Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Easy to control the amount added" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

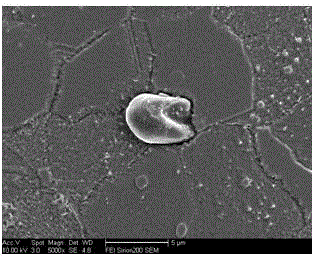

Fining agent used for magnesium alloy and its preparation method

InactiveCN1410566AAdding process is simpleEasy to control the amount addedCooking & bakingChemical composition

A crystal grain fining agent for Mg-alloy contains Al (72.5-99.8%), C (0.02-20%) and Mg (0-10 %), and is prepared through proportionally mixing aluminium powder, graphite powder and magnesium powder,baking, die pressing, and calcining at 700-1000 deg.C in vacuum or under inertial gas for at least 25 min.

Owner:SHANDONG UNIV

Low surface energy liquid control release type marine anti-fouling paint

InactiveCN101845262AOvercoming effectOvercoming toxicityAntifouling/underwater paintsPaints with biocidesCross-linkAcrylic resin

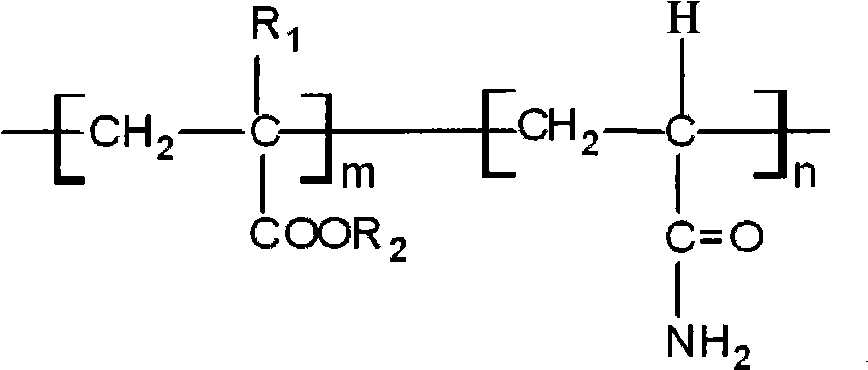

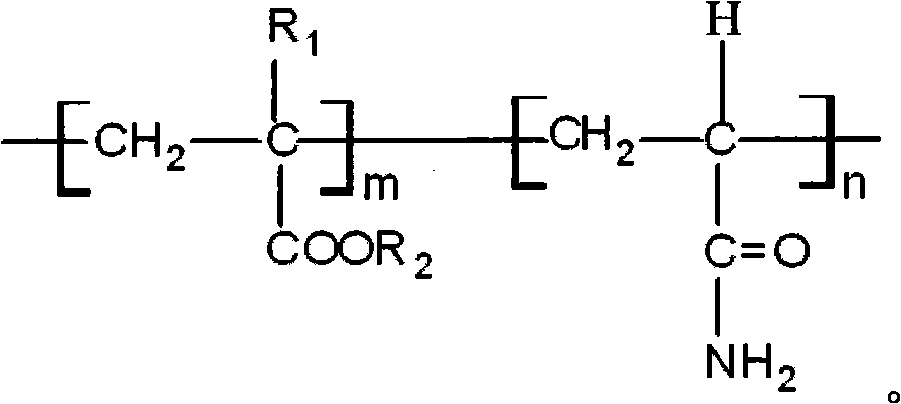

The invention discloses a low surface energy liquid control release type marine anti-fouling paint, comprising the following components in parts by weight: 30.0-55.0 parts of film-forming resin, 7.0-18.0 parts of lamella cross-linking silicone oil microcapsule, 1.0-10.0 parts of plasticizer, 1.0-3.0 parts of defoaming agent, 15.0-35.0 parts of added pigment and 5.3-22.7 parts of solvent. The lamella cross-linking silicone oil microcapsule is obtained by polymerizing an oil-in-water system in situ; the core material of the lamella cross-linking silicone oil microcapsule is one or several of methyl silicone oil, hydroxy silicone oil, amino silicon oil and alkoxy silicone oil; and the wall material of the lamella cross-linking silicone oil microcapsule can be one of polyacrylamide, polyacrylic acid, polymaleic anhydride and the like which can be swelled in the water. The anti-fouling paint has the advantages of remarkable anti-fouling effects, no pollution to a marine environment, low cost and applicability for industrial application production. The film-forming resin is acrylic resin, the structural general formula of which is shown in the specification of the invention.

Owner:NINGBO HAITENG NEW MATERIALS CO LTD

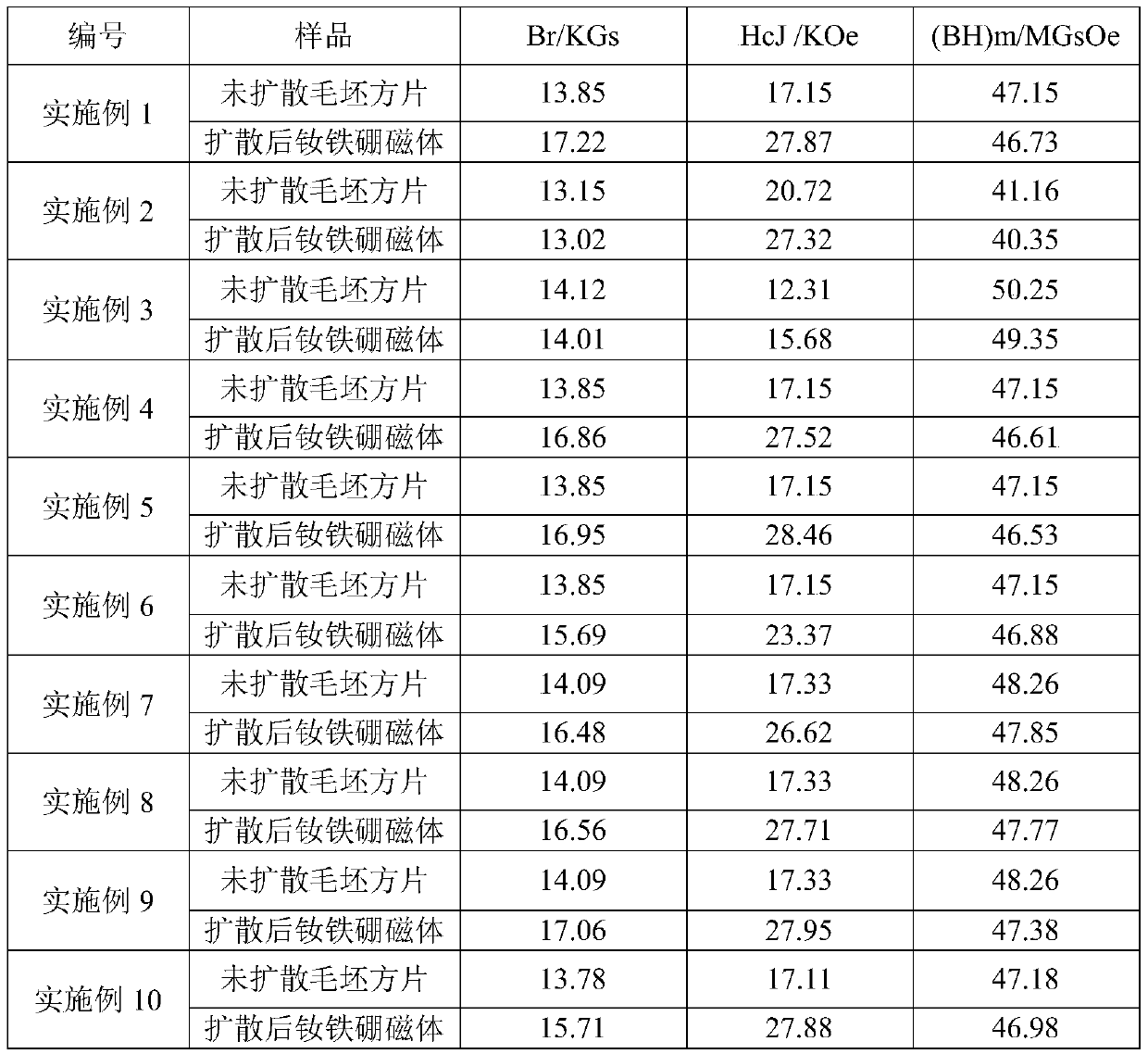

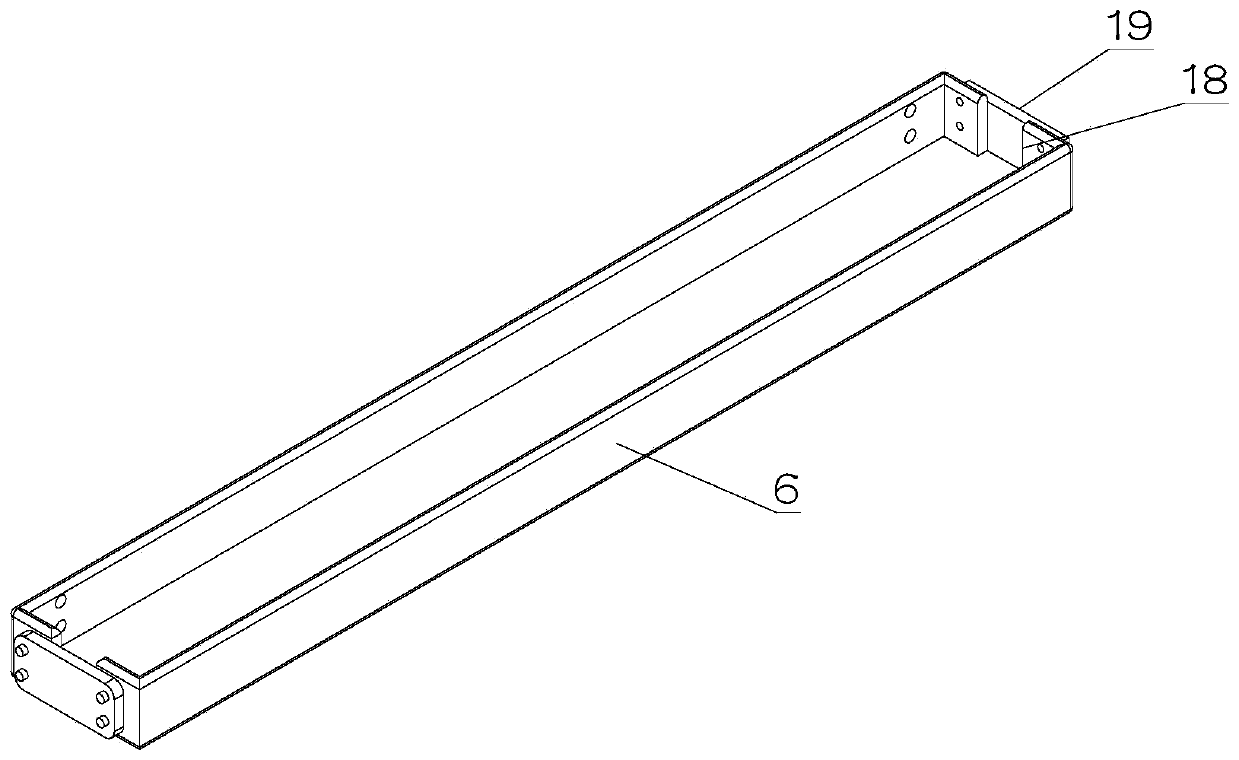

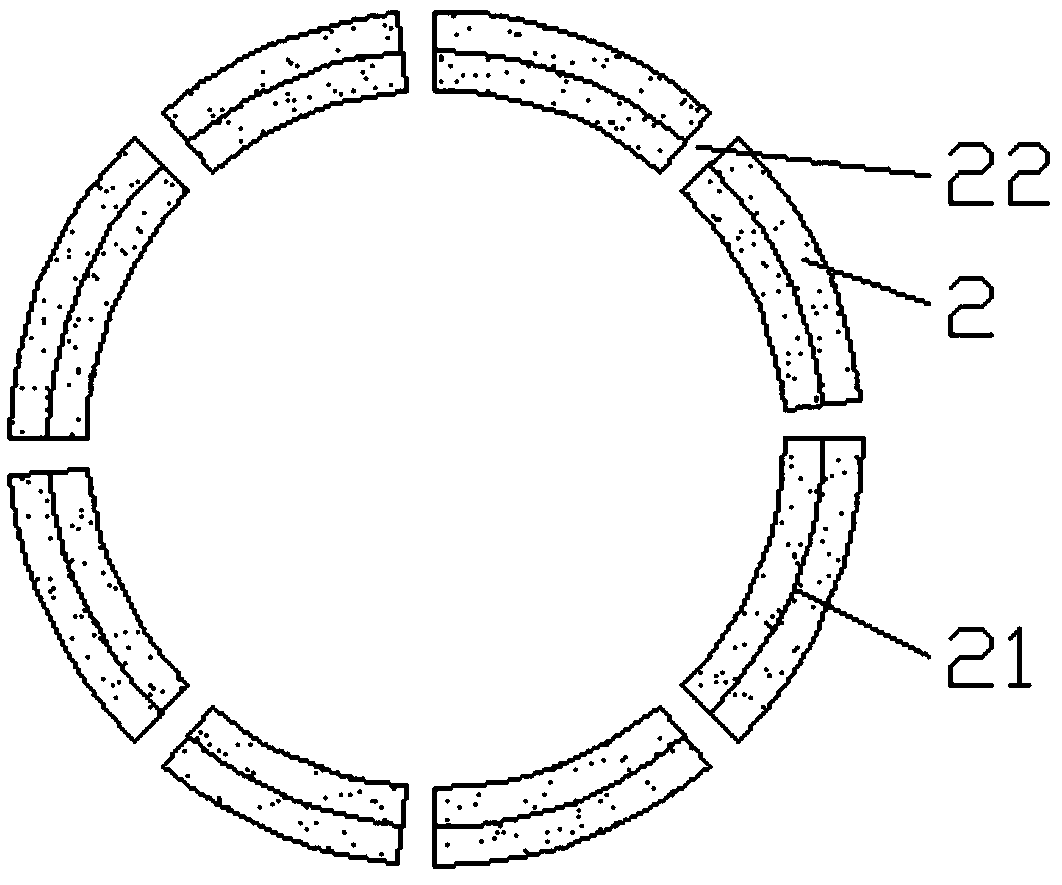

Rare earth neodymium iron boron magnet grain boundary diffusion method

InactiveCN111383833AAchieve magnetic hardeningImprove the heterosexual fieldInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementNeodymium iron boron

The invention relates to the technical field of permanent magnet preparation, and discloses a rare earth neodymium iron boron magnet grain boundary diffusion method. The method comprises the followingsteps: preparing an RTM alloy cast sheet containing heavy rare earth elements; preparing a neodymium-iron-boron magnet blank, and processing the neodymium-iron-boron magnet blank into a blank squaresheet; performing surface activation on the blank square sheet; placing the RTM alloy cast sheet and the blank square sheet subjected to surface activation in a graphite box in an up-down overlappingmanner until the graphite box is full of the RTM alloy cast sheet and the blank square sheet; and carrying out vacuum heat treatment on the graphite box filled with the product to obtain the neodymium-iron-boron magnet subjected to diffusion treatment. The grain boundary diffusion process is adopted, the heavy rare earth elements in the RTM alloy casting piece enter the magnet from the surface ofthe magnet through grain boundary diffusion and exist in a grain boundary area, magnetic hardening of a main phase grain surface layer area is achieved, the residual magnetism of the prepared sinteredneodymium-iron-boron magnet high in intrinsic coercive force is reduced by a small amplitude, and the consumption number of the heavy rare earth elements is obviously reduced.

