Defoaming agent and preparation method thereof

A defoamer and dispersant technology, applied in the field of defoamer and its preparation, can solve the problems of poor portability, low surface tension, control the amount of defoamer added, etc., so as to improve the portability, reduce surface tension, The effect of good defoaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

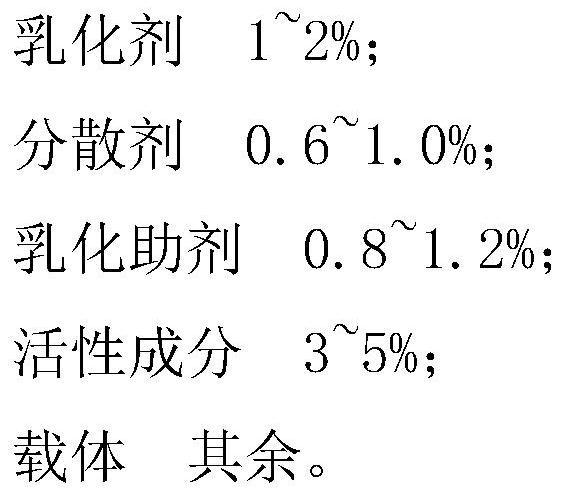

[0028] A kind of defoamer of the present invention comprises following composition:

[0029] Emulsifier 1.5%;

[0030] Dispersant 0.8%;

[0031] Emulsifying aid 1.0%;

[0032] Active ingredient 3.5%;

[0033] Carrier the rest.

[0034] The carrier includes sodium humate and activated carbon powder, and the ratio of sodium humate and activated carbon powder is 1:9.

[0035] The active ingredient is a mixture of polymethylsiloxane, hydroxymethylcellulose, silicone oil and graphene powder, and the addition ratio of each ingredient is 1:2:1.5:2.

[0036] The dispersant is a mixture of sodium pyrophosphate and polyacrylamide.

[0037] A kind of preparation method of antifoaming agent, comprises the following steps:

[0038] S1. Prepare the carrier binder: add water to the sodium humate while stirring until the sodium humate is mixed into a viscous shape;

[0039] S2. Mixing of carrier materials: Grind and sieve the activated carbon powder and add it to the binder prepared in...

Embodiment 2

[0049] A kind of defoamer of the present invention comprises following composition:

[0050] Emulsifier 1%;

[0051] Dispersant 0.6%;

[0052] Emulsifying aid 1.2%;

[0053] active ingredient 4%;

[0054] Carrier the rest.

[0055] The carrier includes sodium humate and activated carbon powder, and the ratio of sodium humate and activated carbon powder is 1:10.

[0056] The active ingredient is a mixture of polymethicone and hydroxymethylcellulose in a ratio of 1:3.

[0057] The dispersant is sodium tripolyphosphate.

[0058] A kind of preparation method of antifoaming agent, comprises the following steps:

[0059] S1. Prepare the carrier binder: add water to the sodium humate while stirring until the sodium humate is mixed into a viscous shape;

[0060] S2. Mixing of carrier materials: Grind and sieve the activated carbon powder and add it to the binder prepared in S1, and continue stirring and mixing until the materials are mixed into agglomerates;

[0061] S3. Knead...

Embodiment 3

[0070] A kind of defoamer of the present invention comprises following composition:

[0071] Emulsifier 2%;

[0072] Dispersant 1.0%;

[0073] Emulsifying aid 0.8%;

[0074] active ingredient 3%;

[0075] Carrier the rest.

[0076] The carrier includes sodium humate and activated carbon powder, and the ratio of sodium humate and activated carbon powder is 1:10.

[0077] The active ingredient is a mixture of polymethylsiloxane, hydroxymethylcellulose and graphene powder, and the addition ratio of each ingredient is 1:2.5:1.8.

[0078] The dispersant is a mixture of sodium tripolyphosphate, sodium pyrophosphate and polyacrylamide.

[0079] A kind of preparation method of antifoaming agent, comprises the following steps:

[0080] S1. Prepare the carrier binder: add water to the sodium humate while stirring until the sodium humate is mixed into a viscous shape;

[0081] S2. Mixing of carrier materials: Grind and sieve the activated carbon powder and add it to the binder pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com