Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Control joining speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

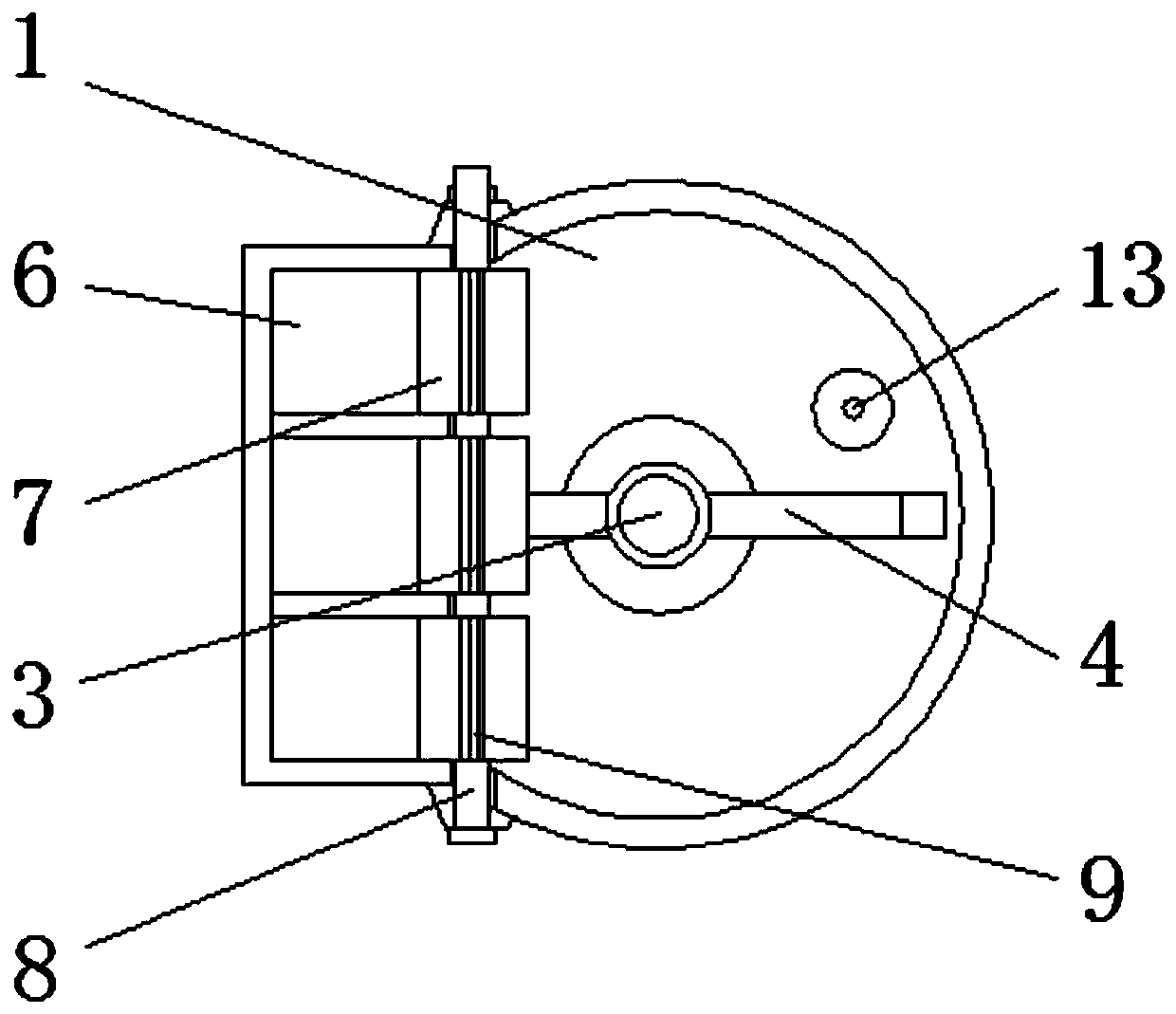

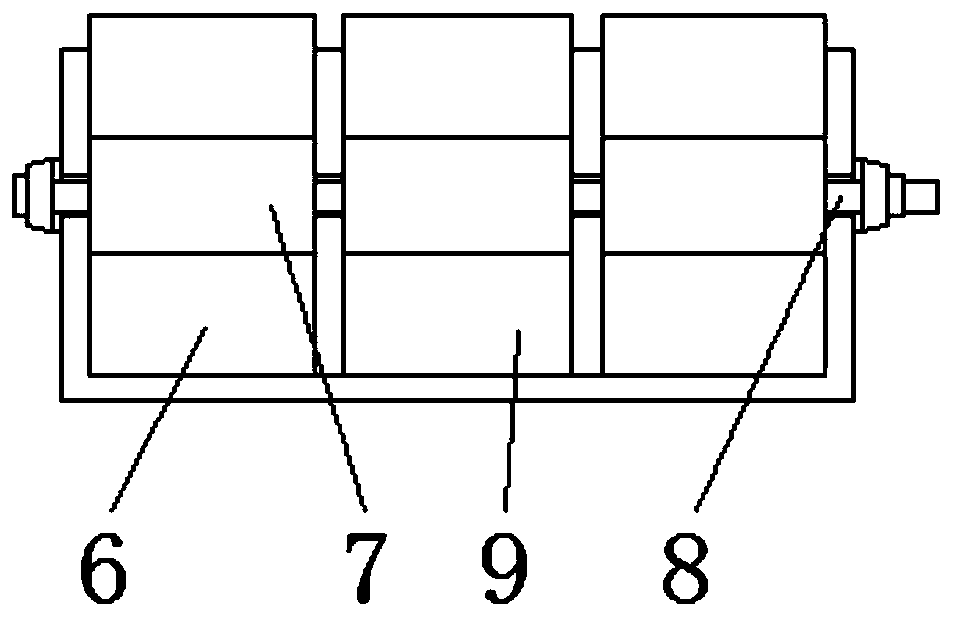

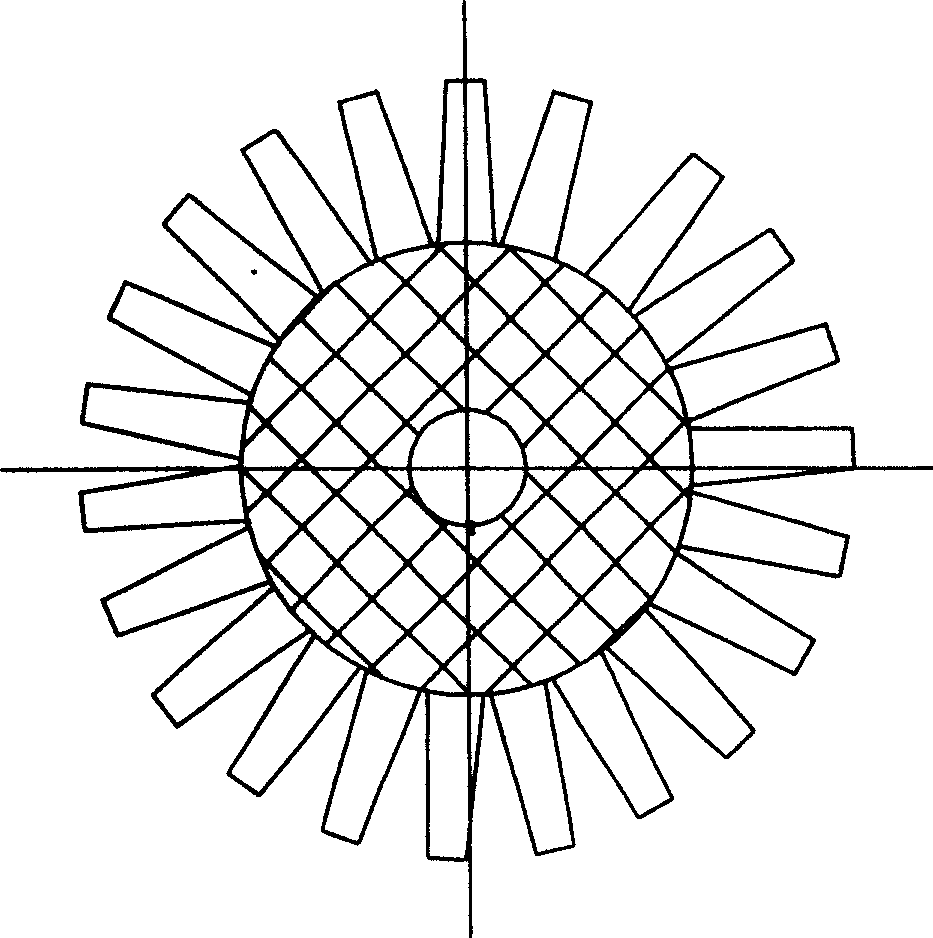

Short fiber feeding device for fiber reinforced thermoplastic plastics screw extruding machine

The invention discloses a chopped fiber feeder of the screw extruder which includes the hopper, the motor, the gearbox, the roller with the open slot and the fiber stirring device. The motor fixed on the supporting frame is connected to the gearbox which is connected to the roller by the axis. The roller located in the bottom of the hopper matches with the open slot. It can control the addition and the adding speed of the chopped fiber by controlling the speed of the roller and the roller or the hopper open slot. So it can protect the completeness of the chopped fiber.

Owner:林军

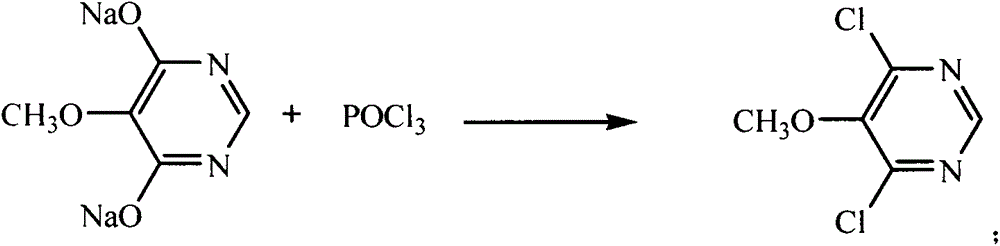

Method for preparing 3-(2-chloroethyl)-2-methyl-4H- naphthyridine[1,2-a]pyrimidine-4-ketone

ActiveCN101328174AControl joining speedReduce dosageNervous disorderOrganic chemistryMethylene DichlorideKetone

The invention provides a method for preparing 3-(2-Chloroethyl)-2-methylpyrido[1,2-a]pyrimidin-4-one. The method uses 2-aminopyridine and 2-acetylbutyrolacton as raw materials and comprises steps of reactants preparation and separation and purification. The reactants are prepared by the following steps of: placing the 2-aminopyridine and the 2-acetylbutyrolacton into toluene, mixing and stirring the mixture to obtain a reactant liquid, heating the reactant liquid, diluting phosphorus oxychloride with the toluene in advance, dripping the diluted phosphorus oxychloride into the liquid, keeping the temperature at 110 DEG C, carrying out reflux, and obtaining the reactants. The invention can well control the dripping speed of the phosphorus oxychloride, thereby solving the problems of multiple solvents and complex operation caused by ammonia, methylene dichloride, isopropanol, etc. in the following operation, simplifying the process of separation and purification, improving the product yield, and achieving the pure product rate of more than 70 percent.