Owner:ZHEJIANG DONGYANG DMEGC RARE EARTH MAGNET CO LTD

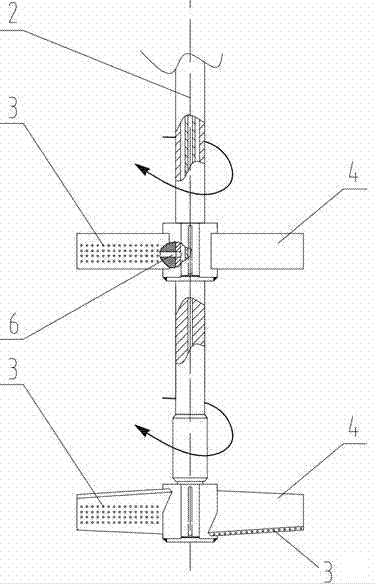

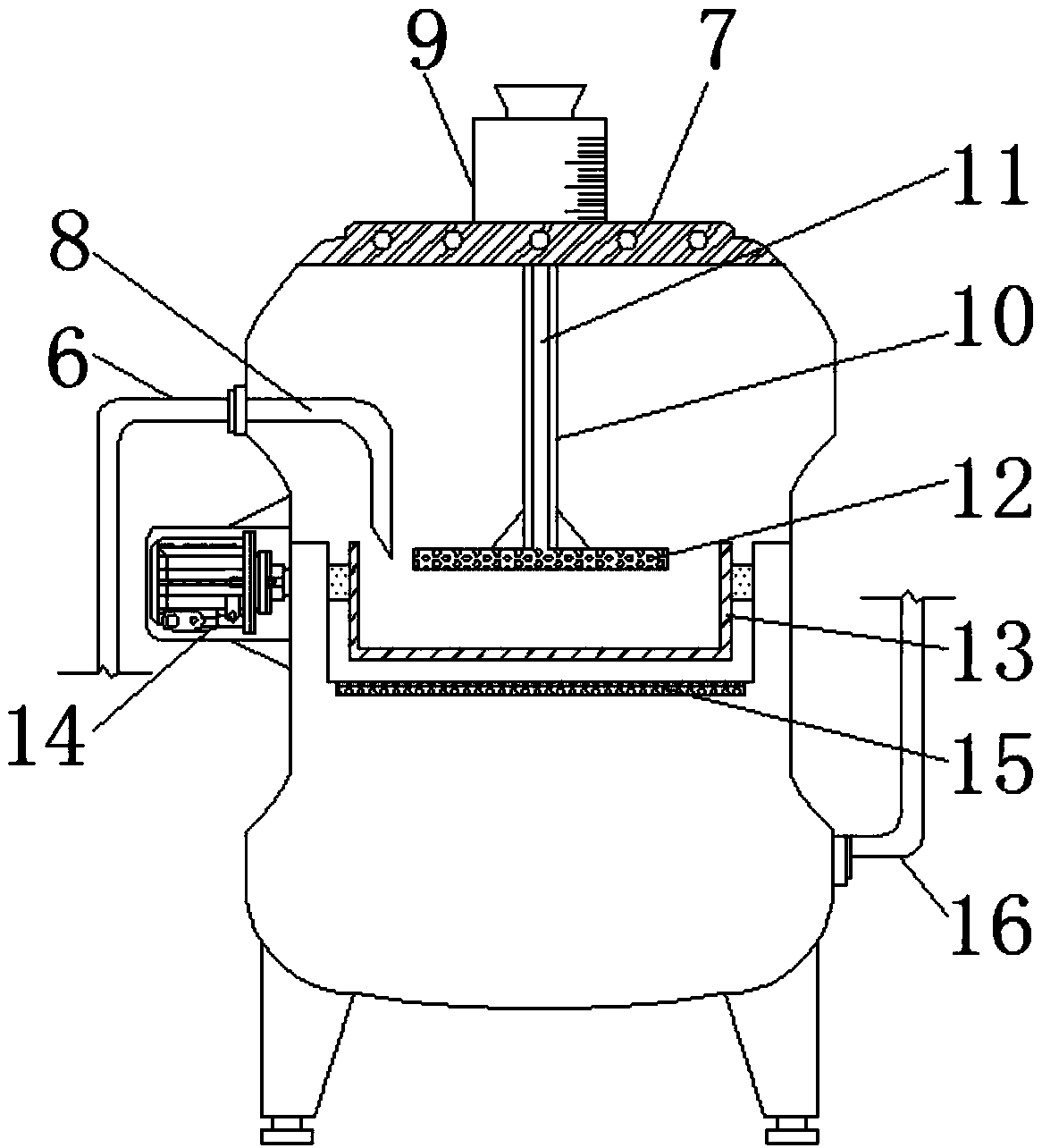

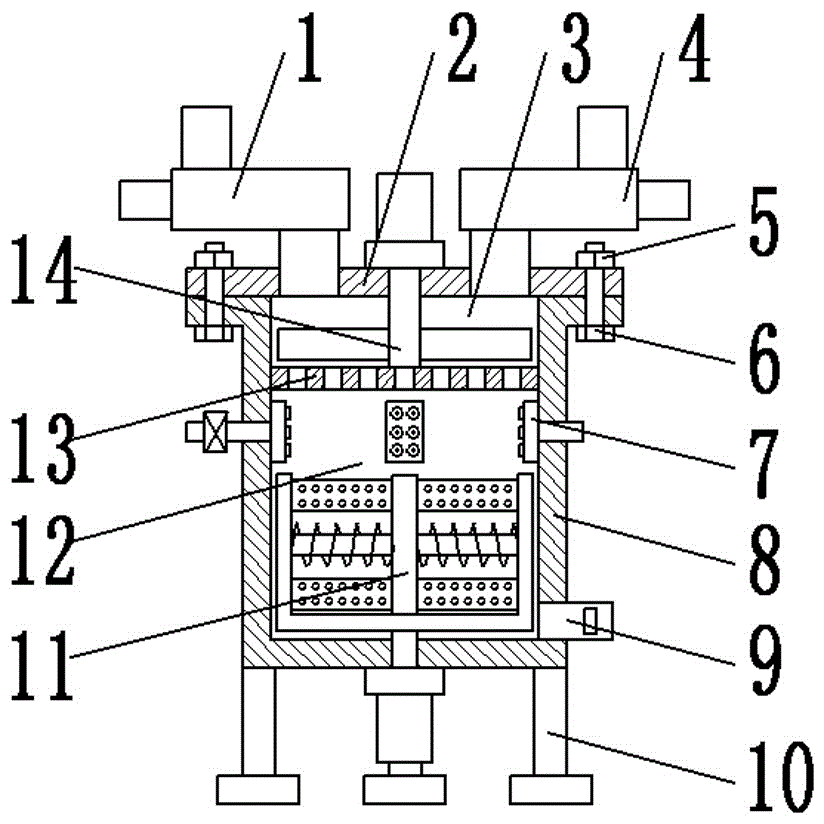

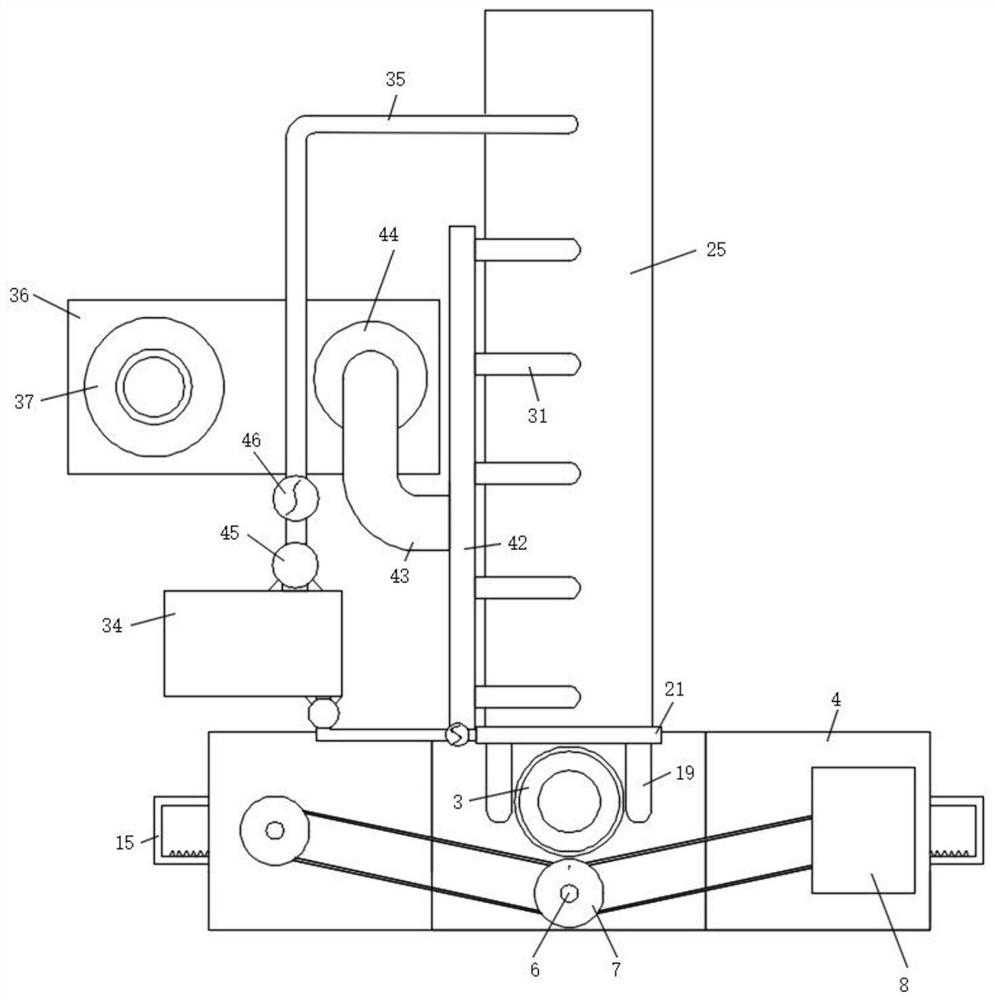

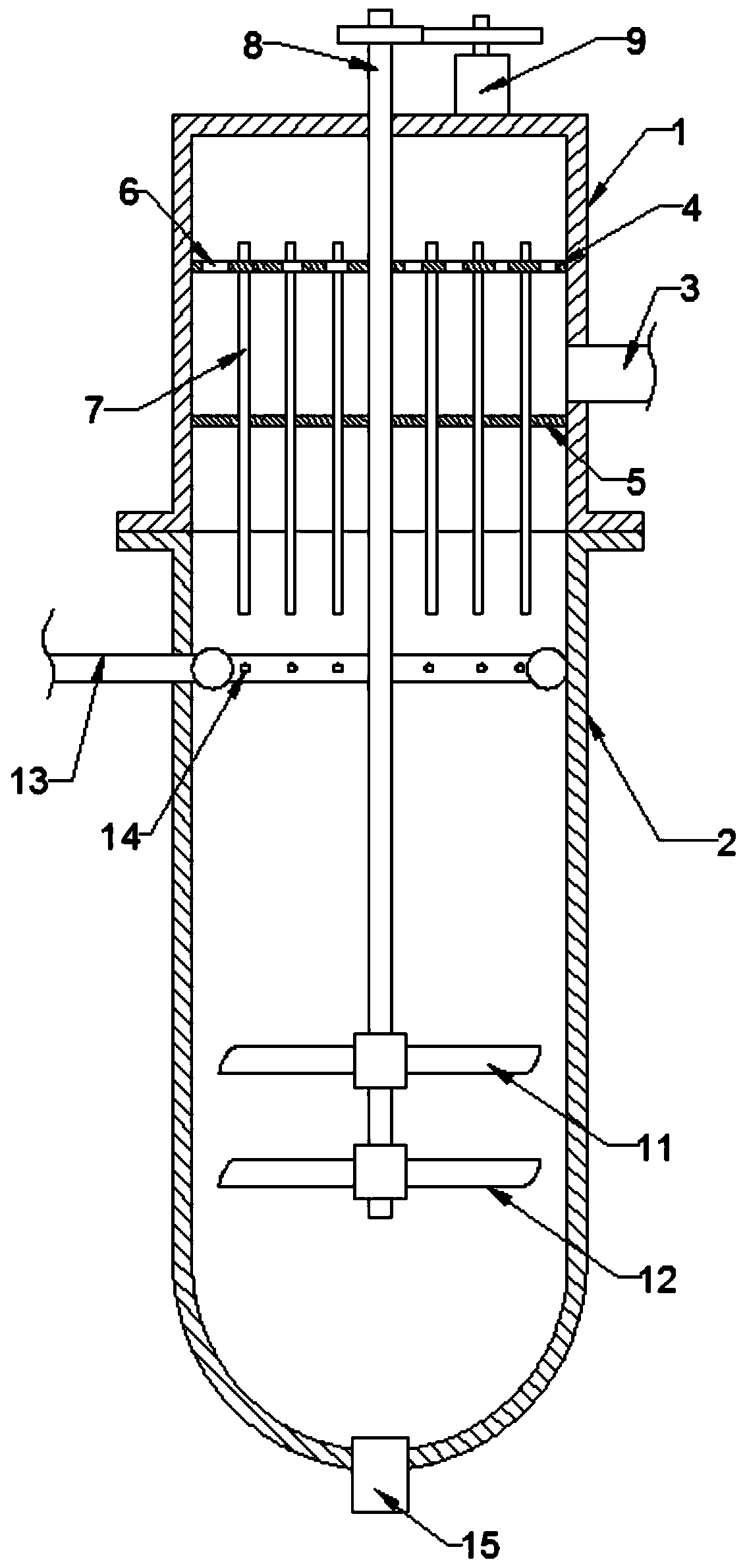

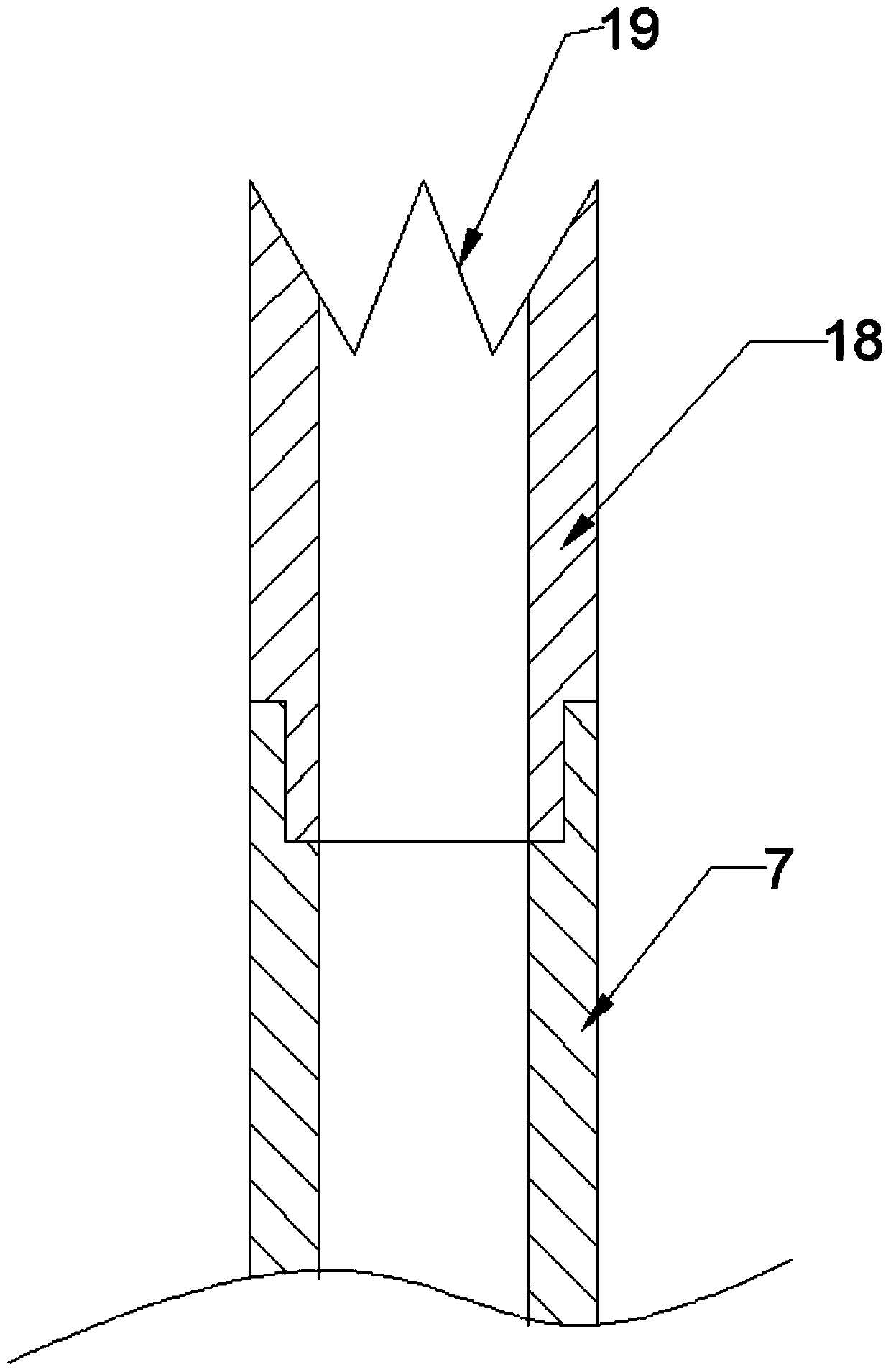

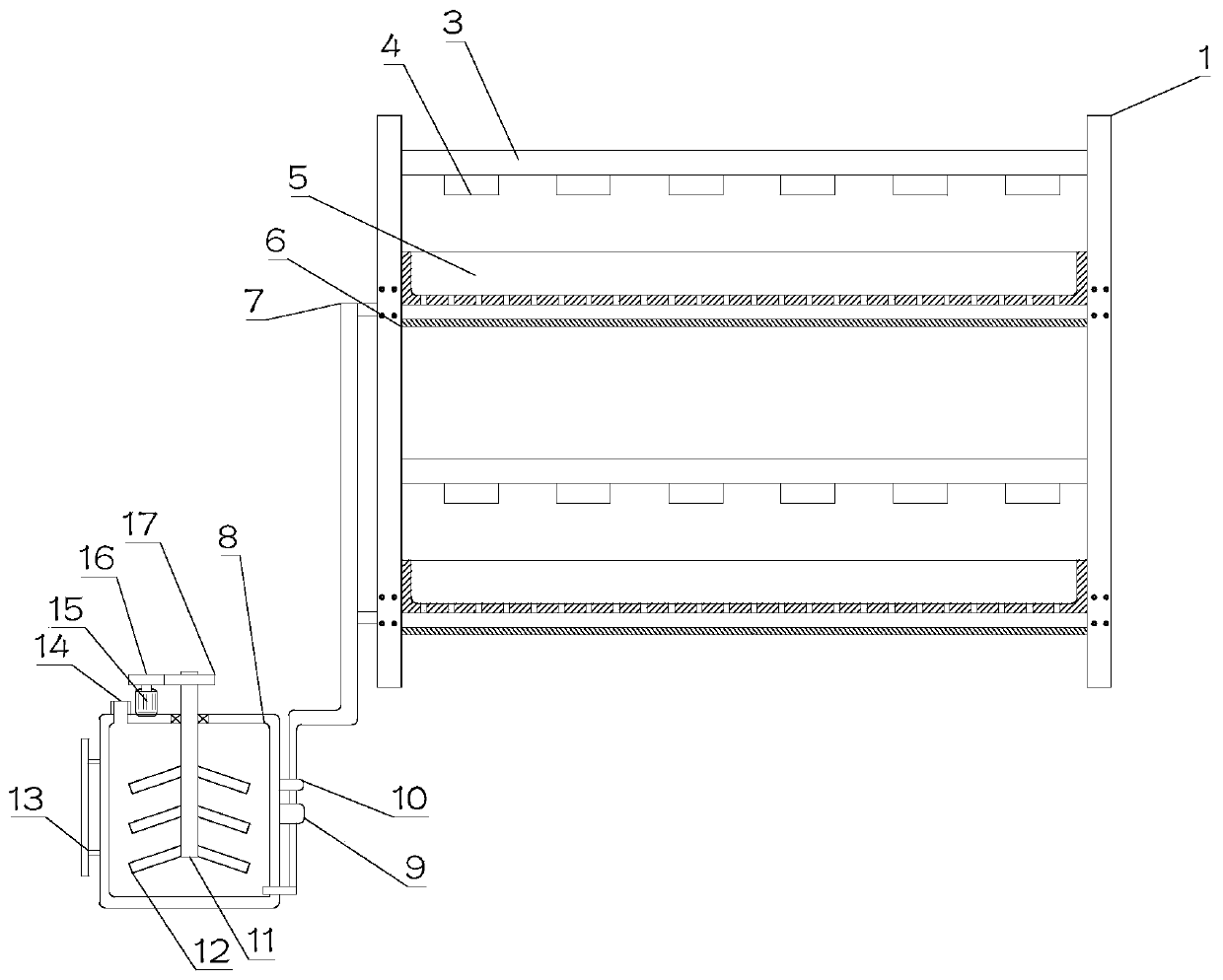

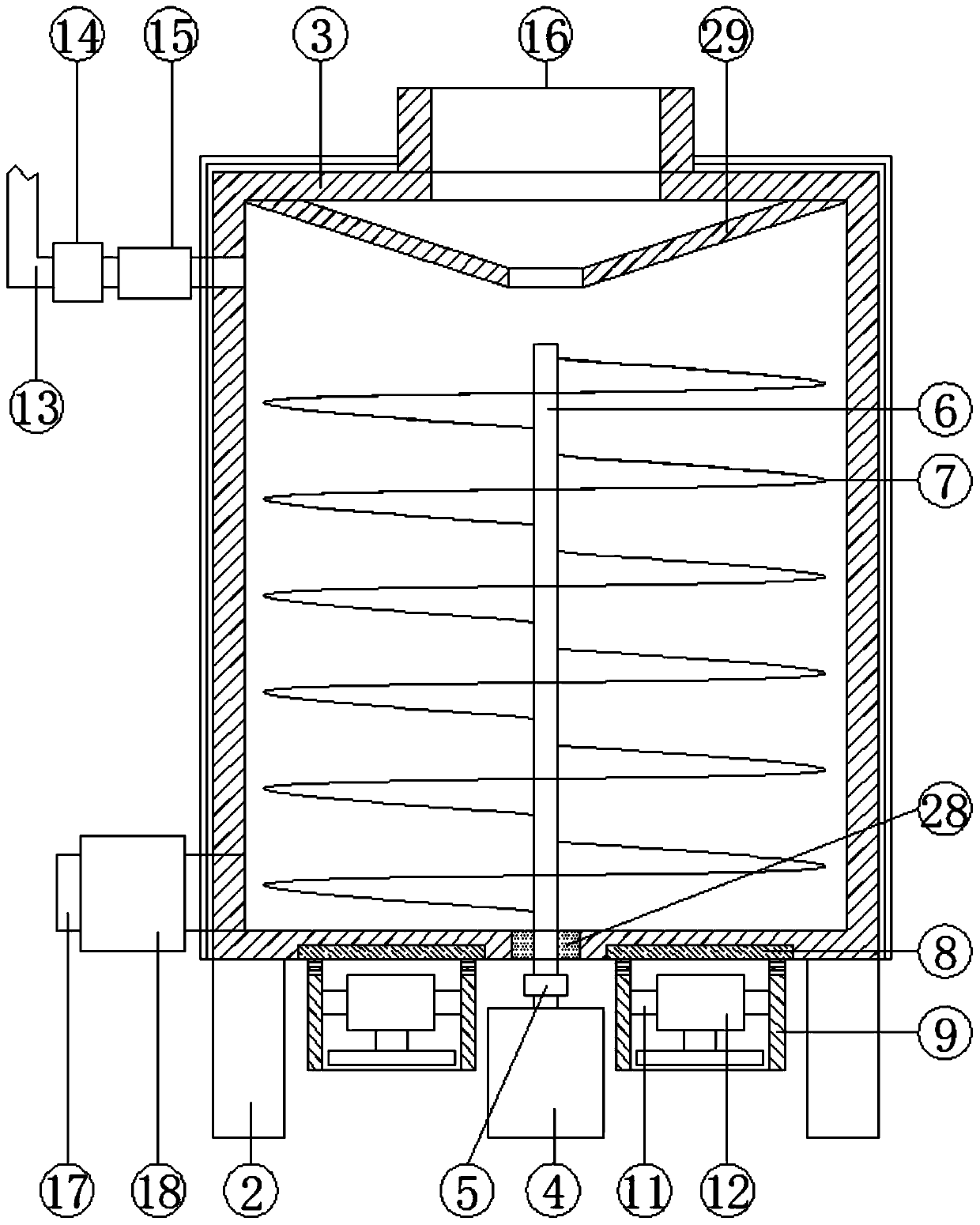

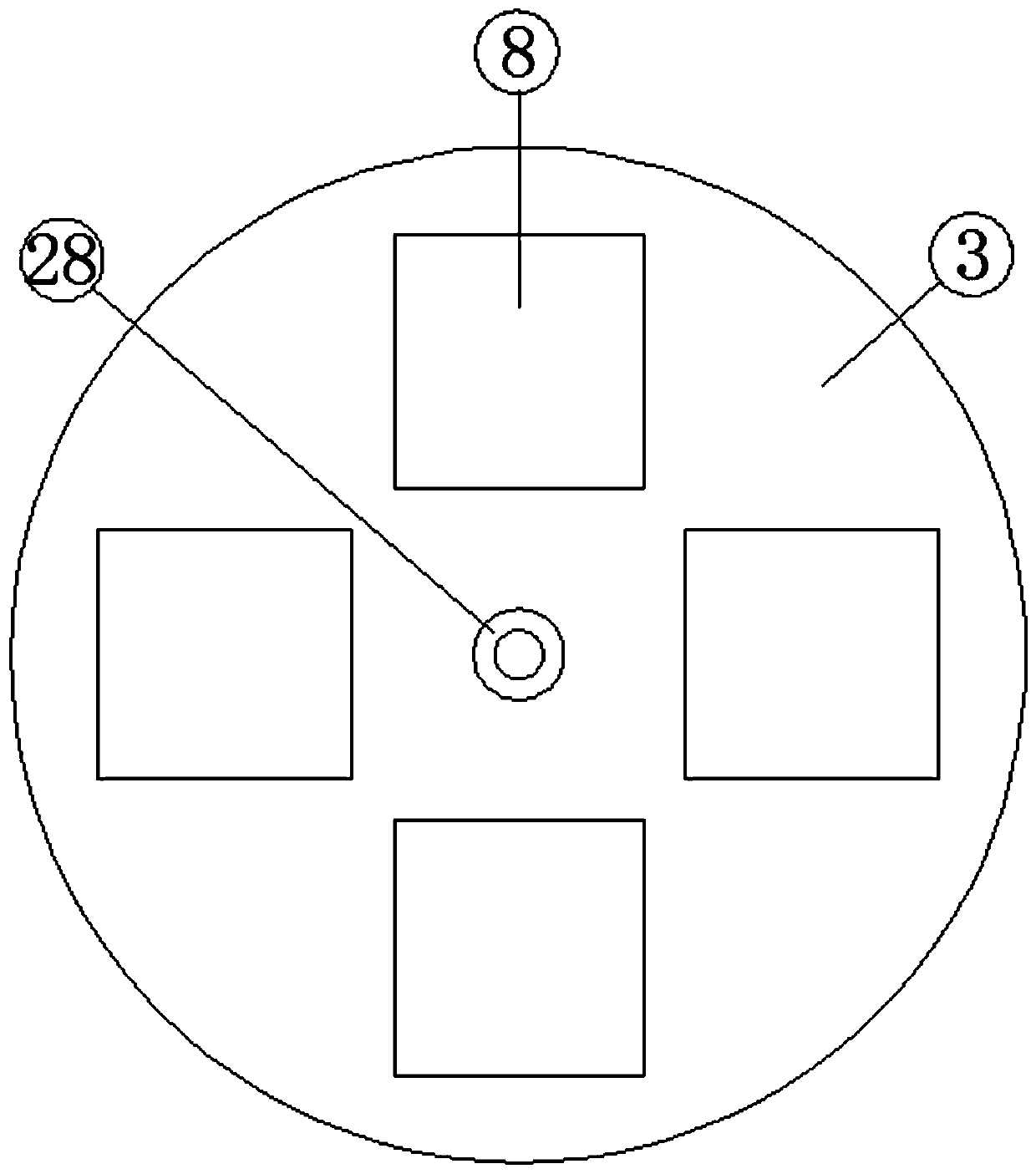

Feeding stirring device of wet metallurgy reactor

InactiveCN102965497AAdd evenlyAdd, and then add evenly through multiple sets of feeding holes on the stirring paddleRotary stirring mixersProcess efficiency improvementEngineeringReaction system

The invention discloses a feeding stirring device of a wet metallurgy reactor, relates to an improved feeding stirring device of a reactor for wet-process smelting and especially leaching, neutralizing, settling and crystallizing in wet metallurgy. The feeding stirring device structurally comprises a stirring shaft and stirring paddles arranged on the stirring shaft. The feeding stirring device is characterized in that the stirring shaft is a hollow rotating shaft, the upper end of the rotating shaft is provided with a feeding hole, positions, which are provided with the stirring paddles, on the stirring shaft are provided with discharging holes, the stirring paddles are provided with feeding through holes communicated with the discharging holes of the stirring shaft, and the blades of the stirring paddles are provided with discharging holes. According to the feeding stirring device disclosed by the invention, gas and / liquid is uniformly added in a reaction system effectively, so that the utilization rate is increased, the adding quantity is conveniently controlled, and the loss is reduced.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

