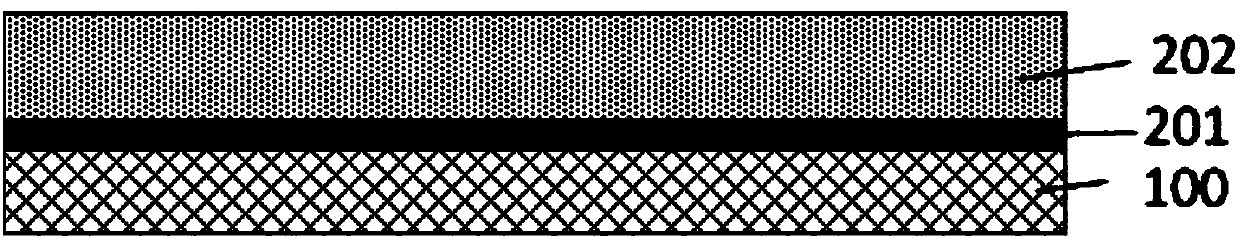

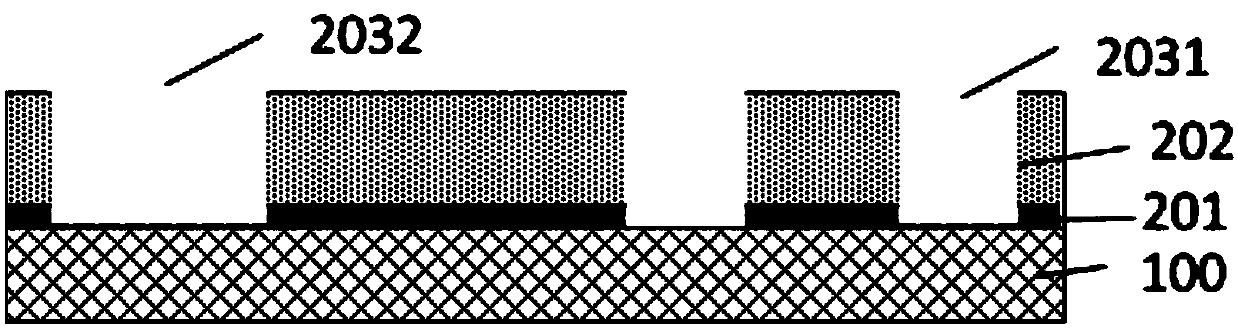

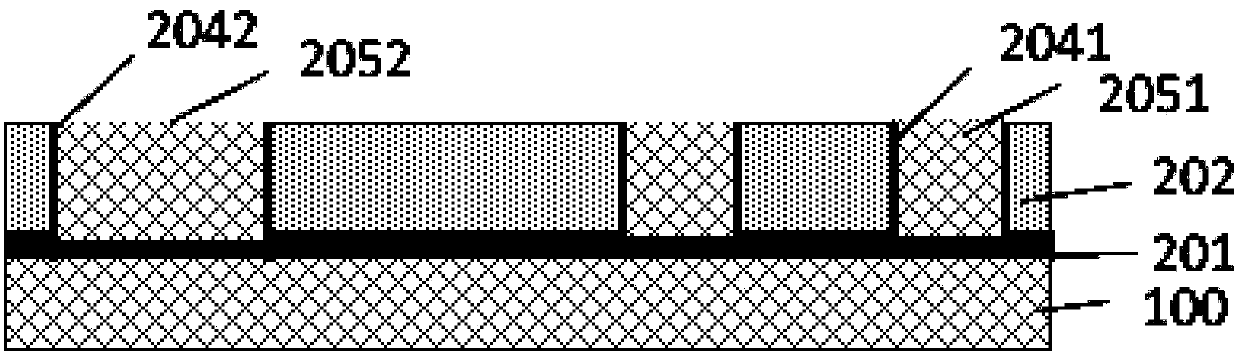

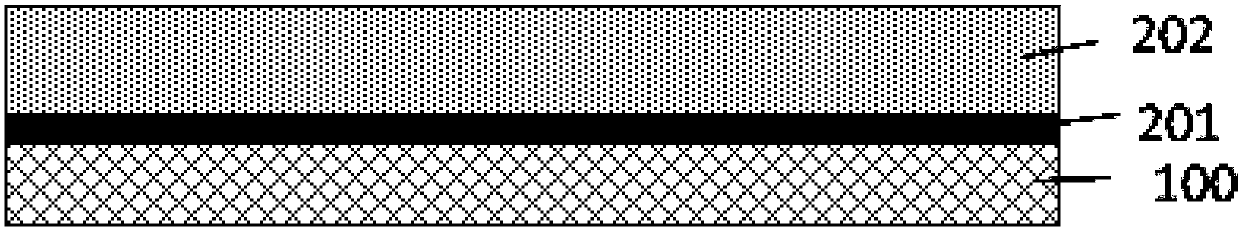

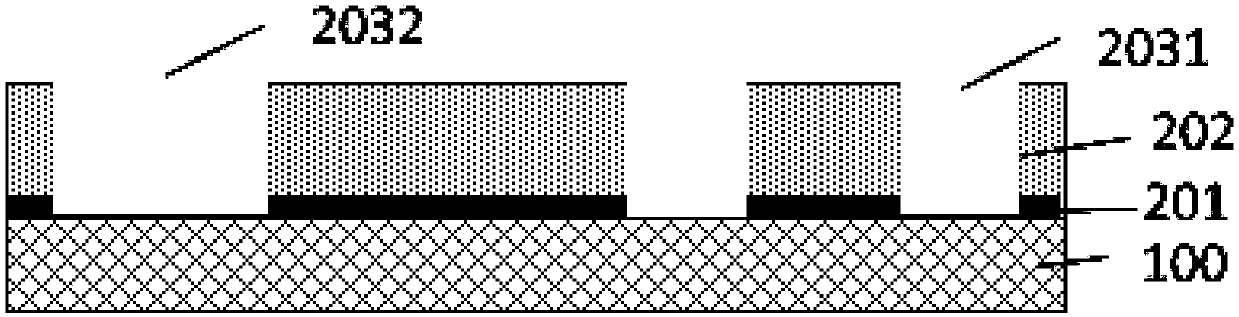

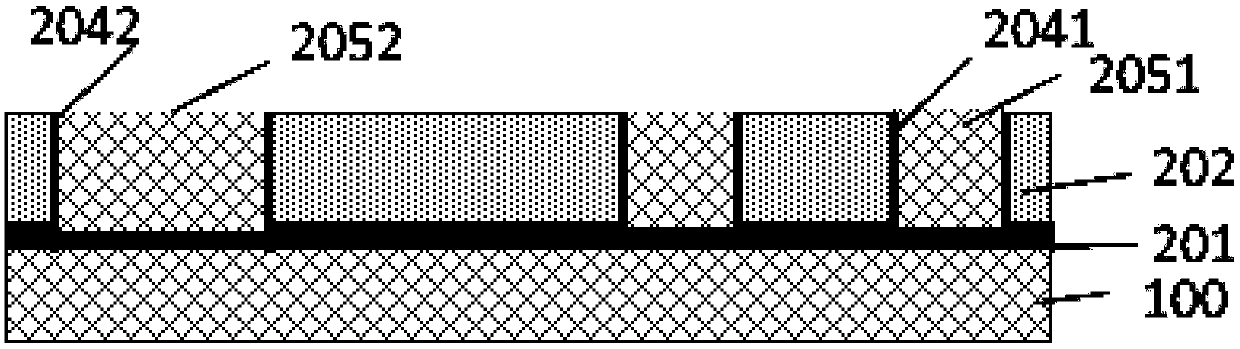

Manufacturing method of magnetic radom access memory unit array and peripheral circuit connecting wires

InactiveCN109545957AImproved magnetic/electrical propertiesEffective partitionSolid-state devicesGalvano-magnetic device manufacture/treatmentCMOSElectrical performance

The invention provides a manufacturing method of a magnetic radom access memory unit array and peripheral circuit connecting wires. The manufacturing method comprises the steps of: (1) providing a surface-polished CMOS substrate with metal connecting wires, forming bottom electrode vias in the substrate, then filling the bottom electrode vias with non-copper metal and grinding the surface of the metal to be flat; (2) making memory region bottom electrode contact manufacturing a magnetic tunnel junction array on the bottom electrode vias in a memory region, and making logic region bottom electrode contact on the bottom electrode vias in a logic region; (3) and forming top electrode vias, and manufacturing metal connecting wires realizing connection with a logic / memory unit. Thus, a bottom electrode contact metal film and a magnetic tunnel junction multilayer film can be deposited at one time, thereby being conductive to improving the magnetic / electrical performance of the magnetic radomaccess memory, simplifying the complexity of the process and reducing the manufacturing cost.

Owner:SHANGHAI CIYU INFORMATION TECH

Method for manufacturing magnetic random access memory cell array and peripheral circuit connection line

InactiveCN109713119AEffective partitionImprove electrical performanceSolid-state devicesGalvano-magnetic device detailsCMOSRandom access memory

The invention provides a method for manufacturing a magnetic random access memory cell array and a peripheral circuit connection line, comprising the steps of: (1) providing a surface-polished CMOS substrate having a metal connection line, fabricating a bottom electrode via on the substrate, and then filling the bottom electrode via with metal copper; (2) depositing a bottom electrode contact anda magnetic tunnel junction multilayer film on the bottom electrode via, fabricating a memory region bottom electrode contact and a magnetic tunnel junction memory cell array, and fabricating a logic region bottom electrode contact and a dummy magnetic tunnel junction (dummy-MTJ) unit; (3) fabricating a dummy magnetic tunnel junction opening in a logic region; and (4) fabricating a top electrode via and a copper metal connection line connecting the logic unit with the memory unit. A layer of bottom electrode contact is added under the magnetic tunnel junction so as to avoid the direct adjacencyof a CMOS back-end copper via and the etching process in the fabrication of the magnetic tunnel junction array, which is beneficial to the improvement in the electrical performance and yield of the devices.

Owner:SHANGHAI CIYU INFORMATION TECH CO LTD

Tunneling method of slurry shield passing through anchor cable zone in long distance

A tunneling method of a slurry shield passing through an anchor cable zone in a long distance comprises the following steps that 1, reinforcing is conducted on soil masses within the range of 5 m-6 mon the two sides of the central line of a to-be-excavated tunnel; 2, drilling and anchor distributing are conducted on the reinforcing areas; 3, a manual gate valve is mounted between a quarrying boxof a shield mechanism and a slurry discharging gate valve of a soil bin; 4, the quarrying box of the shield mechanism is transformed; 5, a slurry parameter used by the shield mechanism is set; and 6,a shield tunneling parameter is set, till excavation of a designed shield route is completed, and construction is ended. The tunneling method solves the technical problems that a slurry discharging pipe and the quarrying box are clamped deadly or blocked by an anchor cable, a cutter disc is wound, the aperture ratio of the cutter disc is decreased, and a cutter tool is damaged in the long distanceanchor cable zone passing through construction process of a traditional slurry shield.