Owner:CSPC OUYI PHARM CO LTD

Method for preparing aliphatic water reducer without heating

The invention discloses a method for preparing an aliphatic water reducer without heating. The method is used for preparing the aliphatic water reducer from water, sodium sulfite, acetone and formaldehyde as raw materials and comprises the following steps: adding water to a reactor; then adding the sodium sulfite to the water and stirring to dissolve; then adding the acetone to the solution and carrying out sulfonation reaction for 0.5-1h; starting a condensing device, rapidly adding 1 / 3 of formaldehyde, then dropwise adding another 1 / 3 of formaldehyde, powering off the condensing device of the reactor after dropwise addition is finished, and finally rapidly adding the rest 1 / 3 of formaldehyde to react for 1-2h; and after the reaction is finished, cooling to below 50 DEG C to obtain the aliphatic water reducer. The method disclosed by the invention makes full use of energy produced by reaction, is free of heating in the whole production process and saves energy sources.

Owner:JIANGSU BAIRUIJI NEW MATERIAL

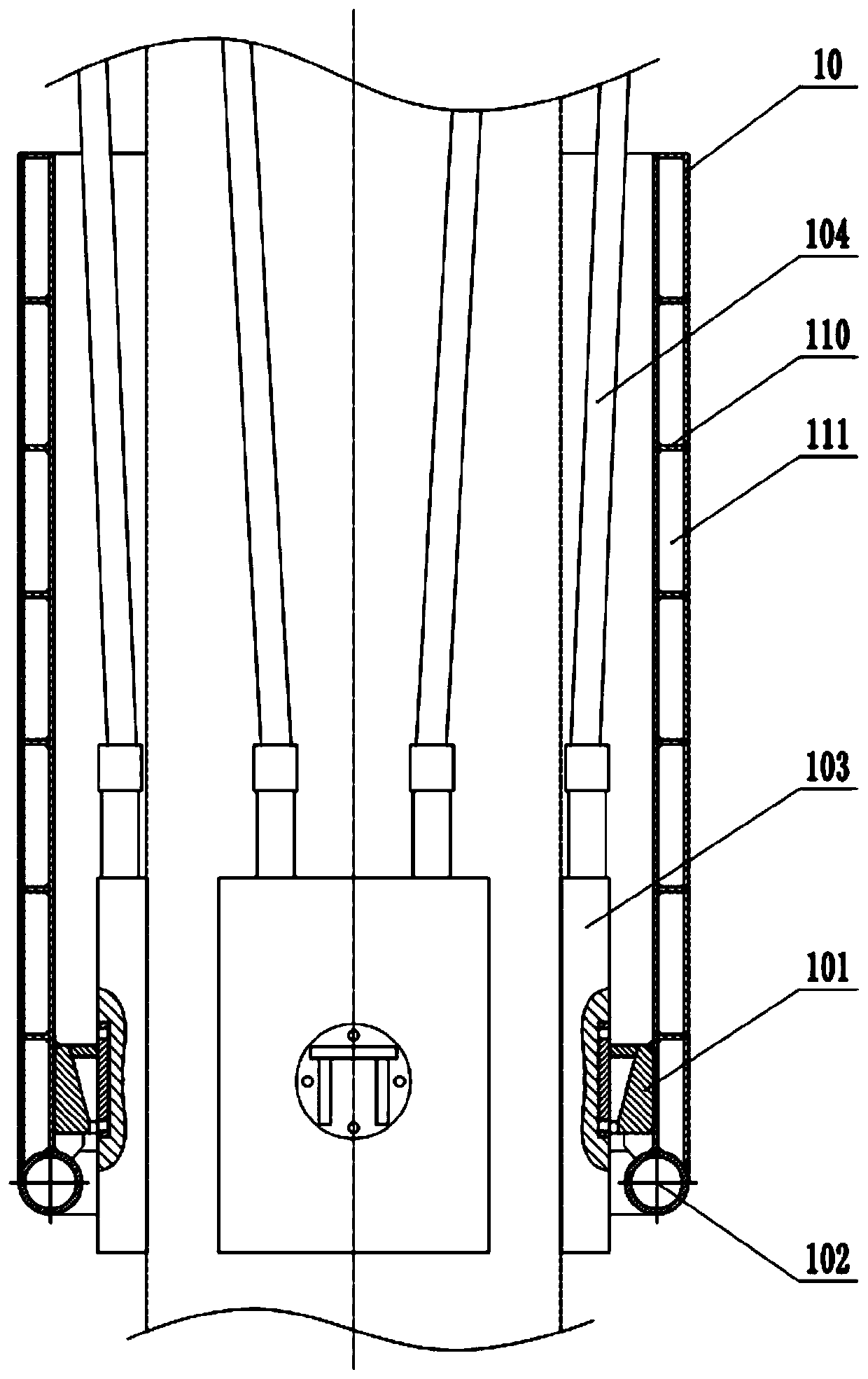

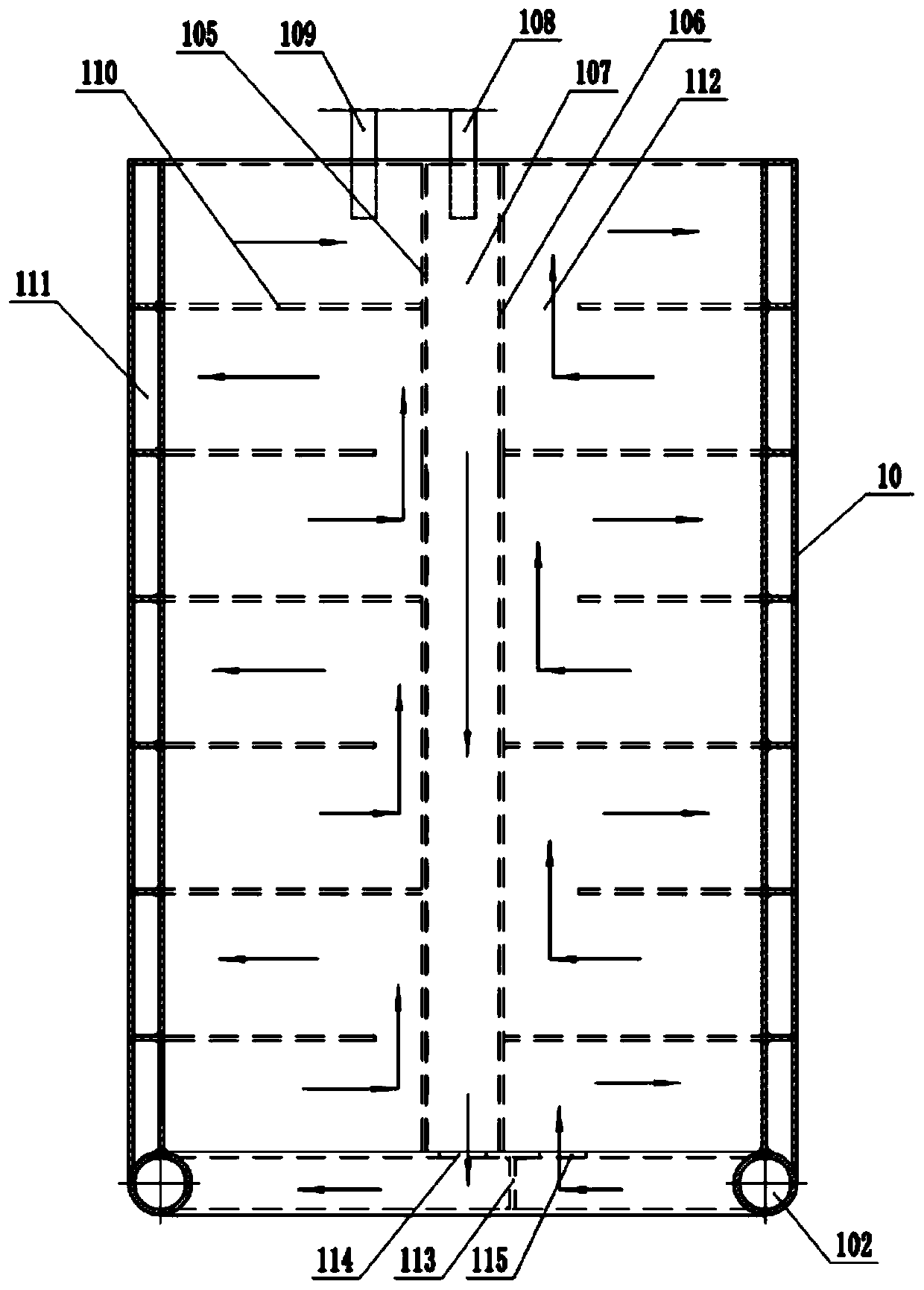

Equipment for treating H-acid production wastewater

InactiveCN102701505ASolving a long-standing technical problem that is intractableEffective neutralizationChemical industryEnergy based wastewater treatmentDistillationEvaporation

The invention relates to equipment for treating H-acid production wastewater. The equipment comprises a neutralization pot, an elevated tank, an evaporation pot, a crystallization tank and a centrifuge which are connected in sequence, wherein a material transferring pump for adding roughly treated feed liquid into the elevated tank is arranged between the neutralization pot and the elevated tank. A new road is opened, water is evaporated in a distillation mode by skillfully utilizing the characteristic that organic matters and the water in the wastewater have different boiling points, the organic matters and inorganic salts are separated, sticky colloidal organic matters and solid inorganic salts are separated in a centrifuging mode, the organic matters are combusted or further separated, the solid inorganic salts containing a large amount of ammonium sulfate can be directly used as a fertilizer, and waste is turned into wealth, so that the long-term technical problem that H-acid waste liquid is difficult to treat is solved.