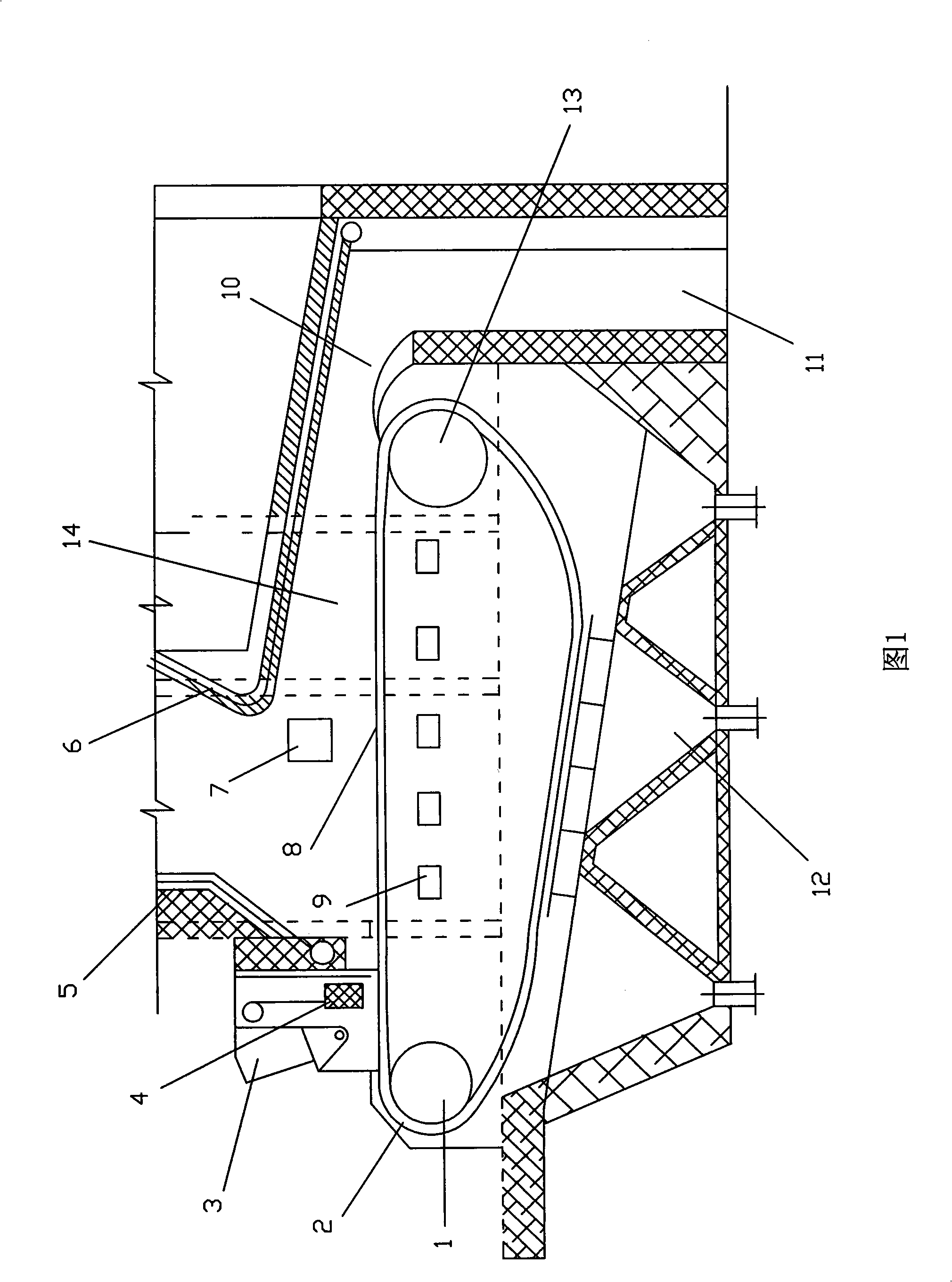

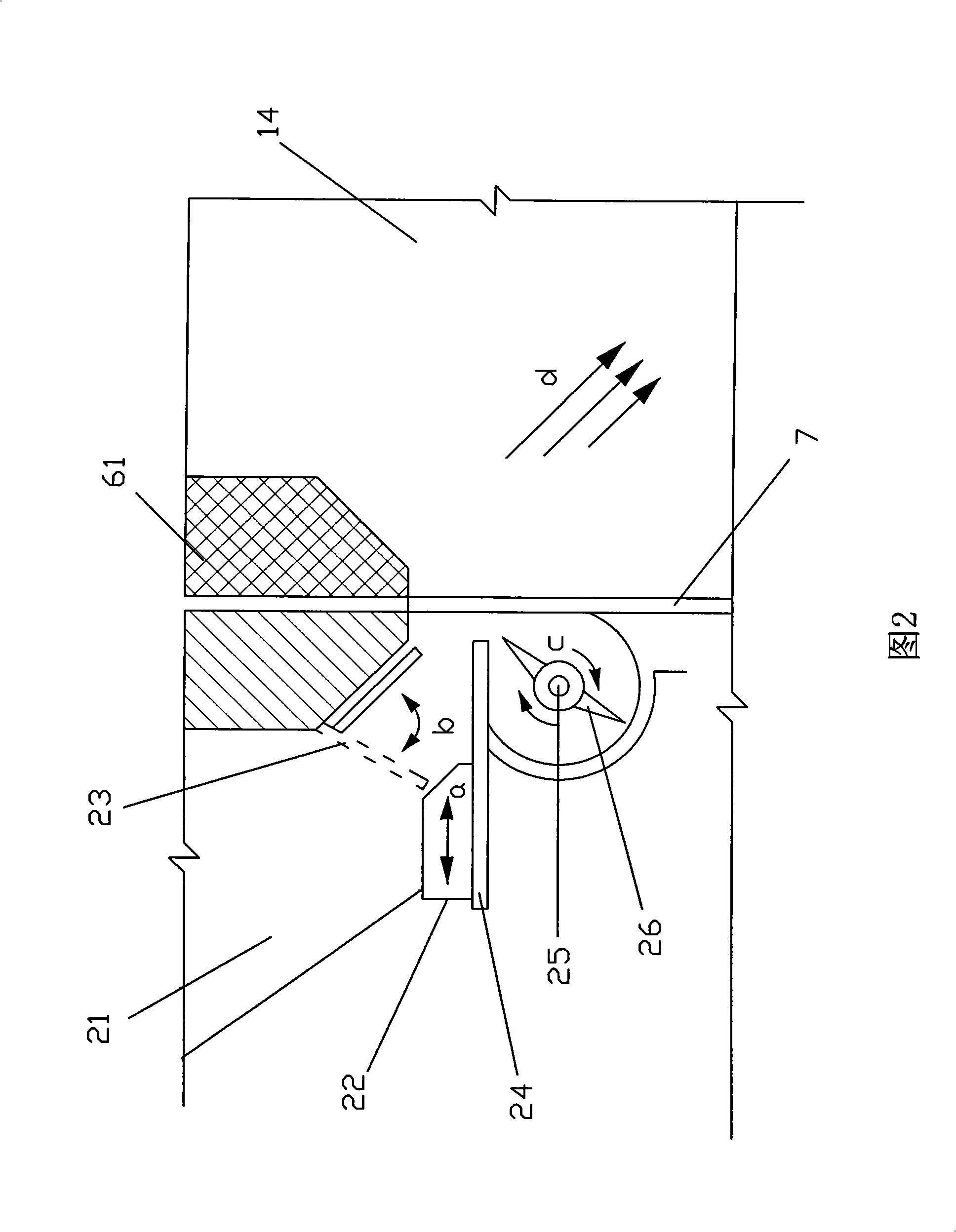

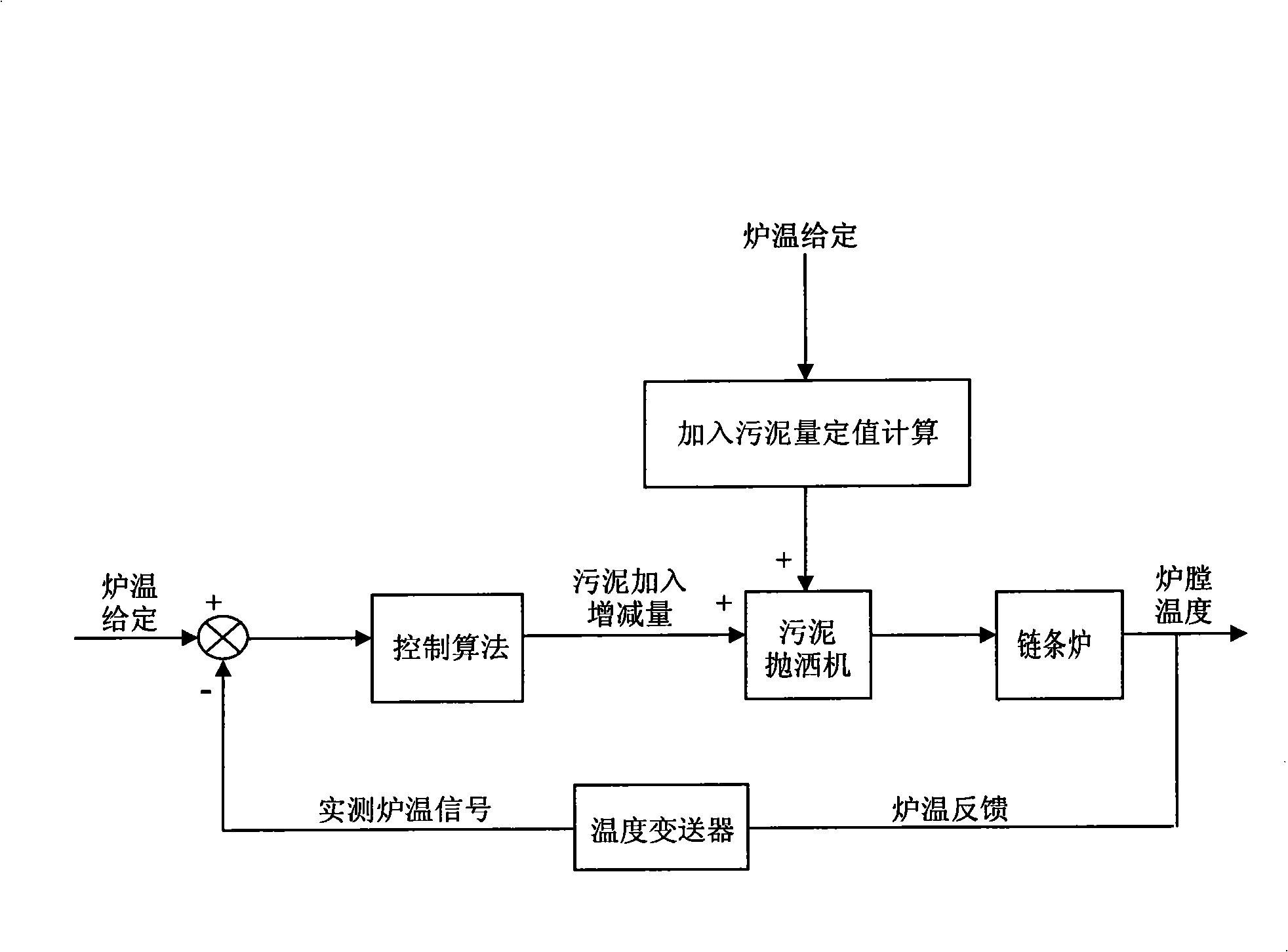

Method for burning sludge of chain furnace

InactiveCN101324337AEasy to control the amount addedHigh thermal efficiencyIncinerator apparatusHeating furnaceDewatered sludge

The invention discloses a method for burning sludge in chain grate. A sludge feeding port is arranged on rear arch on the side surface of the chain grate used in the method; and coal and sludge are respectively added into the furnace of the chain grate. The method comprises following steps: adding the coal into the grates of the chain grate through a coal valve from a coal scuttle in front of the chain grate; preheating, drying, and burning the coal sequentially along with the movement of the grates of the chain grate; uniformly adding the squeezed and dewatered sludge alone from the sludge feeding port into the chain grate, wherein the sludge falls onto the grates in a position in the vicinity to the rear arch at 1 / 2 to 3 / 4 the tail section of the furnace of the chain grate; and igniting and burning the sludge added in the position by the temperature of the tail section of the furnace of the chain grate when the coal burning is substantially ended, wherein the added amount of the sludge is calculated and adjusted in real time according to the heat value of the coal and the temperature when the added amount is stabilized. The chain grate can ensure complete burning of coal when used for burning various kinds of sludge with heat energy utilization value, thus effectively utilizing the heat value of the sludge and improving the heat efficiency of the chain grate.

Owner:ZHEJIANG HUAZHANG TECH

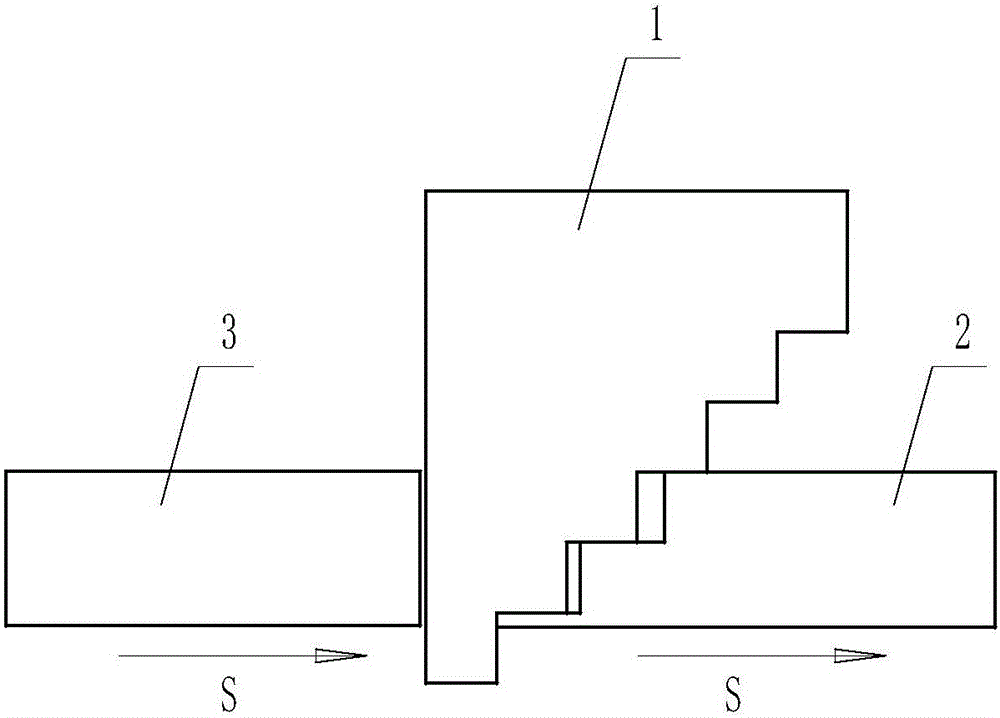

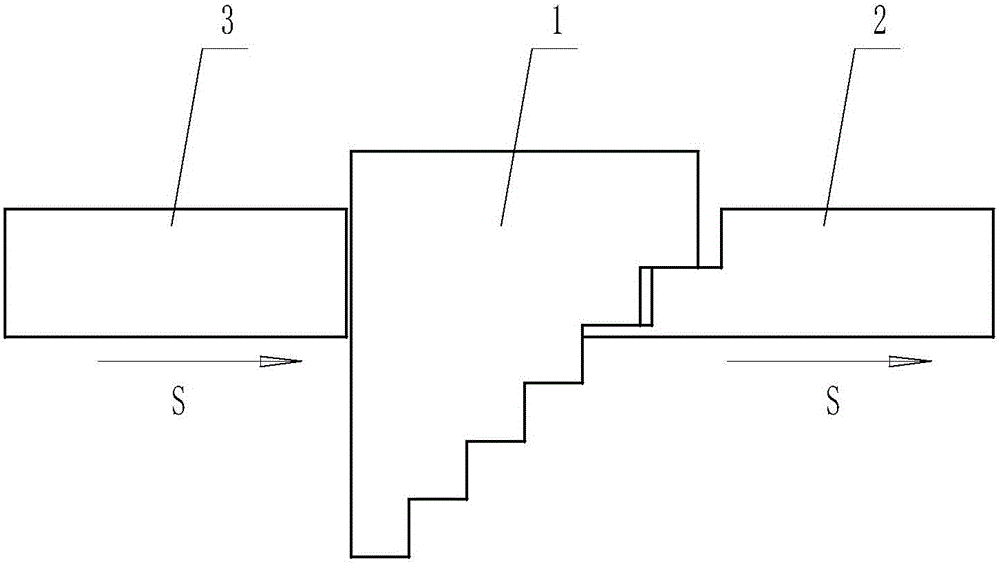

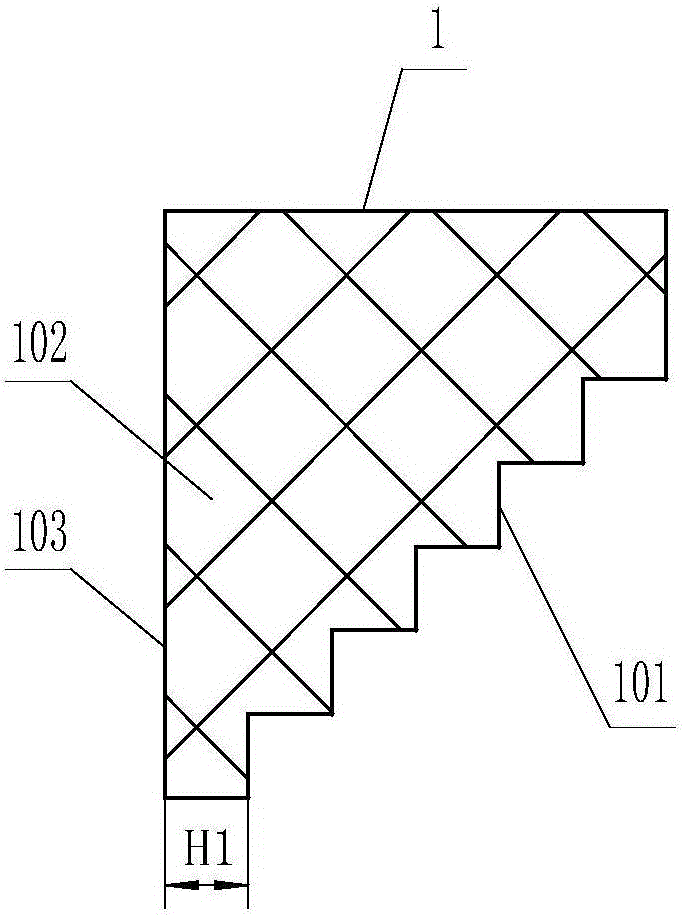

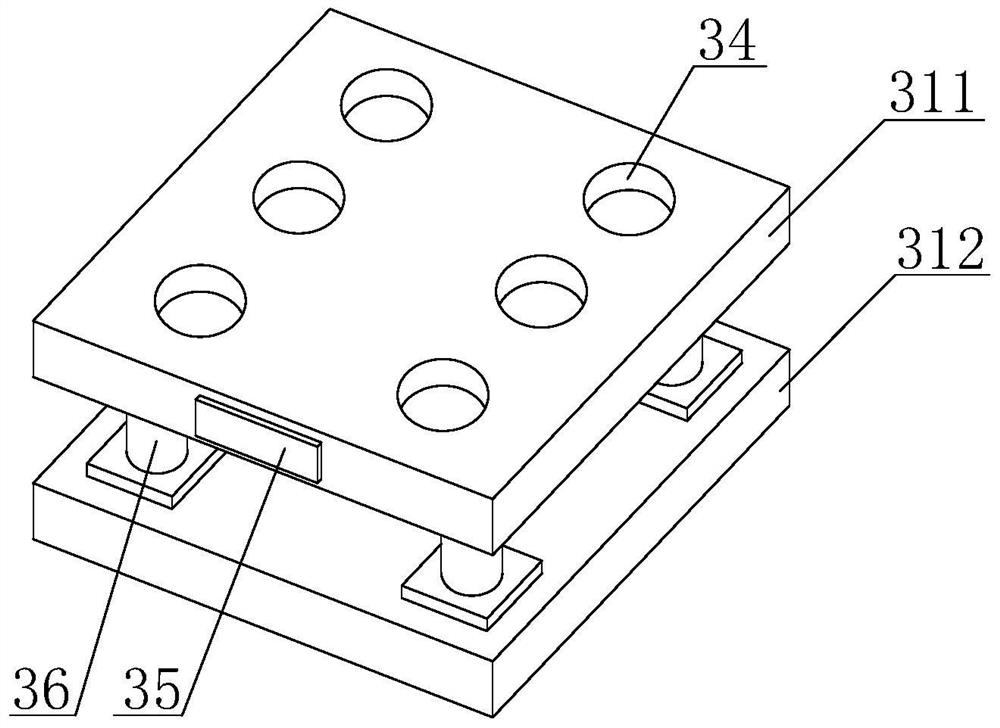

Step type multi-optical path cuvette

InactiveCN105891117AMeet the needs of multi-path measurementEasy to useMaterial analysis by optical meansCuvetteSpectrograph

The invention provides a step type multi-optical path cuvette and relates to a cuvette. The step type multi-optical path cuvette comprises a cuvette body, a step type cuvette table, a sliding baffle block, wherein the cuvette body is a step type cuvette, and a plurality of steps I are arranged on the step type cuvette; the step type cuvette table is arranged on one side of the step type cuvette, steps II matched with the steps I are arranged on the step type cuvette table, and the step type cuvette table is a light-proof body; and the sliding baffle block supports the other side of the step type cuvette. According to the step type multi-optical path cuvette, the optical path is regulated by increasing and decreasing the number of the steps of the step type cuvette, the requirements of multi-optical path measurements can be simultaneously met, the use is convenient, the entry of stray light can be avoided, and the addition of samples can be conveniently controlled; and samples with series of concentrations do not need to be prepared during rough measurement, operations such as semi-quantitative dilution can be directly carried out in the cuvette, so that the measurement conditions can be conveniently selected, and the sample amount can be further saved. The step type multi-optical path cuvette is particularly applicable to field measurement use of spectrographs.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

