Chlorination reaction kettle and chlorination process for ortho-position and para-position products

A chlorination reaction kettle, ortho-paraposition technology, which is applied in the chlorination reaction kettle for ortho-paraposition products and the chlorination process field, can solve problems such as uneven stirring and mixing, and achieve improved uniformity, high product yield, and side effects less responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

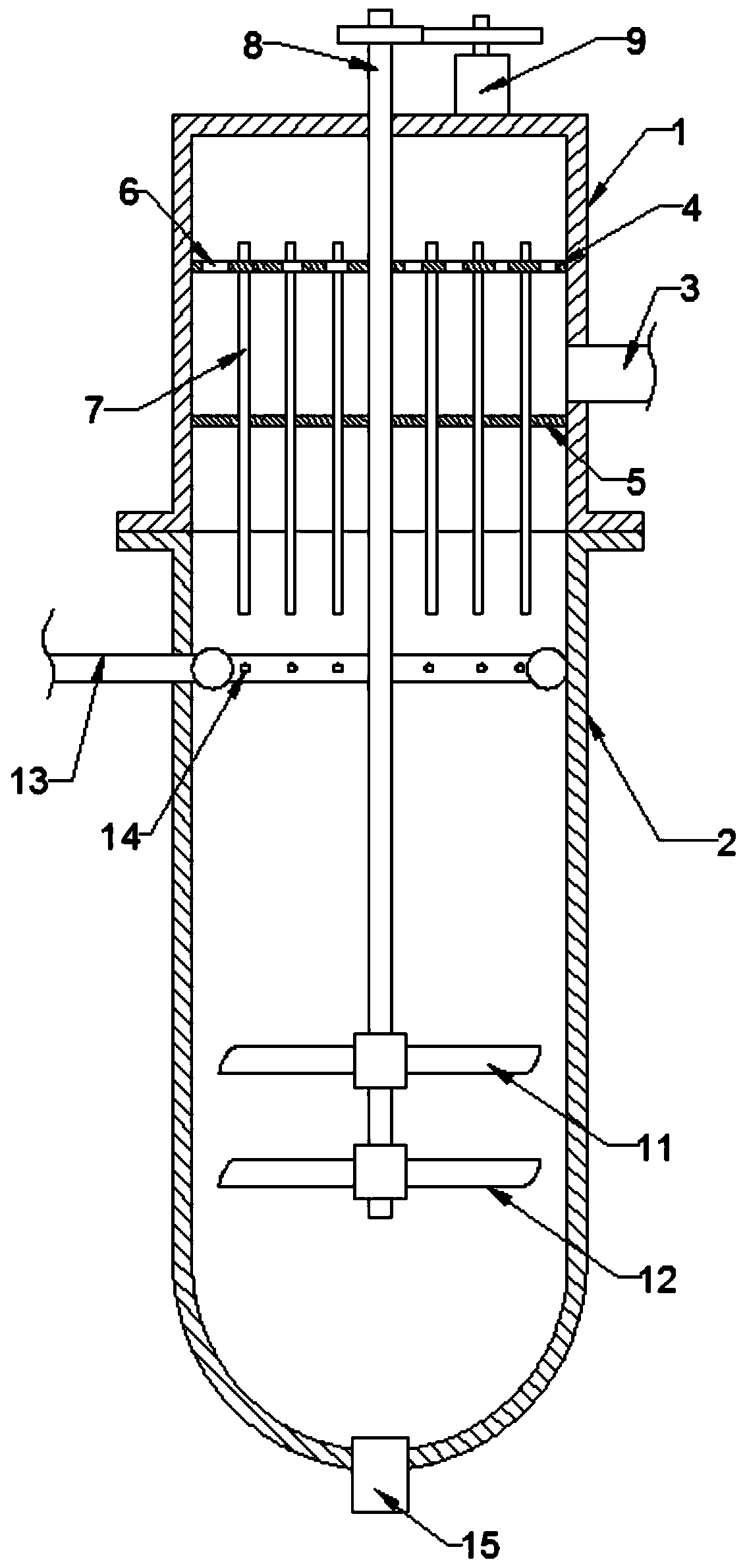

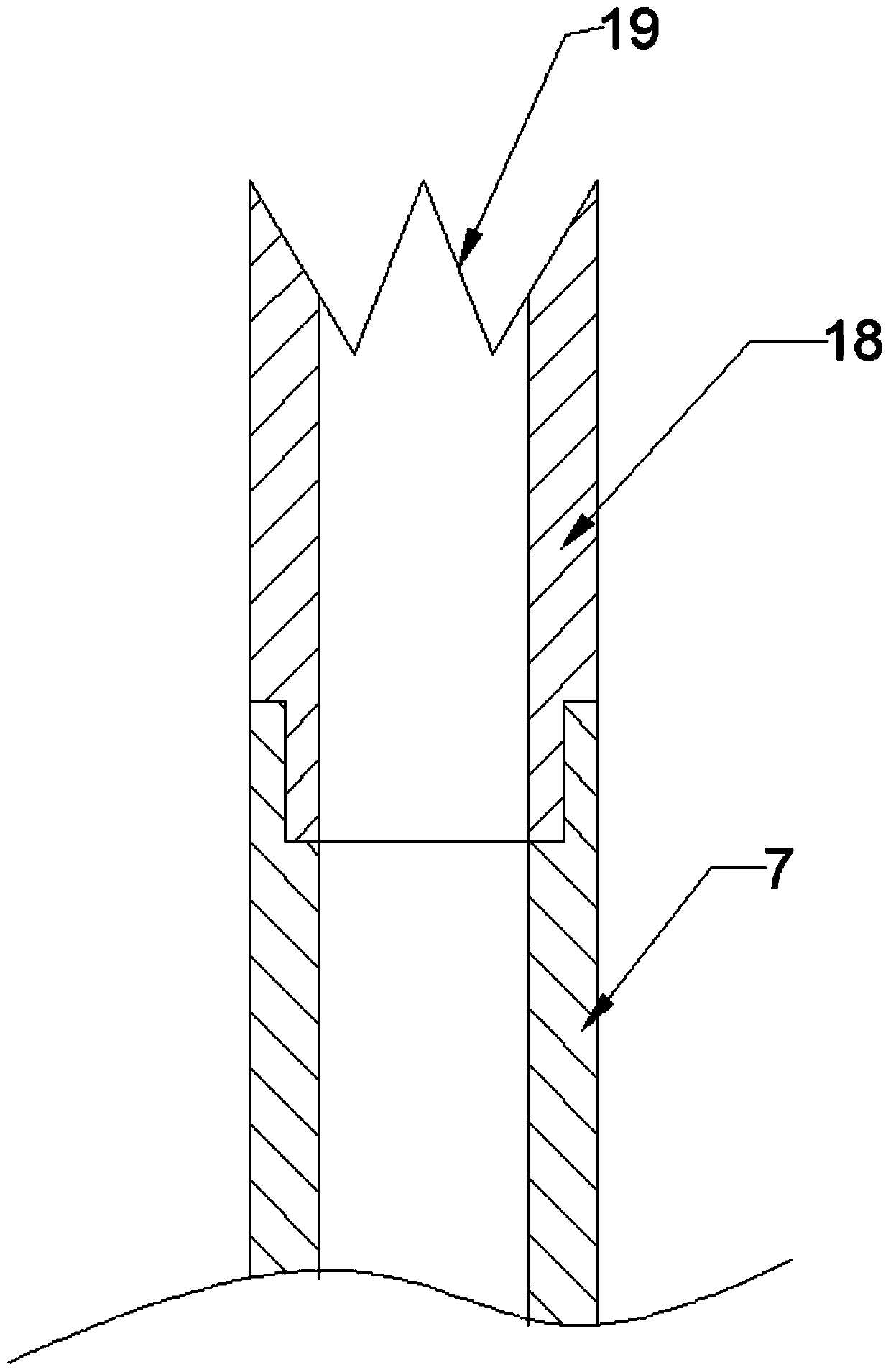

[0036] This embodiment, as a basic embodiment of the present invention, discloses a chlorination reactor for ortho-para products, the specific structure is as follows figure 1 As shown, it includes a sealing cover 1 and a kettle body 2 that are airtightly connected to each other. One side of the sealing cover 1 is provided with a first feed pipe 3 connected to external feeding equipment, and the upper and lower sides of the first feed pipe 3 are respectively provided with An overflow plate 4 and a sealing plate 5, the overflow plate 4 and the sealing plate 5 are fixedly installed in the sealing cover 1 by welding; the overflow plate 4 is provided with an overflow hole 6 and a mounting hole 23, The sealing plate 5 is provided with a corresponding mounting hole 23, and the kettle body 2 is provided with an overflow pipe 7 with both ends open, and one end of the overflow pipe 7 passes through the mounting hole 23 of the overflow plate 4 and the sealing plate 5 and stretches out to...