Owner:CHINA CONSTR COMM ENG GRP UNITED

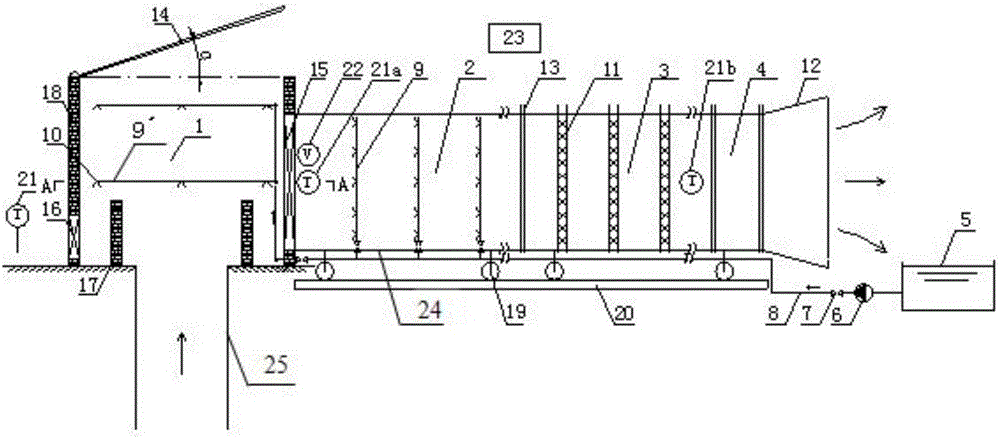

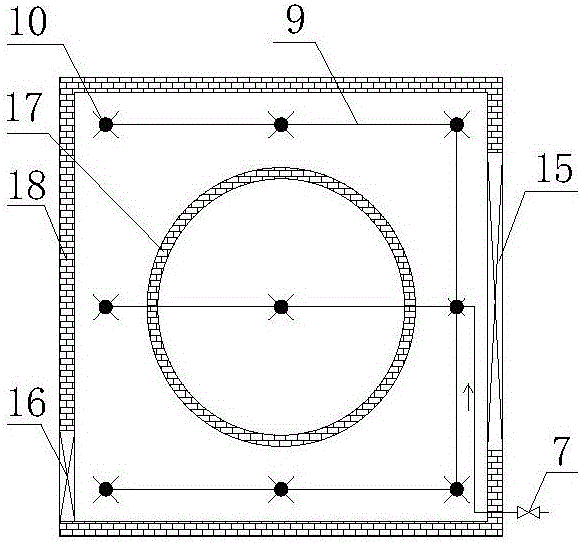

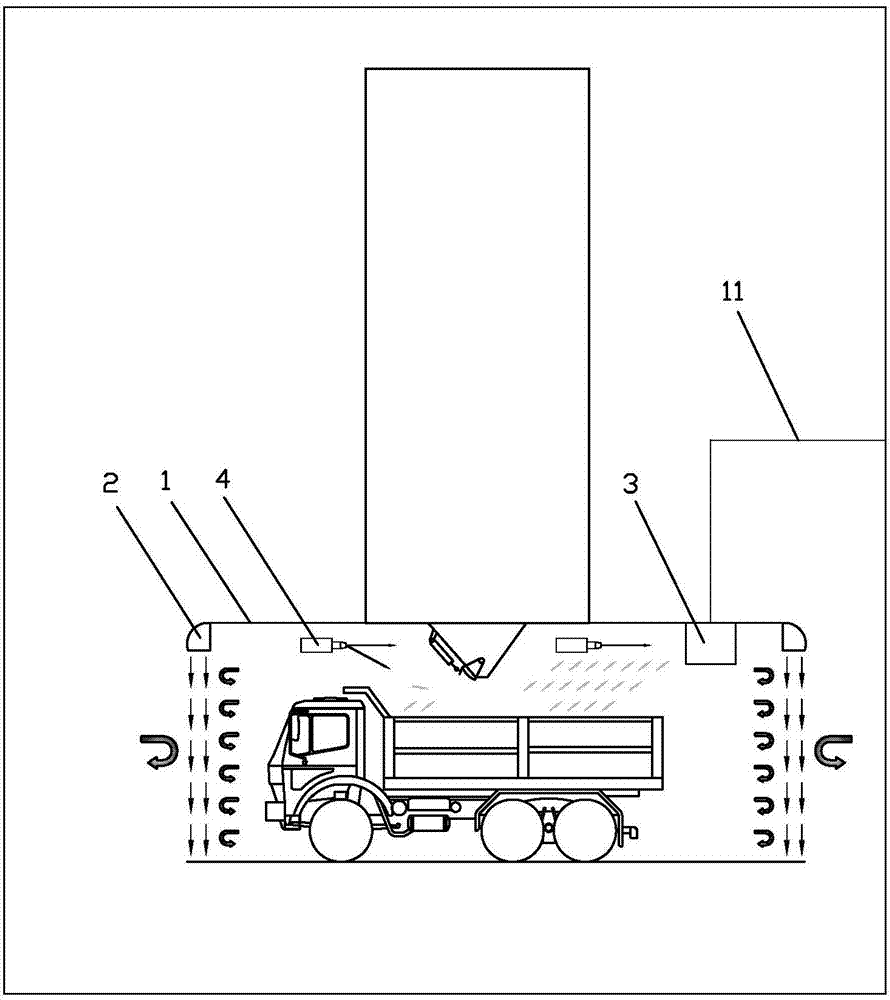

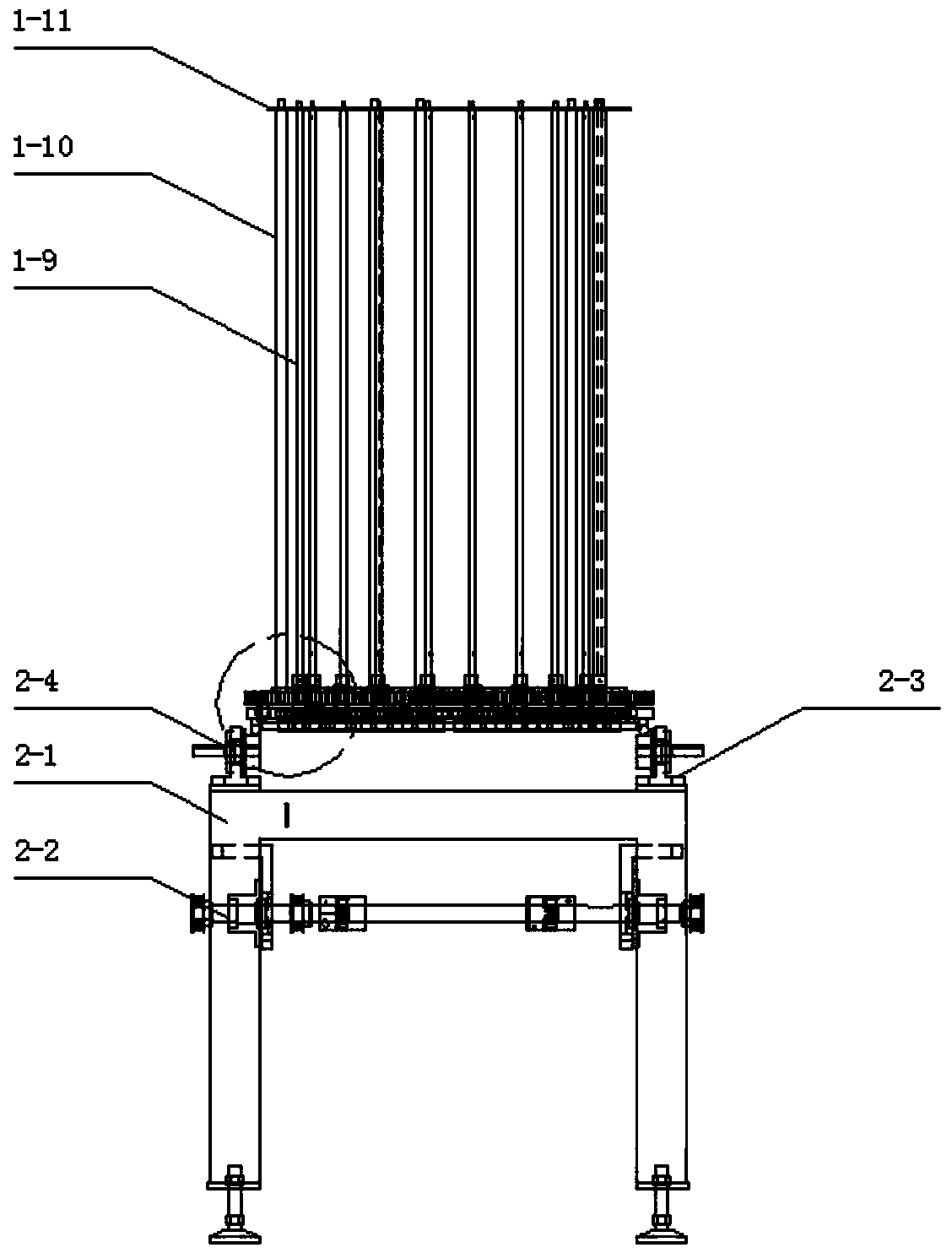

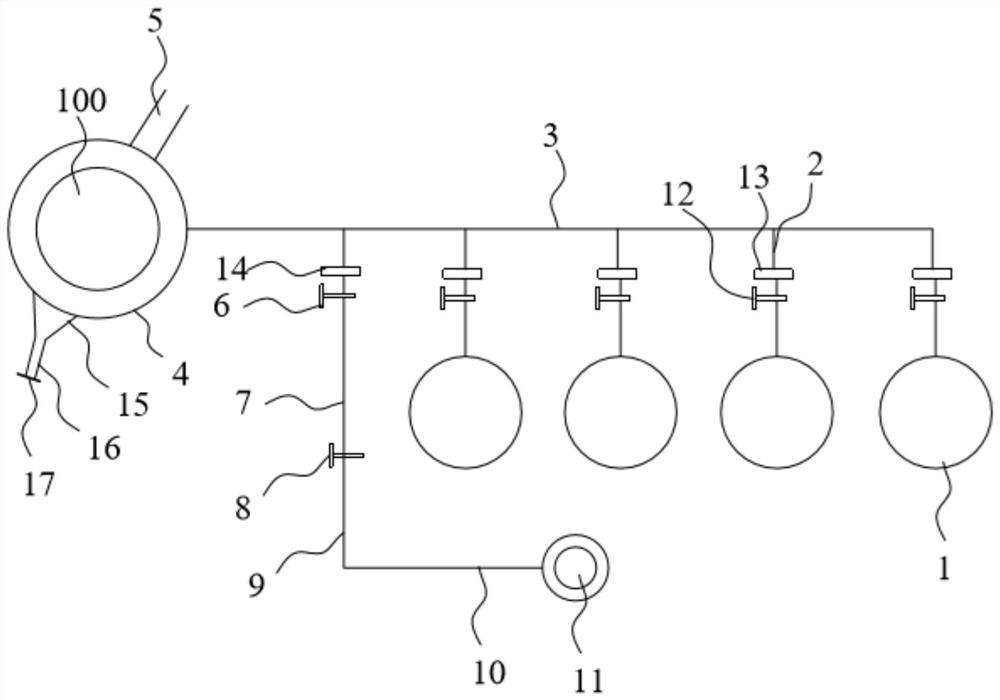

Dehumidification method capable of eliminating white smoke phenomena at return air shaft mouths

ActiveCN106823703AFull pre-cooling and coolingSufficient pre-cooling and cooling of hot air and atomizationGas treatmentDispersed particle separationAtmospheric temperatureEngineering

The invention discloses a dehumidification method capable of eliminating white smoke phenomena at return air shaft mouths. The dehumidification method is implemented by a high-temperature saturated wind current dehumidification device. The high-temperature saturated wind current dehumidification device comprises a confluence zone (1), an atomization zone (2), a dehumidification zone (3), a current discharge zone (4), rollers (19) and a guide rail (20). A cover plate (14) is mounted on the top of the confluence zone (1), an electric gate (15) is mounted on a side surface of the confluence zone (1), and an atmosphere temperature sensor (21) is mounted outside the confluence zone (1); a hot-air temperature sensor (21a) and a wind speed sensor (22) are mounted at an inlet of the atomization zone (2); the dehumidification zone (3) is provided with filter screens (11), and a dehumidified air temperature sensor (21b) is mounted at an outlet of the dehumidification zone (3); the cover plate (14), the electric gate (15), an electric valve (7) and a spray pump (6) are controlled by a PLC (programmable logic control) system (23). The dehumidification method has the advantages of structure optimization, sufficient atomization, high defogging efficiency and low ventilation energy consumption. Besides, dehumidification can be carried out as needed according to requirements of change of wind temperatures and wind volumes.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