Owner:SHANDONG YUYUAN GROUP

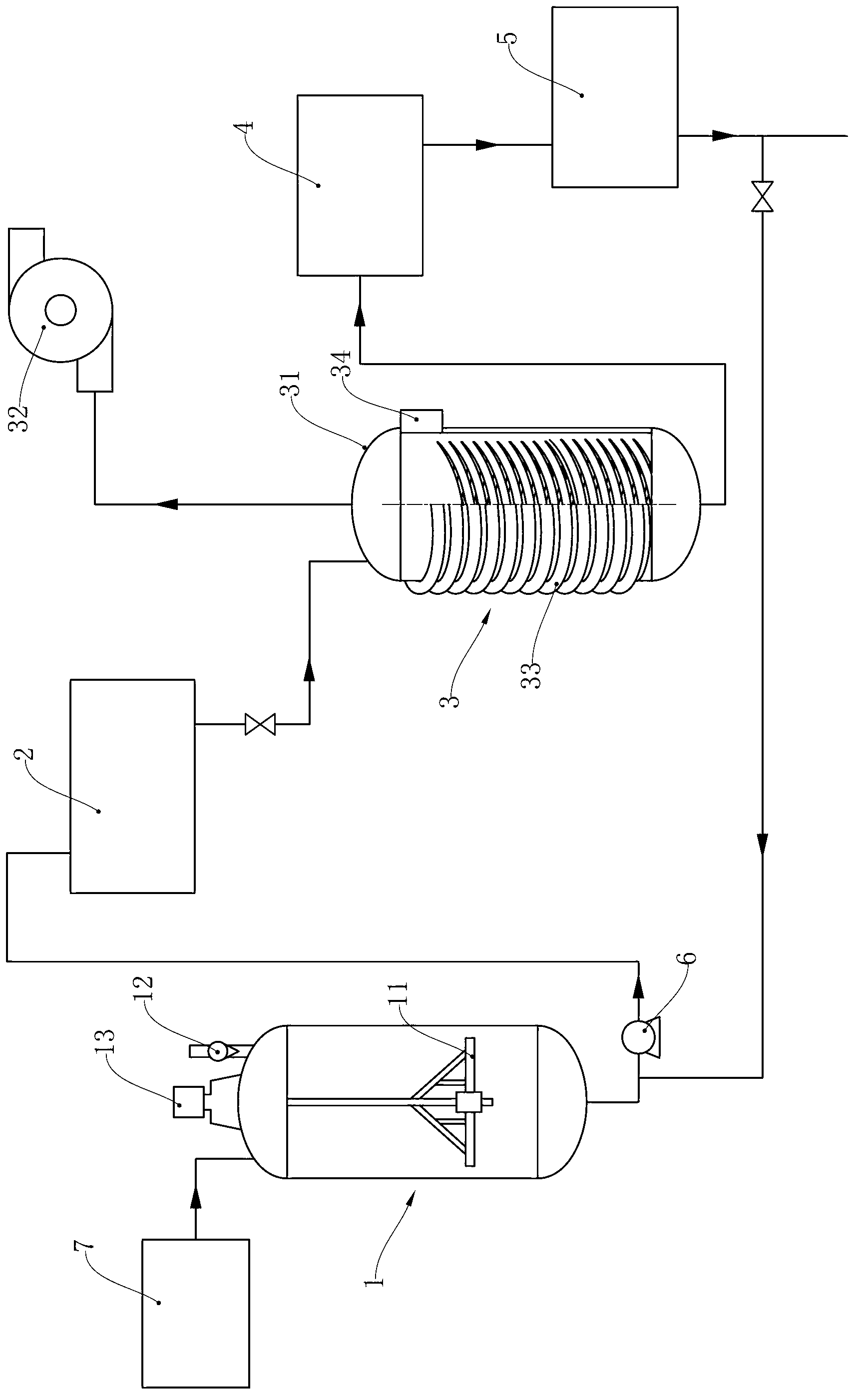

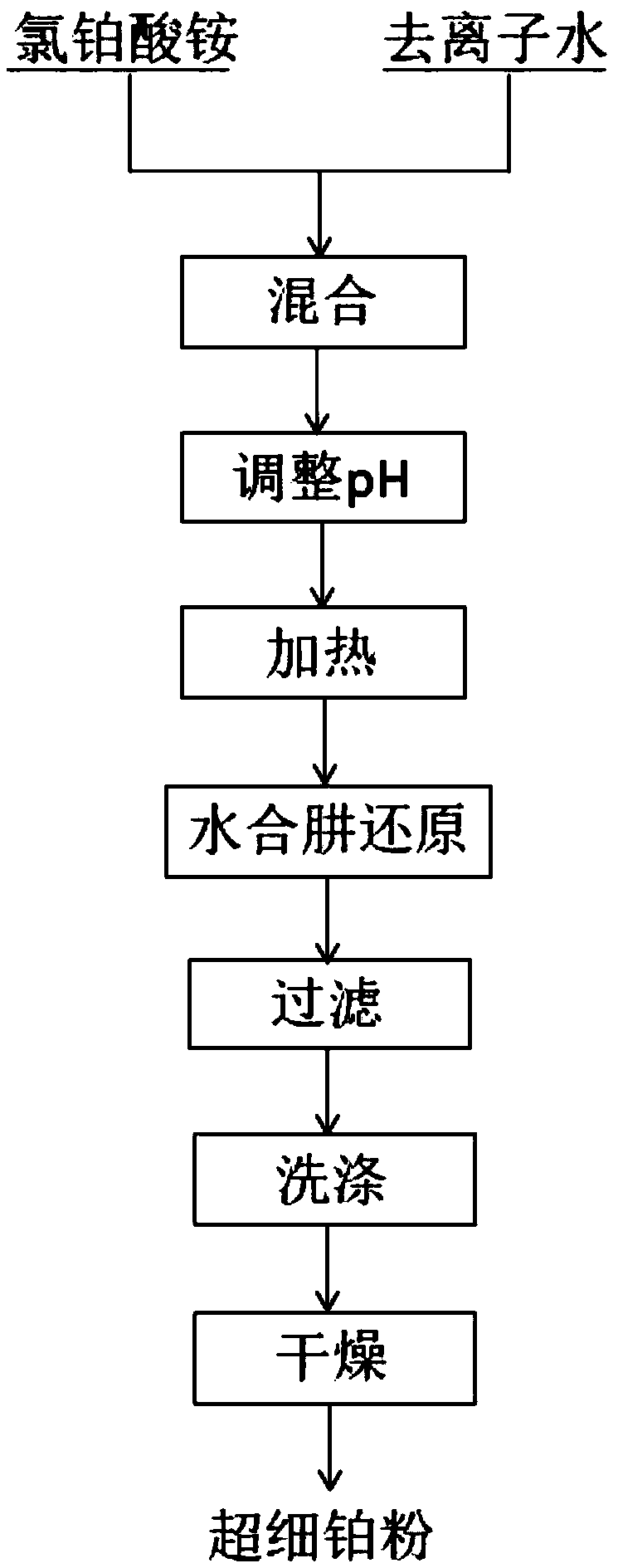

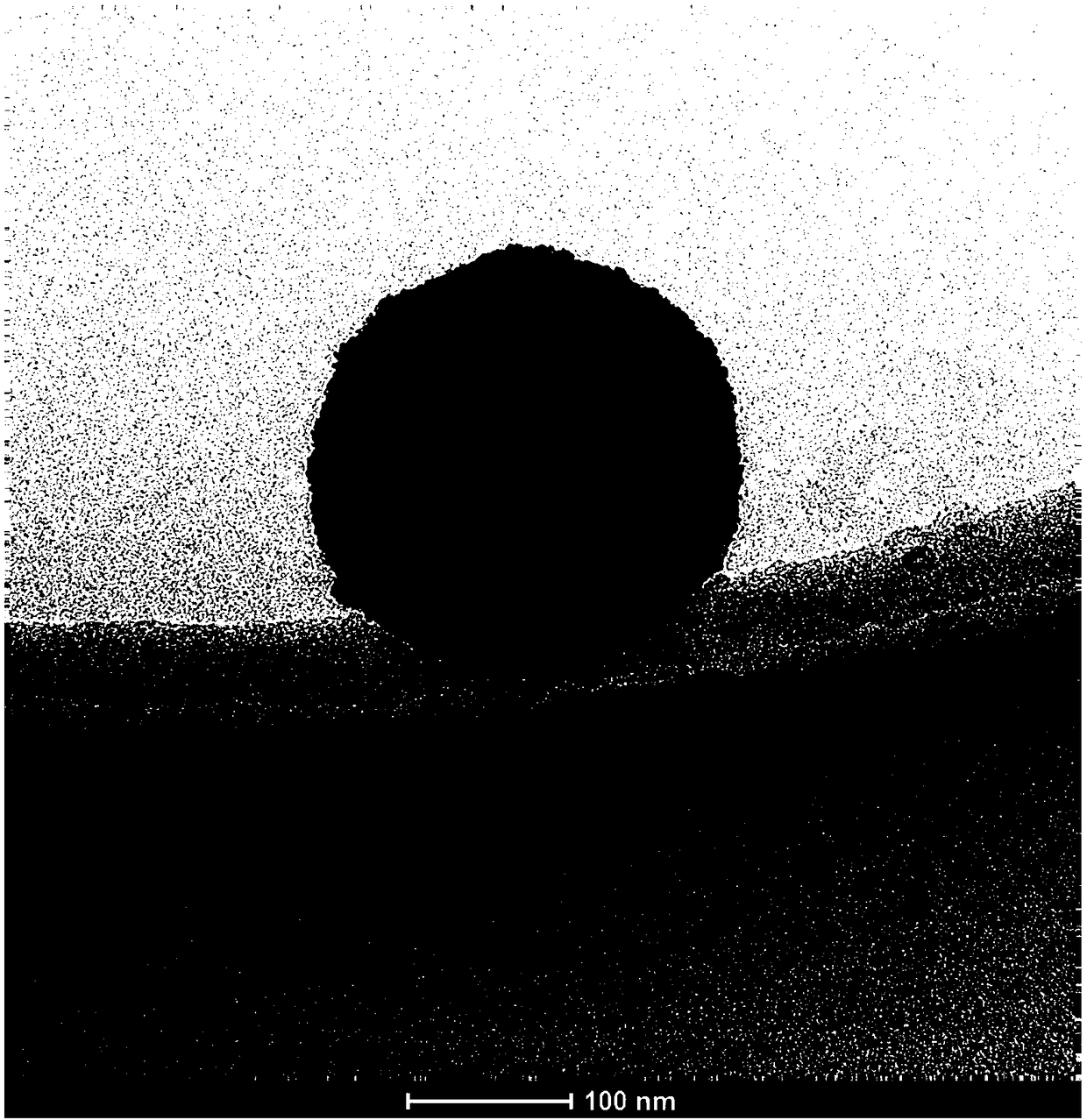

Method for short process preparation of superfine platinum powder

The invention discloses a method for short process preparation of superfine platinum powder. Specifically, a certain amount of ammonium chloroplatinate solid is weighed, deionized water is added, andthe specific value of the volume of the deionized water to the mass of the ammonium chloroplatinate solid is (10-20):1 (ml / g); aqueous alkali is used for adjusting the aqueous phase pH to be 4-8; a hydrazine hydrate solution with the mass fraction being 40% is weighed, attenuation is carried out to enable the mass fraction to be 20%, and the solution obtained after attenuation is used as a reducing agent for standby application, and the using amount of the hydrazine hydrate is 2-4 times the theoretical using amount of reducing platinum; heating is carried out, and the system temperance is maintained to be 40-50 DEG C; under the stirring condition, a reducing agent is dropwise added into a platinum containing water phase slowly, the aqueous alkali is used for adjusting the aqueous phase pHin the phase, and the pH value is maintained to be 4-8; after the reducing agent is completely added, stirring is carried out for 0.5-1 h; and the superfine platinum powder is obtained after filtering, washing and drying. According to the method, a solid phase reduction method is adopted, the ammonium chloroplatinate solid is restored directly, meanwhile, the superfine platinum powder with the small prepared size can be prepared under the condition that a dispersing agent is not added, the technology is simple, and the flow is short.

