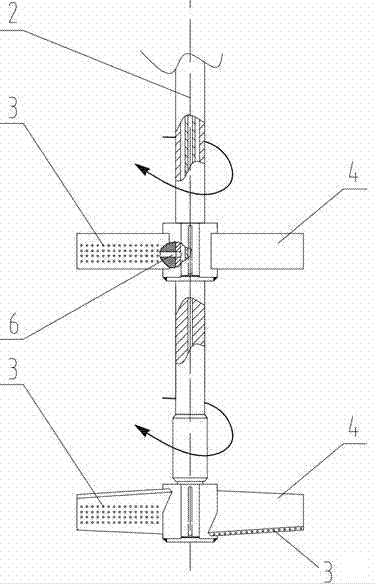

Feeding stirring device of wet metallurgy reactor

A stirring device and hydrometallurgy technology, applied in mixers with rotating stirring devices, improvement of process efficiency, chemical instruments and methods, etc., can solve the problem that the addition amount cannot be accurately controlled, the reaction system cannot be uniformly added, and the utilization rate is low And other problems, to achieve the effect of easy addition, increase utilization rate and reduce loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Leaching of materials containing valuable metals, using image 3 Add two kinds of medium double-layer stirring device as shown, after the stirring device starts to stir the reaction system, sulfur dioxide gas and hydrogen peroxide are respectively added from the rotary sealed feeder, and then enter the stirring blades respectively through the hollow stirring shaft, and the sulfur dioxide gas enters the lower stirring paddle leaves, hydrogen peroxide enters the upper stirring blade, and is added into the reaction system through multiple groups of feeding holes on the stirring blade, so that the SO 2 The gas is evenly dispersed in the reaction system, which improves the utilization efficiency and shortens the reaction time.

Embodiment 2

[0019] Hydrometallurgical neutralization precipitation, using figure 2 The single-medium double-layer stirring device shown is added. After the stirring device starts to stir the reaction system, ammonia water is added from the rotary sealed feeder, and enters the stirring blade through the hollow stirring shaft, and is added into the reaction system through multiple groups of feeding holes on the stirring blade. , so that the ammonia water is evenly dispersed in the reaction system, while improving the utilization efficiency, it makes the reaction smooth and easy to control the reaction end point.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com