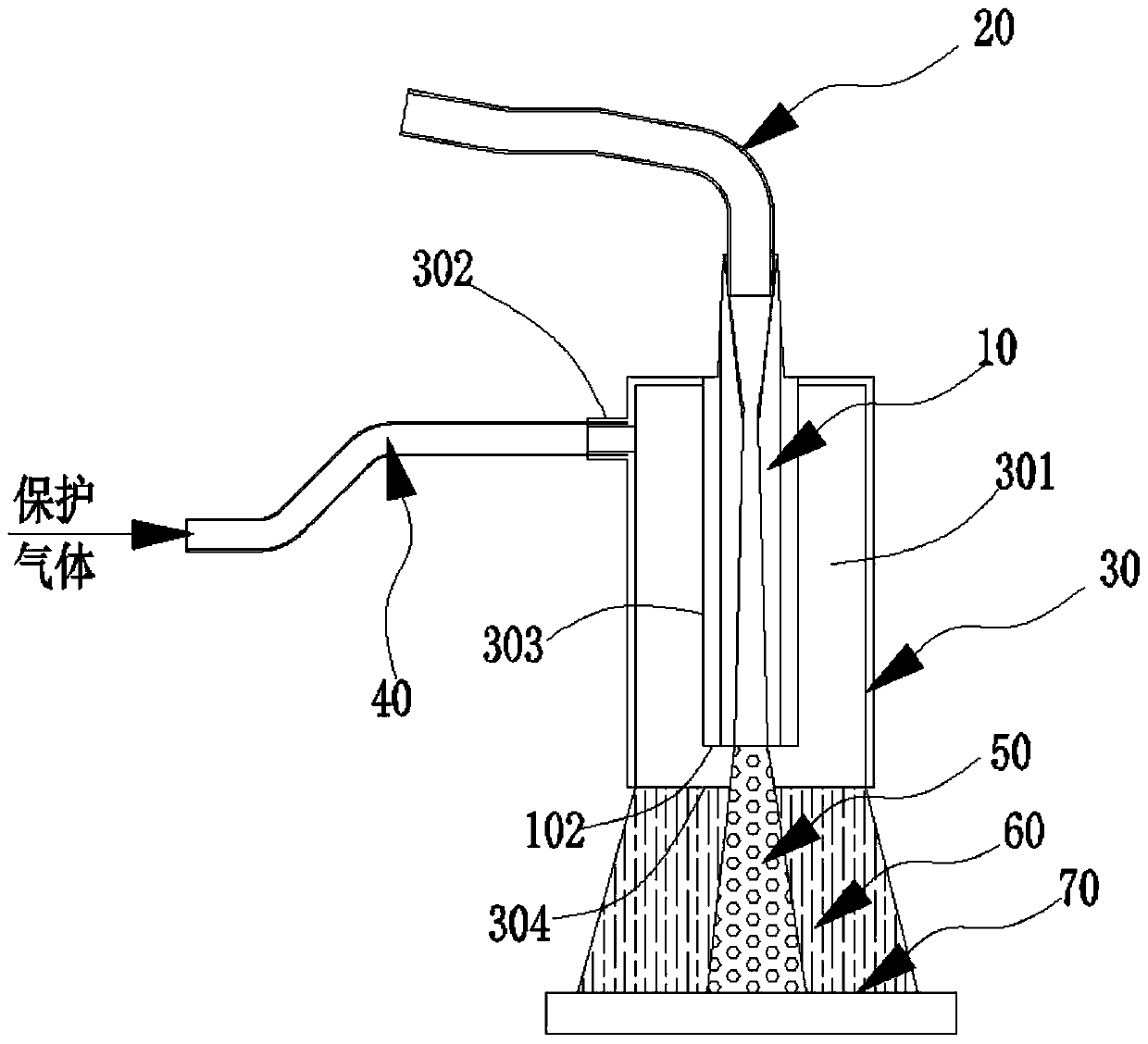

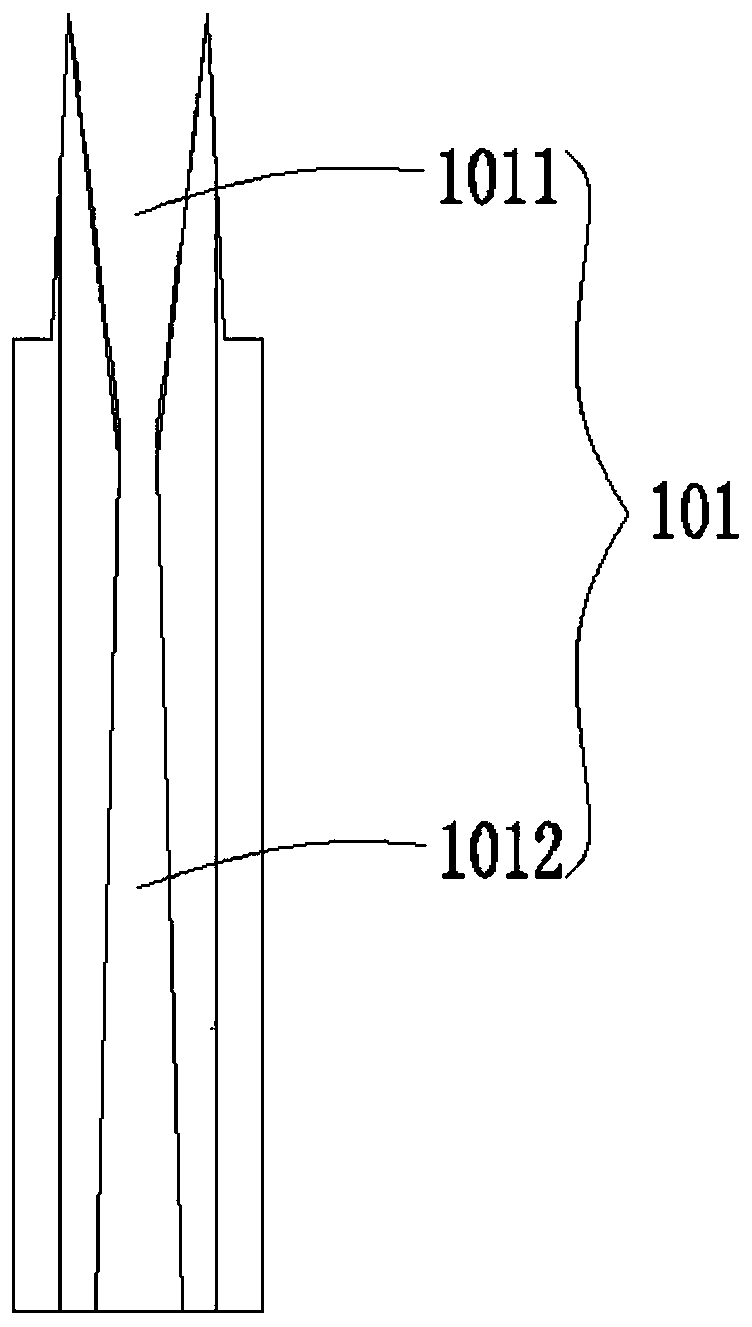

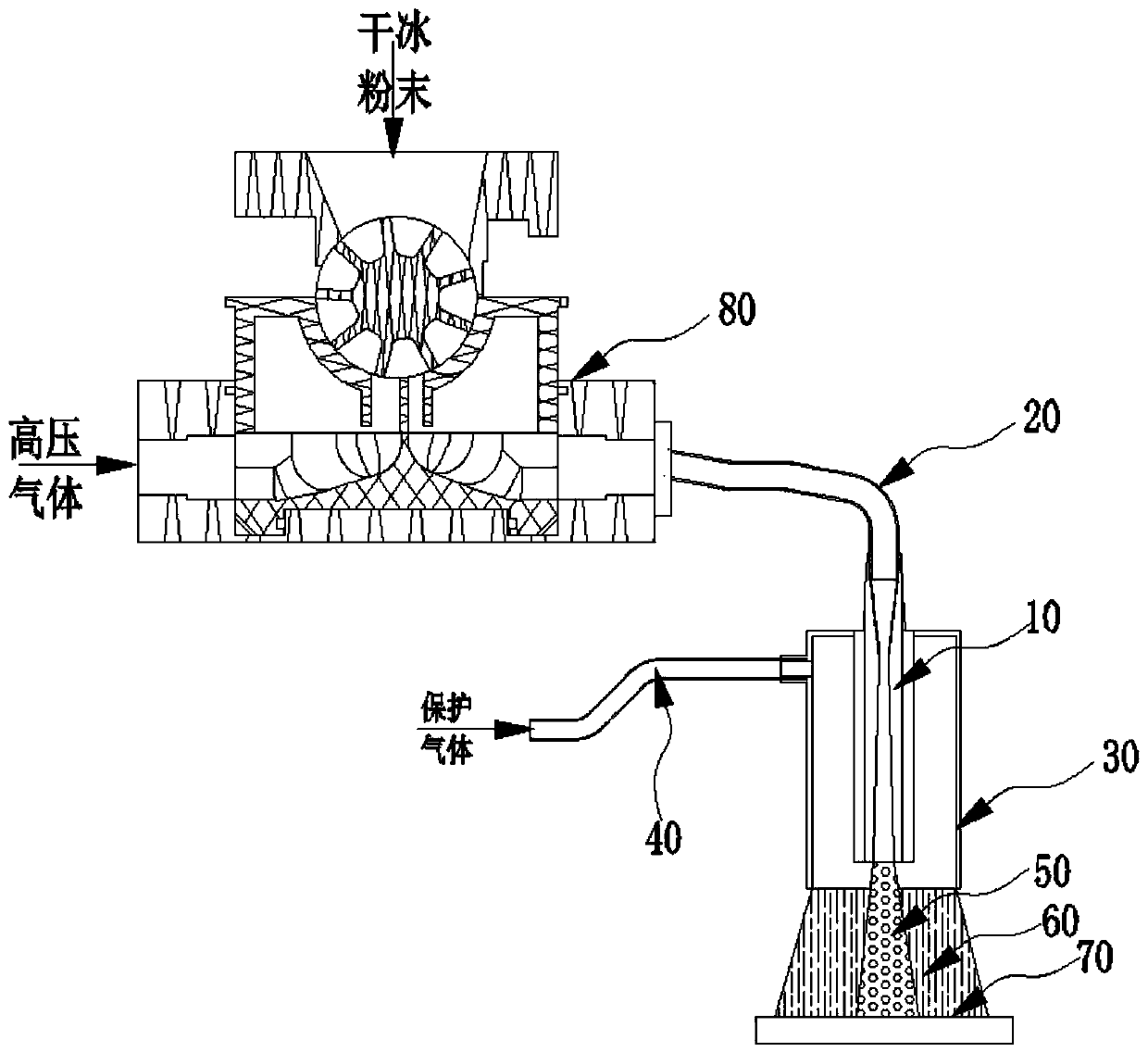

Dry ice cleaning spray nozzle, dry ice cleaner and secondary pollution preventing dry ice cleaning method

PendingCN110369403AAvoid contactSolve the problem of condensation foggingCleaning using gasesPollutantDry ice

The invention discloses a dry ice cleaning spray nozzle, a dry ice cleaner and a secondary pollution preventing dry ice cleaning method. The dry ice cleaning spray nozzle comprises a spray nozzle mainbody, and a gas curtain spray nozzle, wherein the spray nozzle main body is provided with a structure connecting a dry ice conveying tube and a dry ice gas flow injection channel; the gas curtain spray nozzle surrounds the periphery of the spray nozzle main body, and comprises an inner cavity which surrounds the periphery of the spray nozzle main body and a connecting hole which communicates withthe inner cavity, and is connected to a protective gas source through a protective gas tube; and the gas curtain spray nozzle defines a protective gas curtain which surrounds the periphery of dry icejet flow jetted by the spaying nozzle main body. According to the scheme adopted by the invention, the protective gas curtain formed by protective gas is arranged at the periphery of the dry ice jetflow, and a cleaning surface can be effectively isolated from outside air, so that pollutants such as impurities and water vapor are prevented from being in contact with the cleaning surface; and meanwhile, the cleaned surface is swept through the protective gas curtain, so that the cleaned surface can be dried and can be restored to the room temperature, and therefore, the problem that water vapor is condensed and fogged is solved, protection can be performed throughout the process, and the cleaning effect is guaranteed.

Owner:儒众智能科技(苏州)有限公司

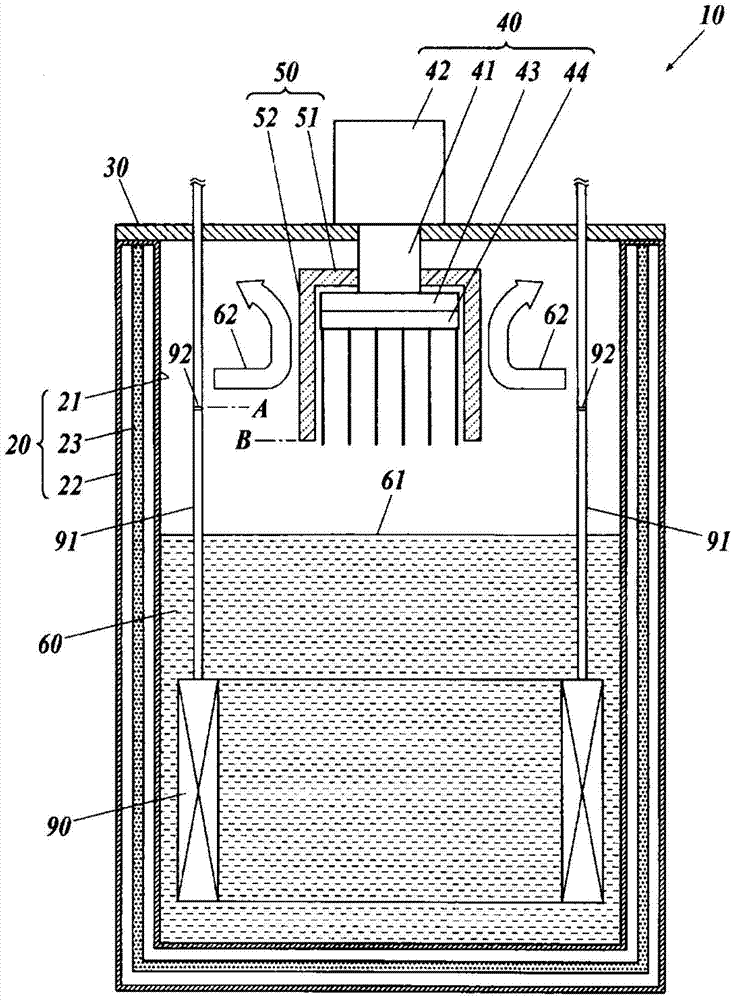

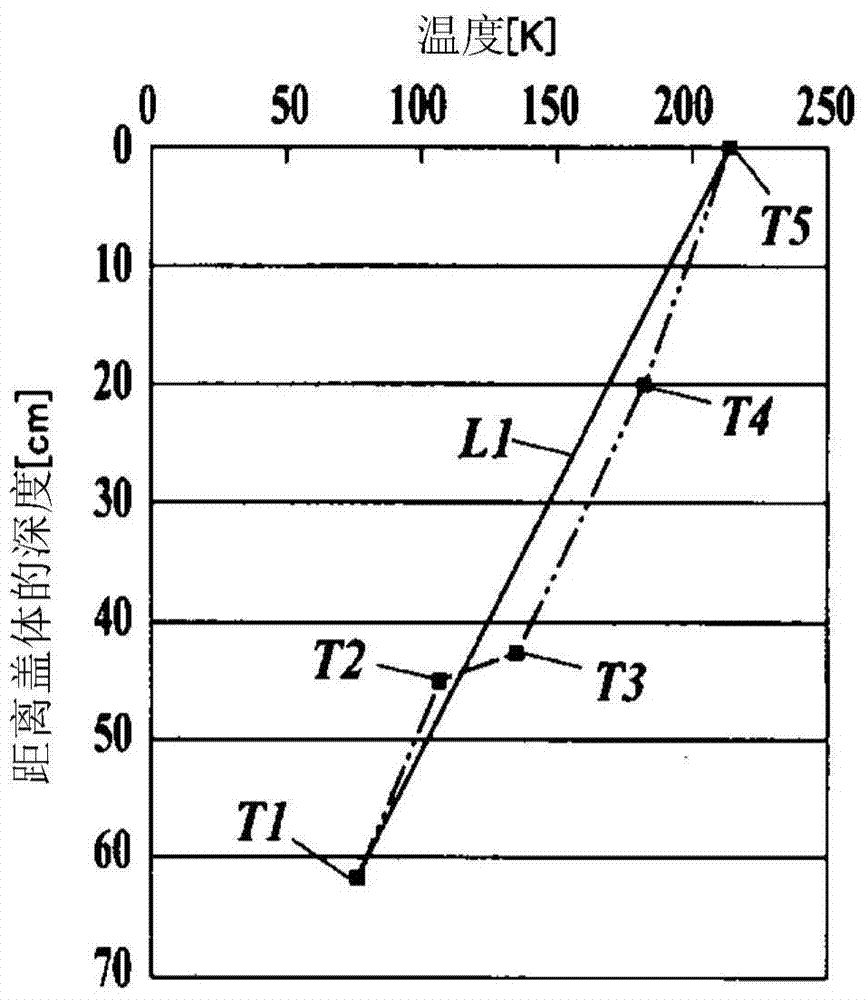

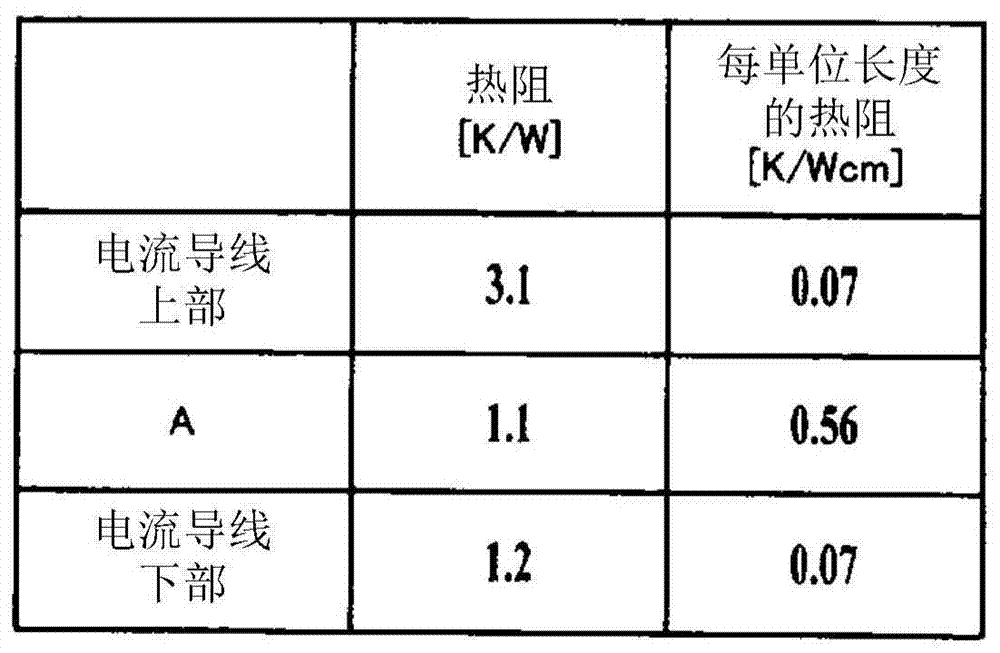

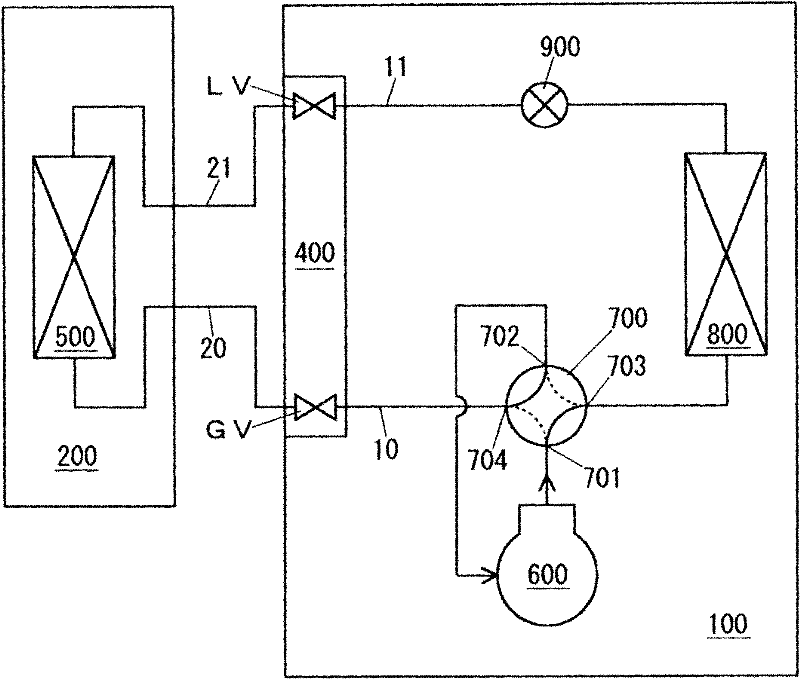

Cooling container

ActiveCN104335375AInhibition of heat intrusionImprove cooling effectSuperconductors/hyperconductorsCompression machinesElectric current flowRefrigerant

A cooling container includes a coolant container (20) for accommodating an object to be cooled (90) and a liquid coolant (60) in the inside, a lid member (30) capable of closing the upper opening of the coolant container, a cooling means (40) hung from and supported by the lid member and having a cooling section at the lower end, and electric current leads (91) hung from and supported by the lid member, for making electric current flow into the object to be cooled inside the coolant container. The electric current leads each have a thermal resistance section (92) having a higher thermal resistance than the surrounding portions, at a position above the liquid surface of the liquid coolant in the coolant container. Between the thermal resistance sections and the cooling section of the cooling means, a partition section (50) made from a heat insulation material is provided such that the lower end of the partition section is below the thermal resistance sections. As a result, the effect of penetrating heat can be prevented to allow the inside of the coolant container to be efficiently cooled.