Owner:XUZHOU GUOMAO VALUABLE & RARE METAL COMPREHENSIVE UTILIZATION INST +1

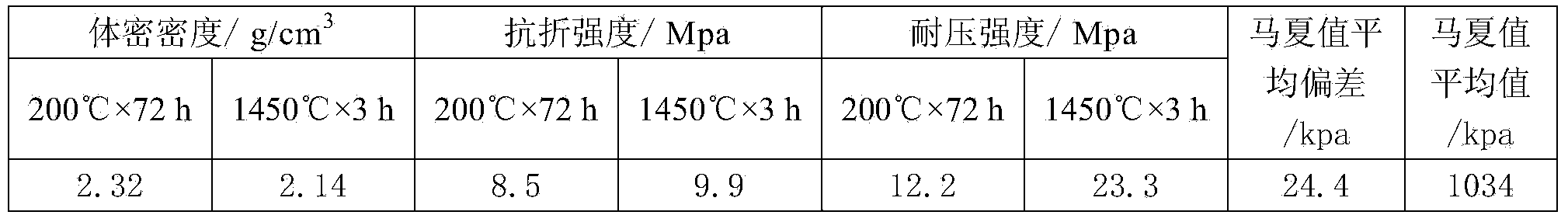

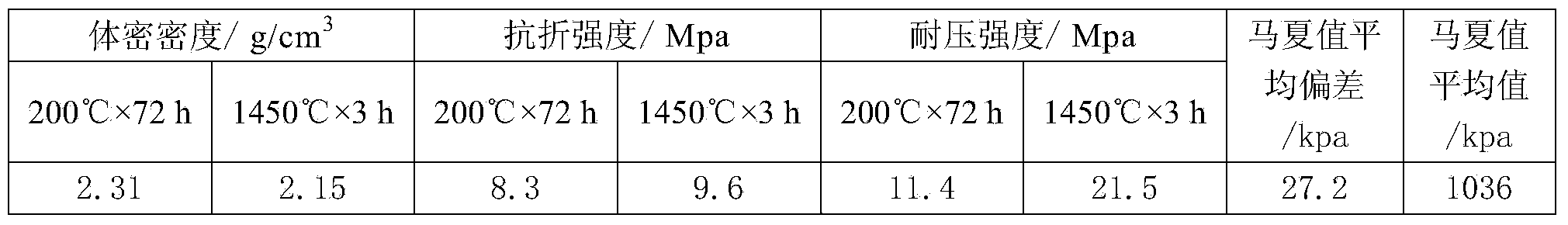

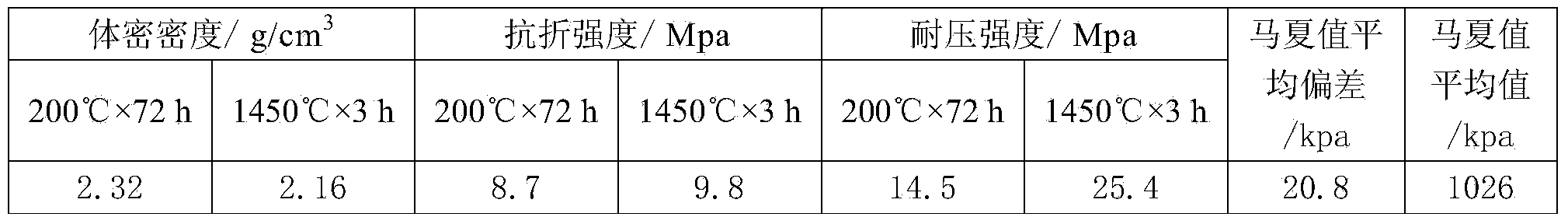

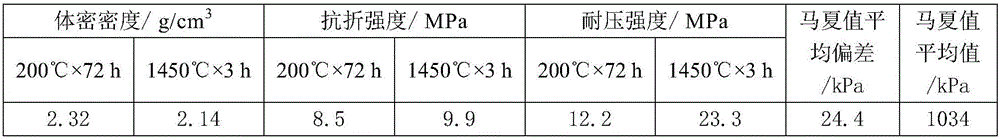

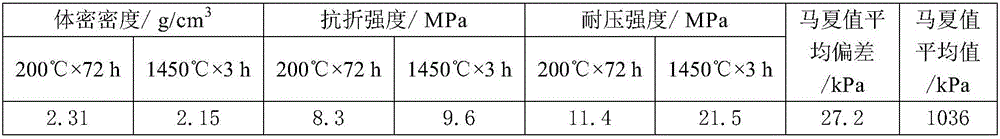

Dumping furnace smelting brown aluminum oxide self-baking electrode and production technology thereof

ActiveCN110430632AQuality improvementSuitable for smeltingElectric discharge heatingCopperVolume density

The invention relates to the electric furnace metallurgy technology field and especially relates to a dumping furnace smelting brown aluminum oxide self-baking electrode. The electrode is formed through roasting an electrode paste of a 9 to 12% weight percentage of a volatile content, an electrode barrel with an inner diameter of 690 to 710 mm is fixed in a fixing sleeve, a copper tile in the fixing sleeve holds the electrode barrel tightly, and the electrode barrel is fixed to a load-bearing steel platform through a holding system. An electrode paste feeding mechanism is used to add the electrode paste into the electrode barrel for roasting, and a height of an electrode paste column is controlled between 300 and 500 mm. When the electrode paste in the electrode barrel is roasted, coolingwater is injected into the fixing sleeve to form a self-baking electrode with a diameter of 690-710 mm and a volume density of 1.3-1.5 g / cm<3>. Through adopting the technical scheme, the self-bakingelectrode which is not suspended and pasted, and does not generate chipping is manufactured, and the electrode is suitable for smelting of a brown aluminum oxide and is worth promoting.

Owner:重庆市赛特刚玉有限公司

Method for preparing 3-(2-chloroethyl)-2-methyl-4H- naphthyridine[1,2-a]pyrimidine-4-ketone

ActiveCN101328174BControl joining speedReduce dosageNervous disorderOrganic chemistryMethylene DichlorideKetone

The invention provides a method for preparing 3-(2-Chloroethyl)-2-methylpyrido[1,2-a]pyrimidin-4-one. The method uses 2-aminopyridine and 2-acetylbutyrolacton as raw materials and comprises steps of reactants preparation and separation and purification. The reactants are prepared by the following steps of: placing the 2-aminopyridine and the 2-acetylbutyrolacton into toluene, mixing and stirring the mixture to obtain a reactant liquid, heating the reactant liquid, diluting phosphorus oxychloride with the toluene in advance, dripping the diluted phosphorus oxychloride into the liquid, keeping the temperature at 110 DEG C, carrying out reflux, and obtaining the reactants. The invention can well control the dripping speed of the phosphorus oxychloride, thereby solving the problems of multiple solvents and complex operation caused by ammonia, methylene dichloride, isopropanol, etc. in the following operation, simplifying the process of separation and purification, improving the product yield, and achieving the pure product rate of more than 70 percent.

Owner:CSPC OUYI PHARM CO LTD

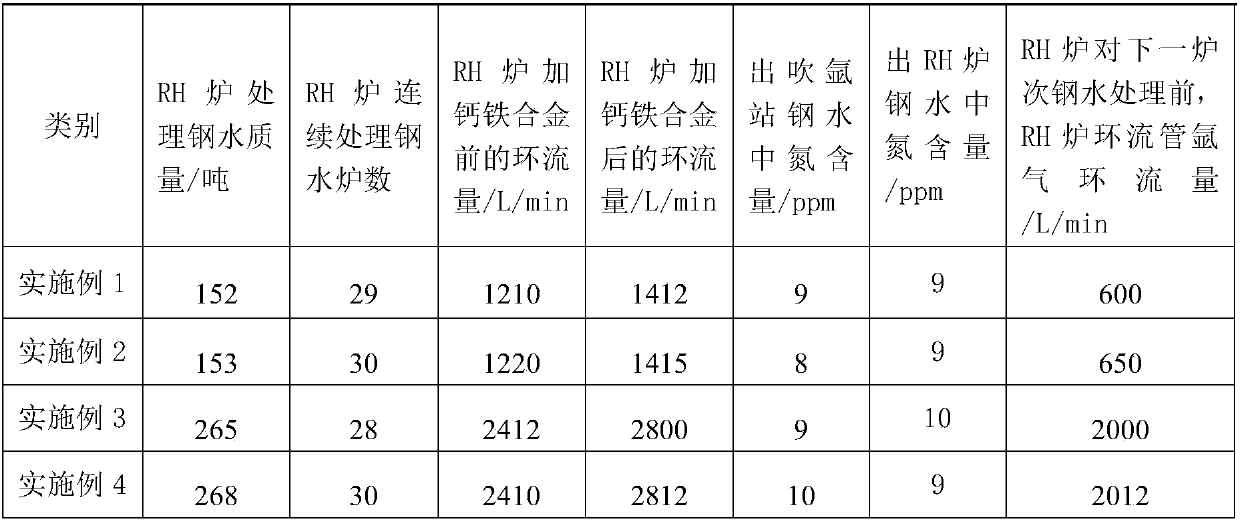

Low-cost calcium treatment method of ultralow-carbon high-aluminum steel

InactiveCN110317927ASolve the splatter problemSolve the fierce industry problemsLight treatmentNitrogen

The invention discloses a low-cost calcium treatment method of ultralow-carbon high-aluminum steel. The technical problems of high cost, molten steel splashing and molten steel nitrogen increasing ofthe calcium treatment conducting on the ultralow-carbon high-aluminum steel by an RH furnace in the prior art are solved. According to the technical scheme, the low-cost calcium treatment method for the ultralow-carbon high-aluminum steel comprises the following steps that decarbonizing is conducted on molten steel; deoxidizing is conducted the decarburized molten steel by adopting silicon; controlling a molten steel treatment mode of the RH furnace to be switched into a light treatment mode; conducting the calcium treatment on the molten steel; introducing argon into a RH furnace circulationpipe before the RH furnace finishes the next-furnace molten steel treatment, circulating the argon in the RH furnace circulation pipe, and the argon circulating flow rate is 500-2400 L / min. Accordingto the method, the cost for conducting the calcium treatment on the ultralow-carbon high-aluminum steel in the RH furnace is reduced, and the production cost of the ultralow-carbon high-aluminum steelis reduced.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