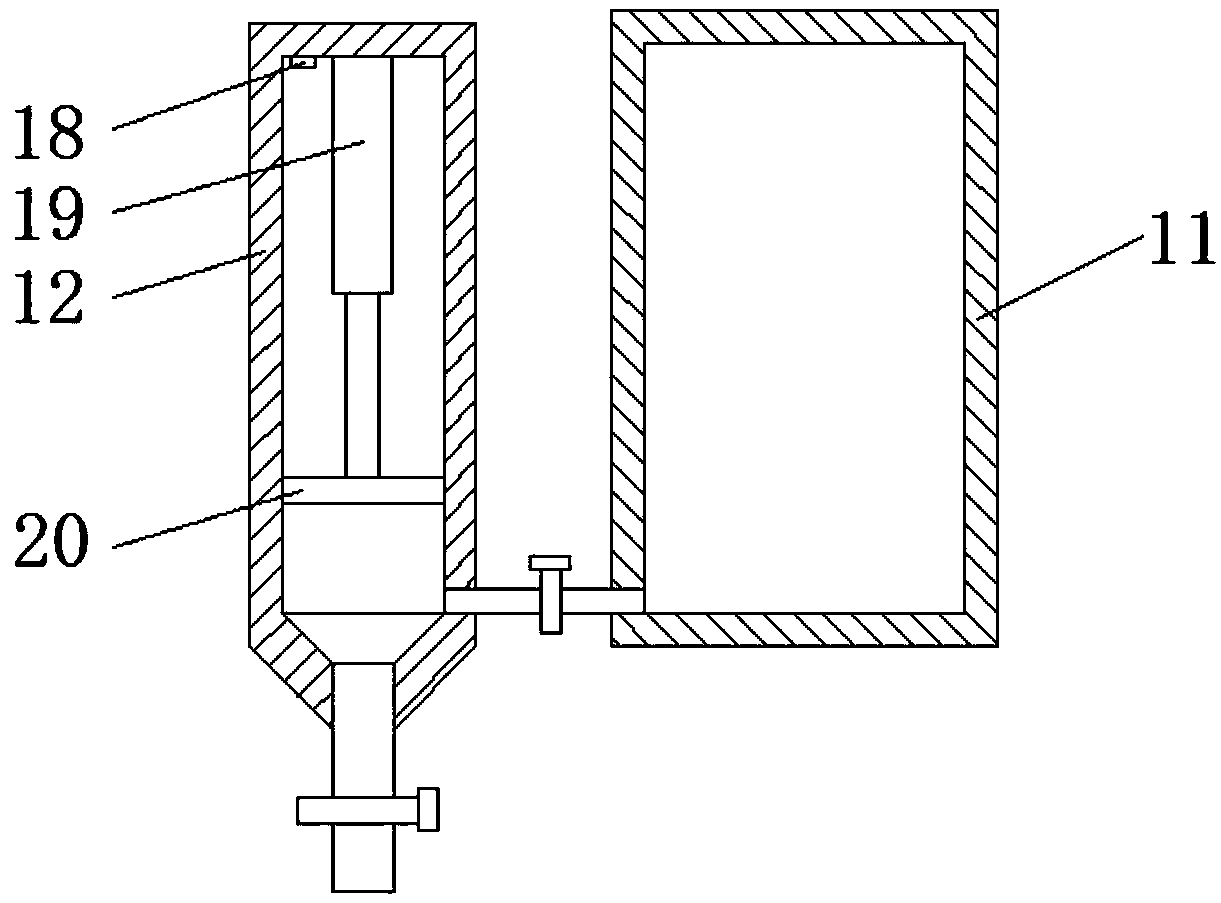

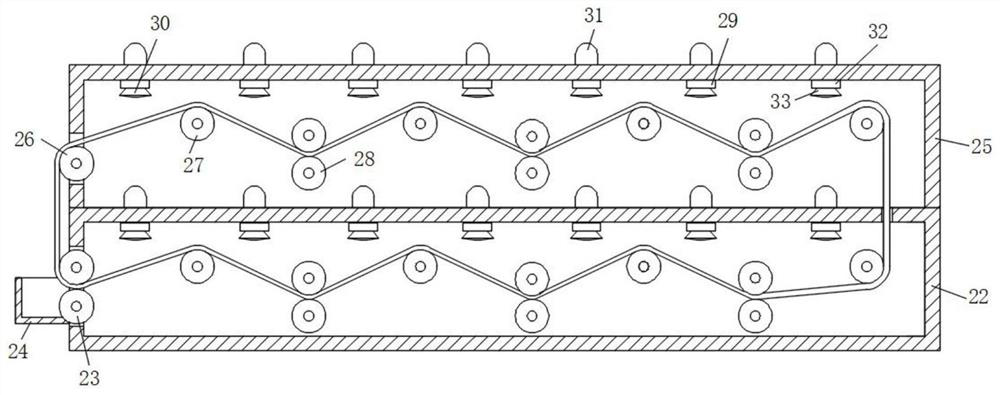

Filtering device for lithium sulfate concentrate for lithium mica production

ActiveCN108905922AIncrease the amount of controlGuaranteed stabilitySolution crystallizationChemical/physical/physico-chemical stationary reactorsLithium sulphateEngineering

The invention discloses a filtering device for a lithium sulfate concentrate for lithium mica production. The filtering device comprises a first kettle body and a first liquid outlet pipe. The upper end of the first kettle body is provided with a liquid inlet. The lower end of a filter plate frame is provided with a first filter net. The first liquid outlet pipe is disposed on the right side surface of the first kettle body. The first liquid outlet pipe passes through a second kettle body and is connected to a first feeding pipe. The fixed upper end of the second kettle body is provided with areagent cartridge. The middle of a connection rod is provided with a flow passage. The lower end of a liquid discharge tray is provided with a reaction tank. The left end of the reaction tank passesthrough the second kettle body and is connected to a first motor. The outer side of the right end of the second kettle body is connected to a second liquid outlet pipe. The filtering device can control the use amount of sodium carbonate, guarantee the reaction stability and prevent individual stirring and washing, has a small occupied area, realizes a low cost and has good centrifugal filtration effects.

Owner:江西海汇龙洲锂业有限公司

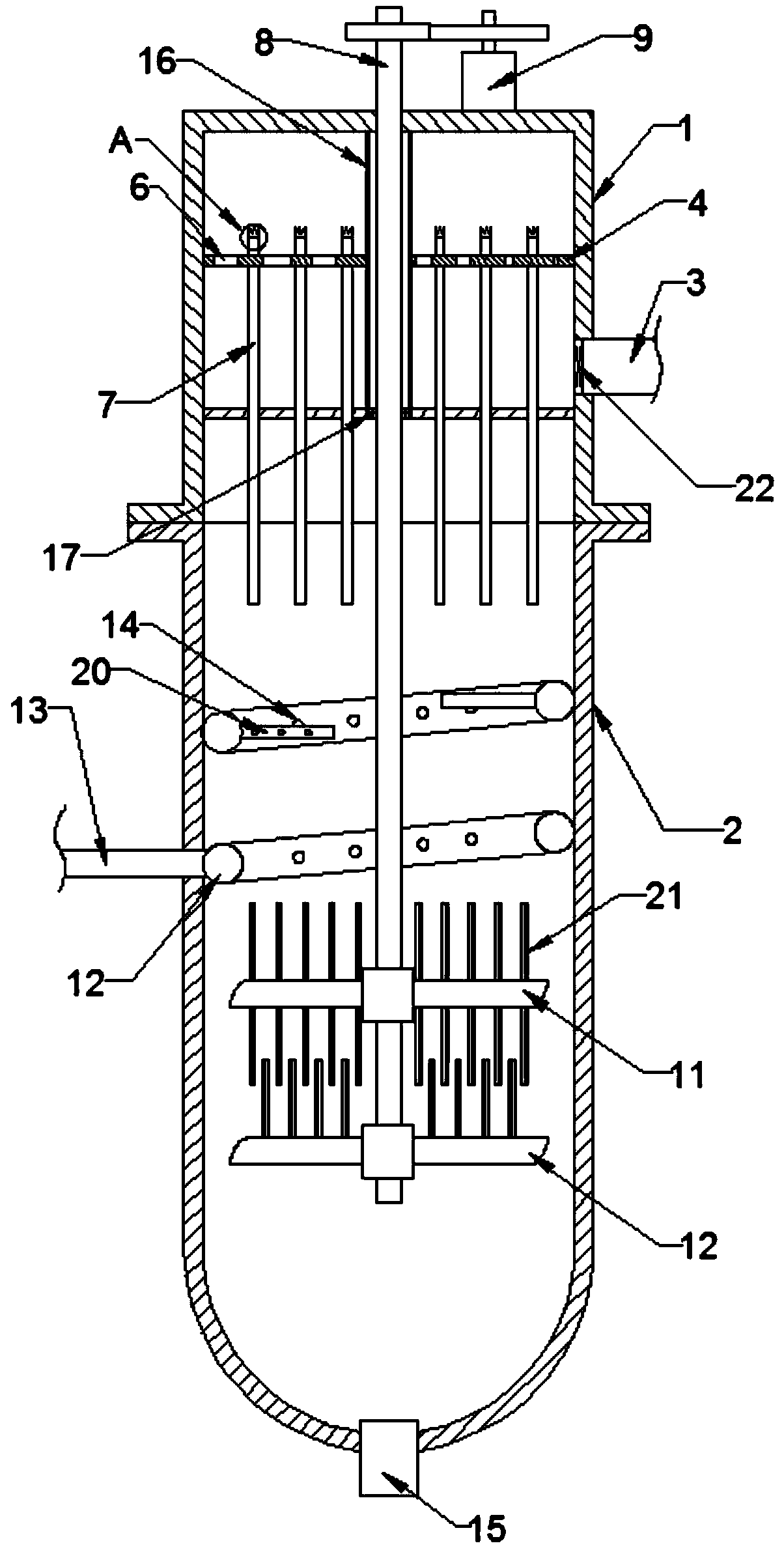

Chemical stirring tank capable of achieving premixing and being conveniently cleaned

InactiveCN106390825AEasy to control the amount addedAvoid uneven mixingRotary stirring mixersTransportation and packagingEngineeringWater pipe

The invention provides a chemical stirring tank capable of achieving premixing and being conveniently cleaned. The chemical stirring tank comprises a tank body and an upper cover; the interior of the tank body is partitioned into a premixing cavity and a stirring cavity through a partition plate; the upper cover is provided with feeding devices which comprise the first feeding device and the second feeding device; a premixing device is arranged in the premixing cavity and composed of a mixing motor, a mixing rotation shaft and mixing sheets; a cleaning device is arranged on the top of the stirring cavity and composed of a water pipe, spray heads and a pressurizing pump; a stirring device is arranged at the bottom of the stirring cavity and composed of a stirring motor, a stirring shaft, stirring sheets and a scraper plate. According to the chemical stirring tank, materials are added into the premixing cavity through the first feeding device and the second feeding device at uniform speed, and therefore the adding amount of the materials can be conveniently controlled; the materials are premixed through the premixing device; the materials are fully stirred through the stirring device.

Owner:李伟科

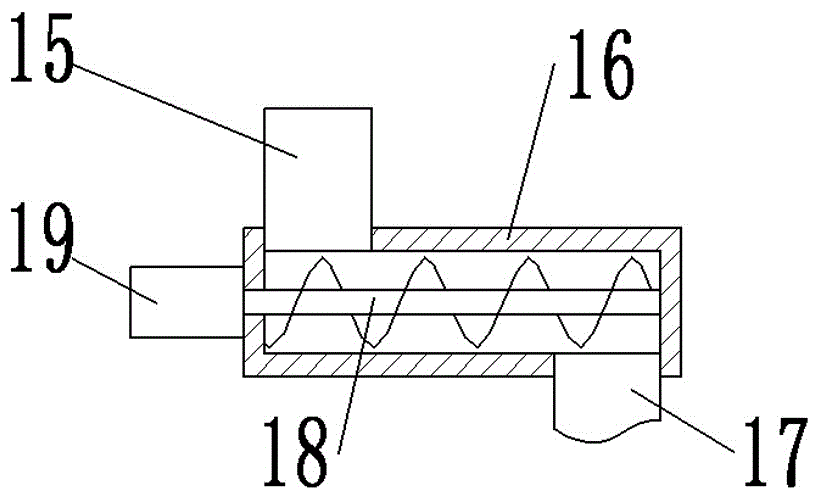

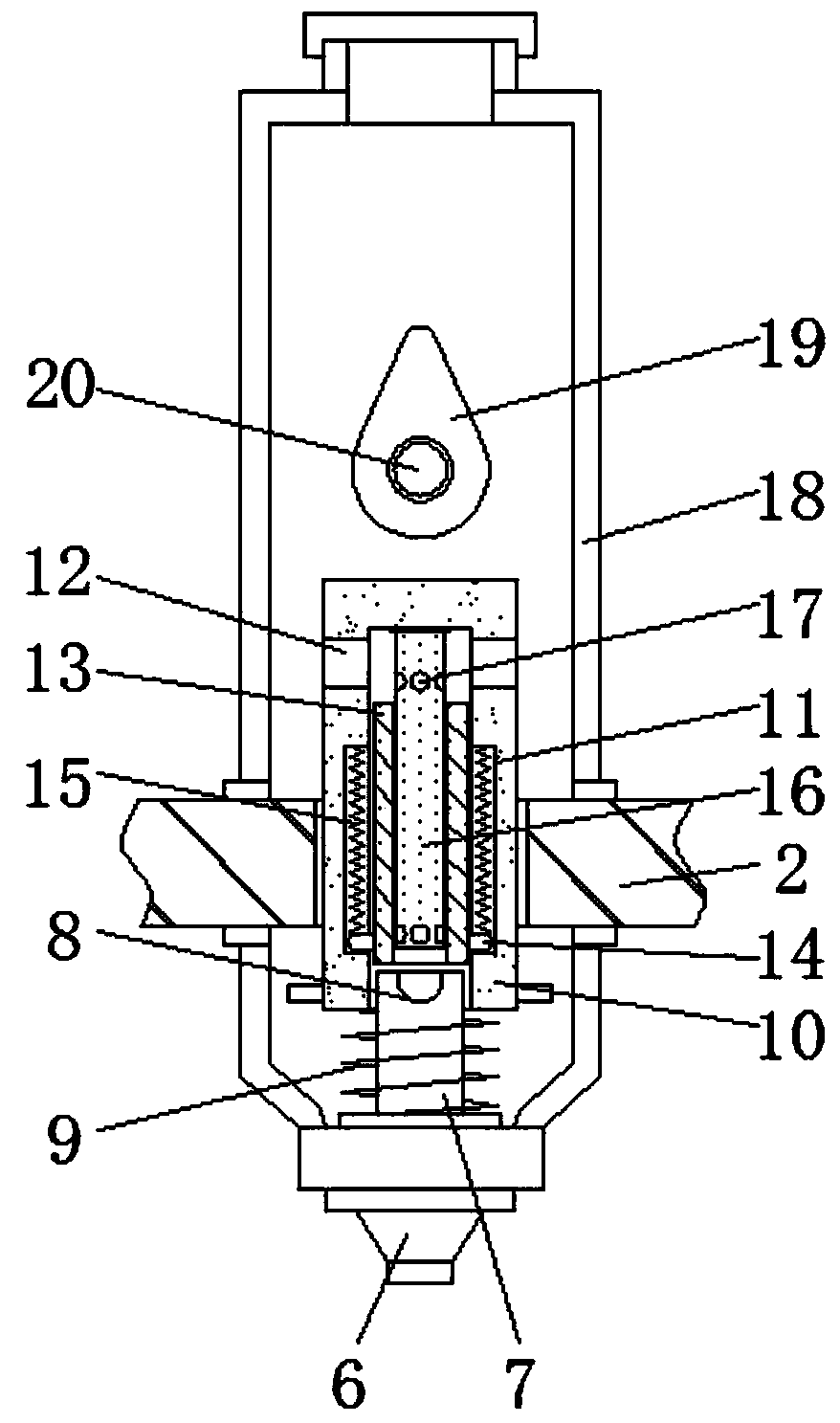

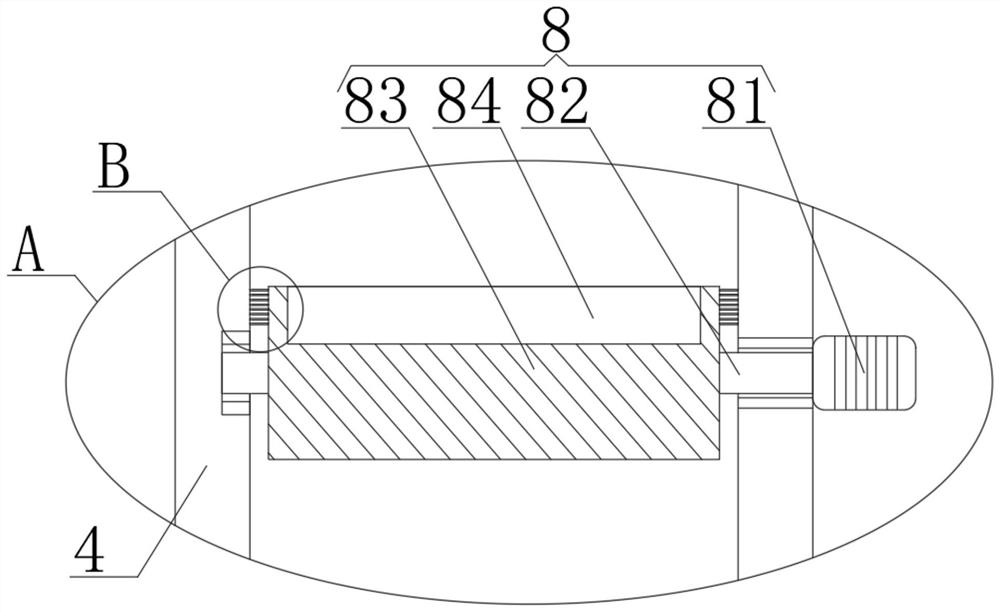

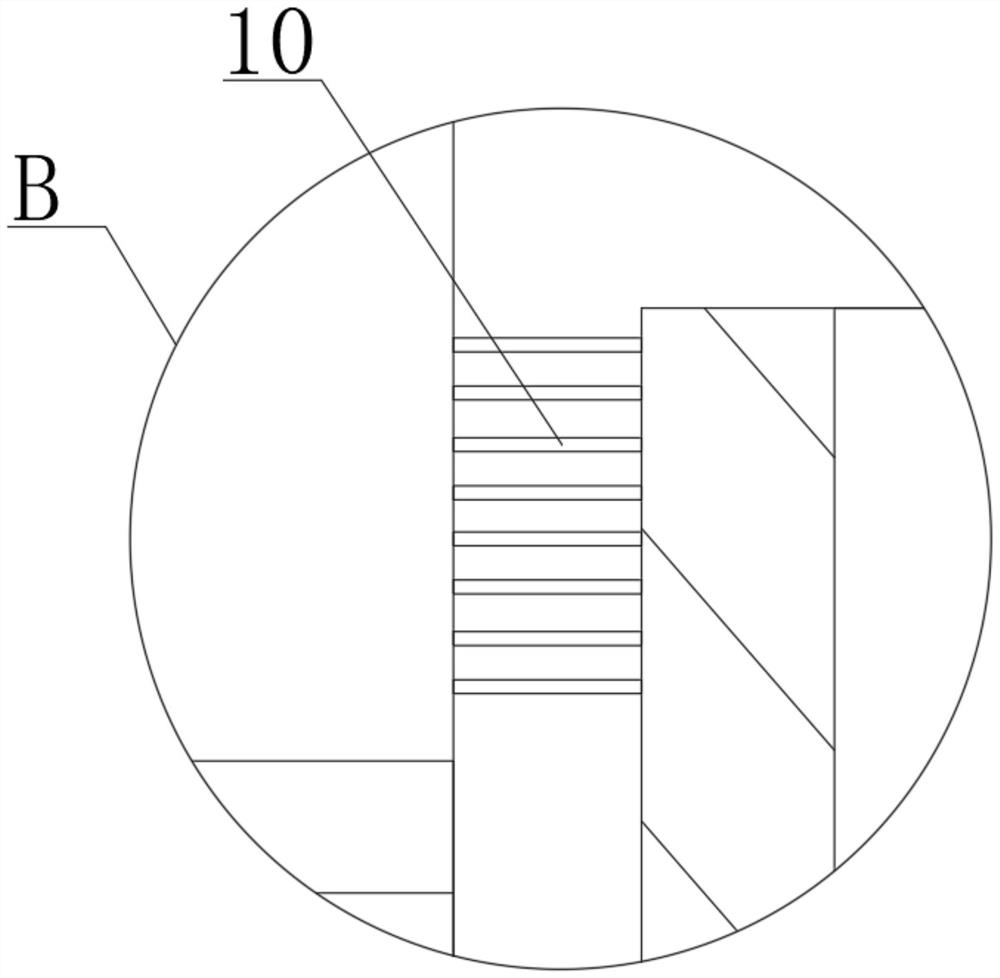

Automatic lubricating oil adding mechanism convenient for adding amount control for reducer

ActiveCN110805688AEasy to control the amount addedAvoid wasting energyGear lubrication/coolingRatchetReduction drive

The invention discloses an automatic lubricating oil adding mechanism convenient for adding amount control for a reducer. The automatic lubricating oil adding mechanism comprises a protection shell, an oil cup, a mounting box and a fourth spring. A groove is formed in the upper end of an oil outlet pipe, and a first spring is arranged on the outer side of the oil outlet pipe. The fourth spring isarranged on the right side of a connecting tooth block and located on the inner side of a storage groove. The connecting tooth block is connected with a vertical rod through the fourth spring. According to the automatic lubricating oil adding mechanism convenient for adding amount control for the reducer, when a third gear moves, the third gear can jack the vertical rod repeatedly, the vertical rod jacked by the third gear can stir and rotate a ratchet wheel through the connecting tooth block, the rotary ratchet wheel can drive a second transmission wheel and a first transmission wheel to rotate through a third transmission wheel, the self motion characteristic of the reducer can be utilized for driving the related lubricating oil adding mechanism to work, and power waste is avoided.

Owner:温州拓日工业设计有限公司

Refiner containing nitrogen for magnesium alloy as well as preparing and using method thereof

The invention provides a process for preparing nitrogen containing refiner for magnesium alloy, which comprises the following steps: respectively adding pure magnesium and pure aluminium in a vacuum electromagnetic induction furnace according to the mass ratio which is 7-9:1-3, adding Mg3N2 powder according to 3%-4% of aluminum-magnesium melt quality after heating up to alloy is completely melted, preserving heat, and casting, wherein percentage by weight of each component of nitrogen containing refiner which is got is that magnesium 70-90%, aluminum 9-29% and aluminium nitride 1-2%, adding refiner in the process for preparing magnesium alloy, wherein the adding amount is 0.5-1.5%, and the addition temperature is 700-750DEG C. The purpose of refining magnesium alloy crystal grain and improving strength toughness and corrosion resistance property of magnesium alloy can be achieved through utilizing the refiner to prepare Mg-Al magnesium alloy, the technique is simple, and addition amount and refining effect are easy to be controlled.