Owner:FURUKAWA ELECTRIC CO LTD

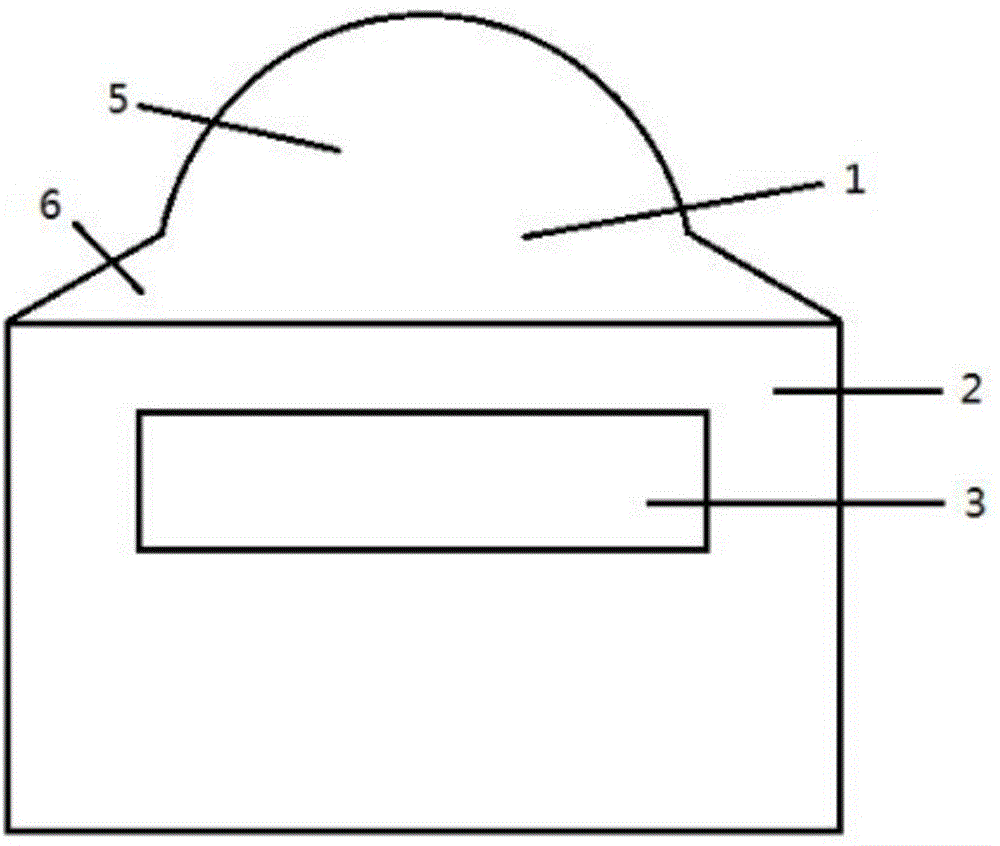

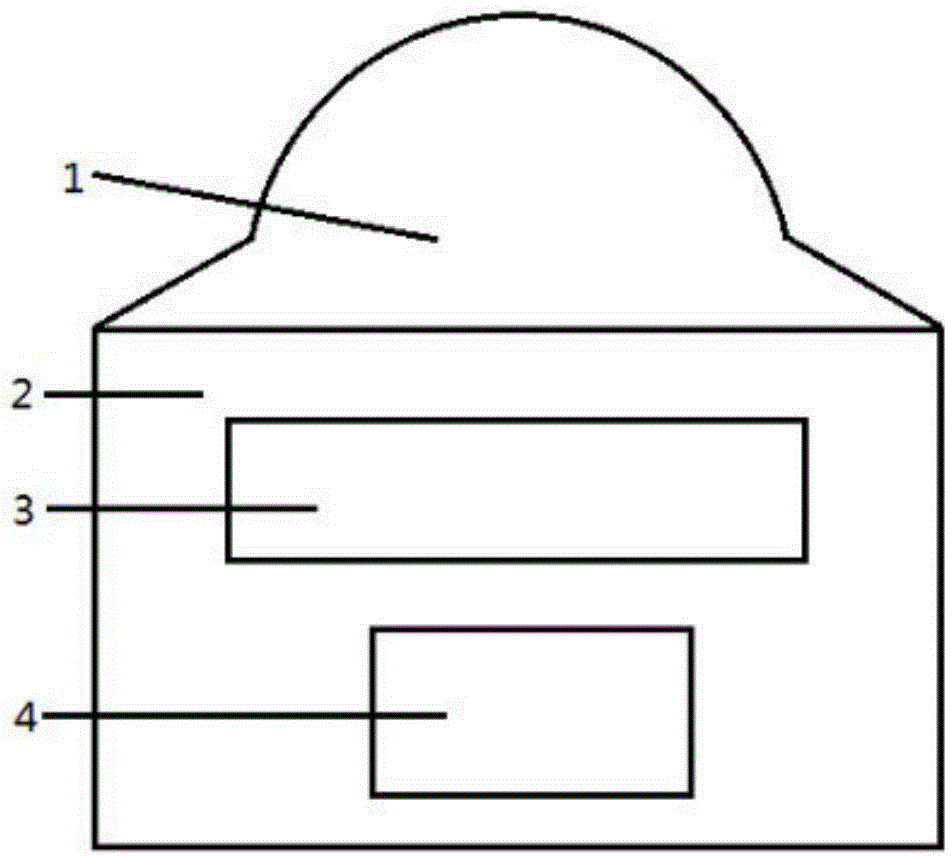

Haze protection cap

The invention discloses a haze protection cap. The haze protection cap comprises a cap body, a cylindrical mask, a transparent viewing window and a waterproof pocket, wherein the cap body comprises a cap crown and a cap brim; the periphery of the cap brim is connected with the cylindrical mask by utilizing a zipper; the transparent viewing window is positioned at the position, close to the cap brim, at the top of the cylindrical mask; the waterproof pocket is arranged at the lower part of the transparent viewing window; soaked water absorption sponge is arranged in the waterproof pocket. The haze protection cap is simple and practical in structure, good in protection effect and capable of completely protecting parts such as the eyes, the ears, the respiratory tract, the skin and the hair of a wearer.

Owner:XUZHOU NORMAL UNIVERSITY

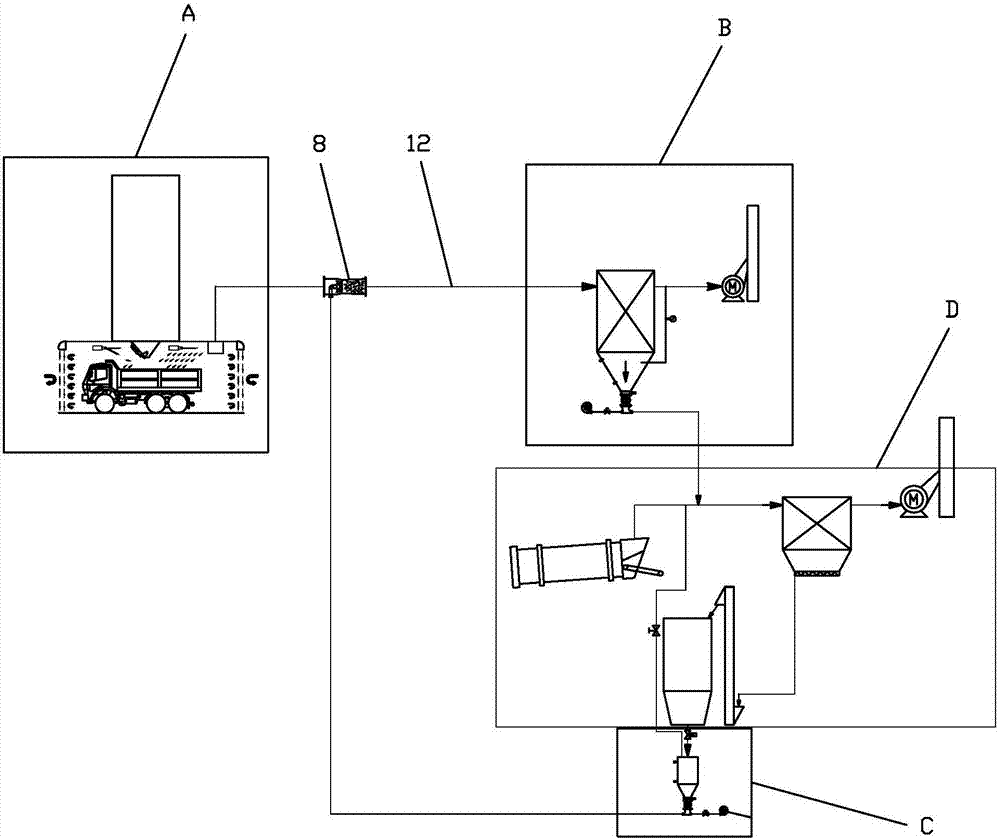

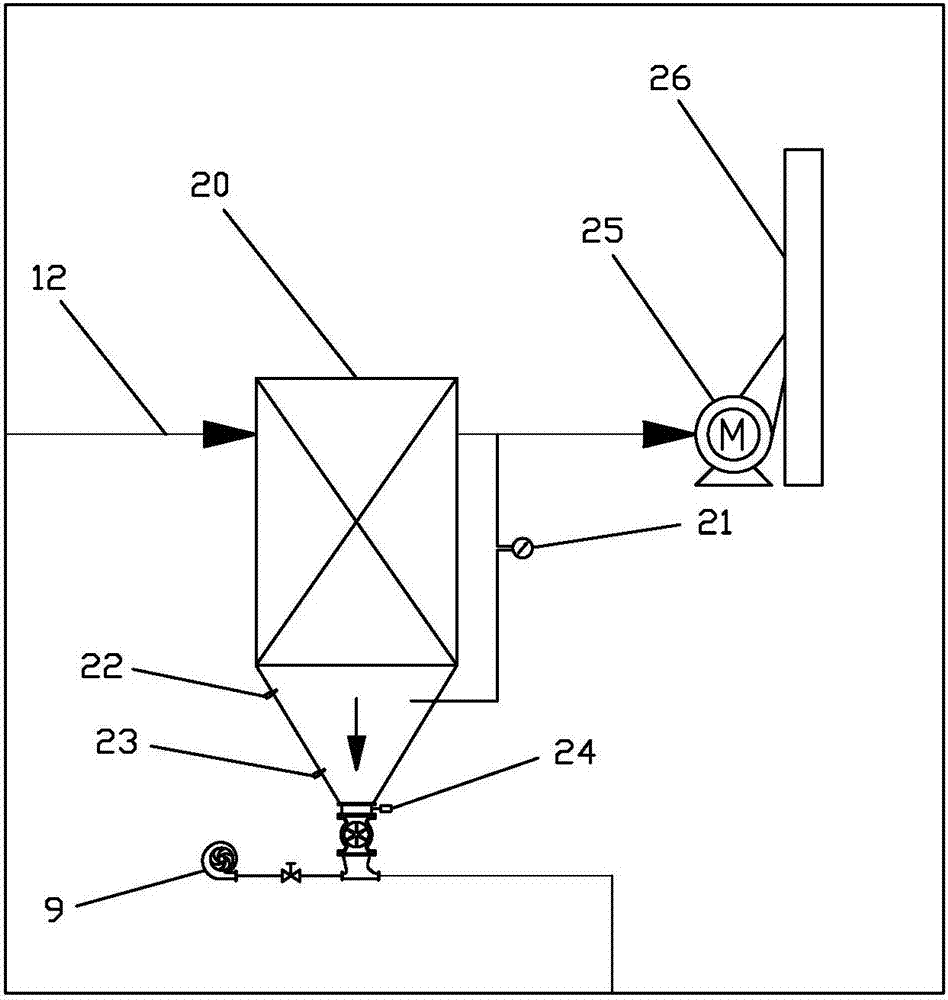

Loading region asphalt smoke adsorption treatment system and treatment method for asphalt agitating plant

PendingCN107243207AEffective partitionPrevent escapeDispersed particle filtrationMembrane filtersDust controlEnvironmental engineering

The invention relates to a loading region asphalt smoke adsorption treatment system for an asphalt agitating plant. The adsorption treatment system comprises a loading region sealing device, an asphalt smoke collection device and an asphalt smoke adsorption device, wherein the asphalt smoke adsorption device comprises an adsorbent temporary storage bin, an adsorbent air transport device, an adsorption mixer, a dedusting system, a waste powder air transport device and an air exhaust system; the adsorbent temporary storage bin is connected with the adsorption mixer through the adsorbent air transport device; the adsorption mixer is connected with the dedusting system through a flue; the dedusting system is connected with an inlet flue of a drying line deduster through the waste powder air transport device; and the adsorbent temporary storage bin is connected with a drying system recovered powder tank of asphalt blending equipment. According to the invention, fine powder recovered by the drying line deduster of the asphalt blending equipment is used as an adsorbent for physical adsorption of asphalt smoke; the recovered powder after oil adsorption can be further used for production of an asphalt mixture; and the whole system is low in air quantity, high in purification efficiency and low in operation cost, and causes no secondary pollution, thereby favorably solving the pollution problem caused by unorganized emission of the asphalt smoke during production of the asphalt agitating plant.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

A Chinese medicinal mask

InactiveCN109171066AHas health functionEffective partitionAntibacterial agentsAntiviralsYarnElectrospun nanofiber

A Chinese herbal medicine mask is composed of a non-woven fabric outer surface layer, a Chinese herbal medicine finishing fabric layer and a non-woven fabric mouth layer arranged from outside to inside successively. The Chinese herbal medicine finishing fabric layer adopts 10-20 [mu]m Chinese herbal medicine particle are prepared by finishing cotton yarn fabric layer; the protective insulation layer is electrospun nanofiber membrane protective insulation layer. The structure can make the mask have the health care function of Chinese herbal medicine, and effectively isolate solid particles in the air, viruses in the air, bacteria, and do not fade in the use or storage process.