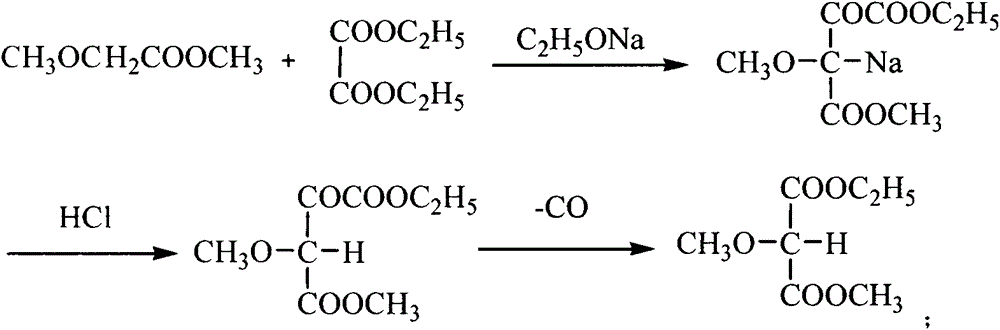

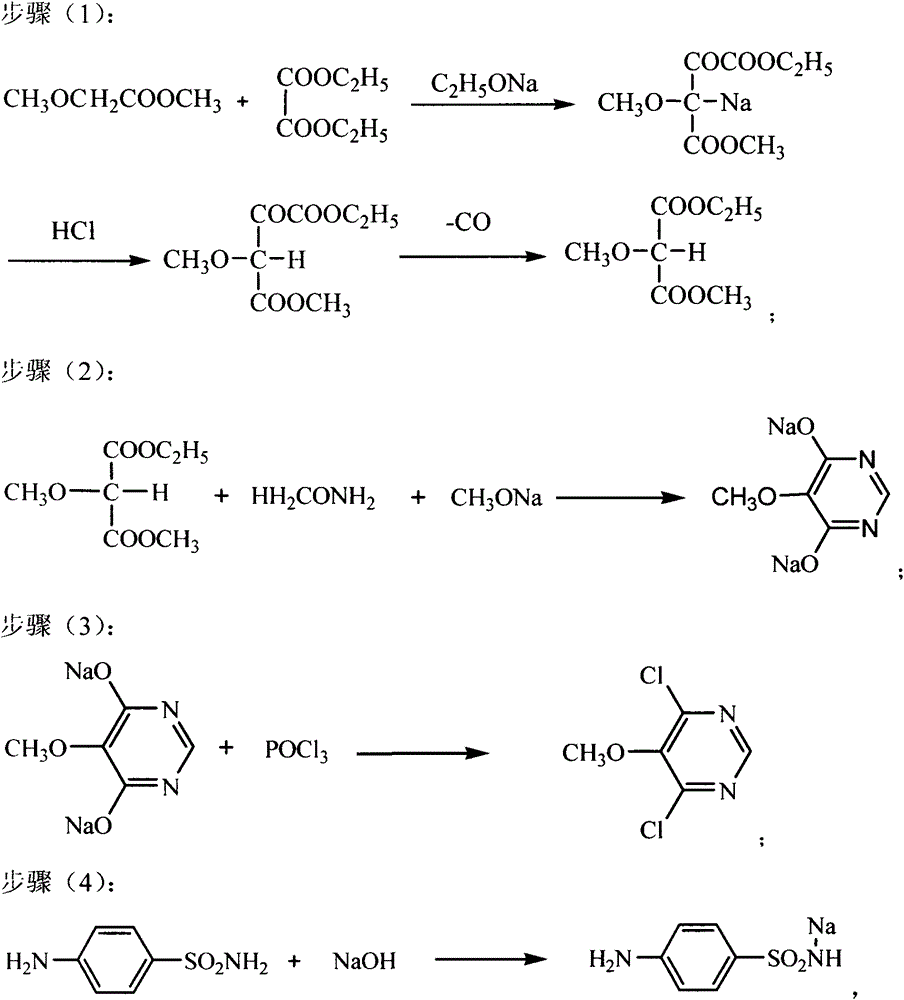

Preparation method of 4,6-dihydroxy-5-methoxypyrimidine sodium

InactiveCN103910684AGood for controlling the speed of additionControl joining speedOrganic chemistrySodium methoxideDistillation

The invention relates to a preparation method of 4,6-dihydroxy-5-methoxypyrimidine sodium. The preparation method comprises following steps: (a) sodium methylate is delivered into a dried container, is stirred and heated to 65 to 68 DEG C, methanamide is added, 2-methoxypropandioic acid ethyl methyl ester is added dropwise, and reaction is carried out at a temperature of 65 to 70 DEG C for 2 to 6h so as to obtain a mixture; and (b) the mixture is subjected to distillation at 25 to 80 DEG C so as to remove methanol, is cooled to 10 to 15 DEG C, and is centrifuged so as to collect a solid material. According to the preparation method of 4,6-dihydroxy-5-methoxypyrimidine sodium, sodium methylate and methanamide are delivered into the dried container, and 2-methoxypropandioic acid ethyl methyl ester is added dropwise, so that on the one hand, damage on reaction caused by residual water in the container is prevented, and on the other hand, the drop-by-drop adding manner is beneficial for controlling of adding speed of 2-methoxypropandioic acid ethyl methyl ester, the reaction temperature can be controlled more accurately, side reaction is inhibited, and yield of needed products is increased.

Owner:CHANGSHU NANHU INDAL CHEM

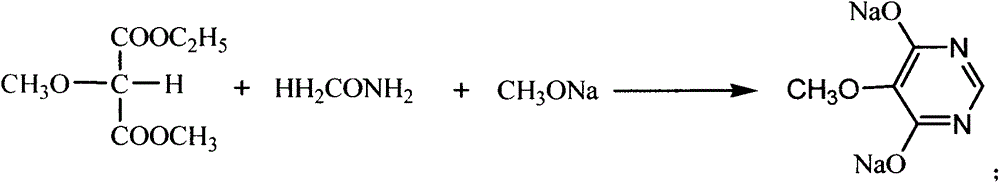

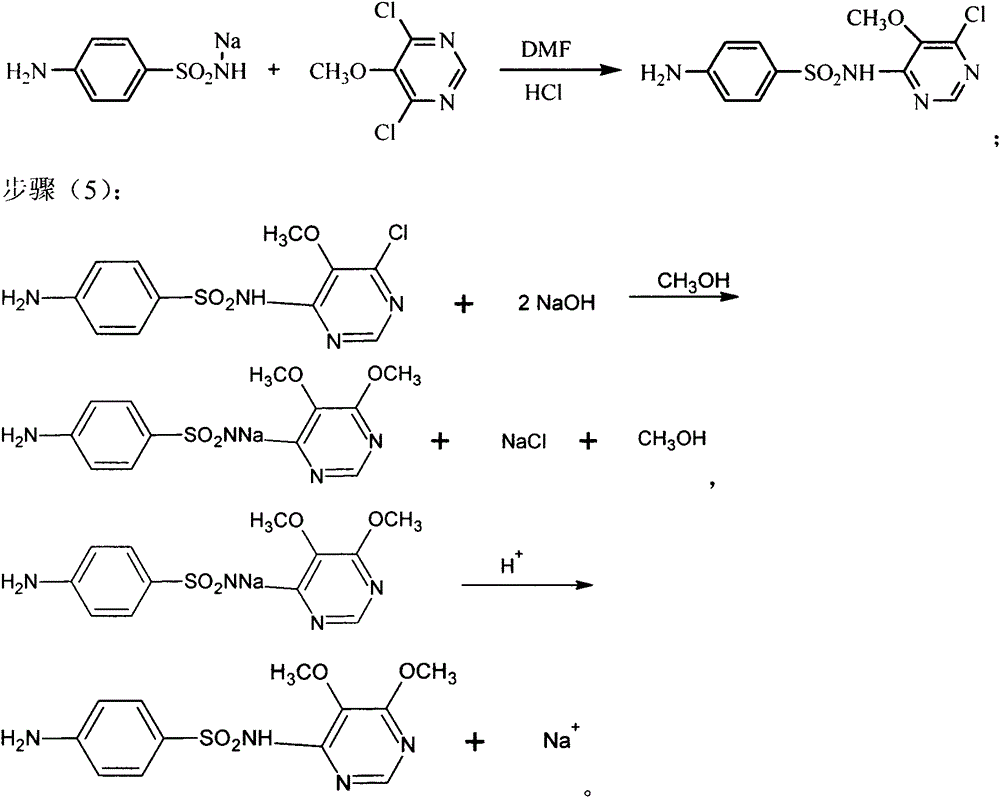

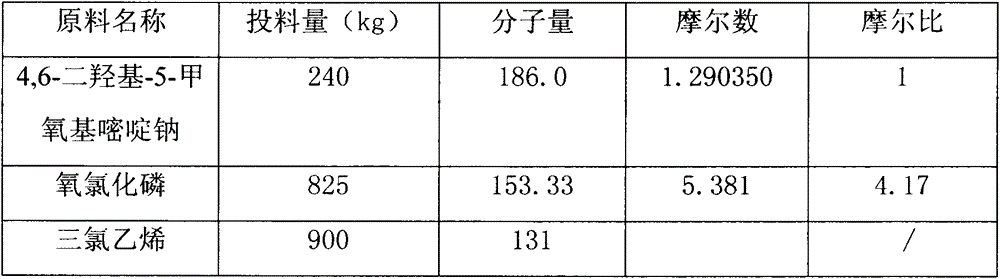

5-methoxyl-4,6-dichloropyrimidine preparing method capable of preventing temperature fluctuation phenomenon from occurring

The invention relates to a 5-methoxyl-4,6-dichloropyrimidine preparing method capable of preventing a temperature fluctuation phenomenon from occurring. The preparing method comprises the following steps that: (a) phosphorus oxychloride is added into a reaction container, then, organic solvents containing 4,6-dyhydroxyl-5-methoxyl pyrimidine sodium are added into the reaction container in a dropwise manner, and a reflux reaction is carried out for 2 to 6 hours at 110 to 120 DEG C to obtain a reaction mixture; (b) the reaction mixture is added into deionized water to be hydrolyzed, still standing layering is carried out, and a first water layer and a first organic solvent layer are formed; (c) alkali liquor is added into the first organic solvent layer for regulating the pH value to 6.5 to 7, the still standing layering is carried out again, and a second water layer and a second organic solvent layer are formed; and (d) the second organic solvent layer is distilled for removing the contained organic solvents. The organic solvents containing the 4,6-dyhydroxyl-5-methoxyl pyrimidine sodium are added into the reaction container in a dropwise manner, so the 4,6-dyhydroxyl-5-methoxyl pyrimidine sodium is diluted by the organic solvents; the adding speed of the 4,6-dyhydroxyl-5-methoxyl pyrimidine sodium can be controlled; the temperature of the reaction system can also be controlled; and the temperature fluctuation phenomenon cannot occur.

Owner:CHANGSHU NANHU INDAL CHEM

Stirring process for water-free taphole clay production process

InactiveCN104139458AImprove stirring efficiencyImprove stabilityClay mixing apparatusTime rangeMaterials science

The invention discloses a stirring process for the water-free taphole clay production process. The stirring process has the advantages that efficiency is high, bonding agents can fully wet aggregates and powder, the uniformity is good, and the stability is high. The stirring process comprises the steps of (1) conducting dry-blending, wherein various kinds of aggregates and powder weighed according to a formula are placed into a mixer for stirring, the stirring speed of a rotor ranges from 72 r / m to 108 r / m, and the stirring time ranges from 60 s to 120 s, (2) adding the bonding agents, wherein the bonding agents weighed according to the formula are placed into the mixer, the adding speed of the bonding agents ranges from 1.2 Kg / s to 2.2 Kg / s, and the stirring speed of the rotor ranges from 72 r / m to 108 r / m, and (3) conducting wet-blending. The stirring process can be widely applied to the water-free taphole clay production field.