Owner:ZHENGZHOU UNIV

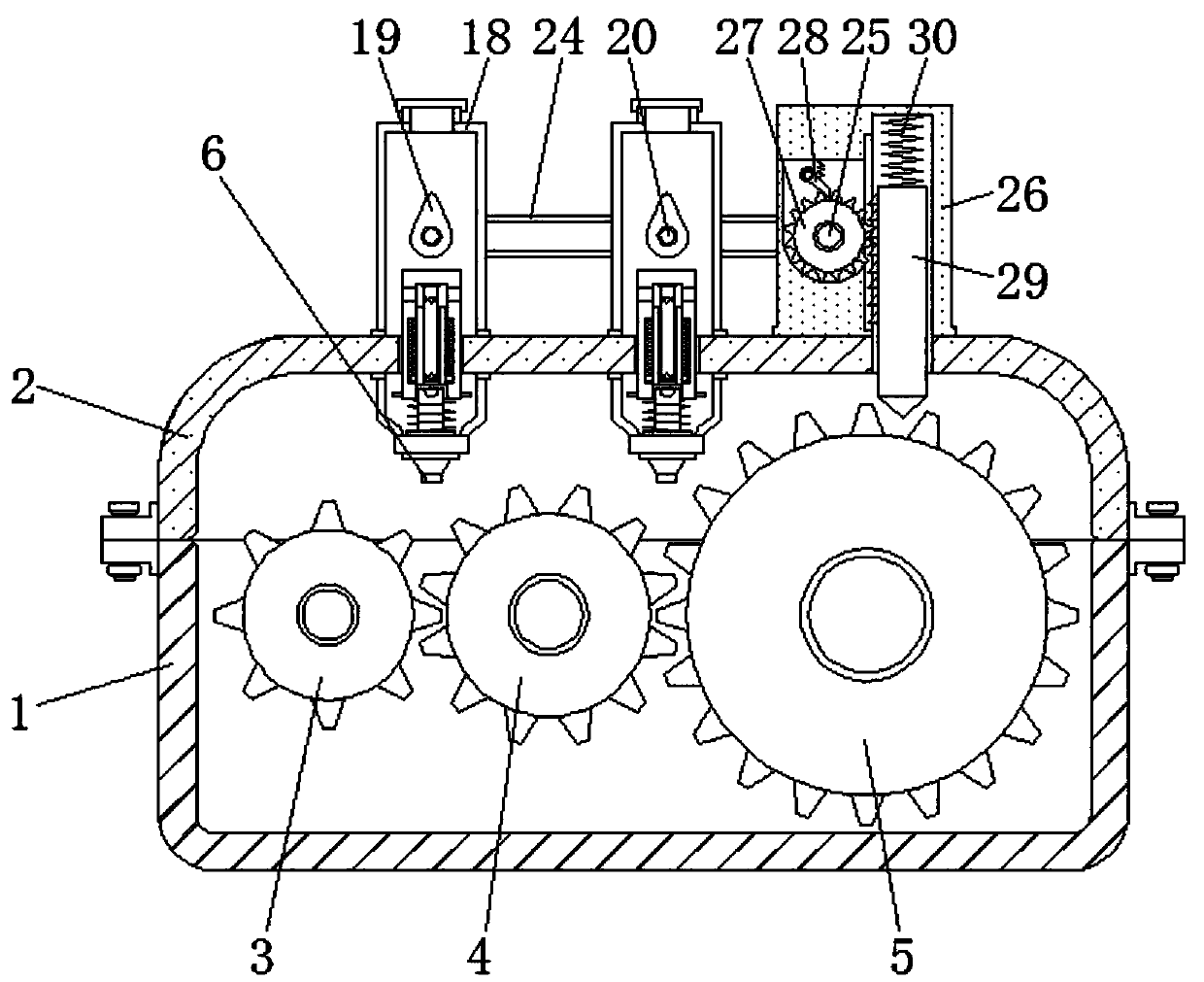

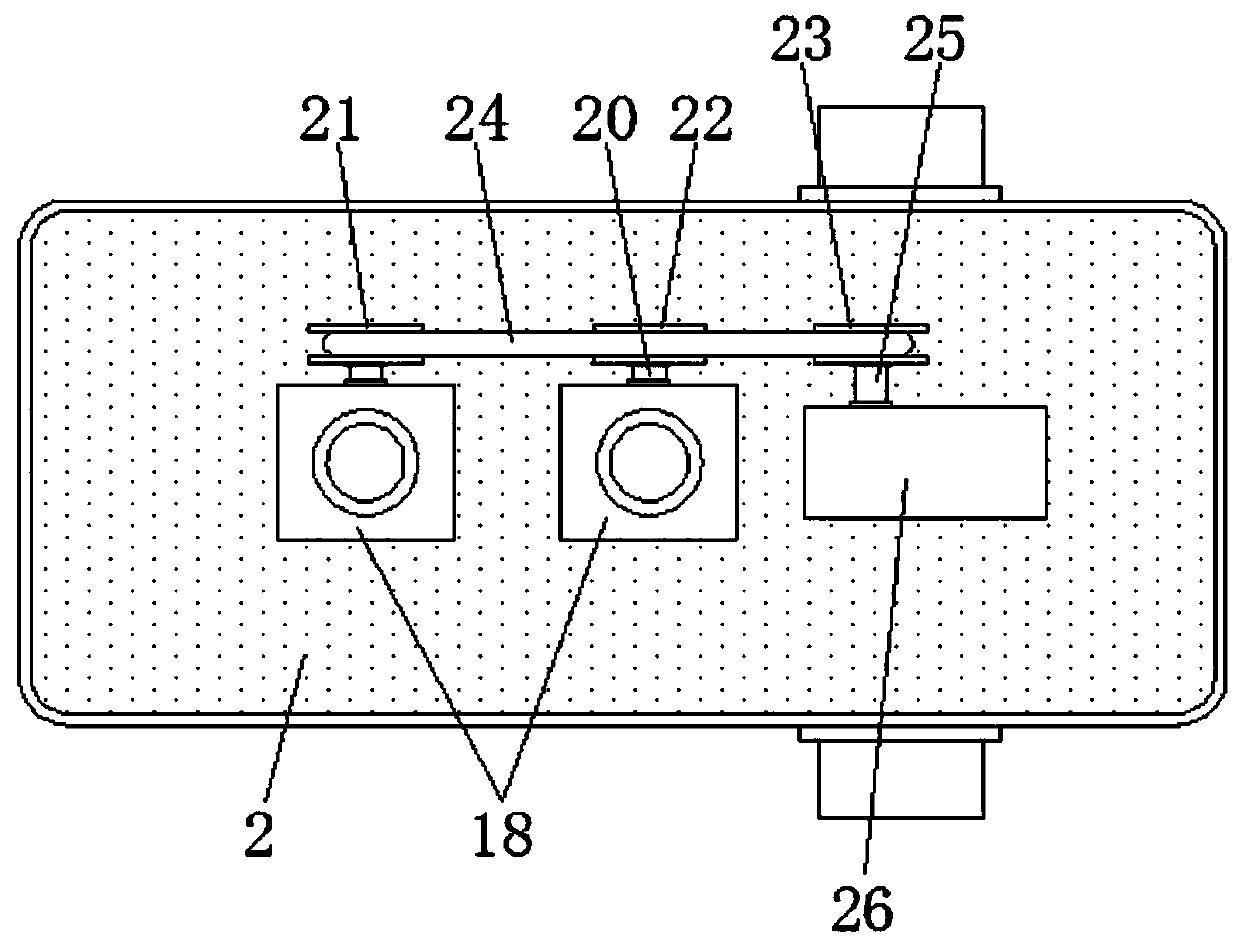

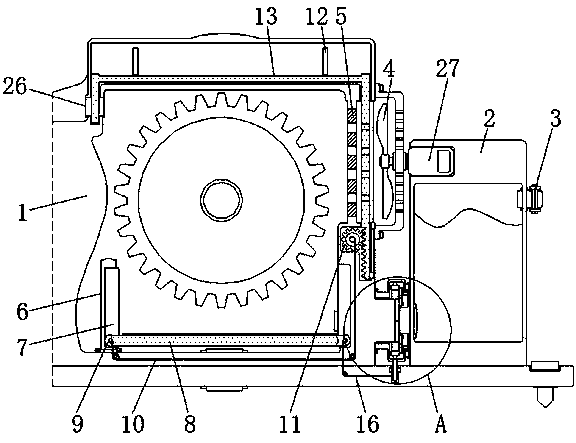

Speed reducer lubricating oil automatic adding mechanism with addition amount convenient to control

InactiveCN110500397AEasy to control the amount addedRealize quantitative addition functionGear lubrication/coolingAutomatic controlGear drive

The invention discloses a speed reducer lubricating oil automatic adding mechanism with the addition amount convenient to control. The mechanism comprises a substrate, fixing plates and a micro motor.An oil collecting box is mounted on the right side of the substrate through bolts, and an oil inlet is formed in the outer surface of the oil collecting box. The micro motor is mounted at the upper end of the oil collecting box, and an output end of the micro motor is fixedly connected with a cooling fan. The cooling fan is connected with the inner surface of the substrate. First air inlets are formed in the inner surface of the upper end of the substrate, and the inner surface of the substrate is fixedly connected with the fixing plates. According to the speed reducer lubricating oil automatic adding mechanism with the addition amount convenient to control, when lubricating oil in the device is consumed after long-time working or evaporates under a high temperature, the height of a movable floating block is moved downwards, accordingly, a transmission gear drives six seal blocks to automatically open through relative reset force of a torsional spring, accordingly, lubricating oil addition work is automatically performed, and an automatic lubricating oil addition function with the addition amount automatically controlled is achieved.

Owner:董涛

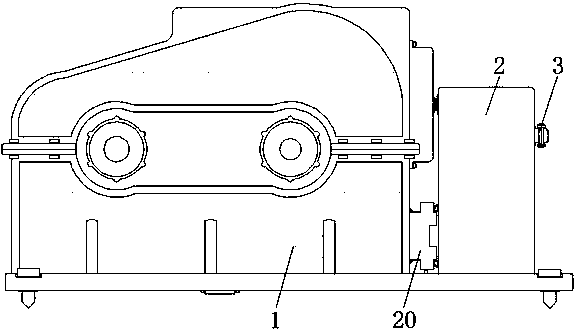

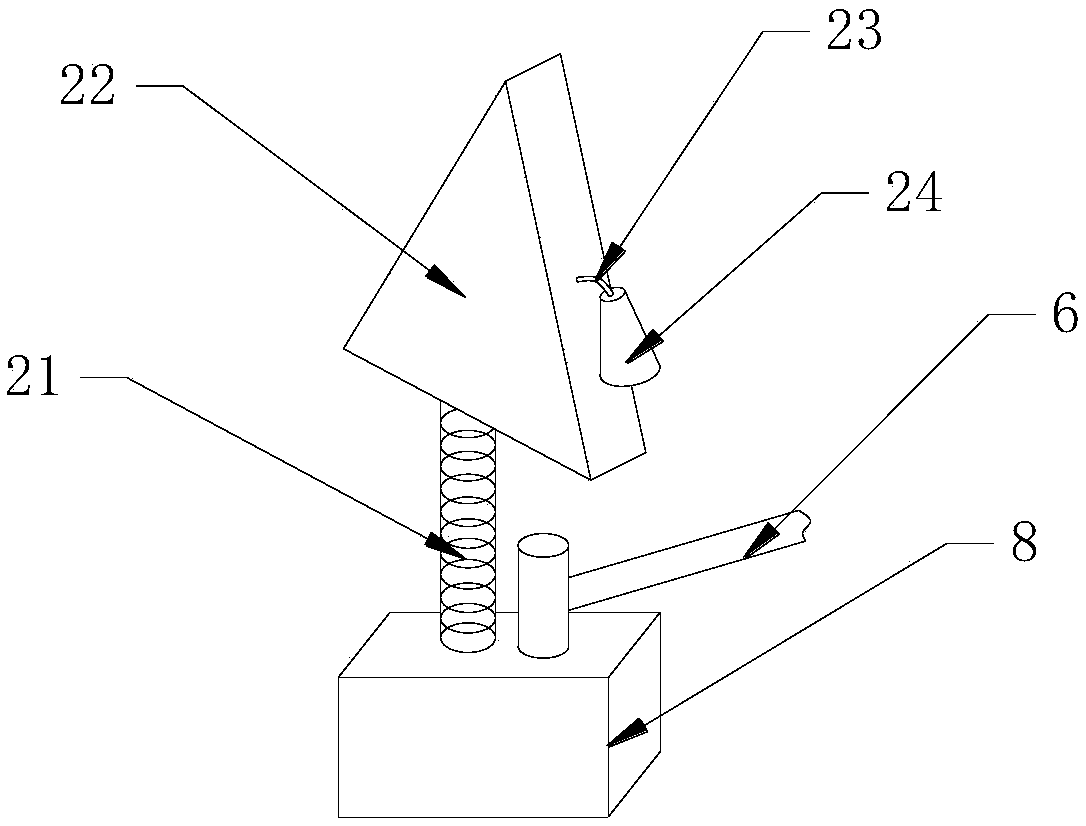

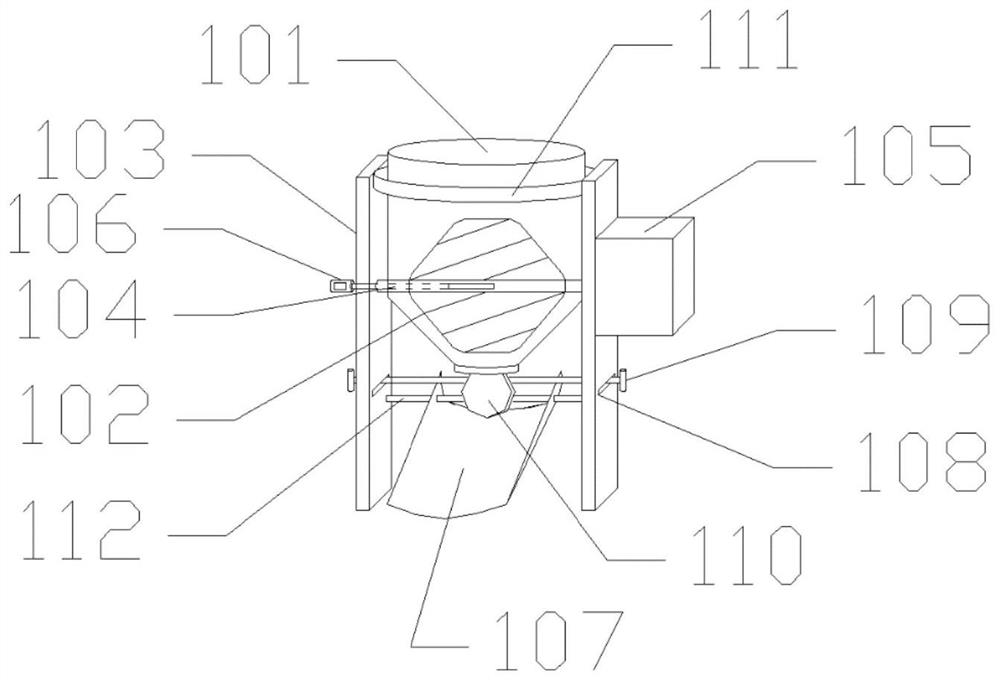

Multifunctional impeller aerator for aquaculture

InactiveCN108925494AEasy to control the amount addedIncrease the amount of controlPisciculture and aquariaAnimal repellantsImpellerFuel tank

The invention provides a multifunctional impeller aerator for aquaculture. The multifunctional impeller aerator for aquaculture comprises a boss, an oil tank, a blocking block, a pull rod, a scale rod, a floating block, a spring, a reflector, a drawstring and a copper bell, wherein the boss is arranged at the annular side surface of a motor, the oil tank is mounted on the right side of the upper end surface of the boss, and the blocking block is assembled at the inner bottom of the oil tank; the lower end of the pull rod is fixed at the middle of the upper end surface of the blocking block, the scale rod is assembled at the upper end of the oil tank, and the lower end of the scale rod runs through the oil tank and is connected with the floating block; the blocking block is disposed insidethe oil tank; and through the design, the addition amount of gear oil can be controlled conveniently, the spring is mounted on the upper end surface of the floating block, the reflector is assembled on the upper end of the spring, and the drawstring is mounted on the outer surface of the reflector; and the copper bell is assembled on the lower end of the drawstring through screws. Through the design, the function of bird repelling can be achieved, and the aerator has simple operation, convenient control on the addition amount of the gear oil, a good bird repellent effect and high practicability.

Owner:南昌智旭企业咨询服务有限公司

Medicament bending device being able to easily control dosage and used for medicine production

InactiveCN108927062AControl volumeEasy to control the amount addedRotating receptacle mixersTransportation and packagingCouplingElectric machinery

The invention discloses a medicament bending device being able to easily control the dosage and used for medicine production. The device comprises a frame, a mobile station sliding slot is arranged inthe bottom inner wall of the frame, the inner wall of the mobile station sliding slot is slidably connected with a mobile station, leading screw mounting holes are arranged in the inner wall at two sides of the mobile station sliding slot, the inner walls of the two leading screw mounting holes are connected with a leading screw by bearings, a driving motor is fixed at the outer wall of one sideof the frame by a bolt, the output shaft of the driving motor is fixed to the outer wall of one end of the leading screw by a shaft coupling, a supporting plate is fixed on the top of the mobile station by a bolt, a supporting shaft is fixed on the top outer wall of the supporting plate by a bolt, and a mixing cylinder sleeves the outer wall of one side of the supporting shaft. The device can control the volumes of raw materials in fixed cylinders, so the addition amounts of drugs can be easily controlled, the labor intensity of workers is reduced, the improvement of the mixing effect of medicament raw materials is improved, dissolving of solid particles is accelerated, and the improvement of the production efficiency is facilitated.

Owner:ZHENGZHOU ZHENGXIAN PHARMA CO LTD

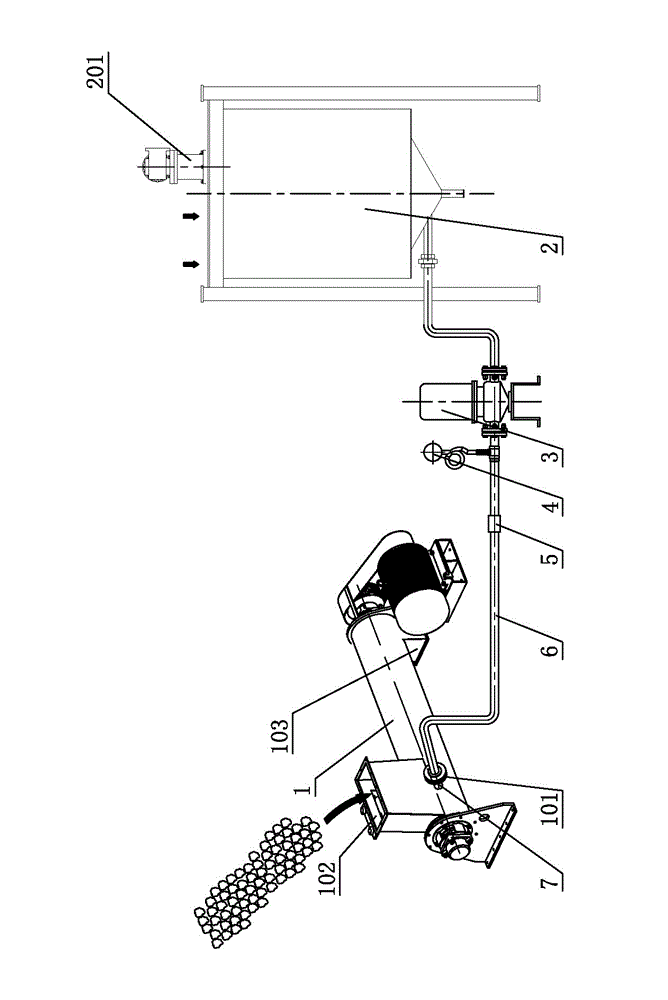

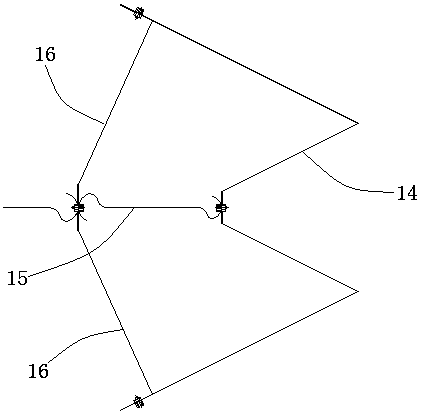

Tracer agent addition device with continuous mixing machine

InactiveCN103149269AAccurate uniformity and consistency controlThe measurement result is accurateMaterial electrochemical variablesAgricultural engineeringNational standard

The invention relates to the technical field of materials, and particularly relates to a continuous mixing tracer agent addition method for testing uniformity. The tracer agent addition device comprises the continuous mixing machine, wherein a tracer agent addition port is arranged in the side wall of a feeding port of the mixing machine and is provided with an atomizing nozzle which is sequentially connected with an infusion pump and a stirring device through a pipeline, wherein a flowmeter and a pressure detecting element are aslo arranged on the pipeline, and a regulating valve is arranged on the atomizing nozzle. When mixing uniformity is determined, after the mixing machine normally works, a tracer agent solution with certain concentration is mixed in a stirring tank and then is added to the mixing machine at a certain flow speed through the atomizing nozzle according to the capacity of the mixing machine, a sample is drawn from a discharging hole of the mixing machine, and the mixing uniformity of the sample is determined according to a national standard GB / T5918-2008 feed-product mixing uniformity determination method. The tracer agent addition device solves the problem that the uniformity indicator of the continuous mixing machine in the prior art cannot be accurately and really detected.

Owner:牧羊有限公司

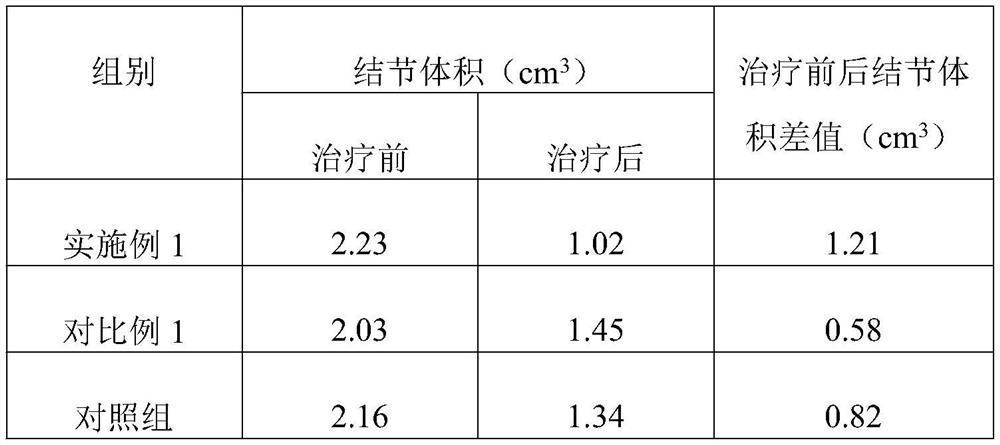

Traditional Chinese medicine composition for softening hardness to dissipate stagnation and preparation method thereof

PendingCN114558085AQi-relieving machineRecovery functionOrganic active ingredientsBird material medical ingredientsPlant sterolPharmaceutical Substances

The invention provides a traditional Chinese medicine composition for softening hardness to dissipate stagnation and a preparation method thereof, and relates to the technical field of pharmaceutical preparations. The traditional Chinese medicine composition for softening hardness to dissipate stagnation is prepared from the following raw materials in parts by weight: 20 to 40 parts of fructus citri, 5 to 20 parts of phytosterol, 10 to 40 parts of rhizoma nelumbinis, 5 to 20 parts of raw malt, 30 to 60 parts of pericarpium citri reticulatae, 1 to 15 parts of radix platycodonis, 10 to 30 parts of flos rosae rugosae, 20 to 40 parts of herba taraxaci, 5 to 15 parts of fructus citri sarcodactylis, 10 to 25 parts of radix angelicae sinensis and 20 to 35 parts of concha ostreae. The medicine disclosed by the invention has the effects of softening hardness to dissipate stagnation, removing stasis and dredging collaterals, can effectively treat thyroid nodules and breast nodules, and also can treat hysteromyoma, ovarian cyst, pulmonary nodules and lipoma. The preparation method can effectively extract the effective components in the traditional Chinese medicine, so that the content of the effective components in the medicine is high, and the efficacy of the medicine is improved.