Owner:MINJIANG UNIV

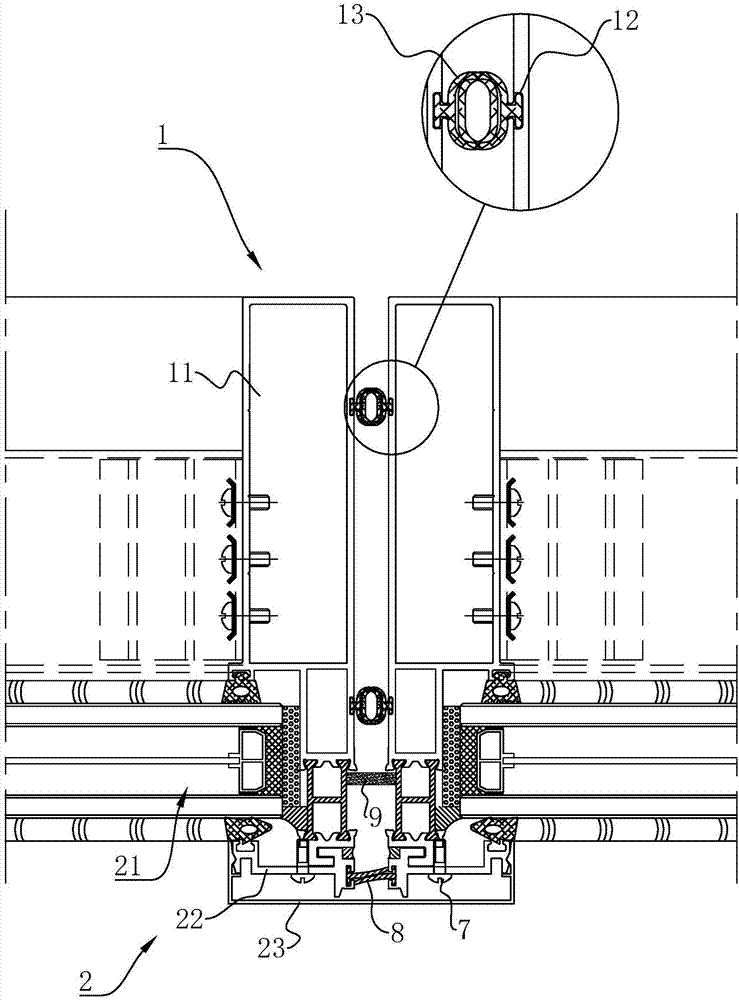

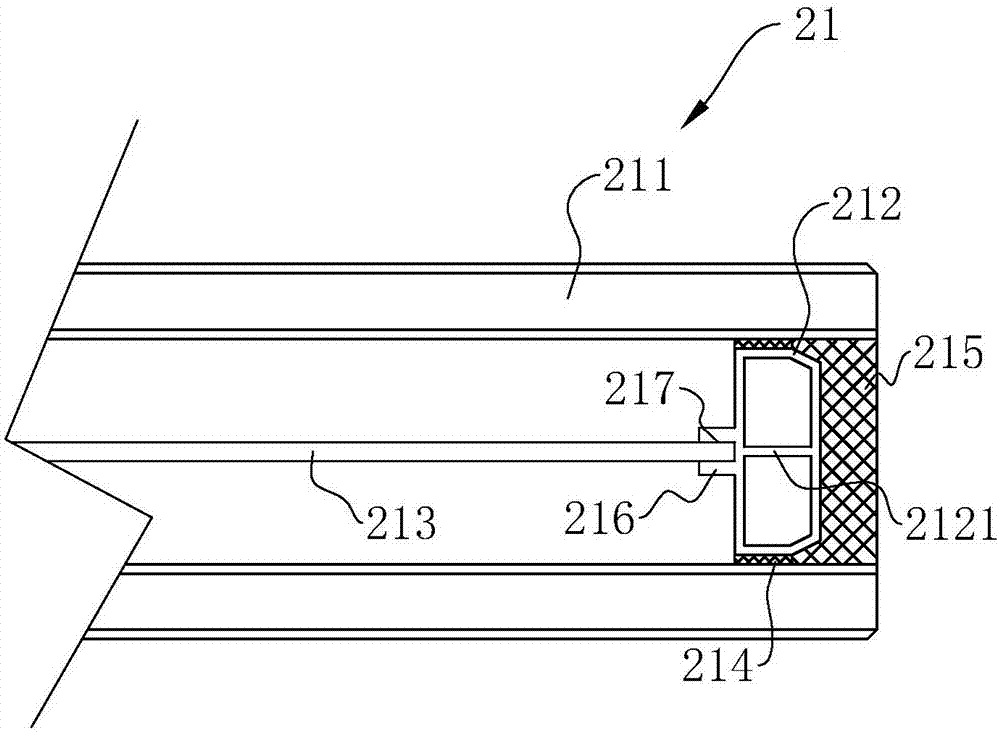

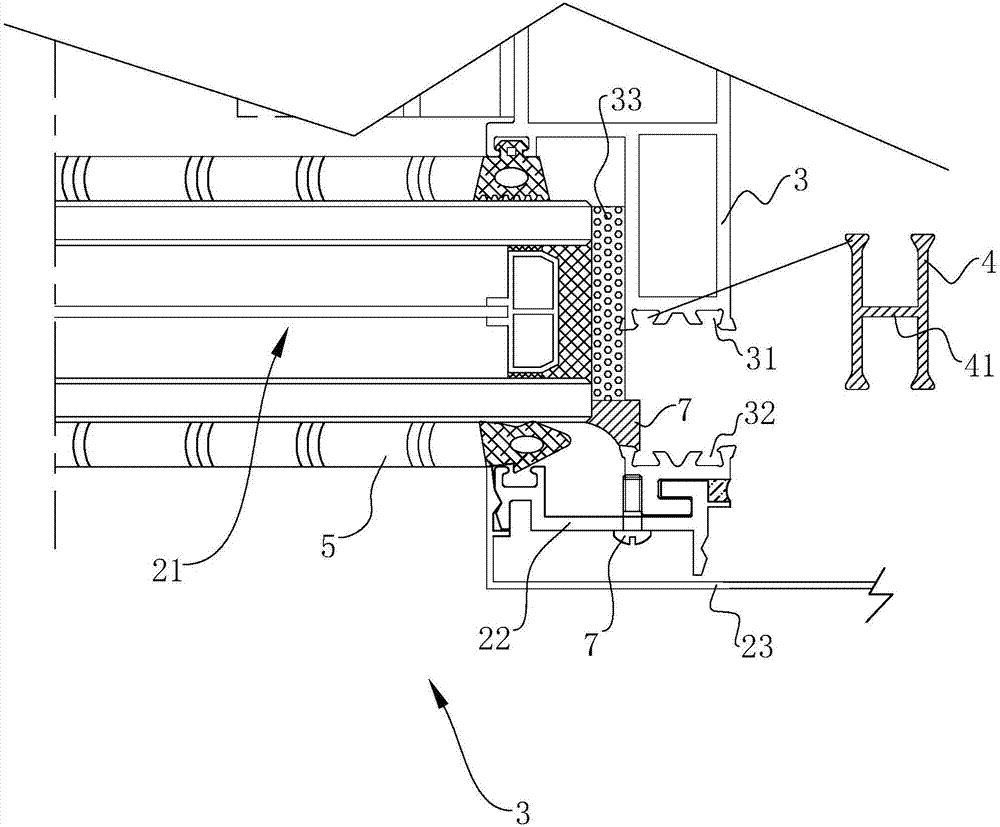

Super heat preservation press connection exposed frame unit body curtain wall system

InactiveCN107035040AGuaranteed insulation performanceEnvironmental protection is goodWallsEngineeringWater block

The invention discloses a curtain wall system of super thermal insulation crimping exposed frame units, which comprises at least two mutually symmetrical exposed frame units, the exposed frame units include upright columns and thermal insulation structure parts, the upright columns are bonded and fixed to each other, the The thermal insulation structure part includes the exposed frame pressing plate, the hollow glass layer clamped between the exposed frame pressing plate and the column; the curtain wall system also includes a decorative buckle cover, which is fastened outside the two exposed frame pressing plates; the exposed frame pressing plate Water-blocking adhesive strips are arranged between them; heat-insulating adhesive strips are arranged between the hollow glass layers, and the heat-insulating adhesive strips provided can block the outside world from entering the gap and exchange heat with the room, saving energy and environmental protection.

Owner:GRAND FACADE DECORATION ENG CO LTD

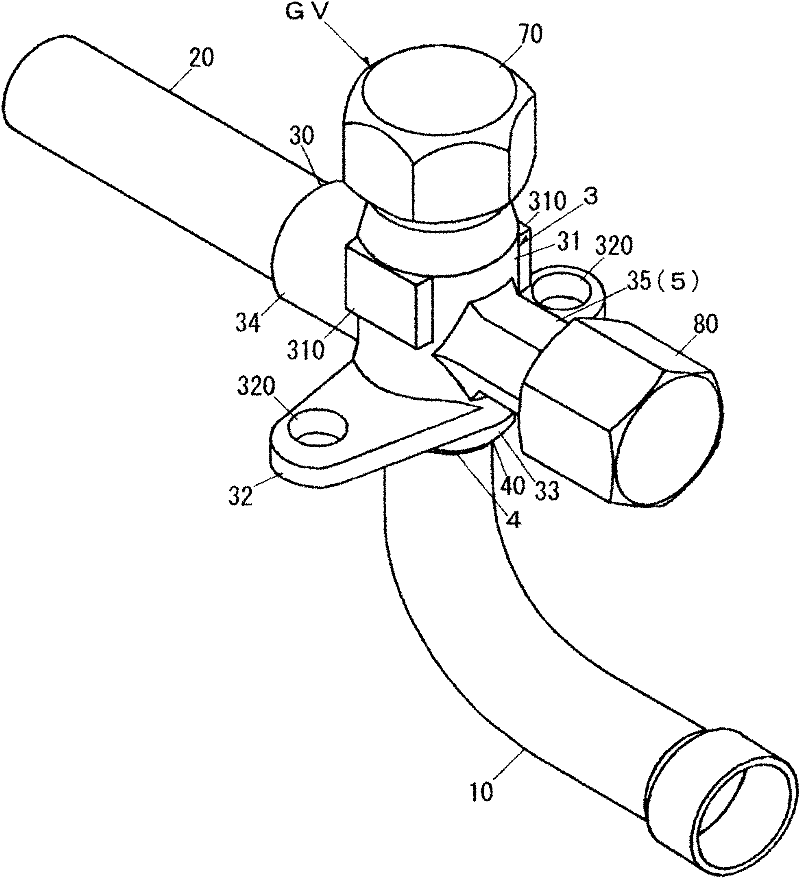

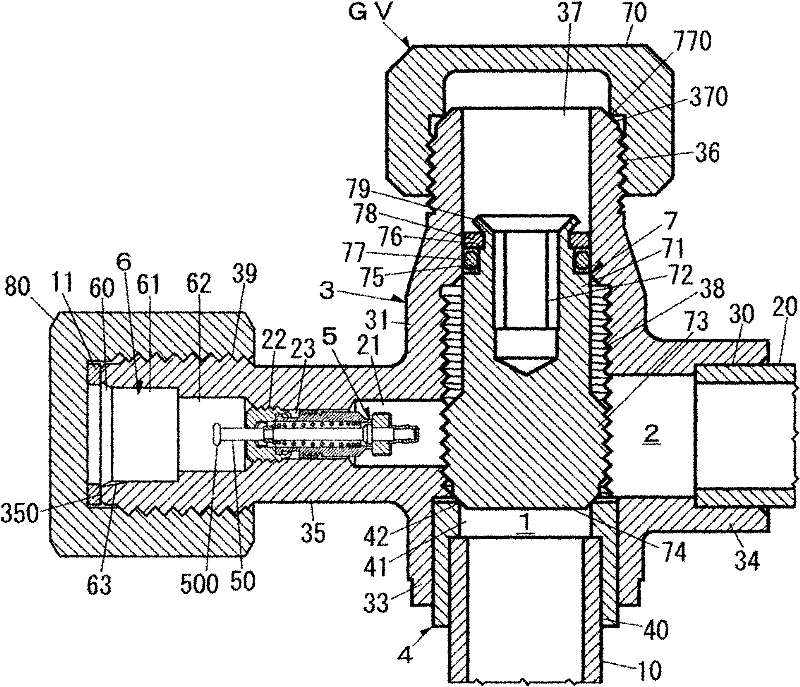

Valve device

InactiveCN102313026AGuaranteed tightnessAvoid forceful extrusionSpindle sealingsLift valveInternal pressureEngineering

The invention provides a valve device, which can well maintain the sealing performance of the valve core part even if a relatively high-pressure refrigerant, such as the CO2 type refrigerant is adopted, and further make an inflating flexible pipe connected with a vacuum pump well removed from a maintenance opening part in a way that the O ring of a pressure bar part will not break. The maintenance opening part (35) is provided with a pressure bar receiving hole (6) having a preset depth and applied for installing and uninstalling the pressure bar part (9) with an O ring (90). The operating end part (500) of a central pin (50) of the valve core (5) is made to face the inner part of the pressure bar receiving hole (6). Meanwhile, in the sealing contact starting end side located inside the pressure bar receiving hole (6) and contacting with the O ring (90) of the pressure bar part (9), an internal-pressure relieving path (63) is equipped on a part where the pressure bar part (9) and the central pin (50) leave. The internal-pressure relieving path (63) allows the axial communication when the O ring (90) is clamped.

Owner:CHIYODA KUCHOKIKI

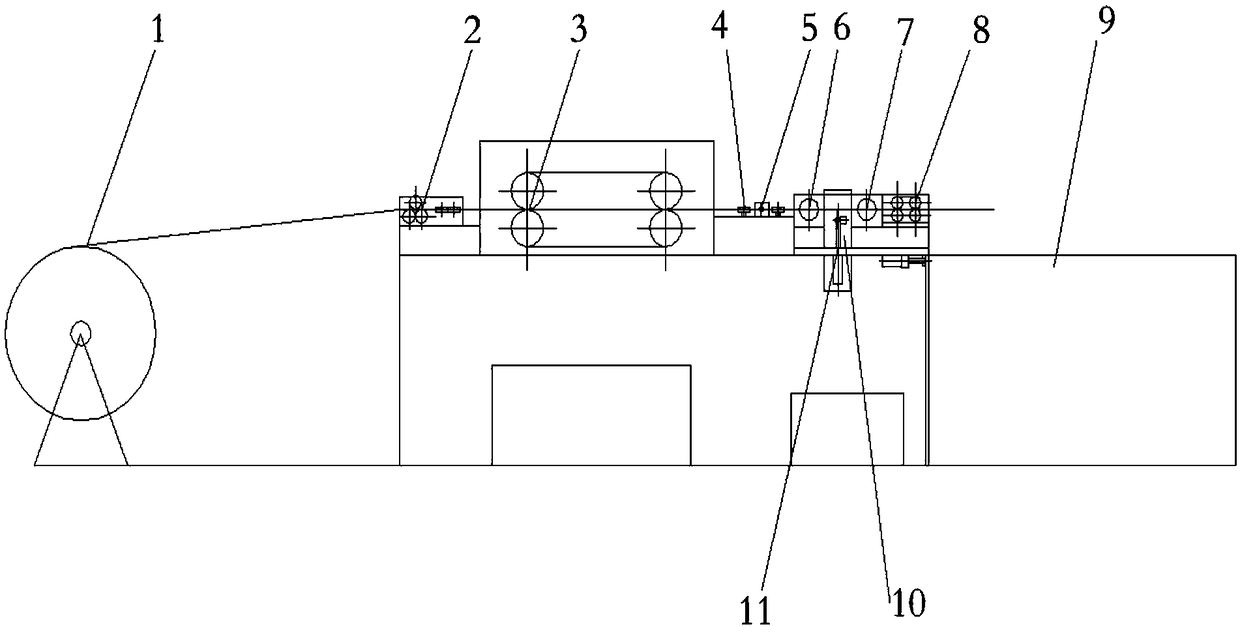

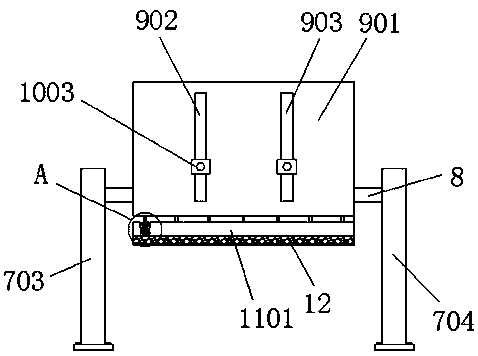

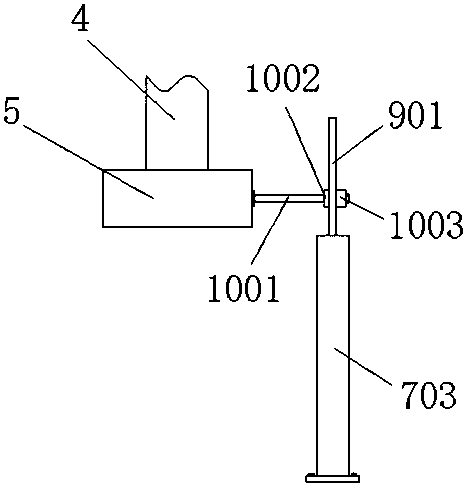

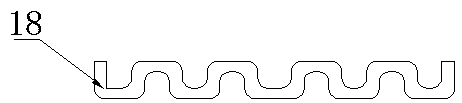

Full-automatic stretching and cutting equipment for helical corrugated pipe

InactiveCN108817977AEasy to controlPrecise positioningOther manufacturing equipments/toolsPositioning apparatusOperation modeUltimate tensile strength