Owner:CHINA JINGYE ENG TECH CO LTD +2

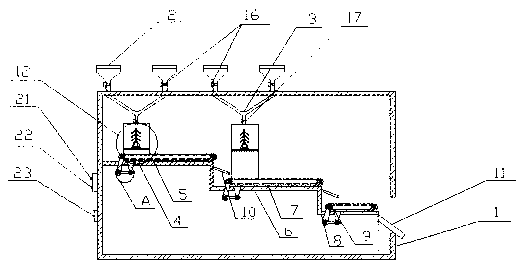

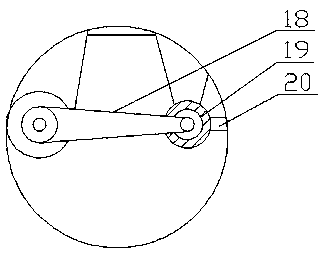

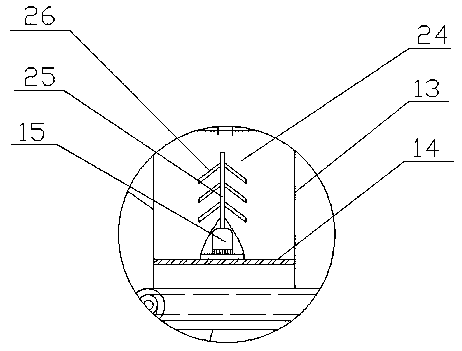

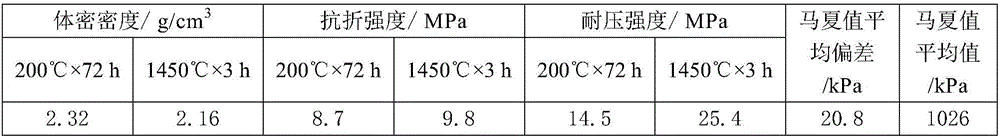

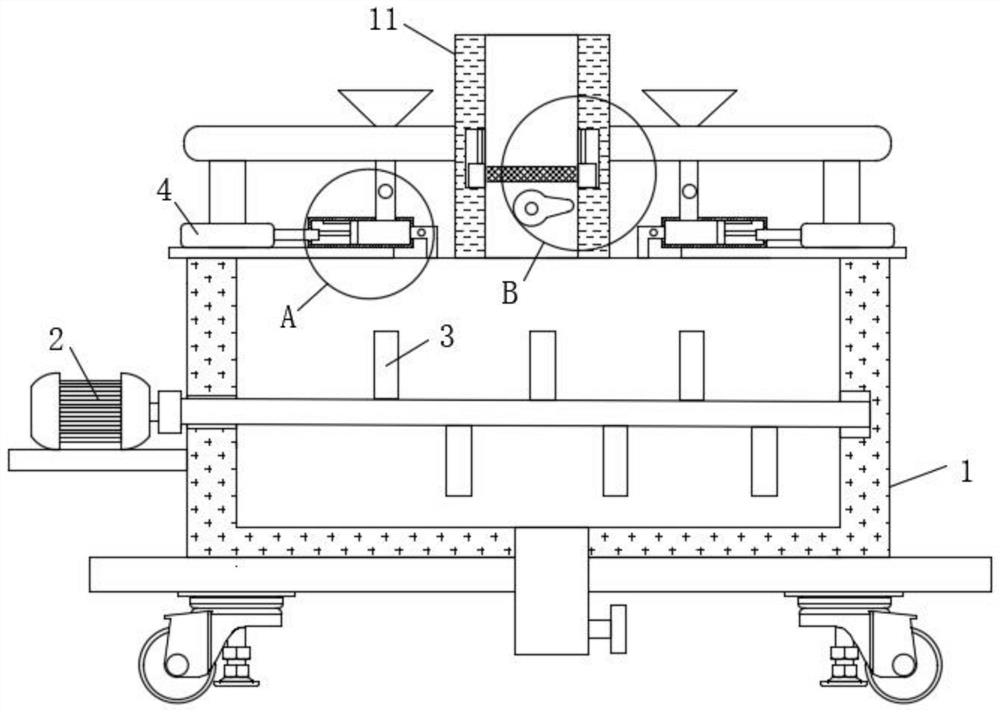

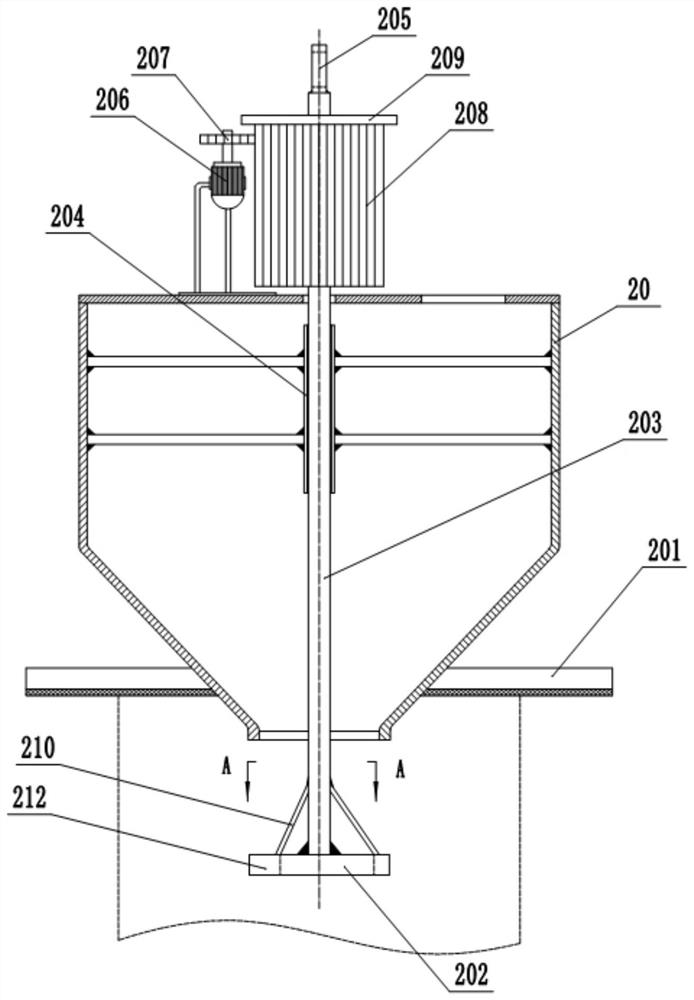

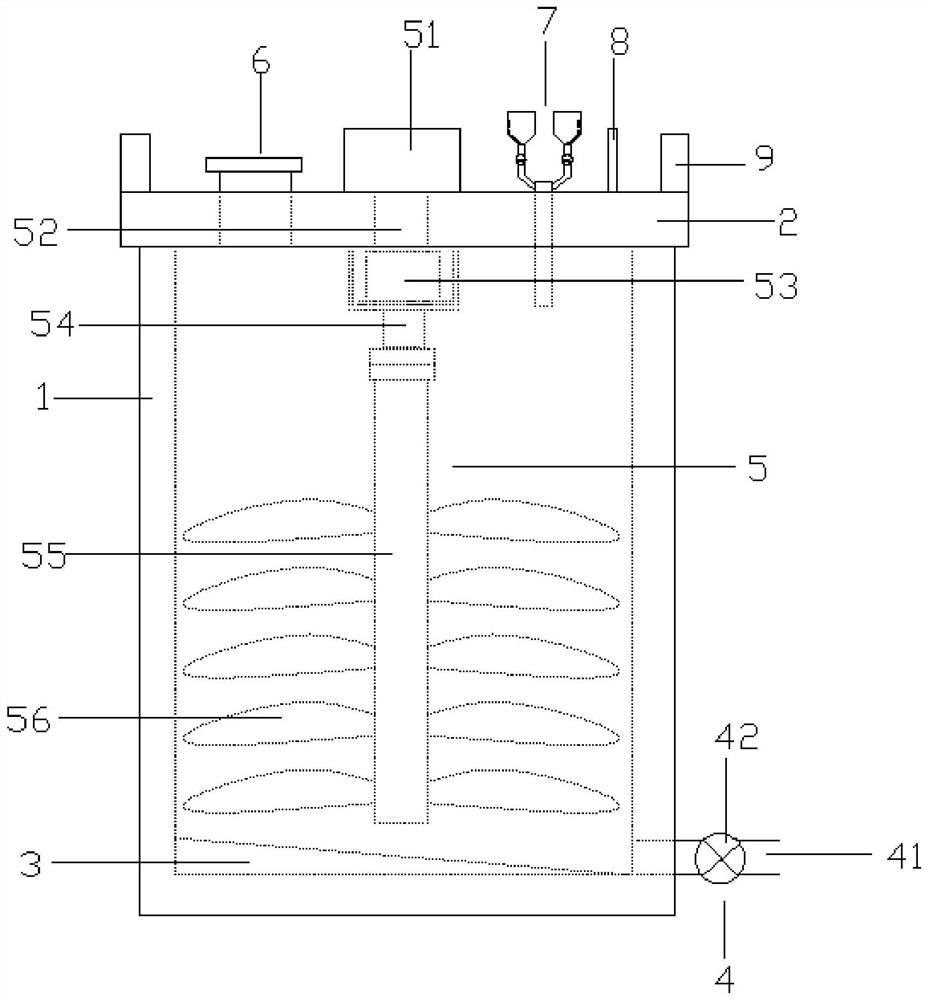

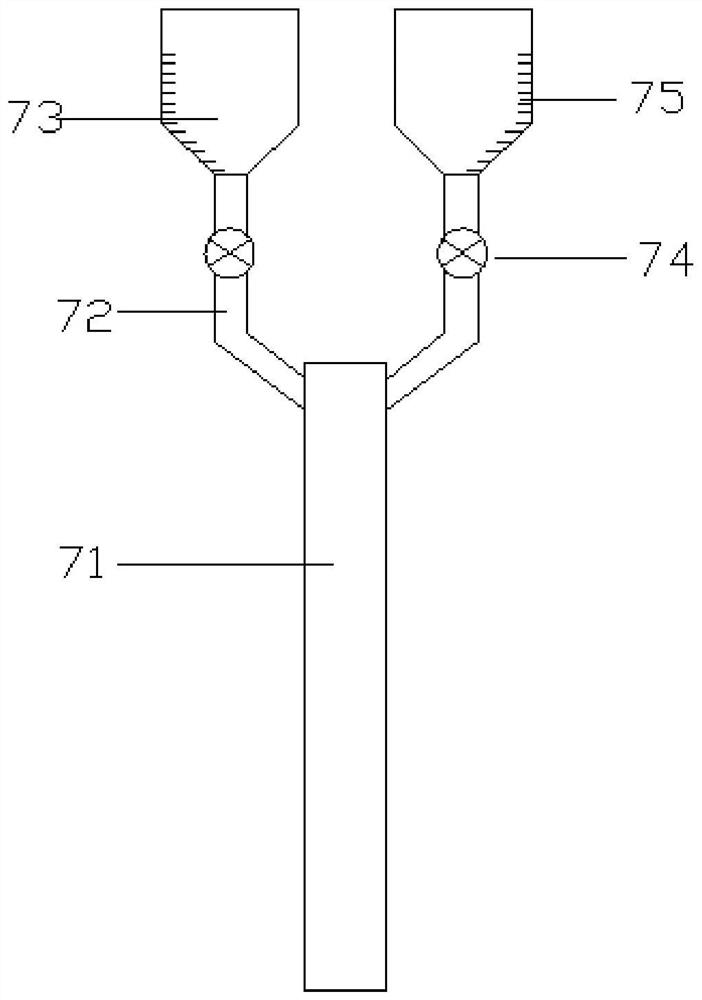

Mixing system favorable for improving cattle and sheep culture feed mixing degree

InactiveCN109107468ARealize the shipping processWell mixedFeeding-stuffTransportation and packagingHybrid systemThird platform

The invention provides a mixing system favorable for improving the cattle and sheep culture feed mixing degree. The mixing system comprises a frame body, wherein feeding hoppers are arranged at the upper side of the frame body; the two feeding hoppers are connected through a Y-shaped pipe; a first platform is arranged in the frame body; a first conveying belt is arranged on the first platform; a second platform is arranged at one side of the first platform; a second conveying belt is arranged on the second platform; a third platform is arranged at one side of the second platform; a third conveying belt is arranged on the third platform; a dispersion device is arranged on the first platform and the second platform and comprises a dispersion box; a transverse rod is arranged in the dispersion box; the transverse rod is provided with a rotating motor; a cover body is arranged outside the rotating motor; a tree-shaped body is arranged on the rotating body and comprises a rod body; a dispersion rod body is arranged on the rod body. Through the arrangement of platforms with different heights to be matched with the conveying belts, different ingredients can be added according to the sequence; the sufficient mixing on each ingredient of the compound feed is realized; according to the arrangement of the platforms with different heights, the uniformity of the feed can be further improvedby using the height difference between the platforms.

