Loading region asphalt smoke adsorption treatment system and treatment method for asphalt agitating plant

An asphalt mixing plant and adsorption treatment technology, applied in separation methods, chemical instruments and methods, membrane filters, etc., can solve the problems of unorganized emission of asphalt smoke, high purification efficiency, low operating costs, etc., and achieve good sealing effect, The effect of high purification efficiency and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below through specific embodiments.

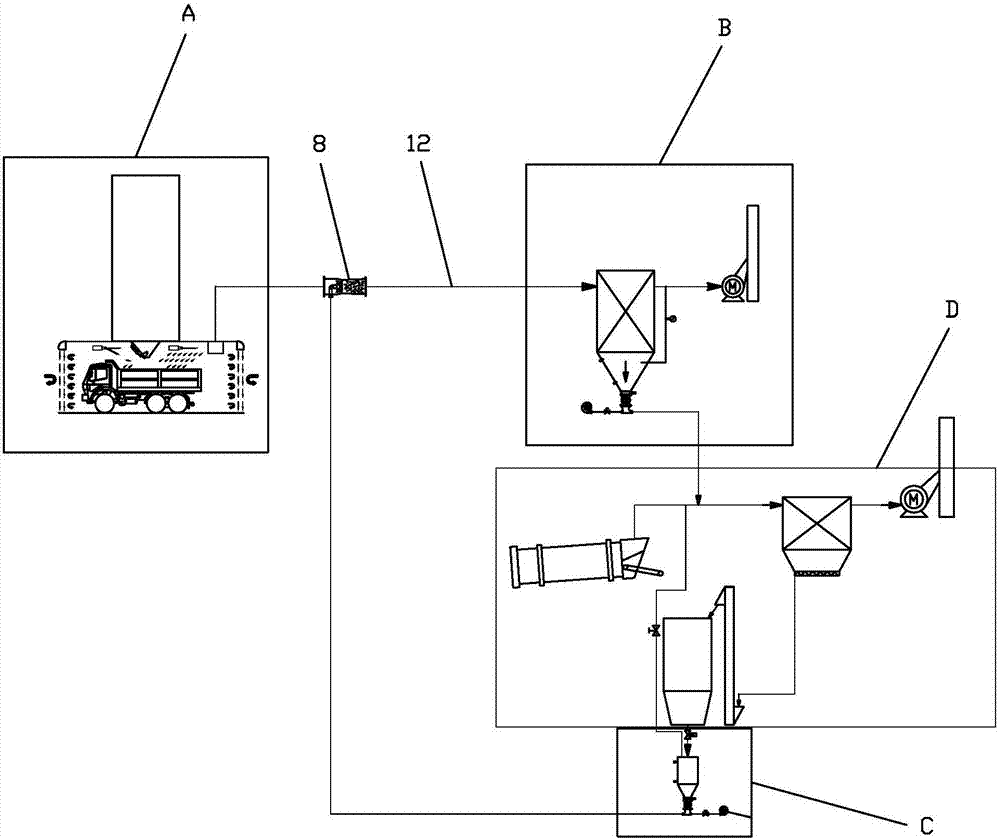

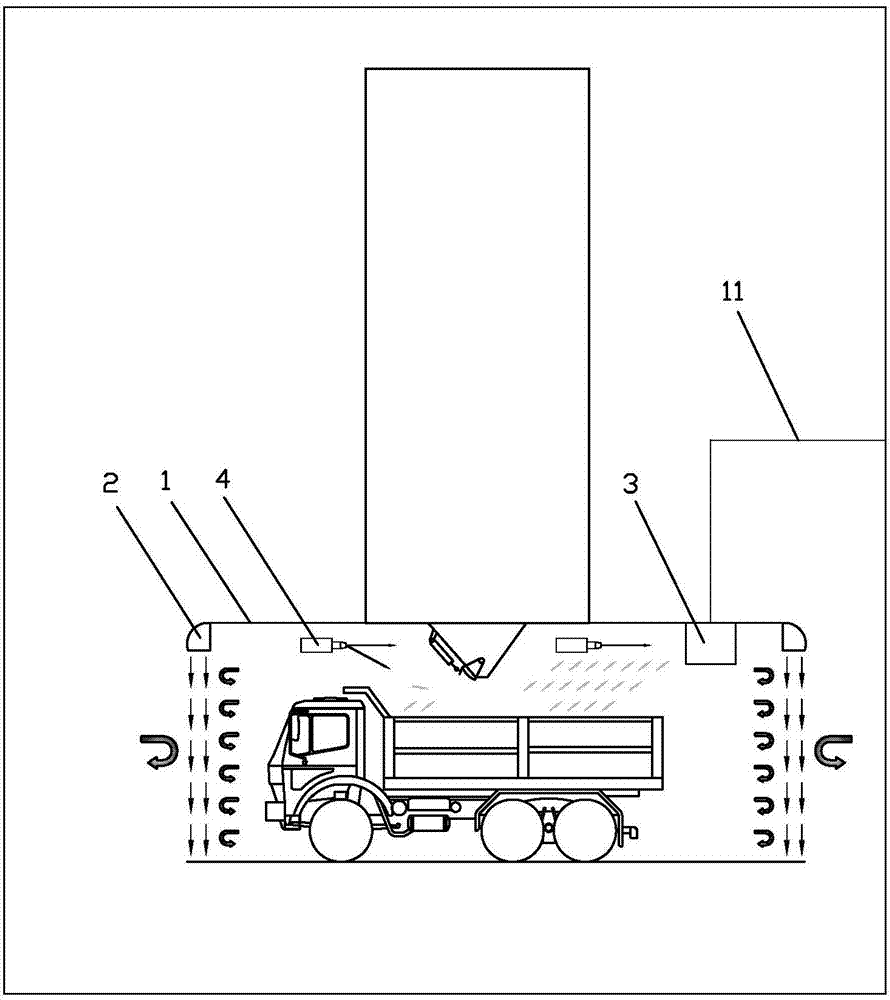

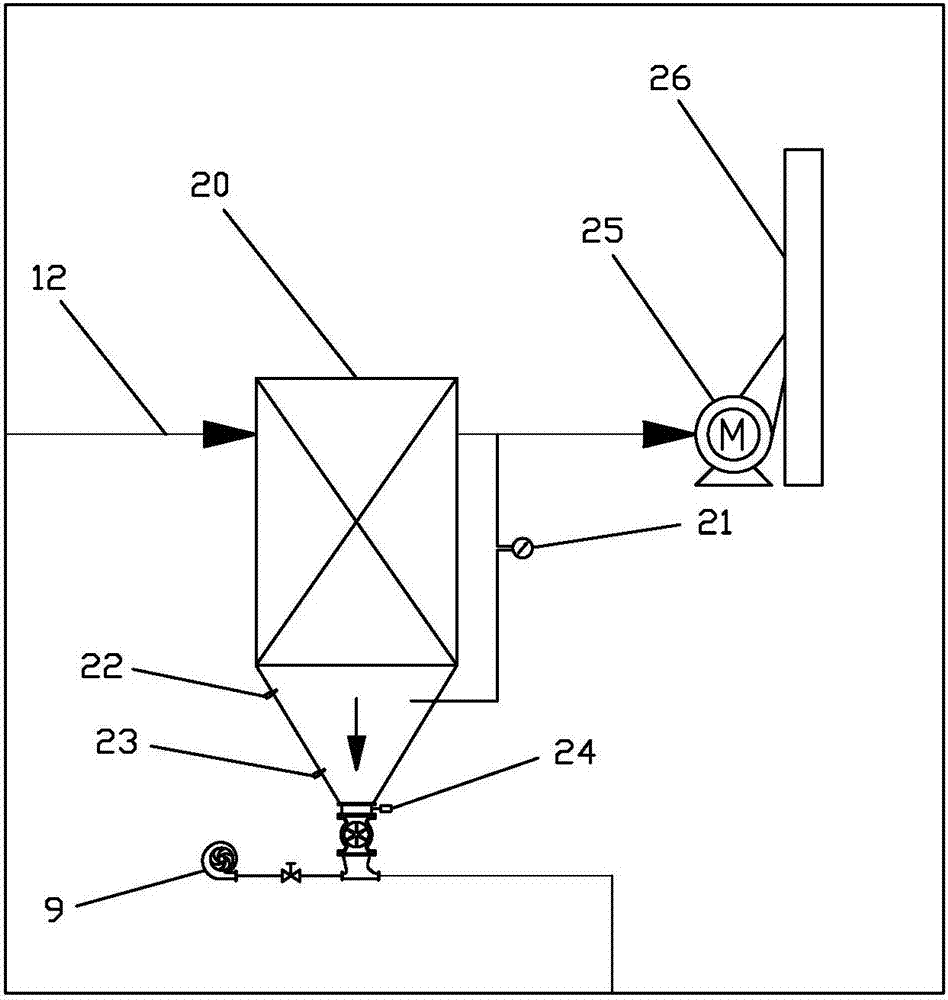

[0041] refer to Figure 1 to Figure 6 , an asphalt fume adsorption treatment system in the loading area of an asphalt mixing plant according to the present invention includes a sealing device in the loading area, an asphalt fume collection device and an asphalt fume adsorption device.

[0042] The sealing device for the loading area includes an outer seal 1 for the loading area with front and rear openings and an air curtain machine 2 for forming a sealing air curtain at the front and rear openings of the outer seal 1 for the loading area. Air curtain machine 2 generates high-speed airflow, which can effectively block polluted gas and prevent asphalt fume from escaping. At the same time, it prevents a large amount of fresh air from pouring into the loading area from all sides, which helps to improve the collection efficiency of asphalt fume.

[0043] The asphalt smoke collection dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com