Preparation method of infrared laser protective film

A technology of infrared laser and protective film, which is applied in the field of information security, can solve the problems of loss of work meaning, inability to effectively prevent information leakage, and affect eavesdropping on laser signals, etc., and achieve simple and reliable preparation methods, prevent information leakage, and increase stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment discloses a method for preparing an infrared laser protective film, comprising the following steps:

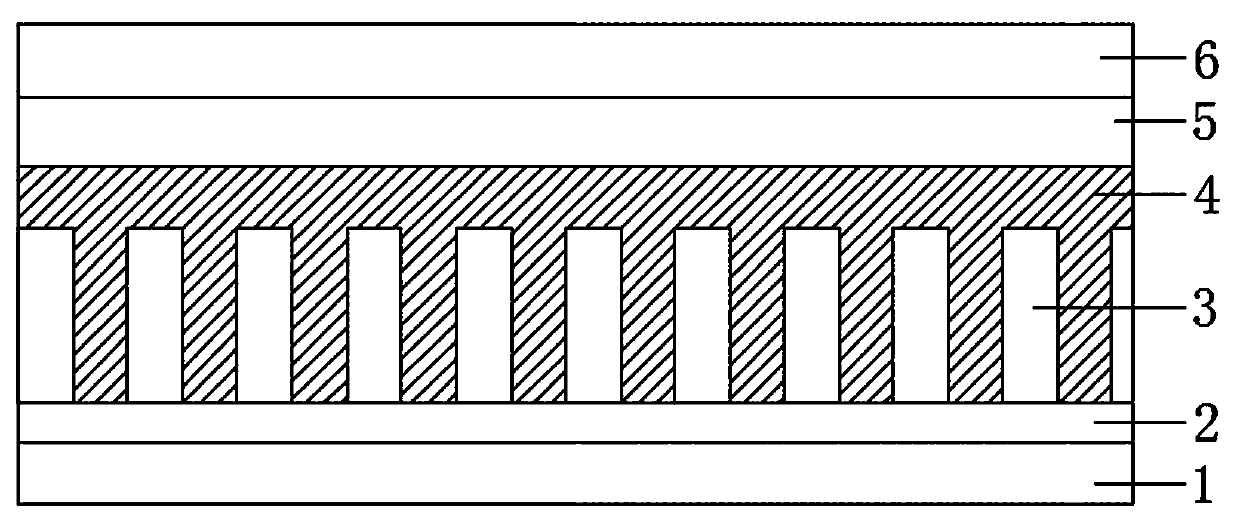

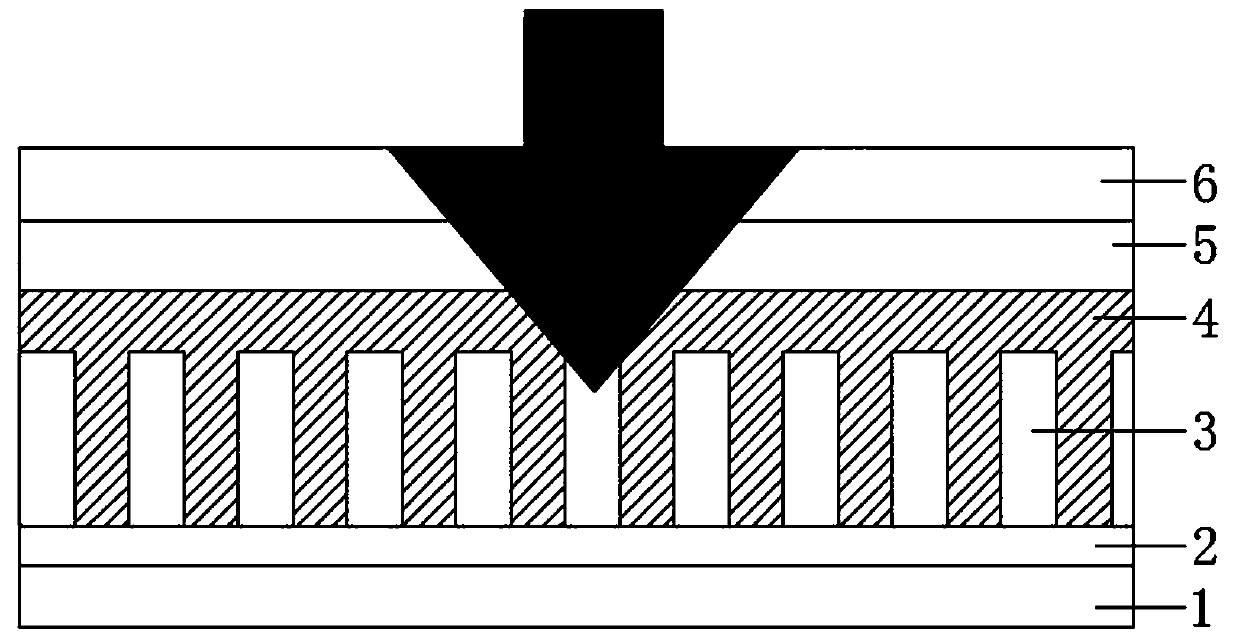

[0042] (1) Coating an adhesive on the base layer 1 to form the adhesive layer 2 .

[0043](2) First mix antimony oxide, indium oxide and carbon nanotubes with a mass ratio of 1:1:1 evenly, then disperse the mixture into polyethylene terephthalate material to obtain a masterbatch, and then pass it through a belt The extruder of the grating die head extrudes the masterbatch onto the first adhesive layer 2 to form an infrared laser grating treatment layer 3 with grating intervals. Specifically, before the masterbatch enters the extruder, it is first heated and melted, and then extruded from a grating die through a filter, and after solidification, an infrared laser grating treatment layer 3 with grating intervals is obtained.

[0044] (3) A protective layer 3 is set on the infrared laser grating treatment layer 3, and the protective layer 3 is uniformly mi...

Embodiment 2

[0049] This embodiment discloses a method for preparing an infrared laser protective film, comprising the following steps:

[0050] (1) A low-density polyethylene film is used as the base layer 1, and an adhesive is coated on the base layer 1 to form an adhesive layer 2. Wherein, the thickness of the base layer 1 is 10-70 μm, preferably the thickness of the base layer 1 is 40-50 μm. The adhesive used for the adhesive layer 2 is preferably polyvinyl acetate adhesive.

[0051] (2) First mix antimony oxide, indium oxide and carbon nanotubes with a mass ratio of 1:1:1 evenly, then disperse the mixture into polyethylene terephthalate material to obtain a masterbatch, and then pass it through a belt The extruder of the grating die head extrudes the masterbatch onto the first adhesive layer 2 to form an infrared laser grating treatment layer 3 with grating intervals. Specifically, before the masterbatch enters the extruder, it is first heated and melted, and then extruded from a gr...

Embodiment 3

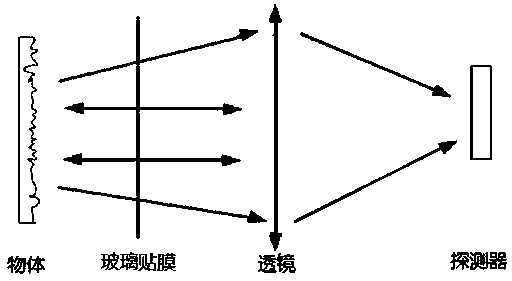

[0071] This embodiment has verified the technical solution described in embodiment 1 and embodiment 2, specifically as follows:

[0072] Use infrared lasers to actually eavesdrop on the indoor area without protective film and pasted the disclosed protective film of embodiment 1 or embodiment 2 respectively. The infrared laser intensity of emission is 10mw, and adopting diameter at 100 meters is that the 100mm lens receives. When the protective film is attached, the intensity of the returned light is 1nw, which can clearly restore the voice information caused by the vibration of the object caused by speaking. After the protective film is attached, the returned light is 10pw at a distance of 1 meter, and the signal is too weak to restore. Voice message. This proves that the information leakage prevention effect of the present invention is very good, and can effectively prevent information leakage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com