Owner:贵州省正安县林下生态养殖有限责任公司

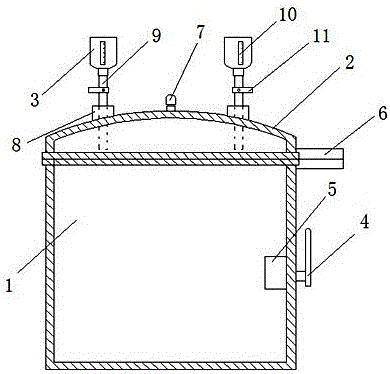

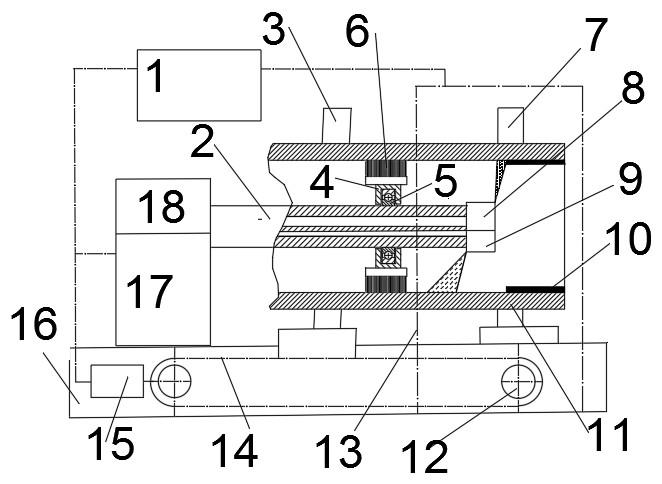

Novel efficient high-pressure reaction kettle

InactiveCN105879781ALearn about additionsControl joining speedPressure vessel componentsPressure/vacuum vesselsSpray nozzleEngineering

The invention provides a novel efficient high-pressure reaction kettle which comprises a kettle body, a sealing cover, a raw material cup and a thermometer. The novel efficient high-pressure reaction kettle is characterized in that the edge of the kettle body and the edge of the sealing cover are connected in a threaded mode and each provided with a handle, a temperature sensor is arranged on the inner wall of the kettle body and connected with the thermometer, the sealing cover is provided with a gas spraying nozzle and a sealing block, a feed pipe is arranged on the sealing block and provided with a valve, and the raw material cup is arranged at one end of the feed pipe and provided with a dividing ruler. The temperature sensor is arranged on the inner wall of the kettle body, so the temperature generated during raw material reaction can be conveniently reflected on the thermometer in time; the gas spraying nozzle is arranged on the sealing cover, so the dangerous situations generated when the pressure in the kettle body is large are avoided, structural design is reasonable, manufacturing cost is low, and work efficiency is improved.

Owner:彭超昀莉

Preparation method of 2-acrylamido-2-methylpropanesulfonic acid

InactiveCN112430198AControl joining speedLess impuritiesOrganic compound preparationSulfonic acid preparationOrganic synthesisAcrylonitrile

The invention relates to the technical field of organic synthesis preparation, in particular to a preparation method of 2-acrylamido-2-methylpropanesulfonic acid, which can improve the purity of the 2-acrylamido-2-methylpropanesulfonic acid finished product, reduce the impurity content, avoid the influence on the molecular weight in the subsequent polymer preparation process, and reduce influenceon the use effect of 2-acrylamido-2-methylpropanesulfonic acid; the method comprises the following steps: S1, preparing a sulfuric acid mixed solution; S2, performing cooling treatment; S3, firstly introducing acrylonitrile into a reaction kettle, then introducing a sulfuric acid mixed solution into the reaction kettle, and finally gradually introducing isobutene into the reaction kettle to carryout a mixed reaction, wherein a sulfuric acid mixed solution is firstly introduced, then acrylonitrile is introduced and isobutene is finally introduced, and continuously carrying out a stirring reaction for 1-2 hours after the addition of the materials is completed, wherein the reaction process needs to be carried out in a helium atmosphere; S4, filtering and separating; S5, preparing a solution;S6, carrying out recrystallization treatment; and S7, performing drying treatment.

Owner:潍坊奥瑞环保科技有限公司

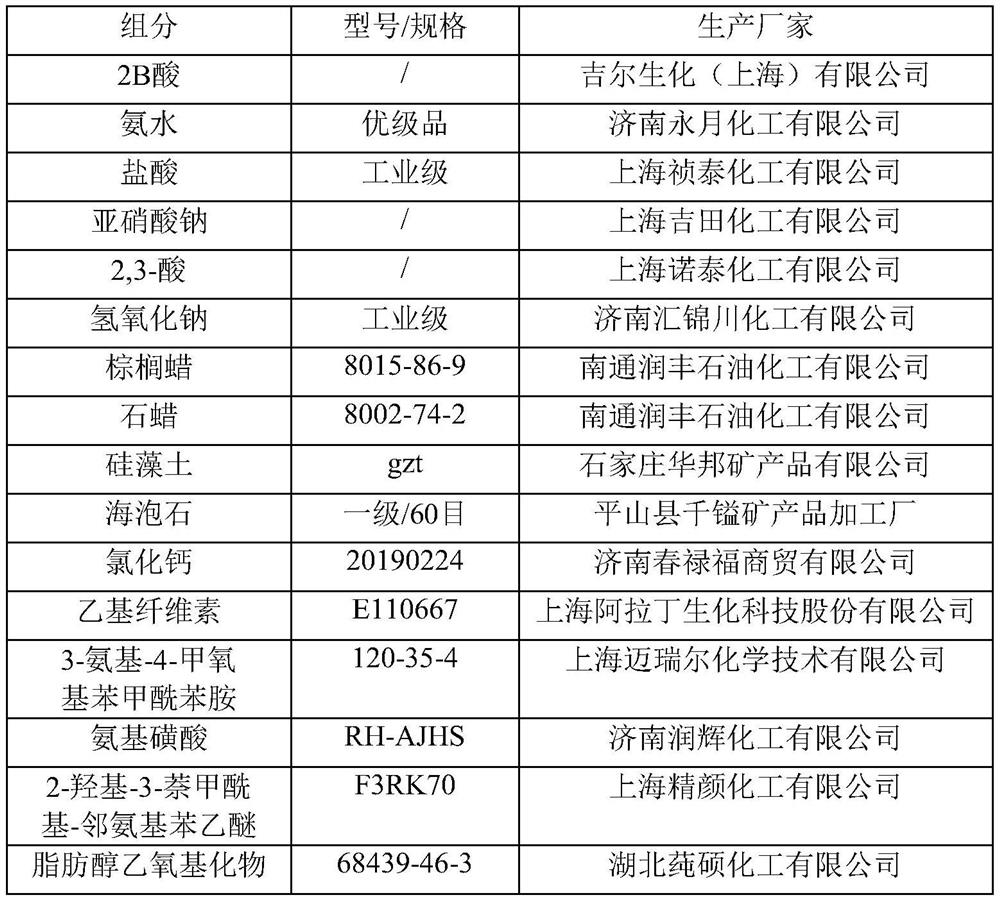

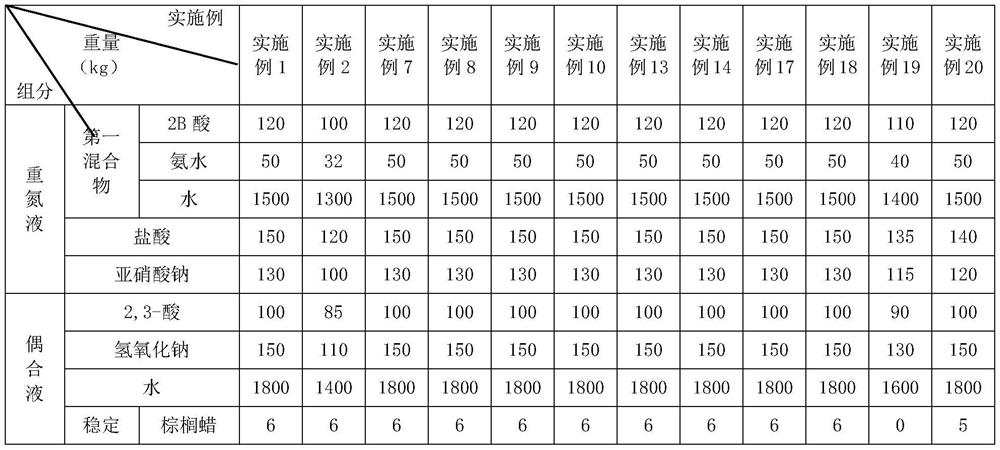

Preparation method of azo pigment

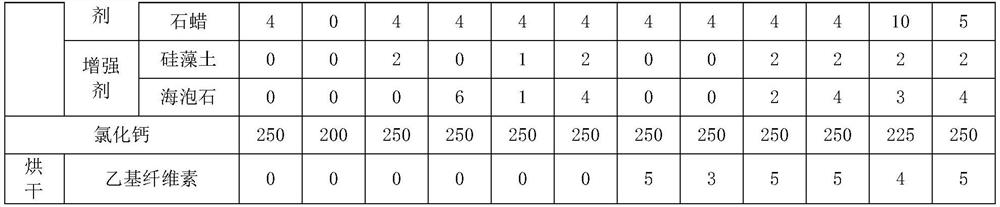

ActiveCN113462189AImprove conversion rateImprove thermal stabilityMonoazo dyesParaffin waxAcid dissolution

The invention relates to the technical field of pigment production, and particularly discloses a preparation method of an azo pigment, which comprises: mixing 100-120 parts by weight of 2B acid, 32-50 parts by weight of ammonia water with a weight percentage of 20-25%, and 1300-1500 parts by weight of water, adding 120-150 parts by weight of hydrochloric acid with a weight percentage of 30-40% after the 2B acid is dissolved, uniformly mixing, adding ice cubes to a temperature of 0-10 DEG C, then adding 100-130 parts by weight of a sodium nitrite aqueous solution with the weight percentage of 30-35% to obtain a diazonium solution; mixing 85-100 parts by weight of 2, 3-acid, 110-150 parts by weight of sodium hydroxide with the weight percentage of 20-30% and 1400-1800 parts by weight of water, adding 6-10 parts by weight of a stabilizer, and uniformly mixing to obtain a coupling solution; mixing the diazo liquid and the coupling liquid, controlling the pH value at the end point of the reaction to be 8-10, then adding 200-250 parts by weight of a calcium chloride aqueous solution, and then carrying out filter pressing, rinsing, drying, inspecting and packaging to obtain the azo pigment; wherein the stabilizer comprises at least one of palm wax and paraffin; and the azo pigment provided by the invention has the advantage of good thermal stability.