The invention relates to full-automatic stretching and cutting equipment for a helical corrugated pipe. The equipment comprises a corrugated pipe storing frame, a front guide device, a conveying crawler belt, a rear guide device, a locating system, a front clamping die base, a rear clamping die base, a rear tensioning and conveying device and a collecting disc, wherein the front guide device, theconveying crawler belt, the rear guide device, the locating system, the front clamping die base, the rear clamping die base, the rear tensioning and conveying device and the collecting disc are sequentially connected with the corrugated pipe storing frame. A laser locating system is adopted for accurately locating crest and trough positions and matched with the conveying crawler belt, accuracy ofcorrugated pipe locating is ensured, and the situation that during manual operation, the corrugated pipe is damaged by a clamping die piece is avoided. The cutting-off position of a cutting-off tool can be adjusted slightly in the axial direction, and the situation that the cutting position cannot be controlled during manual operation is avoided. The whole device is beneficial for improving the working efficiency, reducing labor intensity and lowering the technical requirement, and a safe, accurate, efficient, continuous and environment-friendly operation mode is provided.

Owner:SHANGHAI LAINENG IND CO LTD

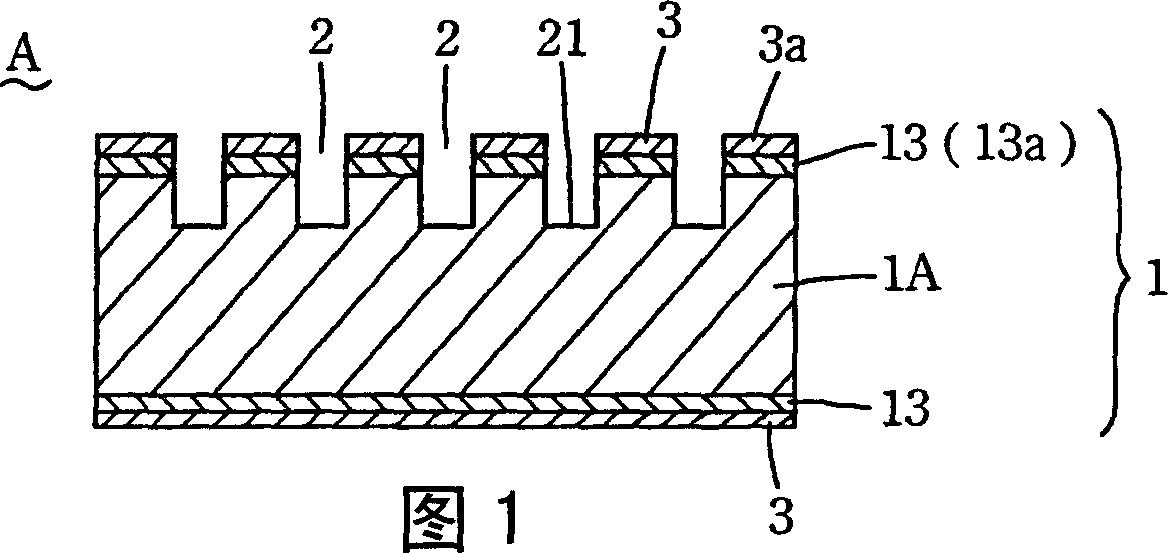

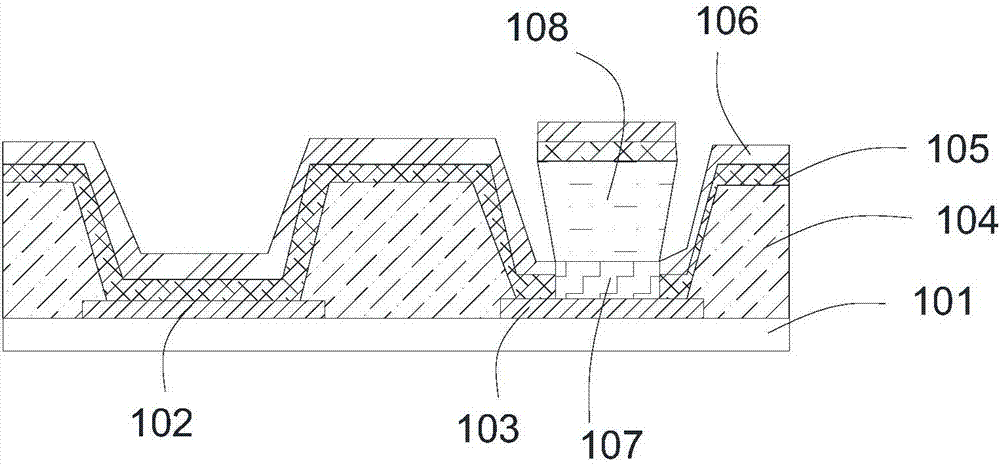

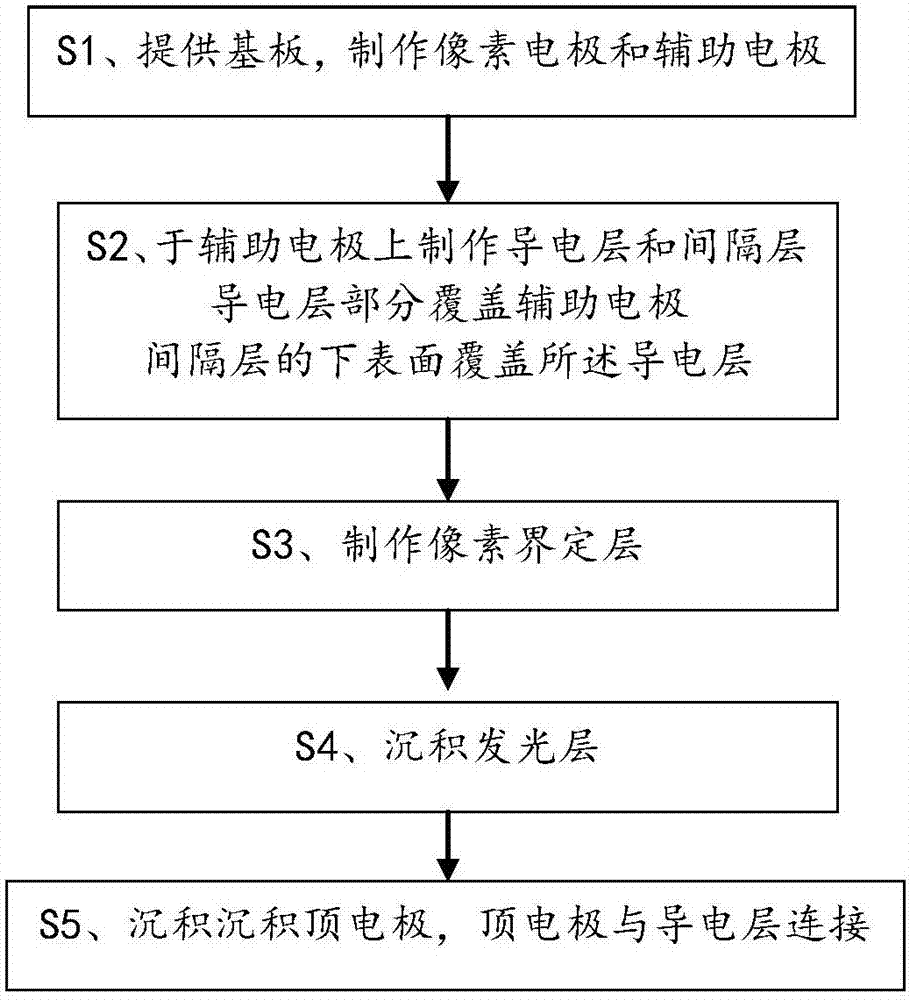

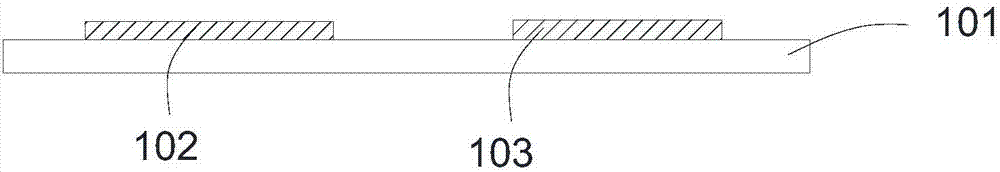

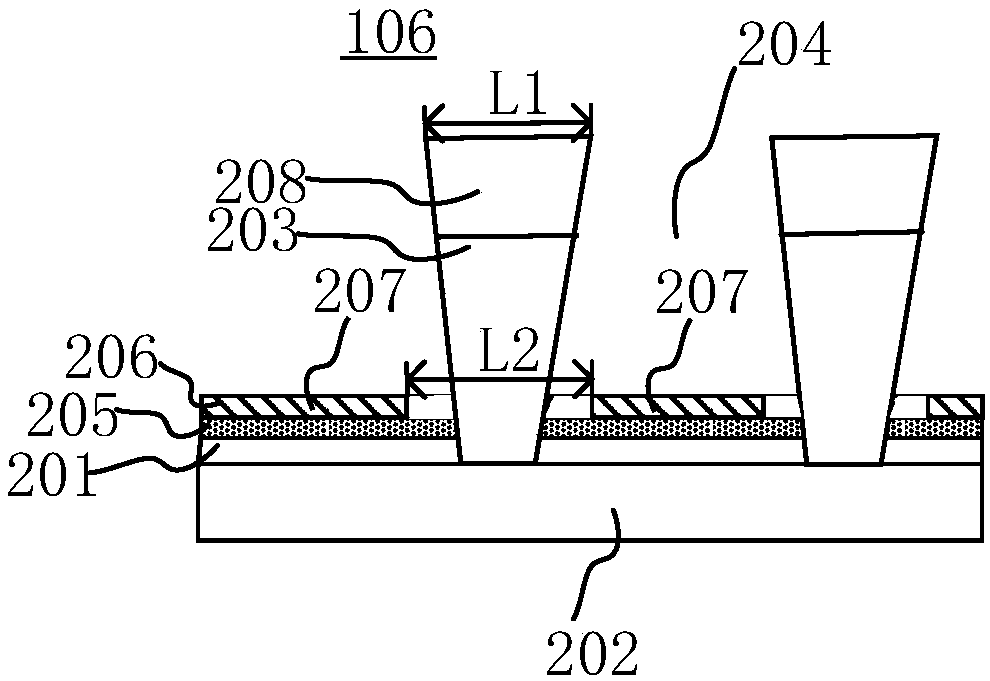

Organic light-emitting device and fabrication method and application thereof

ActiveCN107968155AEffective partitionReduce usageSolid-state devicesSemiconductor/solid-state device manufacturingOrganic light emitting deviceElectrical connection

The invention relates to an organic light-emitting device and a fabrication method and application thereof. The organic light-emitting device comprises a substrate and a pixel defining layer, whereinthe substrate comprises a pixel electrode region and an auxiliary electrode region, the pixel defining layer is formed between the pixel electrode region and the auxiliary electrode region, the pixelelectrode region comprises a pixel electrode, an organic function layer and a top electrode, the auxiliary electrode region comprises an auxiliary electrode, a conductive layer and a spacing layer, and the top electrode is connected with the conductive layer. In the organic light-emitting device, the conductive layer and the inverted trapezoid spacing layer are additionally arranged on the auxiliary electrode, thus, favorable electrical connection between the top electrode and the auxiliary electrode can be formed by the conductive layer, the problem that effective connection between the auxiliary electrode and the top electrode cannot be formed due to coverage of the organic function layer and application of an opening mask is solved, and the fabrication cost is reduced.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

Gas isolation method used during drying of hot-blast stove in iron works

ActiveCN102392091ASafe to useGuaranteed construction periodBlast furnace detailsHeating stovesMortar jointHot blast

The present invention relates to a gas isolation method used during the drying of a hot-blast stove in an iron works, and belongs to the construction method of a hot-blast stove. The method is characterized in that a left and a right high-alumina brick partition walls are arranged near a wind-mixing pipe by corresponding to the left part of a manhole in the inner cavity of a hot-blast main; high-alumina bricks are pre-placed before the left and the right partition walls are made; lines are drawn on arc bricks, and then the arc bricks are finish-machined and numbered; a stove builder makes thewalls layer by layer from the bottom and fills the joints layer by layer, near a right hot-blast branch pipe in the hot-blast main; when the left and the right partitions are made 700mm from the top,the stove builder moves across the left and the right partitions to one side of the wind-mixing pipe to finish making the rest of the walls; the mortar plumpness is up to 95%; the size of mortar joints is 2 mm plus or minus 1mm; the thicknesses of the left and the right partition walls range from 230 to 250mm on average; refractory layers are applied to the outer surfaces of the left and the right partition walls; and the thickness of the refractory layers can range from 2 to 3mm. The method can effectively isolate gas. The hot-blast pipe and a blast furnace are made simultaneously, which guarantees the schedule.