Owner:天津美之旅生物科技有限公司

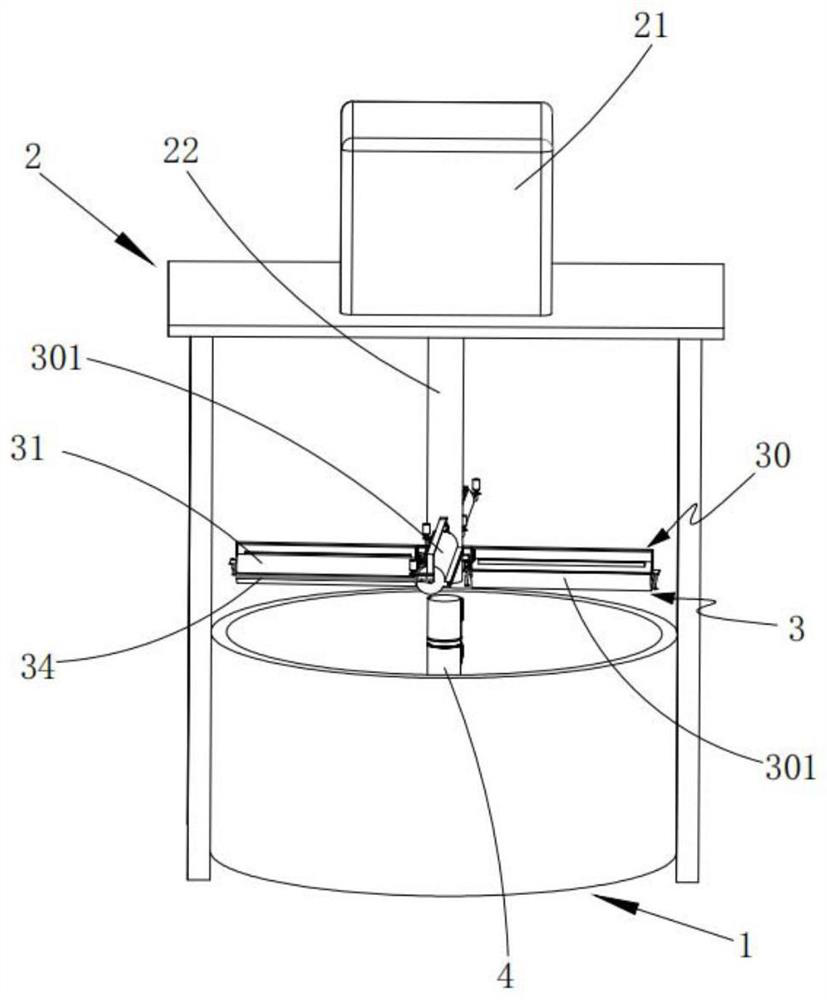

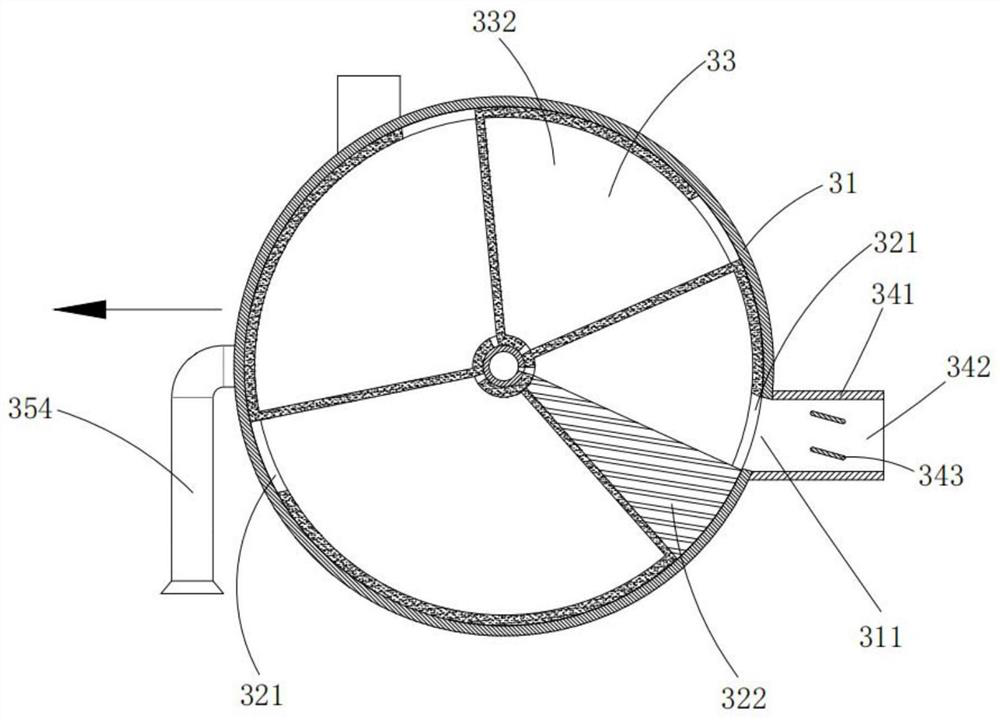

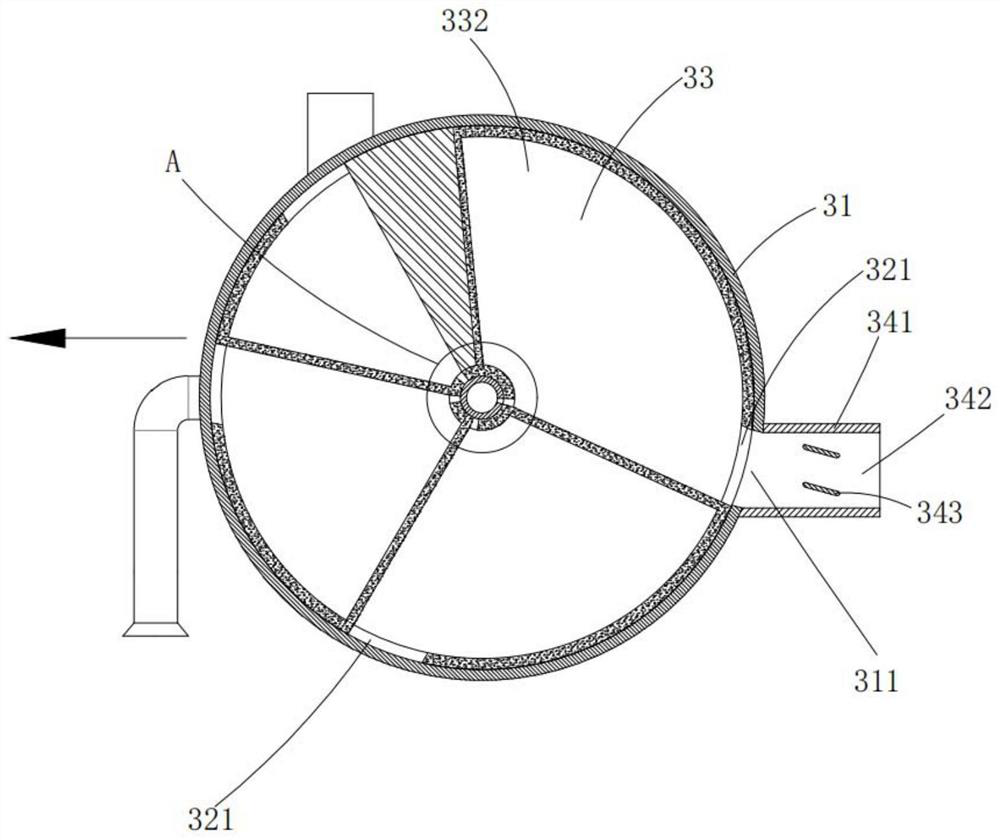

Magnetic coagulation and sedimentation integrated water body purification equipment

ActiveCN112978886AImprove purification effectEasy to control the amount addedWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by flocculation/precipitationFlocculationEngineering

The invention relates to magnetic coagulation and sedimentation integrated water purification equipment which comprises a tank body, a moving device, a scattering device and a control device. A support comprises a power assembly and a sleeve. The material scattering device comprises two groups of material scattering assemblies which are arranged up and down and are used for scattering magnetic powder and a flocculating agent respectively, the material scattering assemblies comprise two groups of material scattering mechanisms which are symmetrically arranged, and each material scattering mechanism comprises a discharging assembly provided with a plurality of material storage spaces, a power assembly and a transmission assembly which is in power connection with the discharging assembly and a rotating column. The control device comprises a stand column, a driving assembly a surrounding the stand column and used for driving the water guiding assembly to guide water, and a driving assembly b vertically arranged on the stand column and in power connection with the transmission assembly. The magnetic powder and the flocculant are evenly distributed in the pool body, and meanwhile sewage in the pool body can be subjected to multiple times of flocculation and sedimentation.

Owner:长兴瑷晟环保科技有限公司

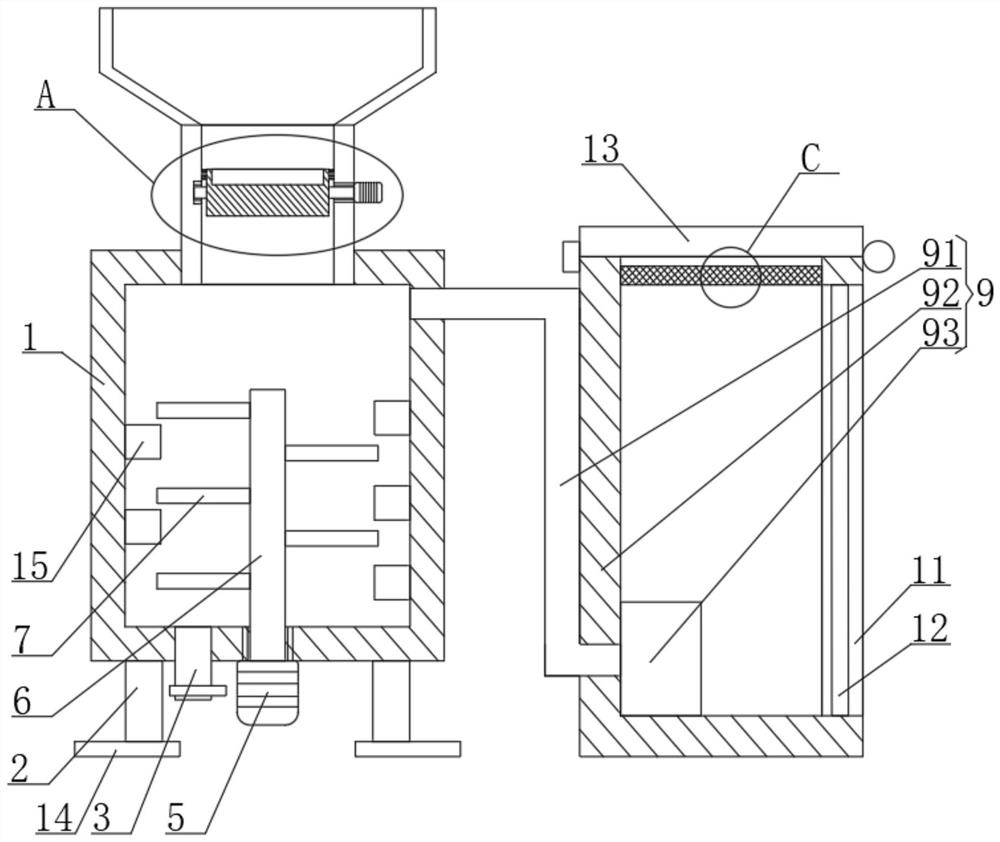

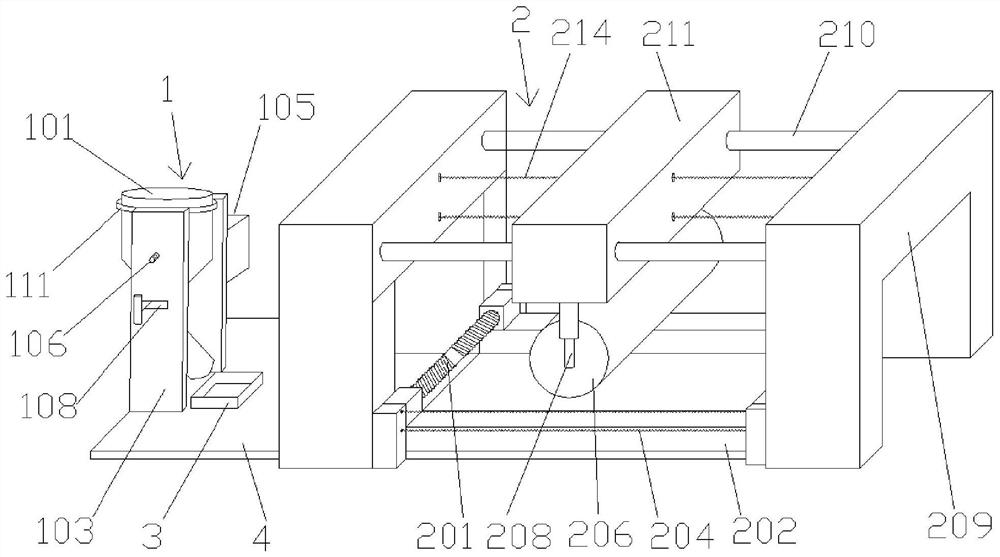

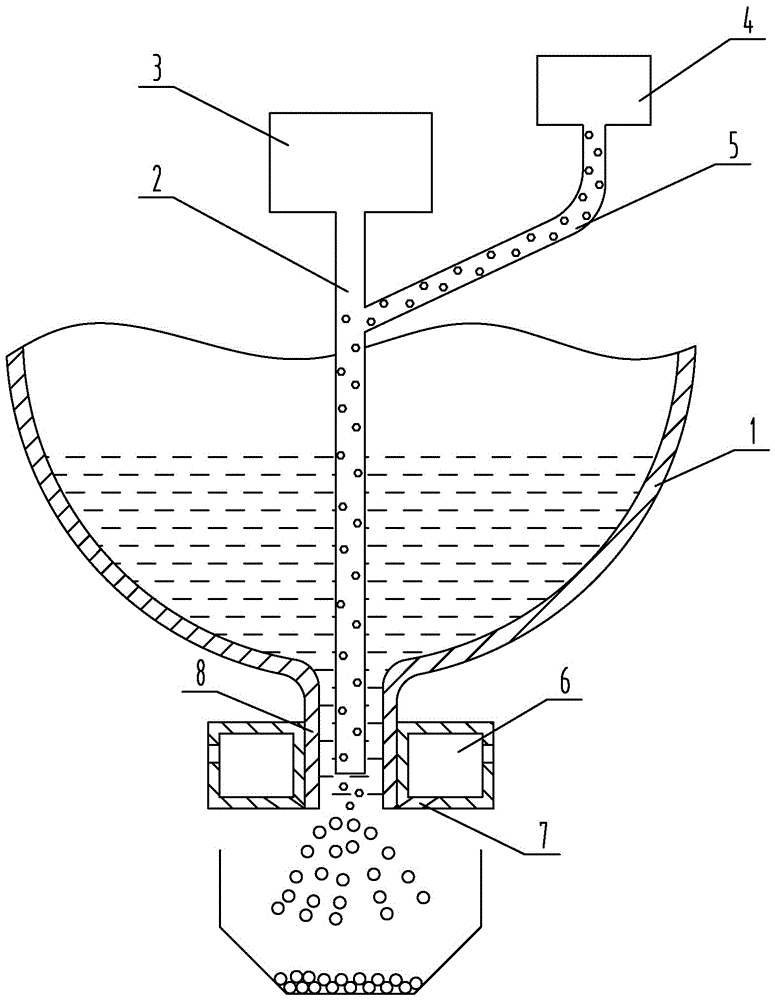

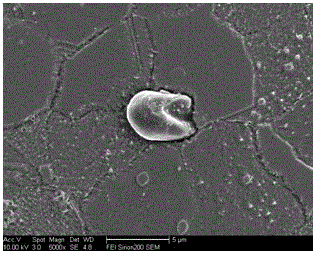

Method for manufacturing gradient composite electrode for electrical spark rough machining and electrical spark finish machining for laser solid forming

ActiveCN104972186AImprove equalization performanceImprove processing qualityElectrical-based machining electrodesElectricityElectric discharge

The invention discloses a method for manufacturing a gradient composite electrode for electrical spark rough machining and electrical spark finish machining for laser solid forming and belongs to the technical field of electric discharge machining. The method comprises the steps that a three-dimensional solid model is generated by means of software, the model is sliced and layered, and the parameters of all slice layers are obtained; then, Cu-based SiC composite micro powder is sintered on a vibrating substrate by means of laser according to the shape parameter of the slice layer on the inner side; finally, Cu powder and graphite powder are sintered on a Cu-based SiC composite sediment layer in a mixing mode by means of laser according to the shape parameter of the slice layer on the outer side. The electrode manufactured through the method is provided with a gradient structure, and electricity is discharged firstly by the Cu-based graphite sediment layer located on the outer layer of the electrode so as to achieve rough machining of a workpiece; then finish machining of the workpiece is achieved by means of the Cu-based SiC composite sediment layer of the electrode. Meanwhile, the Cu-based SiC composite micro powder is formed by blowing SiC particles in molten Cu in a dispersed mode by means of nitrogen and then conducting atomization and cooling, in this way, the distribution uniformity of the SiC particles is improved, and the equilibrium of the electric corrosion resistance of the electrode is improved.

Owner:SHANDONG UNIV OF TECH

Kneading equipment for processing dough with high content of coarse cereals

ActiveCN112167277APress evenlyQuality assuranceMixing/kneading structural elementsDough-sheeters/rolling-machines/rolling-pinsAgricultural engineeringStructural engineering

The invention discloses kneading equipment for processing dough with high content of coarse cereals. The kneading equipment comprises two fixed seats which are symmetrically fixed on a working surface, a kneading barrel is fixedly connected to the top ends of the two fixed seats through screws, a feeding funnel is connected to the top surface of the kneading barrel in a penetrating manner, and horizontal plates are welded to the two sides of the top end of the kneading barrel; rotating rods are rotatably connected between one ends deviating from the kneading barrel, of the horizontal plates and the fixing base, fixing rods are further rotatably connected to the middle of the front side of the top surface of the kneading barrel, and the upper ends of the rotating rods penetrate through thehorizontal plates and are rotatably connected with the fixing rods through a conveying belt; a mounting frame is also fixed to the top surface of one horizontal plate on one side; and servo motors I are fixedly connected to the inner bottom surface of the mounting frame through screws. The kneading equipment is reasonable in design and compact in structure, coarse cereal powder is uniformly pressed during kneading, the early-stage processing quality of dough is well guaranteed, and certain guarantee is provided for subsequent high-quality production of pastries.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Glaze blending equipment for ceramic production and processing

InactiveCN111957225AEasy to control the amount addedPrecise proportionRotary stirring mixersTransportation and packagingElectric machineryEngineering

The invention relates to the technical field of blending equipment, and further discloses glaze blending equipment for ceramic production and processing. The equipment comprises a mixing box, whereinsupporting legs are fixedly connected to four corners of the bottom of the mixing box, the bottom of the mixing box is fixedly communicated with a discharge pipe, the top of the mixing box is fixedlycommunicated with a feeding pipe, the bottom of the mixing box is fixedly connected with a first driving motor, the output end of the first driving motor is connected with a rotating rod through a coupler, the rotating rod is fixedly arranged at the bottom of the mixing box through a first bearing, the first bearing is fixedly arranged at the bottom of the mixing box, the rotating rod penetrates through the inner ring of the first bearing and extends into the mixing box, a plurality of stirring rods are uniformly and fixedly connected to the rod wall of the rotating rod at equal intervals, a feeding mechanism is connected into the feeding pipe, and the mixing box is connected with a water adding mechanism. According to the glaze blending equipment for ceramic production and processing, theaddition amount of the glaze can be conveniently controlled, so that the proportion of the blended glaze is accurate, and the quality of the blended glaze is good.

Owner:ANHUI PROVINCIAL HANSHAN MINSHENG PORCELAIN

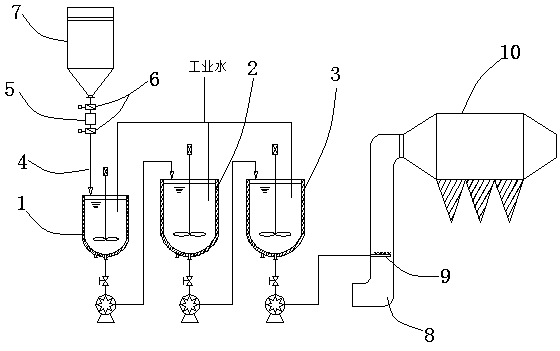

Flue gas treatment system based on chemical aggregation and electric precipitation

PendingCN108080148AIncrease moisture contentEasy to removeExternal electric electrostatic seperatorEmulsionCompound (substance)

The invention provides a flue gas treatment system based on chemical aggregation and electric precipitation. The flue gas treatment system comprises an aggregation liquid preparation unit, an atomization spraying unit and an electric precipitation unit, wherein the aggregation liquid preparation unit comprises an emulsification tank, a preparation tank and a mixing tank, the emulsification tank isprovided with a solid agglomerant inlet, a first water filling nozzle and an emulsion outlet, the preparation tank is provided with a liquid agglomerant inlet, an emulsion inlet, a second water filling nozzle and a liquid mixture outlet, the emulsion inlet communicates with the emulsion outlet, the mixing tank is provided with a liquid mixture inlet, a third water filling nozzle and an aggregation liquid outlet, the liquid mixture inlet communicates with the liquid mixture outlet, and the aggregation liquid outlet is connected with the atomization spraying unit arranged on an inlet flue of the electric precipitation unit through a material conveying pipeline. According to the flue gas treatment system, the chemical aggregation and the electric precipitation unit are combined, so that aggregation liquid is sprayed into the flue, the moisture content of flue gas is increased, fine particles in the flue gas grow up so as to be convenient to remove by the electric precipitation unit, andthe dedusting efficiency and the stability of the flue gas treatment system are greatly increased.

Owner:武汉天空蓝环保科技有限公司

Chlorination reaction kettle and chlorination process for ortho-position and para-position products

PendingCN111250025AUniform controlWell mixedRotary stirring mixersTransportation and packagingWater chlorinationElectric machinery

The invention discloses a chlorination reaction kettle for ortho-position and para-position products. The reaction kettle comprises a sealing cover and a kettle body, wherein a first feeding pipe is arranged on the sealing cover; an overflow plate and a sealing plate are arranged on the two sides of the first feeding pipe respectively; overflow holes are formed in the overflow plate; a plurality of overflow pipes are arranged on the sealing plate; one end of each overflow pipe is located above the overflow plate, and the other end of each overflow pipe is located in the kettle body; a rotatingshaft is rotationally arranged in the kettle body and connected with a rotating motor; the other end of the rotating shaft is connected with a first cutting and stirring paddle and a second cutting and stirring paddle; a spraying pipe is arranged in the kettle body; the spraying pipe communicates with a second feeding pipe; spraying heads are arranged on the spraying pipe; and a discharging opening is formed in the bottom of the kettle body. Through the overflow plate and the sealing plate, the conveying of materials is more gentle, controllable and accurate; and the second feeding pipe conveys materials in a spraying mode, different materials are mixed in a collision mode firstly and then stirred and then mixed in a cutting and stirring mode, so product yield is increased.

