Full-automatic stretching and cutting equipment for helical corrugated pipe

A technology of spiral bellows and cutting equipment, which is applied in metal processing equipment, other manufacturing equipment/tools, maintenance and safety accessories, etc., and can solve the problems of no effective protective measures at the cutting operation site, noise generated by cutting, metal particles splashing, etc. , to achieve the effect of reducing labor intensity and skill requirements of workers, preventing noise pollution and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

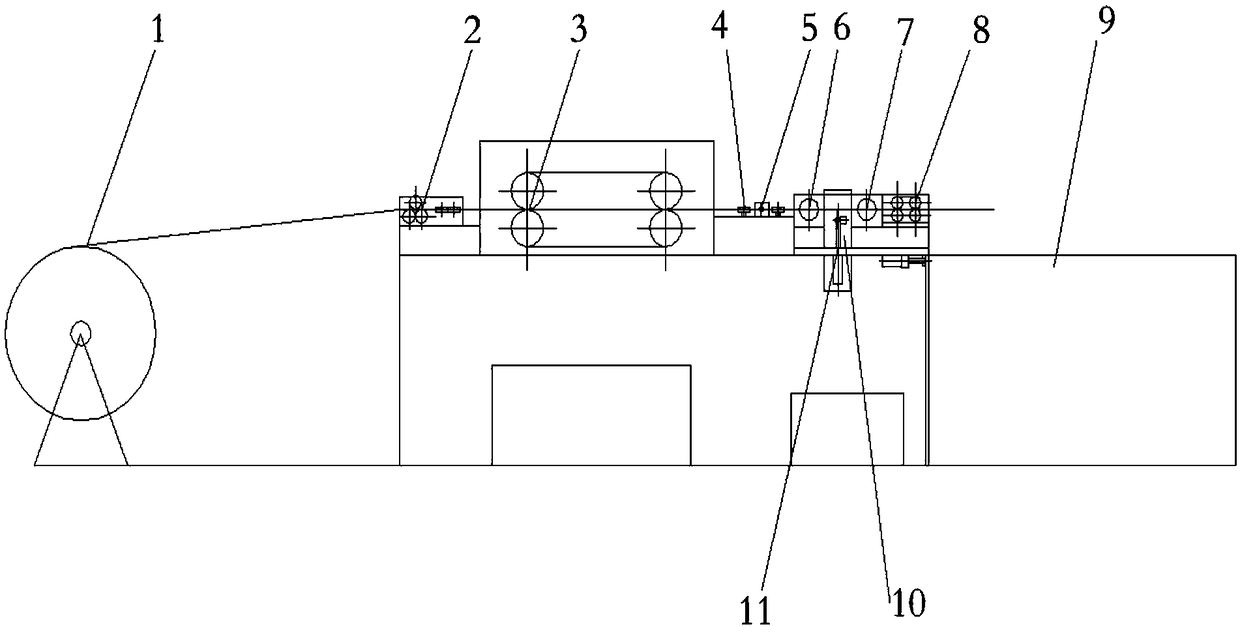

[0023] Such as figure 1 As shown, a spiral corrugated pipe automatic stretching and cutting equipment includes a corrugated pipe discharge rack 1 and a front guide device 2 connected to it in sequence, a conveying track 3, a rear guide device 4, a positioning system 5, and a front clamping mold base 6. The rear clamping mold base 7, the rear tensioning conveying device 8 and the receiving tray 9, a cutting tool 11 driven by a high-speed motor is arranged between the front clamping mold base 6 and the rear clamping mold base 7, and the The cutting tool 11 is integrally installed on a support base that can move up and down. The up and down movement of the support base is completed by the cylinder installed below the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com