Owner:CHINA MCC17 GRP

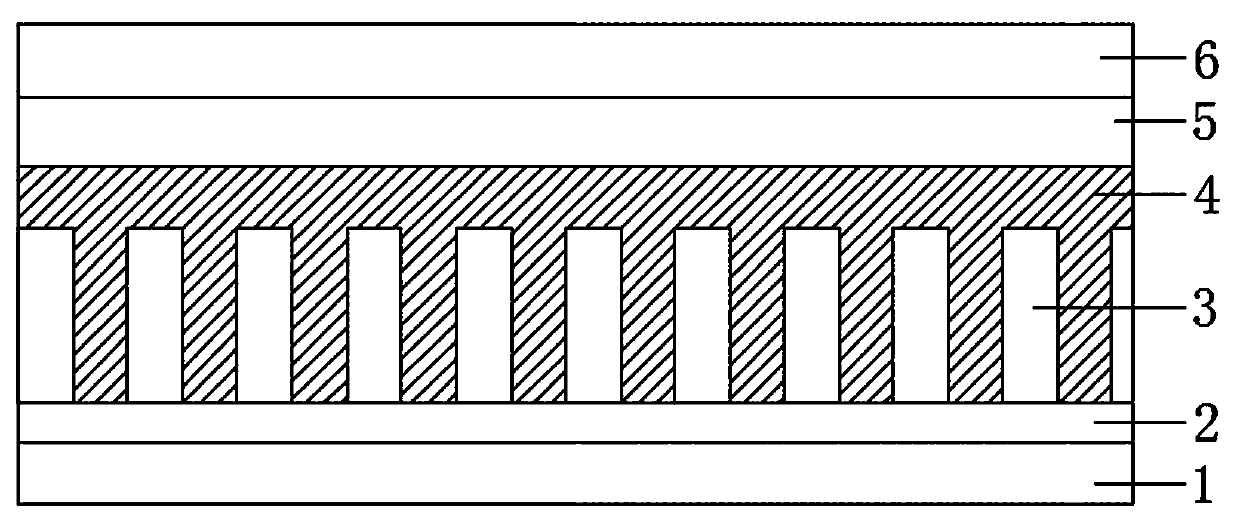

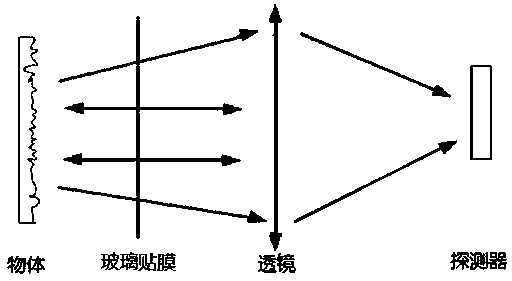

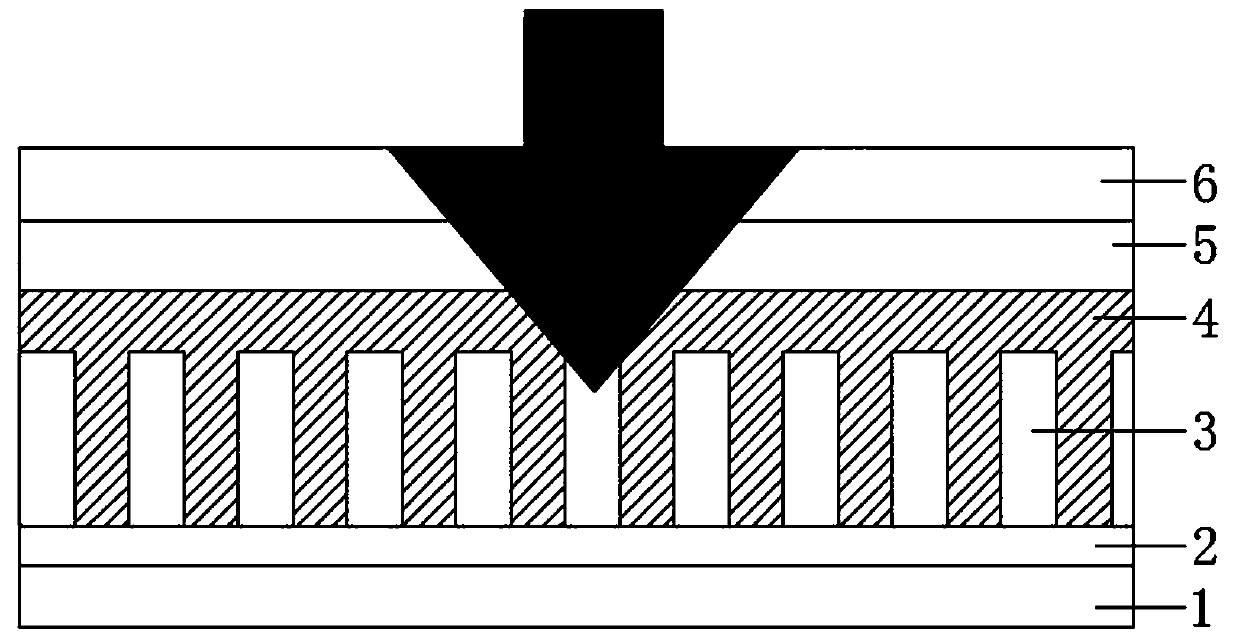

Preparation method of infrared laser protective film

ActiveCN111269666AQuick installationImprove stabilityFilm/foil adhesive primer layersPolyethylene terephthalate glycolIndium

The invention discloses a preparation method of an infrared laser protective film. The preparation method comprises the following steps: (1) coating an adhesive on a substrate layer to form an adhesive layer; (2) uniformly mixing antimony oxide, indium oxide and carbon nanotubes according to a mass ratio of 1:1:1, dispersing the mixture into a polyethylene glycol terephthalate material to obtain amaster batch, and extruding the master batch onto the first adhesive layer through an extruder with a grating type die head to form an infrared laser grating treatment layer with grating intervals; (3) arranging a protective layer on the infrared laser grating processing layer; and (4) coating the protective layer with an adhesive to form a mounting adhesive layer, and then adhering a release layer to the mounting adhesive layer to obtain the infrared laser protective film. The preparation method is simple, and the prepared product can effectively prevent information leakage.

Owner:成都立鑫新技术科技有限公司

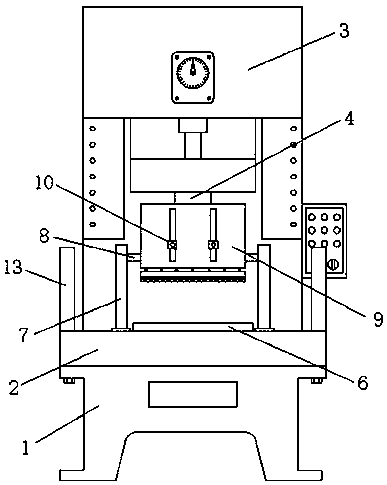

Protective device for punch

The invention provides a protective device for a punch and relates to the technical field of punch protection. The protective device for the punch comprises a punching machine tool. A workbench is arranged in the center of the punching machine tool. A power device is arranged at the top of the punching machine tool. A punching rod is arranged at the bottom of the power device. A punching block isfixedly connected to the bottom of the punching rod. A reset mechanism is arranged at the front end of the top of the workbench. A separation mechanism is slidably connected to the center of the resetmechanism. A buffer mechanism is arranged at the bottom of the separation mechanism. A sponge block is arranged at the bottom of the buffer mechanism. The simply designed mechanical protective deviceis used and is matched with an optical grating protective device, thus double protective effects can be achieved, under the circumstance of a failure of an optoelectronic device, a very good protective effect can still be achieved on workers through the mechanical protective device, work efficiency is improved greatly, and meanwhile risk cost of the workers and a manufacturer is also lowered greatly.

Owner:芜湖明达汽车座椅有限公司

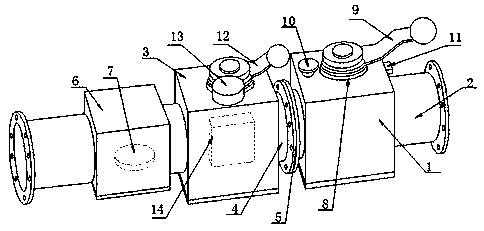

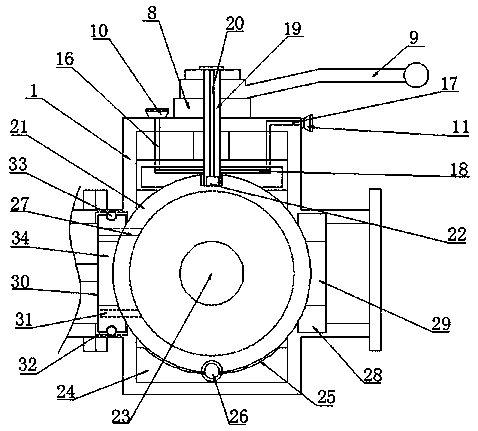

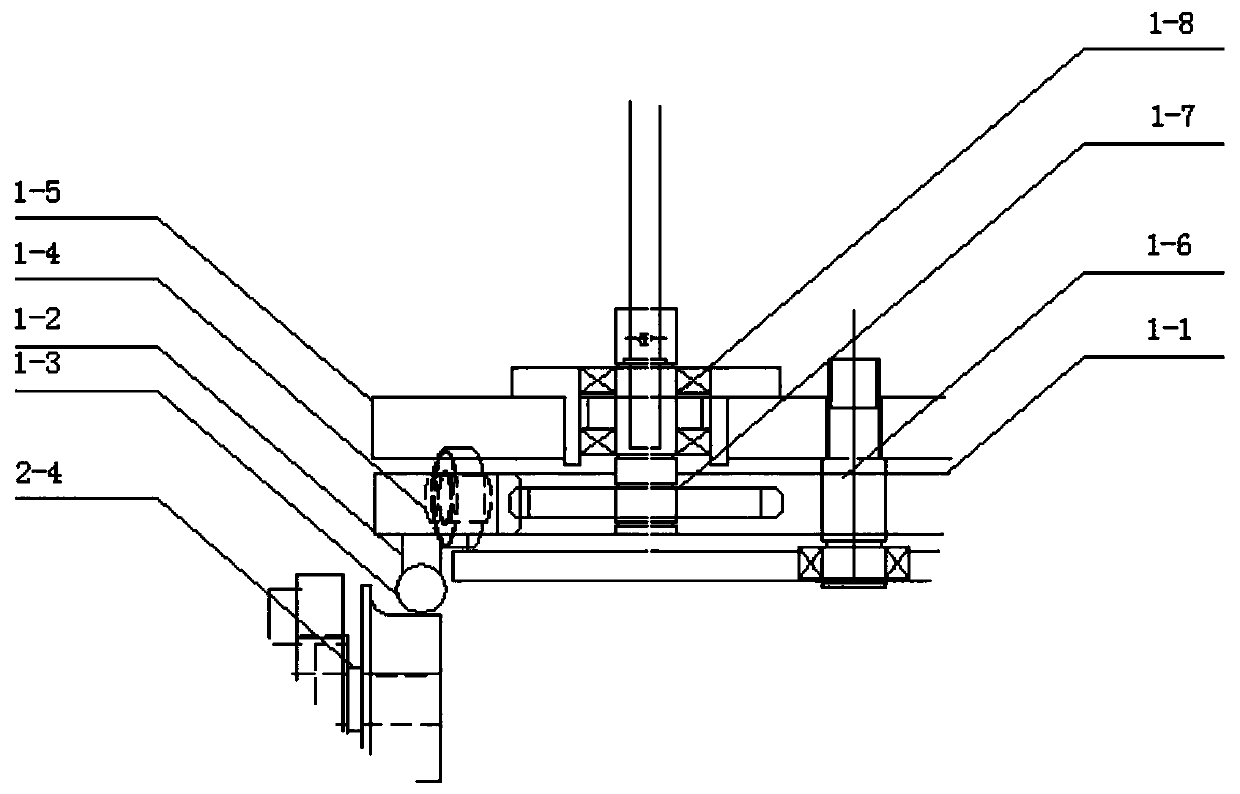

Combined cutoff device for large axial flow pump

InactiveCN108331077AReduce working capacityEffective partitionPumping plantsDrinking water installationAxial-flow pumpDevice form

The invention discloses a combined cutoff device for a large axial flow pump. A straight water outlet flow passage of each water pump is uniformly partitioned into two parts by a concrete partition pier on the plane, the combined cutoff device formed by a rapid gate and a co-seat multi-leaf side-turning flap valve is arranged on each part of the water outlet flow passage of each water pump, and each rapid gate is arranged on one side, close to the corresponding water pump, of the corresponding side-turning flap valve. Each rapid gate is controlled by a hydraulic host, and closed gate shafts are adopted. By cooperation of the rapid gates and the side-turning flap valves, the requirement of valve-opening starting of the axial flow pump can be met, startup-shutdown procedures are simple, cutoff reliability is achieved, and safety of units and pump stations is guaranteed.