Owner:浙江嘉福新材料科技有限公司

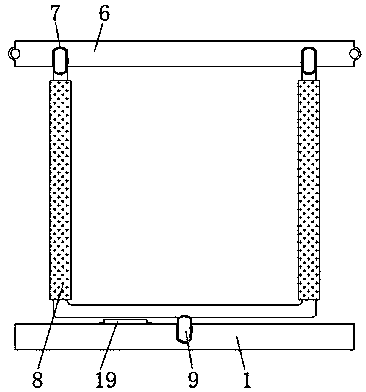

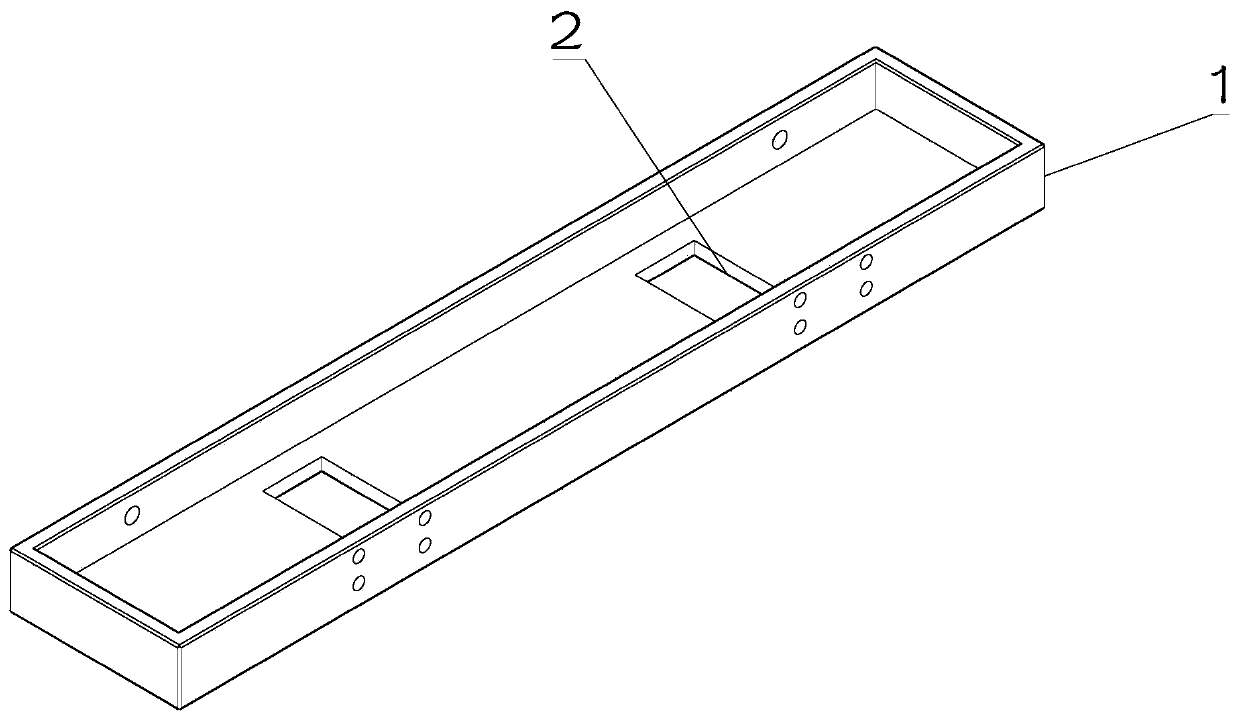

Water storage type wall-mounted plant wall cultivation grid capable of being spliced

PendingCN110012754AEasy to control the amount addedQuality assuranceTransportation and packagingRotary stirring mixersWater storageLiquid storage tank

The invention discloses a water storage type wall-mounted plant wall cultivation grid capable of being spliced and relates to the technical field of wall planting equipment. The water storage type wall-mounted plant wall cultivation grid comprises two support rods and is characterized in that first connecting rods, plant plates and nutrient solution racks are arranged between the two support rods,LED lamps are mounted at the bottom of each first connecting rod, each plant plate is arranged at the bottom of each first connecting rod, the bottom of each plant plate is arranged inside the corresponding nutrient solution rack, the bottom of the each plant plate is provided with through holes, a liquid conveying pipe is arranged on one of the support rods, the outlets of the liquid conveying pipe are arranged in the nutrient solution racks, one end, away from the nutrient solution rack, of the liquid conveying pipe is connected to a flowmeter through a pipeline, the input end of the flowmeter is connected to the output end of a liquid conveying pump, the input end of the liquid conveying pump is connected to the bottom of a liquid storage tank, and a stirring mechanism is arranged inside the liquid storage tank. The water storage type wall-mounted plant wall cultivation grid is convenient to use, convenient to splice, high in nutrient solution quality and low in labor intensity.

Owner:祝少良

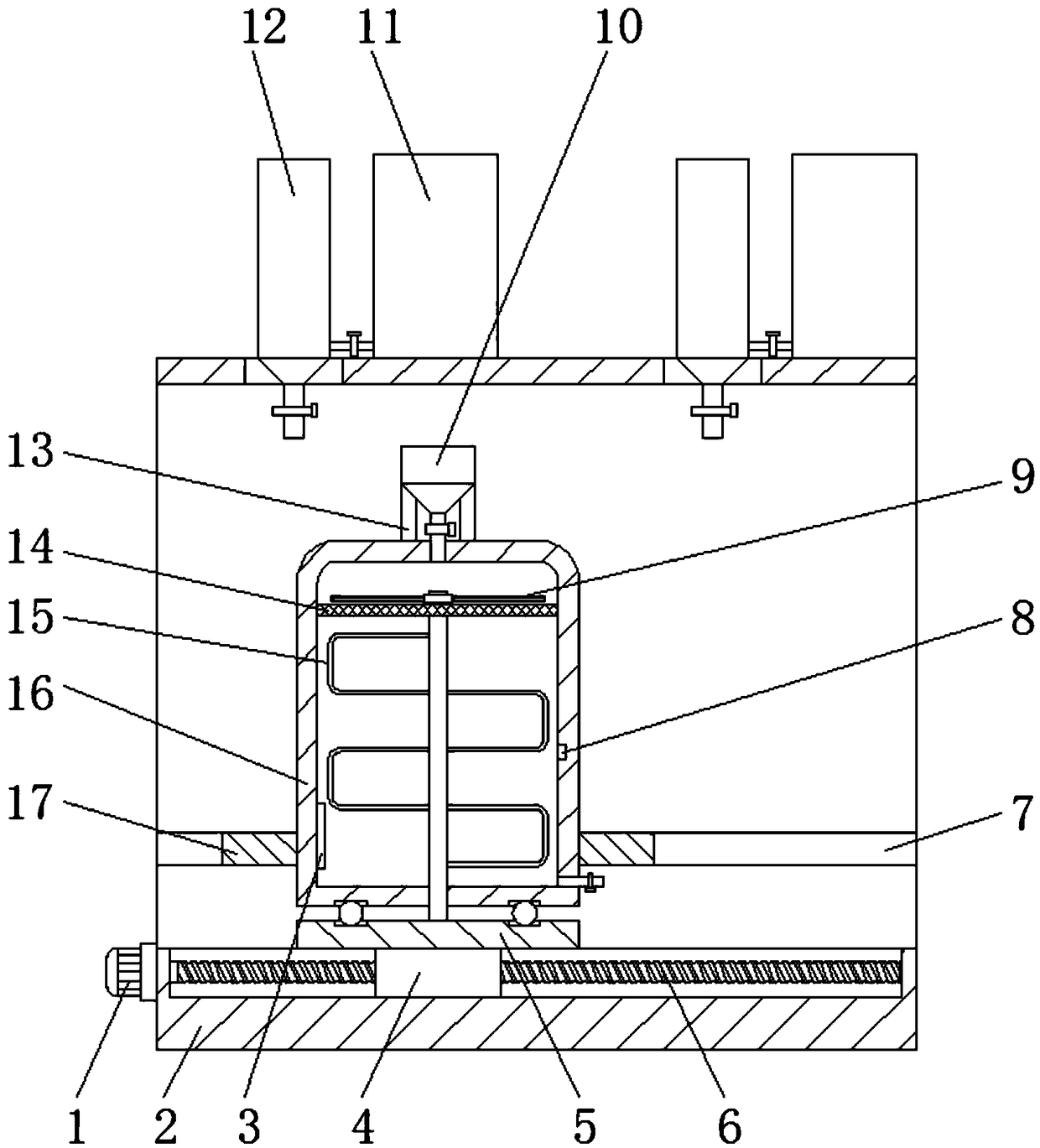

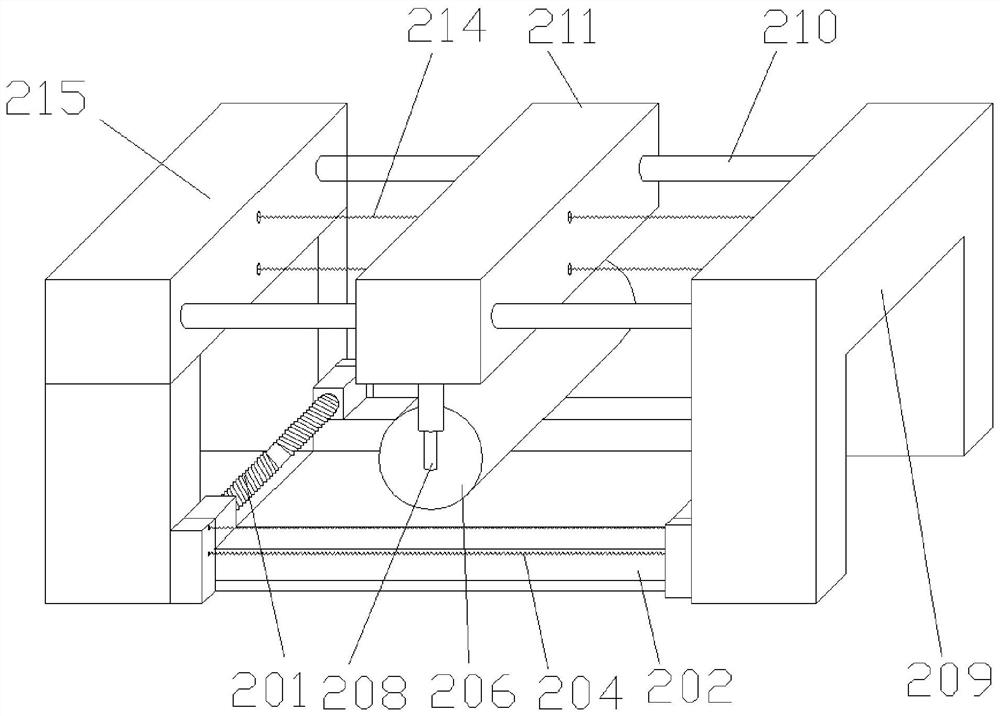

Forming equipment for asphalt mixture test piece and using method

PendingCN112284859AImprove molding efficiencyUniform insidePreparing sample for investigationReciprocating motionEngineering

The invention discloses forming equipment for an asphalt mixture test piece and a using method. A discharging device comprises a material containing device which is through up and down, and stirring blades are arranged in the material containing device; a rolling forming device comprises two threaded rods, two limiting rails, a rolling wheel and a telescopic device used for applying pressure to the rolling wheel, forward threads are formed in each threaded rod from one end to the middle of the threaded rod, reverse threads are formed in each threaded rod from the other end to the middle of thethreaded rod, the two threaded rods are oppositely arranged in parallel, and the two threaded rods can synchronously rotate around the axes of the threaded rods; the two ends of one limiting rail arecorrespondingly connected with the forward threads of the two threaded rods in a matched mode, and the two ends of the other limiting rail are correspondingly connected with the reverse threads of the two threaded rods in a matched mode. The rolling wheel stretches across the two limiting rails, the telescopic device is arranged above the rolling wheel, the two ends of the rolling wheel are rotationally connected with telescopic rods of the telescopic device, and the telescopic device can reciprocate in the direction of the limiting rails. The influence of personal errors is reduced, and theforming efficiency of the test piece is improved.

Owner:CHANGAN UNIV +1

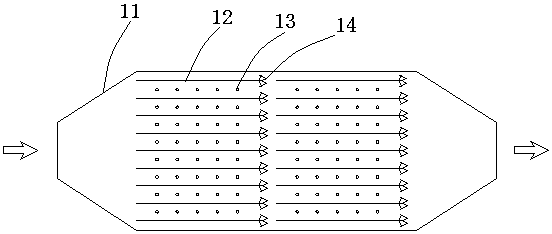

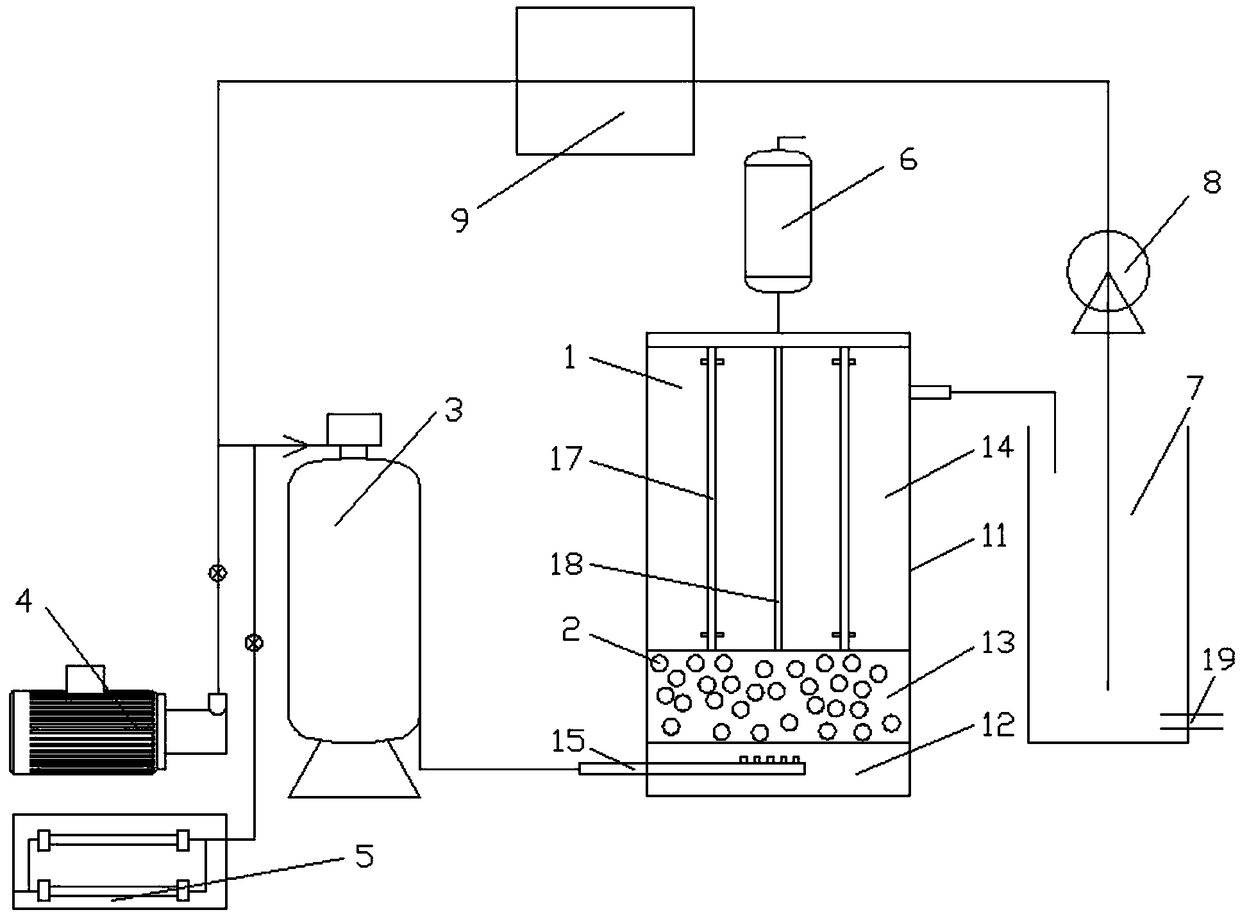

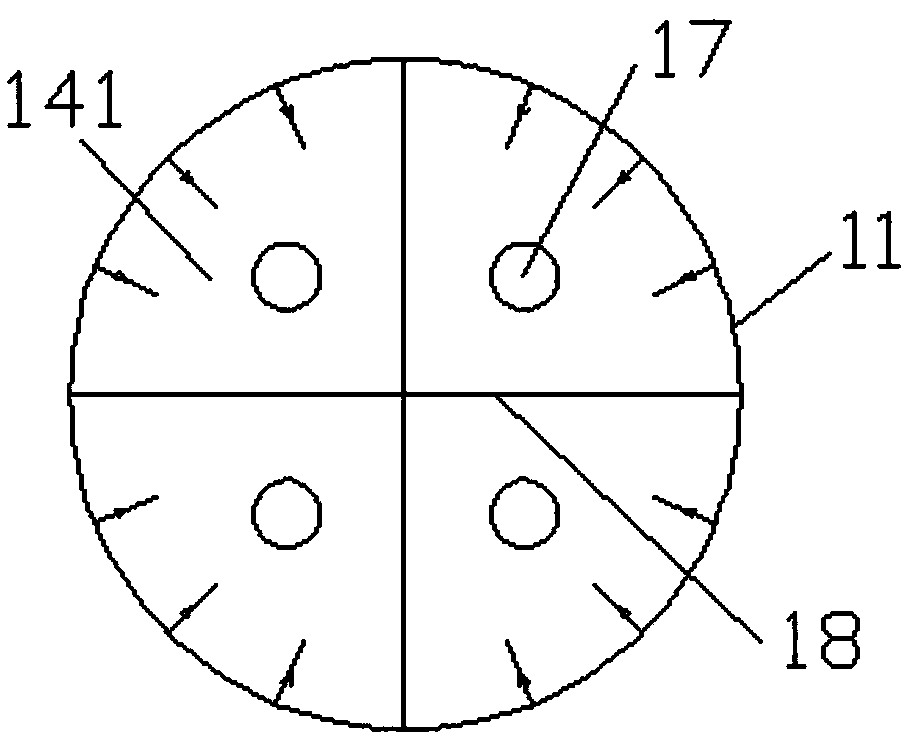

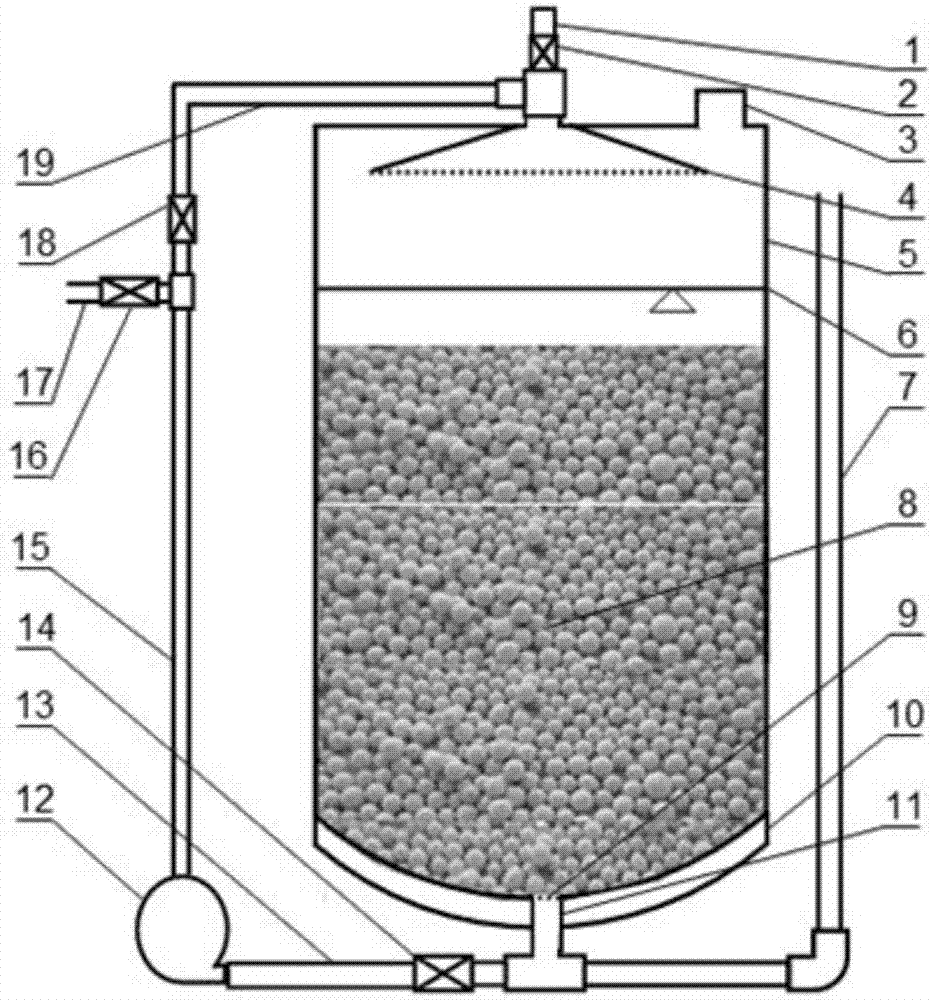

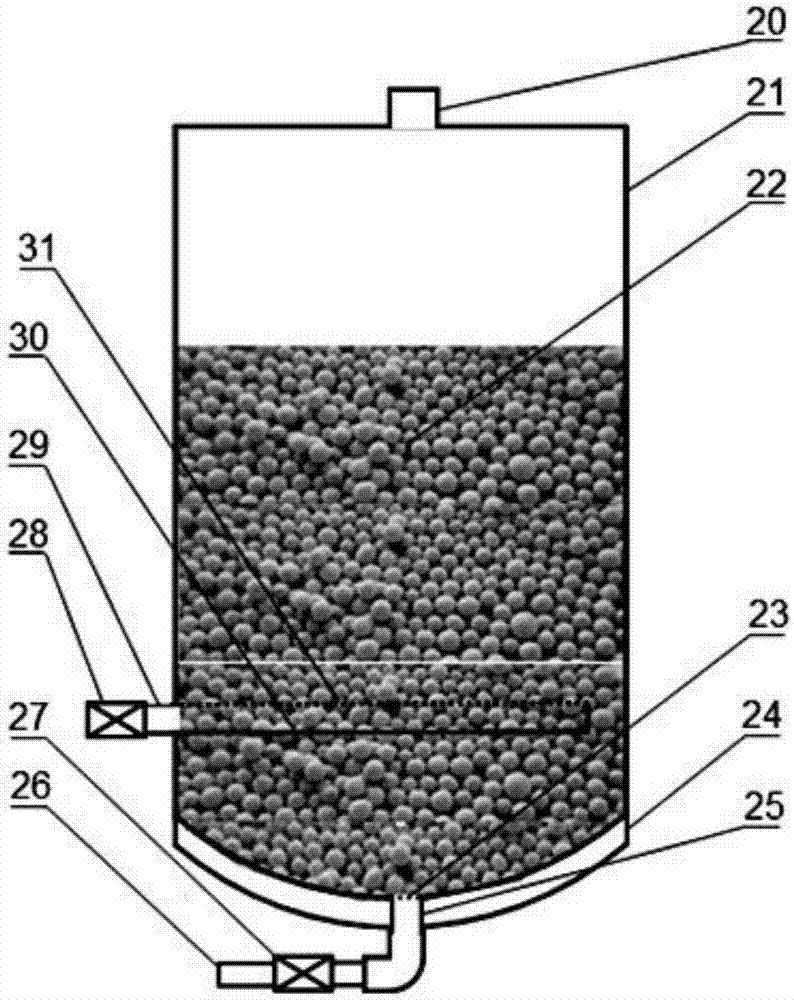

A treatment device for boron-containing organic wastewater

PendingCN108773895AIncrease light intensityImprove the effectWater/sewage treatment apparatusWater/sewage treatment by oxidationPhotocatalysisSewage

A treatment device for boron-containing organic wastewater is disclosed. The device includes a low-pressure dissolved air tank, a sewage draining pump connected to the low-pressure dissolved air tank,an ozone generator connected to the low-pressure dissolved air tank, a catalytic reactor connected to the low-pressure dissolved air tank and a water discharging pipe connected to the catalytic reactor. The low-pressure dissolved air tank increases the dissolved amount of ozone in wastewater. The catalytic reactor includes a reactor shell and includes an aeration zone, a filler zone and a reaction zone which are arranged in order from bottom to top in the reactor shell. The lower part of the aeration zone is provided with a water inlet. The water discharging pipe is arranged at the upper partof the reaction zone. Titanium dioxide catalytic plates are arranged lengthways and divide the reaction zone into a plurality of oxidation zones, an ultraviolet lamp column is vertically disposed inthe center of each oxidation zone, and the catalytic plates are completely in the radiation distance of ultraviolet light. A light-reflecting guide cylinder can reflect ultraviolet light, thus enhancing illumination and increasing the photocatalysis efficiency. The catalytic reactor is connected to a tail gas treatment device to treat tail gas residual after emission.