Embodiment approach 2

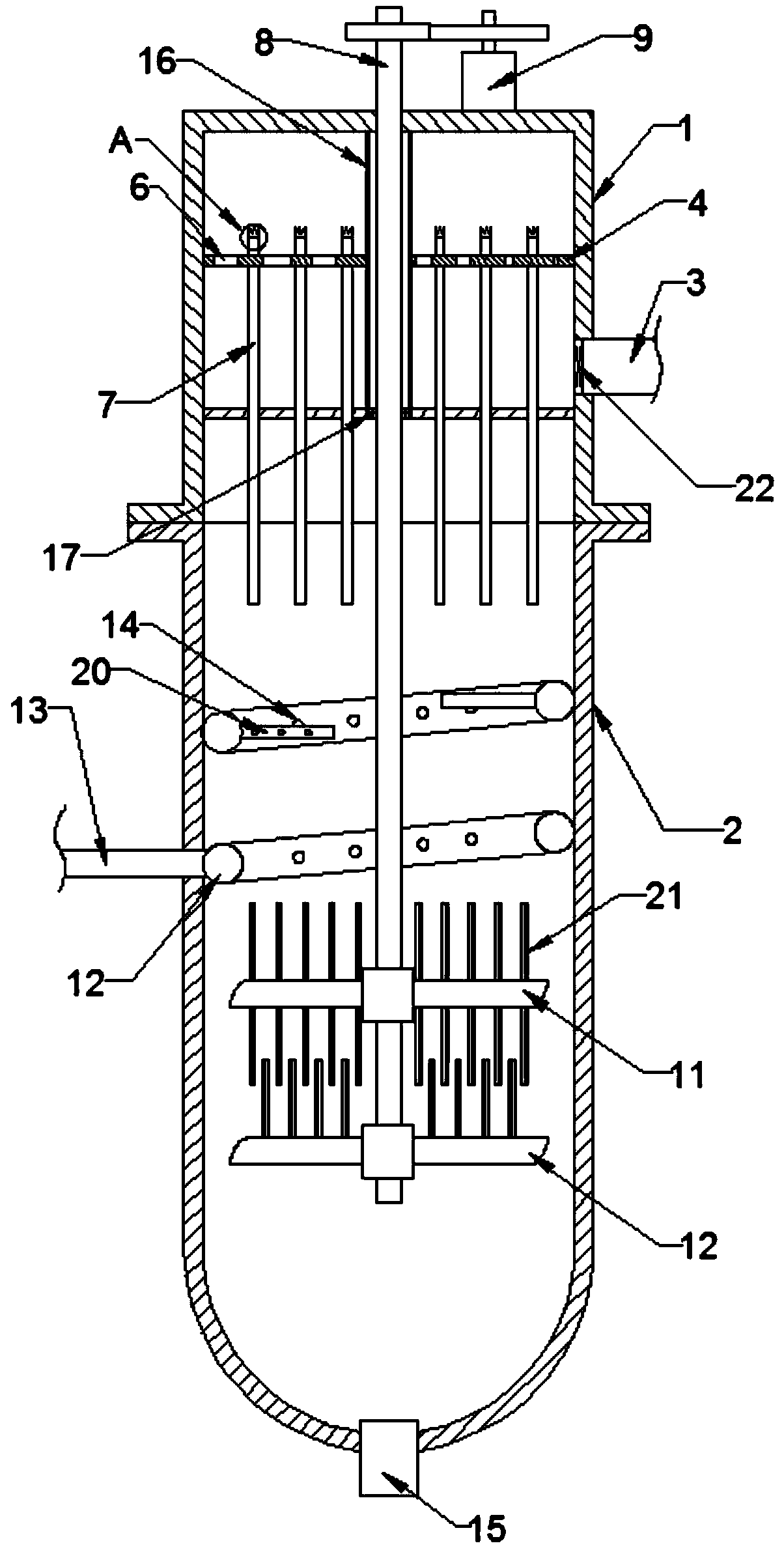

[0039] This embodiment, as a preferred embodiment of the present invention, discloses a chlorination reaction kettle for ortho-para products on the basis of Embodiment 1, including a kettle body 2 and a sealing cover 1. An overflow plate 4 and a sealing plate 5 are fixedly arranged, and a first feeding pipe 3 is arranged between the overflow plate 4 and the sealing plate 5, and a buffer filter screen 22 is fixedly arranged at the outlet end of the first feeding pipe 3; The overflow plate 4 is evenly provided with a plurality of overflow holes 6, and according to the direction away from the first feed pipe 3, the diameter of the overflow holes 6 increases linearly, and at the same time, in the middle of the overflow plate 4 and the sealing plate 5 A central hole 24 for installing the rotating shaft 8 is provided, and the two central holes 24 are connected by a sealing tube 16. Both ends of the sealing tube 16 are open, and one end thereof is fixedly connected to the inner wall o...

Embodiment approach 3

[0045] A kind of chlorination process of adjacent para-position product, comprises the steps:

[0046] S1, in the chlorination reactor for the adjacent para-position product, adopt sulfur trioxide to carry out the sulfonation reaction of toluene;

[0047] S2, then add chlorosulfonic acid and ammonium sulfate to carry out chlorination reaction in the chlorination reactor of the adjacent para-position product;

[0048] Wherein, the chlorination reaction kettle for adjacent para-position products includes a sealing cover 1 and a kettle body 2 that are sealed and connected to each other, and is characterized in that: the sealing cover 1 is provided with a first feeding pipe 3, and the first feeding The upper and lower sides of the tube 3 are respectively provided with an overflow plate 4 and a sealing plate 5; the overflow plate 4 is provided with an overflow hole 6, and the sealing plate 5 is fixedly provided with a plurality of overflow pipes 7, and the overflow pipe The two en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com