Owner:ANHUI SURVEY & DESIGN INST OF WATER CONSERVANCY & HYDROPOWER

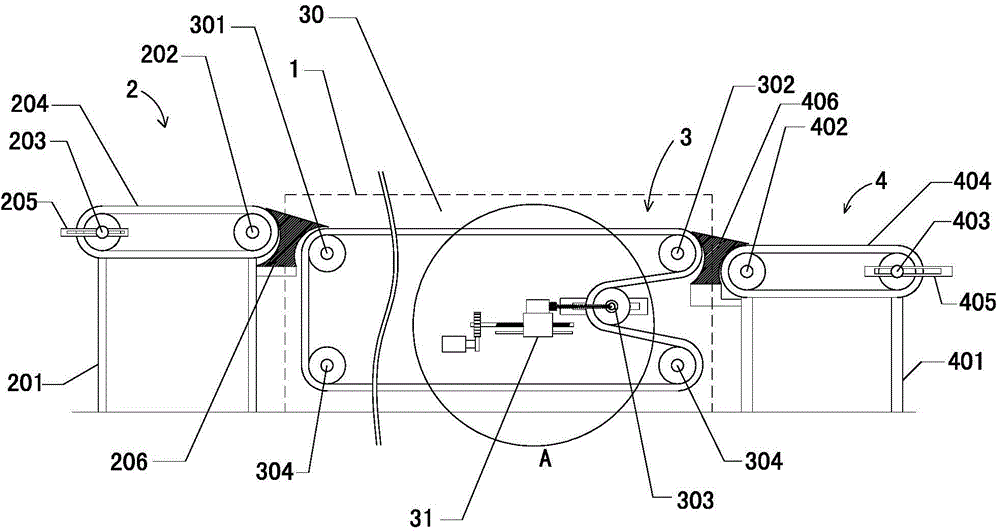

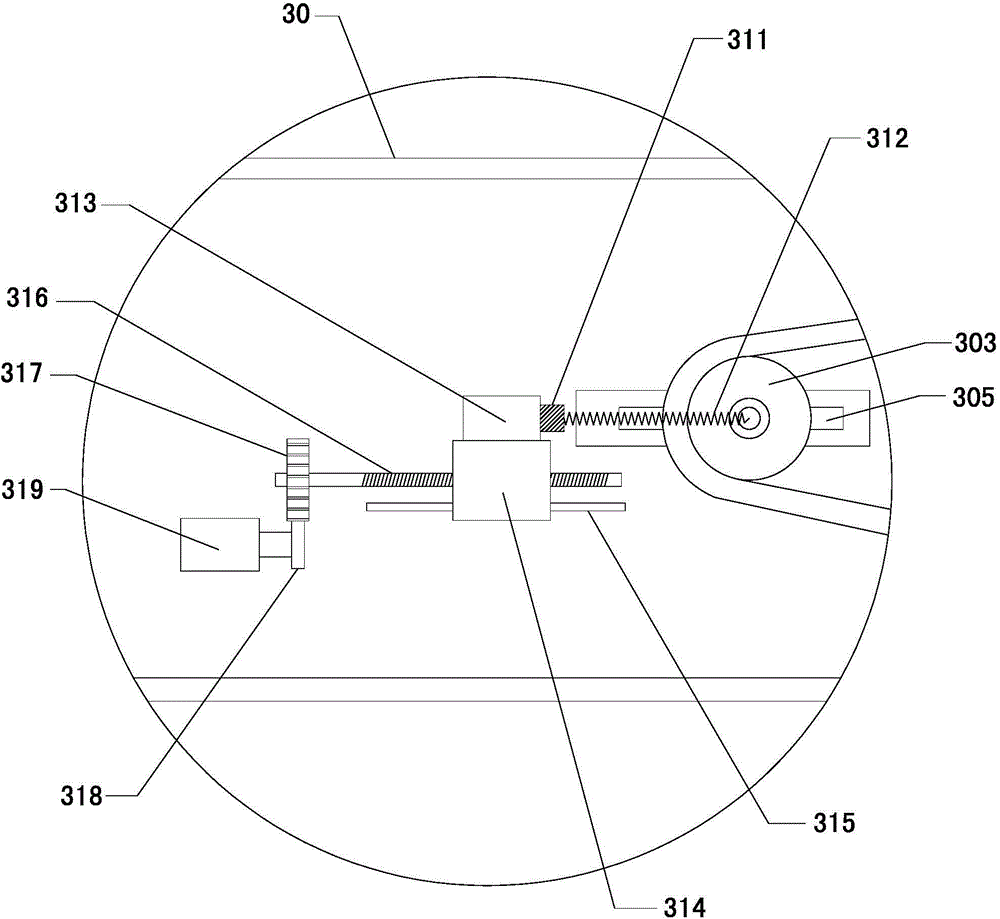

Continuous hot air tempering furnace

The invention relates to the technical field of heat treatment on metal materials and in particular relates to a continuous hot air tempering furnace. The continuous hot air tempering furnace comprises a tempering furnace body and a transmission mechanism, wherein the transmission mechanism comprises a feeding unit, a conveying unit and a discharging unit; the feeding unit comprises a feeding rack, a feeding power device, a feeding driving roller, a feeding driven roller and a feeding belt; the discharging unit comprises a discharging rack, a discharging power device, a discharging driving roller, a discharging driven roller and a discharging belt; the conveying unit comprises a conveying power device, a roller set, a screen belt and a tensioning device; the roller set comprises an incoming end roller, an outgoing end roller, an adjusting roller and two circulation rollers; the tensioning device is in transmission connection with the adjusting roller; the tensioning degree of the screen belt is controlled by adjusting the relative position of the adjusting roller; a feeding slope platform is fixed on the feeding rack; a discharging slope platform is fixed on the discharging rack. The continuous hot air tempering furnace is low in heat loss, is incapable of causing scald to operators and is capable of effectively ensuring the tensioning degree of the screen belt.

Owner:佛山高砂工业窑炉有限公司

System for and method of generating steam for use in oil recovery processes

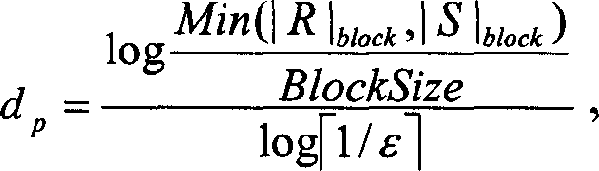

InactiveCN1485766ANo storage requiredEffective partitionImage enhancementData processing applicationsData setData space

A partition-based high dimensional similarity join method allowing similarity to be efficiently measured by beforehand dynamically selecting space partitioning dimensions and the number of the partitioning dimensions using a dimension selection algorithm. A method of efficiently performing similarity join for high dimensional data during a relatively short period of time without requiring massive storage space. The method includes according to the present invention comprises the steps of partitioning a high dimensional data space and performing joins between predetermined data sets. Dimensions for use in partitioning the high dimensional data space and the number of partitioning dimensions are determined in advance before the space partitioning, and the joins are performed only when respective cells of the data sets are overlapping with each other or are neighboring each other.

Owner:SAMSUNG ELECTRONICS CO LTD

Easy-to-open high-pressure hydraulic ball valve

ActiveCN109099207AEffective coolingEffective partitionValve members for heating/coolingPressure relieving devices on sealing facesEngineeringHigh pressure

The invention discloses an easy-to-open high-pressure hydraulic ball valve. The easy-to-open high-pressure hydraulic ball valve comprises a first valve seat. A first pipeline is arranged on each of two sides of the first valve seat, a second valve seat is arranged at one end of one of the first pipelines, second pipelines are symmetrically arranged on two sides of the second valve seat, and the second pipelines and the first pipelines are connected through flanges. A fixing seat sleeves the portion, away from the first valve seat, of each second pipeline. A first adjusting mechanism is arranged in each fixing seat. A flat washer is arranged in the middle of the top end of each of the first valve and the second valve. A first pull handle located at the top end of each flat washer and a first inlet located on one side of the corresponding first pull handle are arranged above the first valve seat. An outlet is aranged at the top end of one side, away from the second valve seat, of the first valve seat. The easy-to-open high-pressure hydraulic ball valve has the advantages that when the valve has a failure, fluids are cut off effectively through the first adjusting mechanisms, so thatcirculation of the fluids is avoided, the performance of devices is improved, and resource waste caused by fluid leakage is avoided.

Owner:SPECIAL VALVE JIANGSU FLUID MASCH MFG CO LTD

Novel continuous film coating production line based on public rotation loading tray

ActiveCN108677160ARealize automated productionImprove cleanlinessVacuum evaporation coatingSputtering coatingProduction lineIsolation valve

The invention discloses a novel continuous film coating production line based on a public rotation loading tray. The novel continuous film coating production line comprises the public rotation tray, afeeding module, vacuum isolation valve modules, a substrate feeding vacuum process module, a film coating vacuum process module, a substrate discharge vacuum process module and a discharge module. One end of the substrate feeding vacuum process module is provided with one vacuum isolation valve module, the other end of the substrate feeding vacuum process module is isolated from one end of the film coating vacuum process module through another vacuum isolation valve module, and the other end of the film coating vacuum process module is isolated from one end of the substrate discharge vacuum process module through another vacuum isolation valve module, and the other end of the substrate discharge vacuum process module is provided with last vacuum isolation valve module. The independent substrate feeding and discharge cavity design is adopted, vacuum isolation is carried out through the independent vacuum isolation valve modules, a conveying system adopts a guide wheel and a guide rod for friction conveying, and stability is good; and film coating full-automatic production is achieved, the participation status of personnel is reduced, and the product yield is improved.

Owner:WUHAN JIUYI INTELLIGENT TECH CO LTD

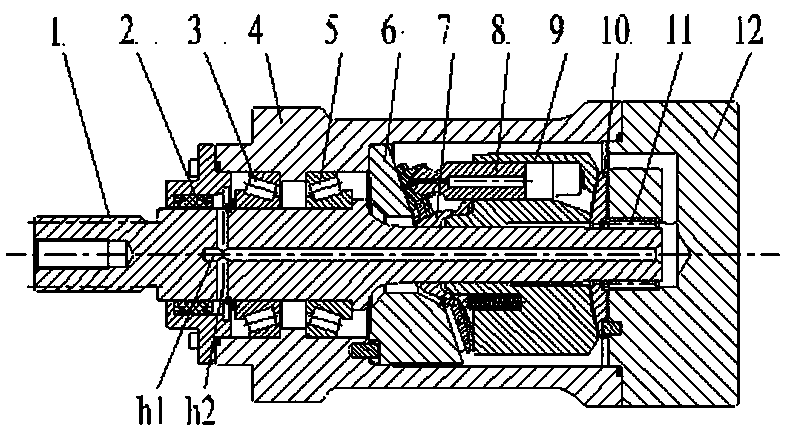

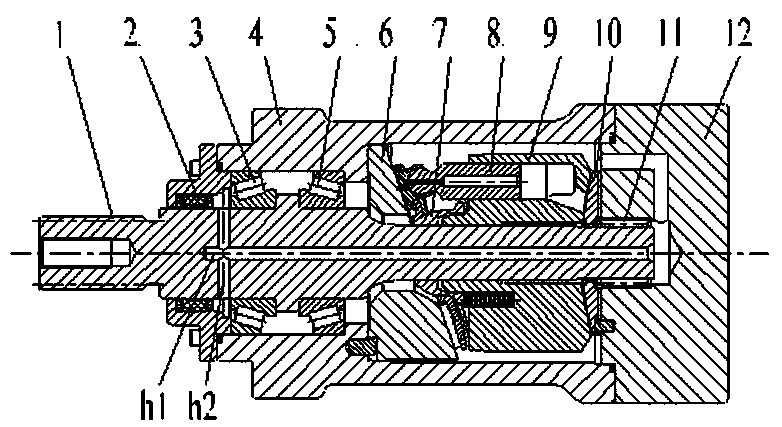

A swash plate hydraulic plunger motor or pump for submersion in water

ActiveCN106401863BExtend your lifeSimple structurePump componentsPump installationsImpellerThrust bearing

Owner:九江七所精密机电科技有限公司 +1

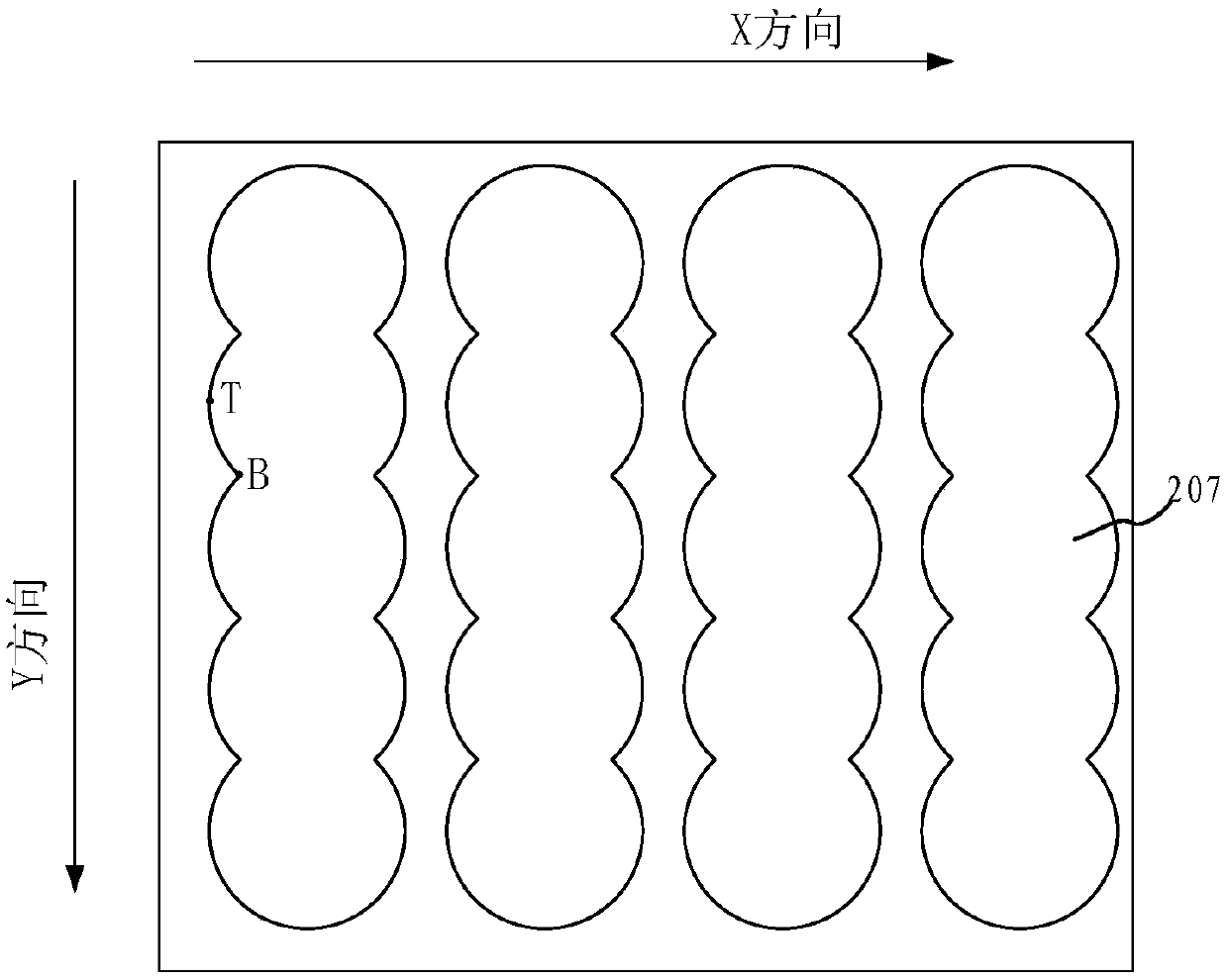

Mask plate, display panel and preparation method thereof, and display terminal

ActiveCN110767689AEffective partitionRealize full screen displaySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

The invention relates to a mask plate, a display panel and a preparation method thereof, and a display terminal. The display panel is provided with a first display area and a second display area whichare adjacent; both the first display area and the second display area are used for displaying dynamic or static pictures; the display panel includes a first display panel arranged in the first display area and a second display panel arranged in the second display area; the material of each structural film layer of the first display panel is made of a transparent material; and the first display panel includes a substrate provided with a first electrode layer, a pixel defining layer formed on the first electrode layer, an organic light emitting layer formed in a pixel opening, and a second electrode layer formed on the organic light emitting layer; wherein the pixel defining layer is provided with isolation pillars, the pixel defining layer has a plurality of pixel openings, and the secondelectrode layer includes a plurality of second electrodes that are insulated from each other. Therefore, the full screen display is realized really.

Owner:YUNGU GUAN TECH CO LTD

A method for maintenance and cooling of hot air pipe system

ActiveCN113124255BImprove cooling efficiencyWon't hurtPipe heating/coolingAir pumpBlast furnace smelting

The invention belongs to the technical field of blast furnace smelting, and in particular relates to a method for maintaining and cooling a hot air duct system, comprising the following steps: step S1, after the blast furnace is completely stopped for wind, remove the tuyere blowing pipe and the elbow, and install the middle section blind plate; step S2, Turn on the combustion-supporting fan to cool down the reverse supply air. The cooling route is followed by the combustion-supporting fan, the combustion-supporting air pipe, the reverse supply air pipe, the mixing air pipe, the hot air main pipe, the hot air surrounding pipe and the reverse flow pipe, until the temperature drops to the first set value; step S3, close the air mixing valve, turn on the first axial flow fan to cool down until the cooling rate is less than the second set value; Step S4, turn on the second axial flow fan to cool down until the temperature drops to the third set value; Step S5, Install hot blast valve blinds, mixing valve blinds, and middle section blinds; check whether the piping system meets the operating conditions. The maintenance and cooling method of the hot air duct system of the present invention greatly improves the cooling efficiency, does not need to draw water in the cooling process, does not cause damage to refractory materials, and improves the safety guarantee capability of construction operations.

Owner:SGIS SONGSHAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com