Owner:SUZHOU FANGZHOU ENVIRONMENTAL PROTECTION TECH CO LTD

Defoaming agent and preparation method thereof

InactiveCN112337141AEasy to control the amount addedImprove portabilityFoam dispersion/preventionActivated charcoal powderActivated carbon

The invention relates to the technical field of defoaming agents, and particularly relates to a defoaming agent and a preparation method thereof which can improve the foam inhibition performance, conveniently control the addition amount of the defoaming agent according to different use requirements and improve the use portability. The defoaming agent comprises the following components: 1-2% of anemulsifier, 0.6-1.0% of a dispersing agent, 0.8%-1.2% of an emulsifying aid, 3-5% of an active component, and the balance of a carrier. The production method of the defoaming agent comprises the stepsof S1, preparing a carrier binder, specifically, mixing the sodium humate into a viscous state; S2, conducting carrier material mixing, specifically, grinding and sieving the activated carbon powder,adding the ground and sieved activated carbon powder into the binder, and continuously stirring and mixing until the materials are mixed into a ball; S3, conducting mixing and kneading treatment; S4,forming carrier particles; S5, carrying out carbonization treatment; S6, conducting dressing mixing; S7, conducting carrier dressing; S8, conducting irradiation curing, specifically, guiding the carrier filled with the dressing into irradiation equipment for irradiation treatment so as to enable the dressing to be cured in apertures of carrier particles; and S9, conducting sub-packaging.

Owner:传辰立新(厦门)科技有限公司

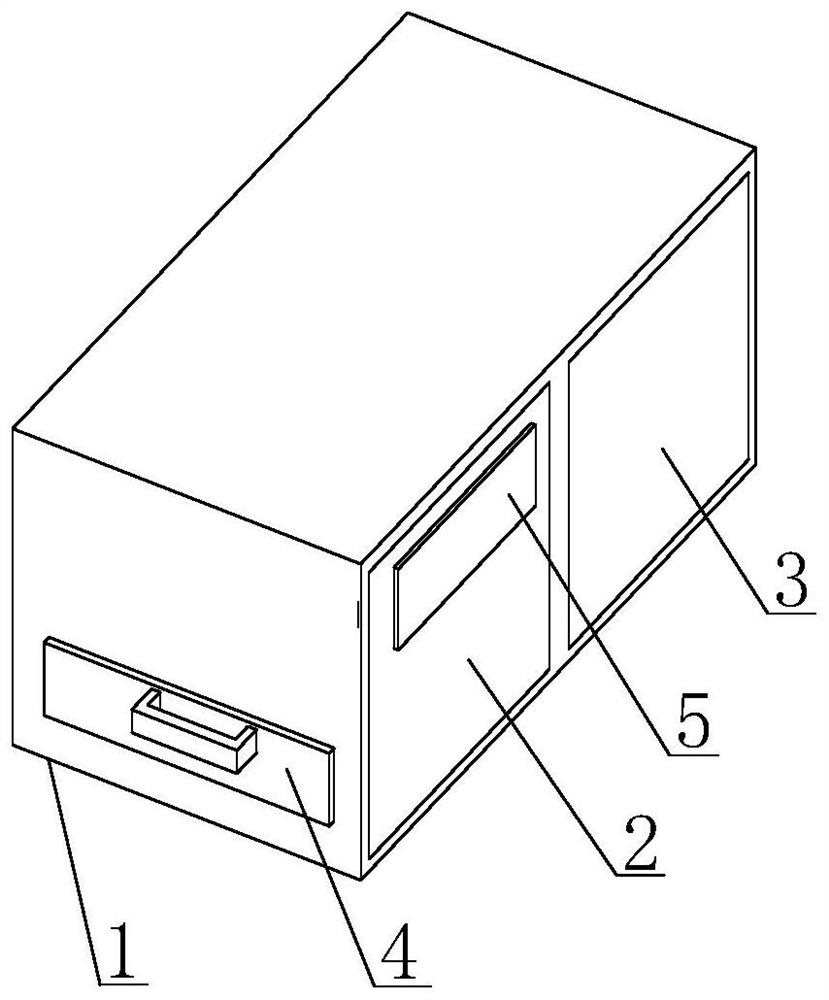

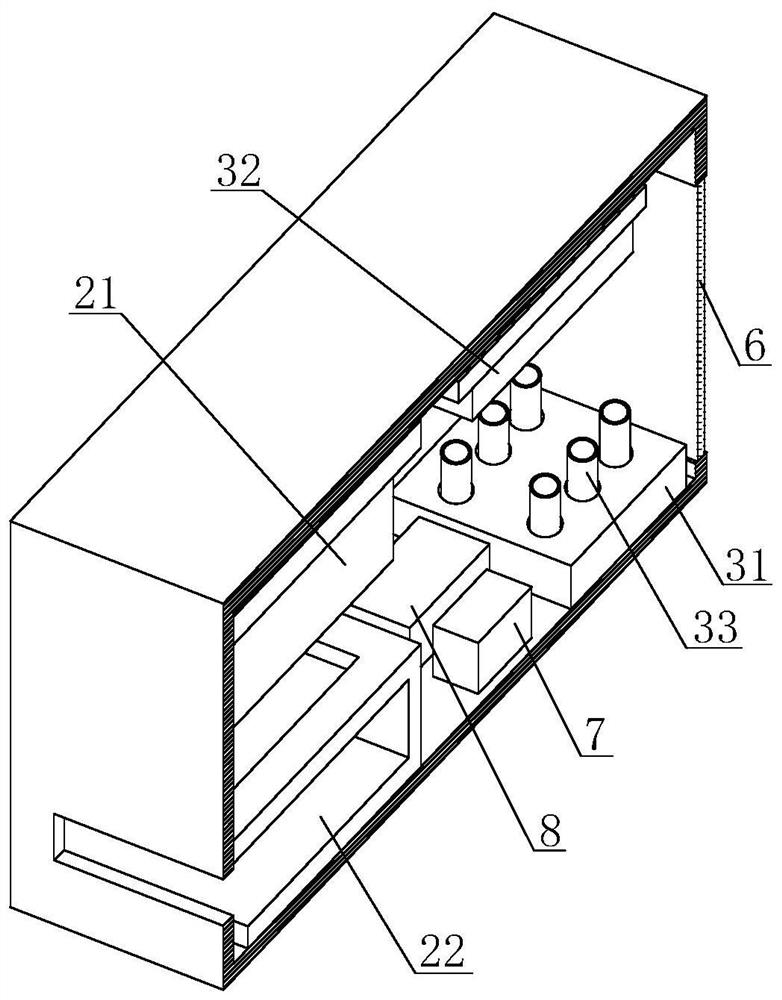

Detection device for ecological environment pollution

PendingCN112675939AStable clampingRealize measurementEarth material testingTest tube stands/holdersEcological environmentAir pump

The invention discloses a detection device for ecological environment pollution, and relates to the technical field of environment detection. The detection device comprises a detection box body, the detection box body comprises a first detection chamber and a second detection chamber, the left side of the detection box body is slidably connected with a placement plate, and the outer wall of the first detection chamber is provided with a display screen. Through cooperation of the air pump and the supporting device, the test tube can be conveniently placed on the first bracket, and the weight of to-be-detected liquid in the test tube can be detected through the supporting device, so that a reagent with a corresponding specific gravity can be added into the test tube through the moisture detector; the test tube can be clamped and fixed in the process that the test tube is placed in the first support, the clamping force of the first support on the test tube can be properly reduced through cooperation of the connecting plate and the bouncing block, and the phenomenon that liquid in the test tube is prone to spilling when the test tube is taken out through external force is avoided.

Owner:骆昌华

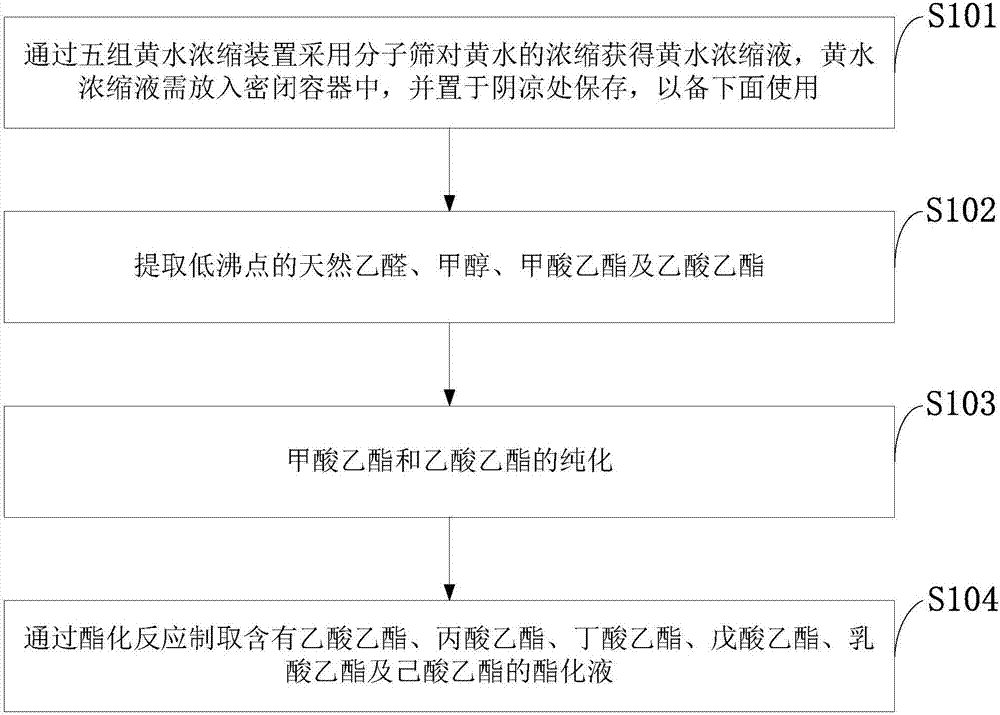

Method for preparation of liquor condiment based on molecular sieve concentrated huangshui fluid

InactiveCN107022461ALow priceImprove performanceAlcoholic beverage preparationPropanoic acidNatural organic matter

Belonging to the technical field of liquor condiment preparation, the invention discloses a method for preparation of a liquor condiment based on molecular sieve concentrated huangshui fluid. The method includes: employing 5 groups of equipment to concentrate huangshui fluid by molecular sieves to obtain concentrated huangshui fluid, putting the concentrated huangshui fluid into a closed container, and storing the closed container in shade for standby use later; extracting low-boiling point natural acetaldehyde, methanol, ethyl formate and ethyl acetate; purifying ethyl formate and ethyl acetate; and finally carrying out esterification reaction to obtain an esterified solution containing ethyl acetate, ethyl propionate, ethyl butyrate, ethyl valerate, ethyl lactate and ethyl caproate. The liquor condiment prepared by the method provided by the invention is a safe and pure natural product without any chemical brought in during preparation. Therefore, the liquor condiment prepared from huangshui fluid as the raw material includes synthetic natural esters and other natural organic matters, is closer to natural products when used for liquor blending, and can be more easily accepted by consumers.

Owner:TAISHAN MEDICAL UNIV

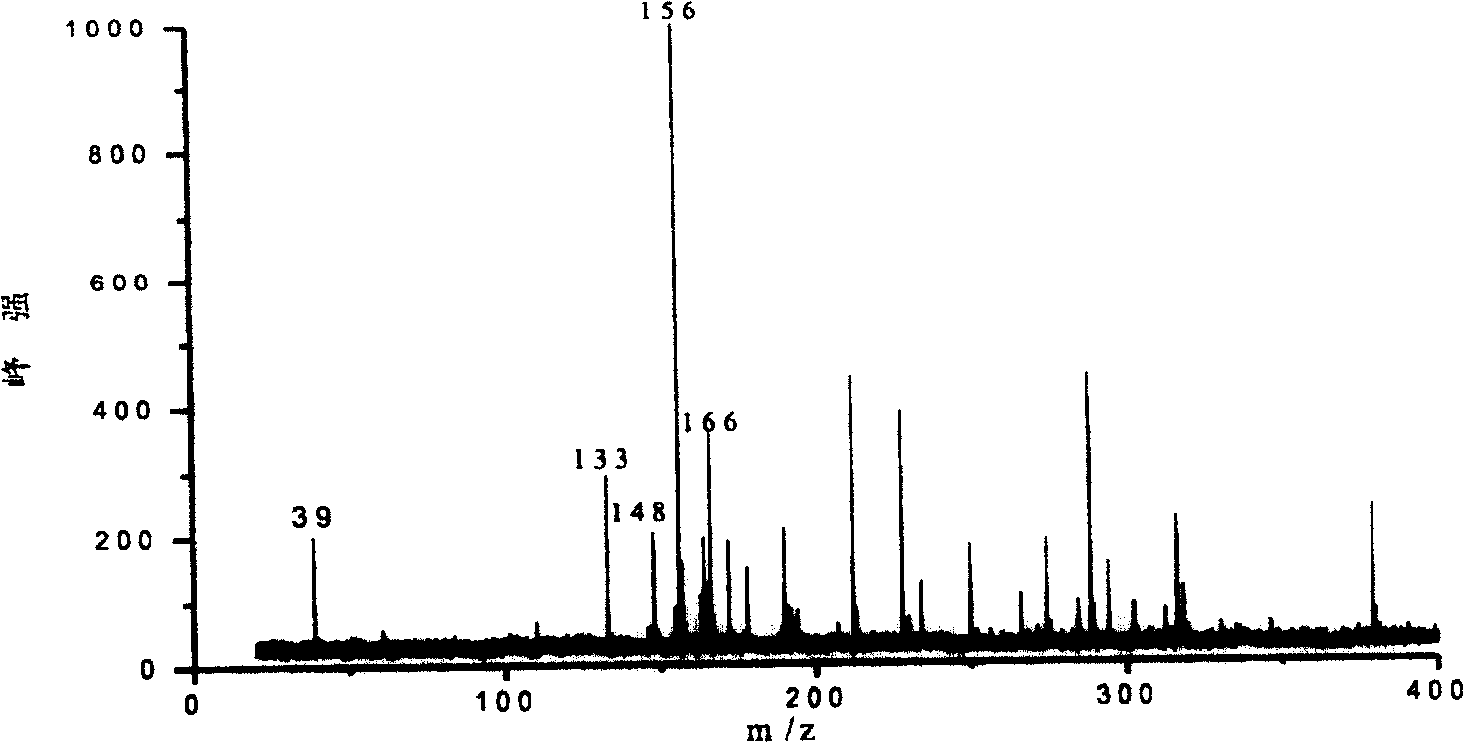

Application of water-soluble multi-wall carbon nanotube as substrate in MALDI-MS

InactiveCN100430724CGood water solubilityEasy to control the amount addedNanostructure manufactureComponent separationCarbon nanotubeWater soluble

The invention uses water-soluble multi-wall carbon nano tube as MALDI matrix for MALDI-MS, overcomes the defect of nano tube self, accelerates analysis for small molecular compound, and realizes quantitative and qualitative analysis fast and accurately.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

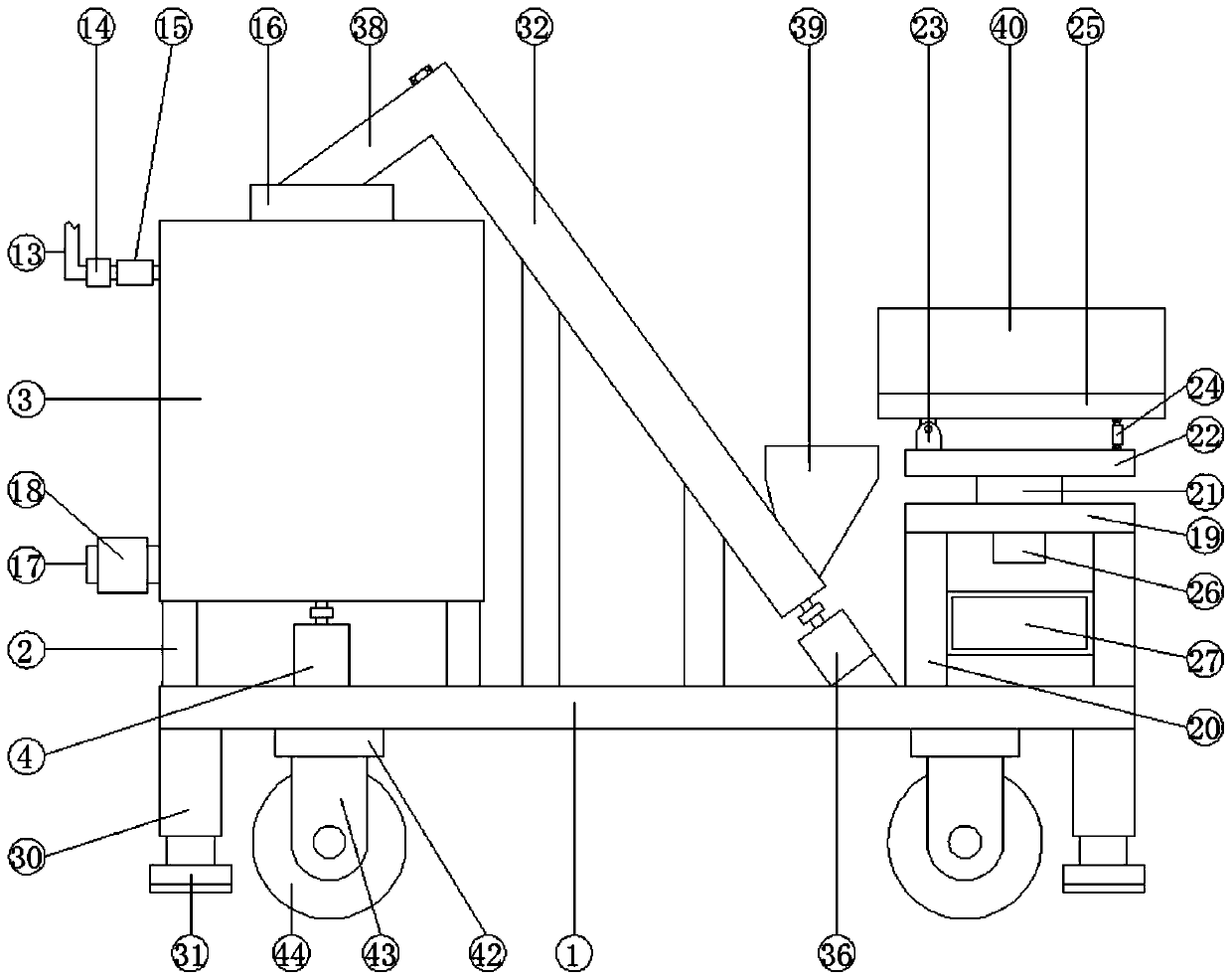

Concrete mixing plant for hydraulic engineering construction

PendingCN111516140AAvoid false coagulationQuality assuranceIngredients weighing apparatusCement mixing apparatusDrive shaftArchitectural engineering

The invention discloses concrete mixing plant for hydraulic engineering construction. The concrete mixing plant for the hydraulic engineering construction comprises a base, a mixing barrel is fixedlyarranged on the base through a first connecting rod, a first motor is fixedly arranged on the base, a transmission shaft is fixedly arranged on a rotating shaft of the first motor through a first coupler, the transmission shaft penetrates through the bottom end of the mixing barrel and extends into the mixing barrel, a plurality of spiral stirring blades are fixedly arranged on the outer wall of the upper end of the transmission shaft, and four semiconductor coolers are fixedly embedded in the outer wall of the bottom end of the mixing barrel at equal intervals in the circumferential direction. The concrete mixing plant for the hydraulic engineering construction has the beneficial effects that the mixing barrel and concrete can be effectively cooled when the concrete is stirred, so that the phenomenon of false setting of the concrete due to over-high temperature can be avoided, a raw material can be weighed and metered, the addition amount of the raw material can be conveniently controlled, the raw material can be strictly added according to a scientific ratio, and therefore, the quality of the produced concrete can be ensured.

Owner:刘伟

Preparation method of graded composite electrode for laser three-dimensional forming electric discharge rough and fine machining

ActiveCN104972186BImprove equalization performanceImprove processing qualityElectrical-based machining electrodesElectric dischargeNitrogen gas

The invention discloses a preparation method of a gradient composite electrode for laser three-dimensional forming electric discharge rough and fine machining, which belongs to the technical field of electric discharge machining, and uses software to generate a three-dimensional solid model, slices and layers the model, and obtains the parameters of each slice layer ; Then use laser to sinter Cu-based SiC composite micro-powder on the vibrating substrate according to the shape parameters of inner slice layers; finally use laser to mix and sinter Cu powder and graphite powder on Cu-based SiC composite deposition according to the shape parameters of outer slice layers layer. The electrode prepared by this method has a gradient structure, and the Cu-based graphite deposition layer located on the outer layer of the electrode is discharged first to realize the rough machining of the workpiece; then the Cu-based SiC deposition layer of the electrode is used to complete the finishing of the workpiece; The composite micropowder is formed by spraying and cooling SiC particles in Cu melt with nitrogen gas, which improves the uniformity of SiC particle distribution and improves the balance of electrode corrosion resistance.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com