Owner:杭州映山花颜料化工有限公司

Method for preparing micronano silver particles in aqueous solution system

Owner:SHANDONG UNIV

Kipp's generator

InactiveCN103272532AControl joining speedAvoid wastingGas generation devicesBiochemical engineeringBottle

The invention belongs to the technical field of chemical experimental instruments, and particularly relates to a Kipp's generator. The Kipp's generator comprises a reaction vessel provided with an opening and a gas guide pipe communicated with the reaction vessel, wherein a rotary piston is arranged on the gas guide pipe; the Kipp's generator further comprises a separating funnel; the opening end of the reaction vessel is covered with a rubber stopper; the bottom end of the separating funnel penetrates through the rubber stopper and extends into the reaction vessel; a solid accommodating bottle is arranged in the reaction vessel, a plurality of through holes are formed in the bottom and the side part of the solid accommodating bottle, and the solid accommodating bottle is communicated with a feeding pipe; the top end of the feeding pipe penetrates through the rubber stopper and extends out of the reaction vessel; and the top end of the feeding pipe is covered with a rubber plug, the part, extending out of the reaction vessel, of the feeding pipe is enclosed, and a pressure meter is arranged at the part. The Kipp's generator is simple in structure, lower in preparation cost and capable of accurately observing conditions of pressure inside the reaction vessel, so that the pressure inside the reaction vessel can be well controlled, the reaction can be performed smoothly, and safety of an operator is guaranteed.

Owner:王璇

A kind of mixing process in the production process of waterless taphole clay

InactiveCN104139458BExtend the mixing timeControl joining speedClay mixing apparatusTime rangePolymer science

The invention discloses a stirring process for the water-free taphole clay production process. The stirring process has the advantages that efficiency is high, bonding agents can fully wet aggregates and powder, the uniformity is good, and the stability is high. The stirring process comprises the steps of (1) conducting dry-blending, wherein various kinds of aggregates and powder weighed according to a formula are placed into a mixer for stirring, the stirring speed of a rotor ranges from 72 r / m to 108 r / m, and the stirring time ranges from 60 s to 120 s, (2) adding the bonding agents, wherein the bonding agents weighed according to the formula are placed into the mixer, the adding speed of the bonding agents ranges from 1.2 Kg / s to 2.2 Kg / s, and the stirring speed of the rotor ranges from 72 r / m to 108 r / m, and (3) conducting wet-blending. The stirring process can be widely applied to the water-free taphole clay production field.

Owner:CHINA JINGYE ENG TECH CO LTD +2

Device and process for preparing graphene heat transfer enhanced organic silicon resin composite pipe

InactiveCN112024242AImprove corrosion resistanceSimple production processPretreated surfacesCoatingsElectric machineryGraphite

The invention discloses a device and a process for preparing a graphene heat transfer enhanced organic silicon resin composite pipe. An outer layer of the composite pipe is a metal pipe, and an innerlayer of the composite pipe is organic silicon resin with graphene added. According to the process principle, the metal pipe which rotates at a high speed and can move axially, a resin conveying pipeand a nozzle which are relatively static are arranged in the metal pipe through a bearing and a steel wire brush, the resin conveying pipe and the nozzle do not participate in rotation and axial movement of the metal pipe, organic silicon resin with graphene added is sprayed to the inner surface of the metal pipe out of the nozzle through a resin pump and a resin conveying pipe, the sprayed metalpipe gradually enters a heat curing device to be heated and primarily cured, a delay controller and a stroke controller are in linkage with a motor to stop rotation of the metal pipe after the resin loses liquidity, the metal pipe is enabled to enter other sections of a curing area, and curing is continued to form the composite pipe.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

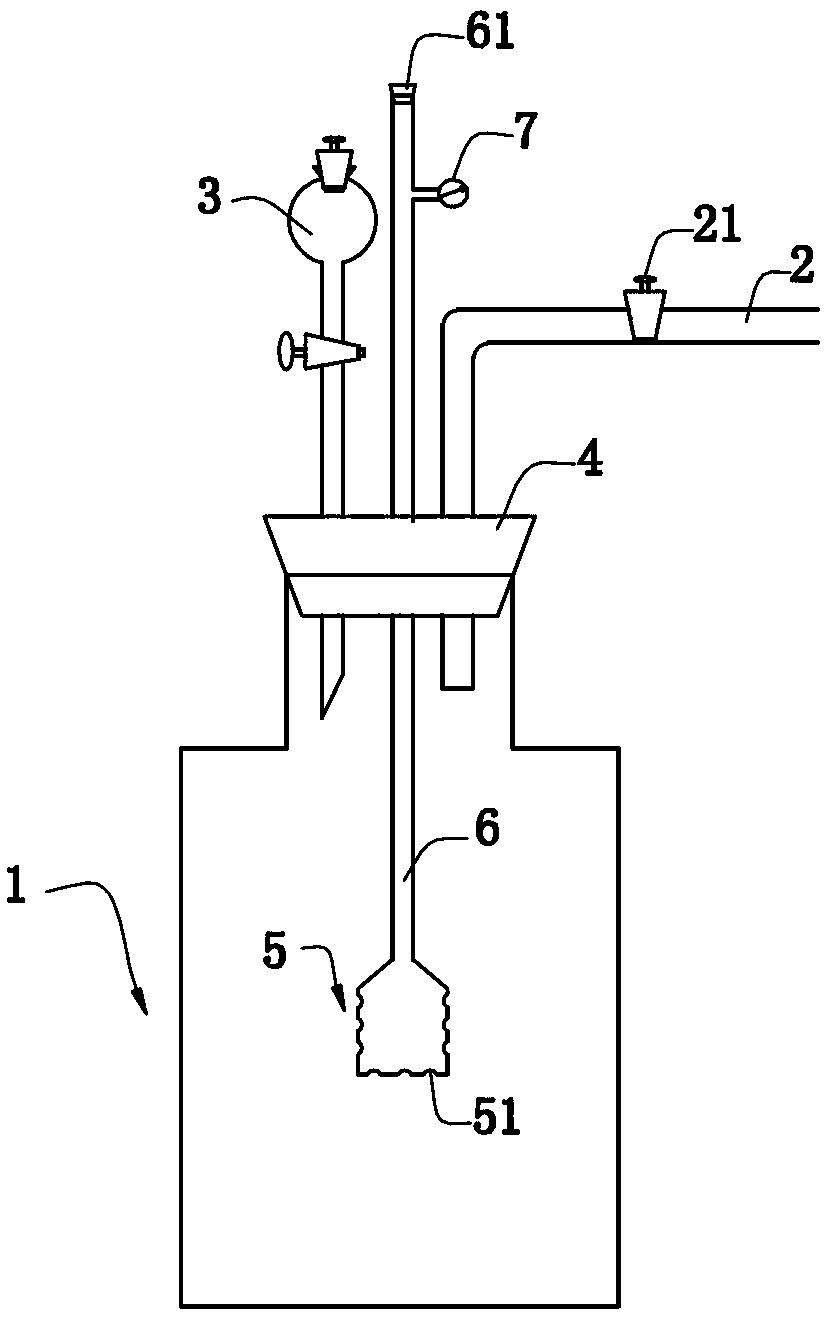

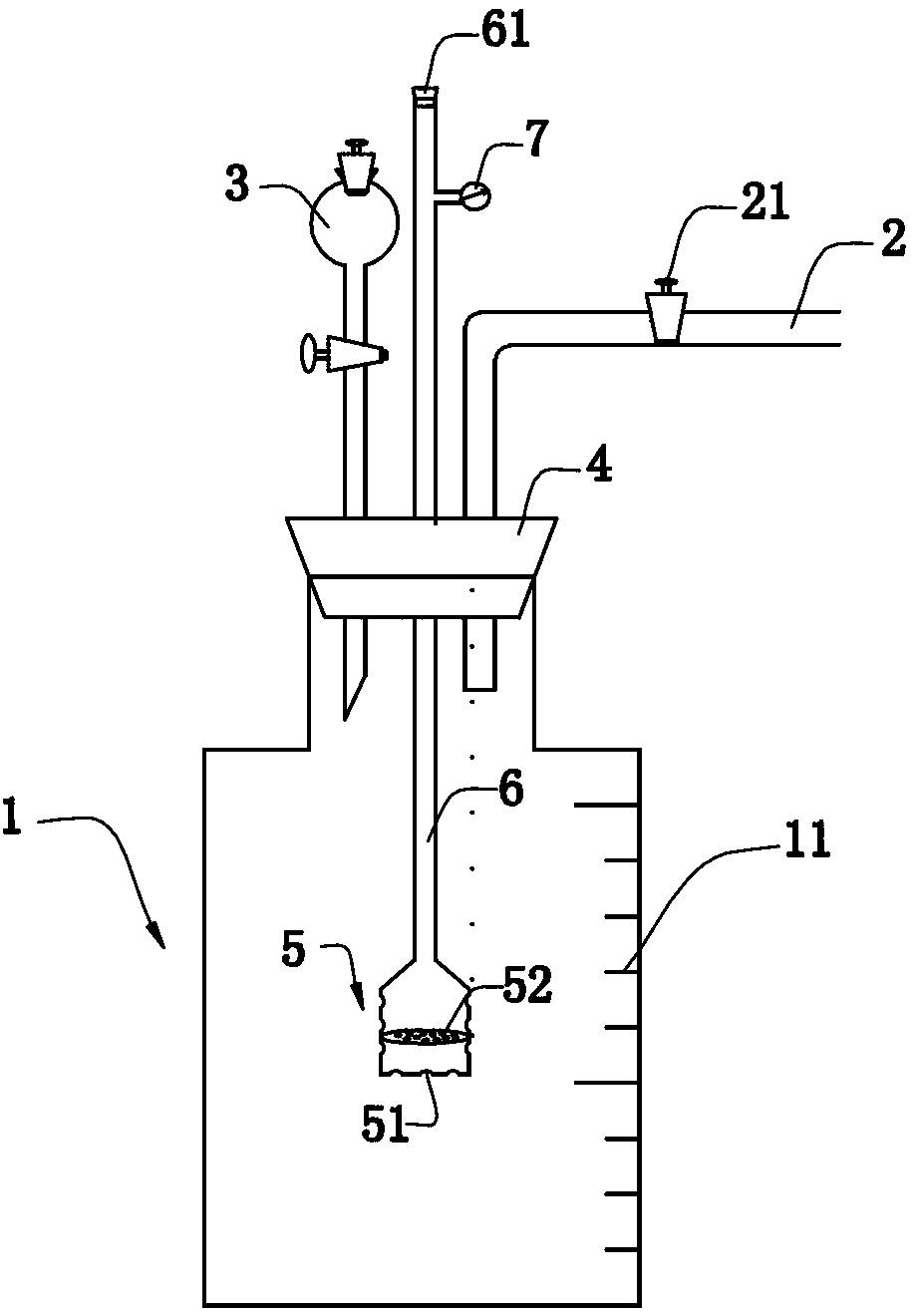

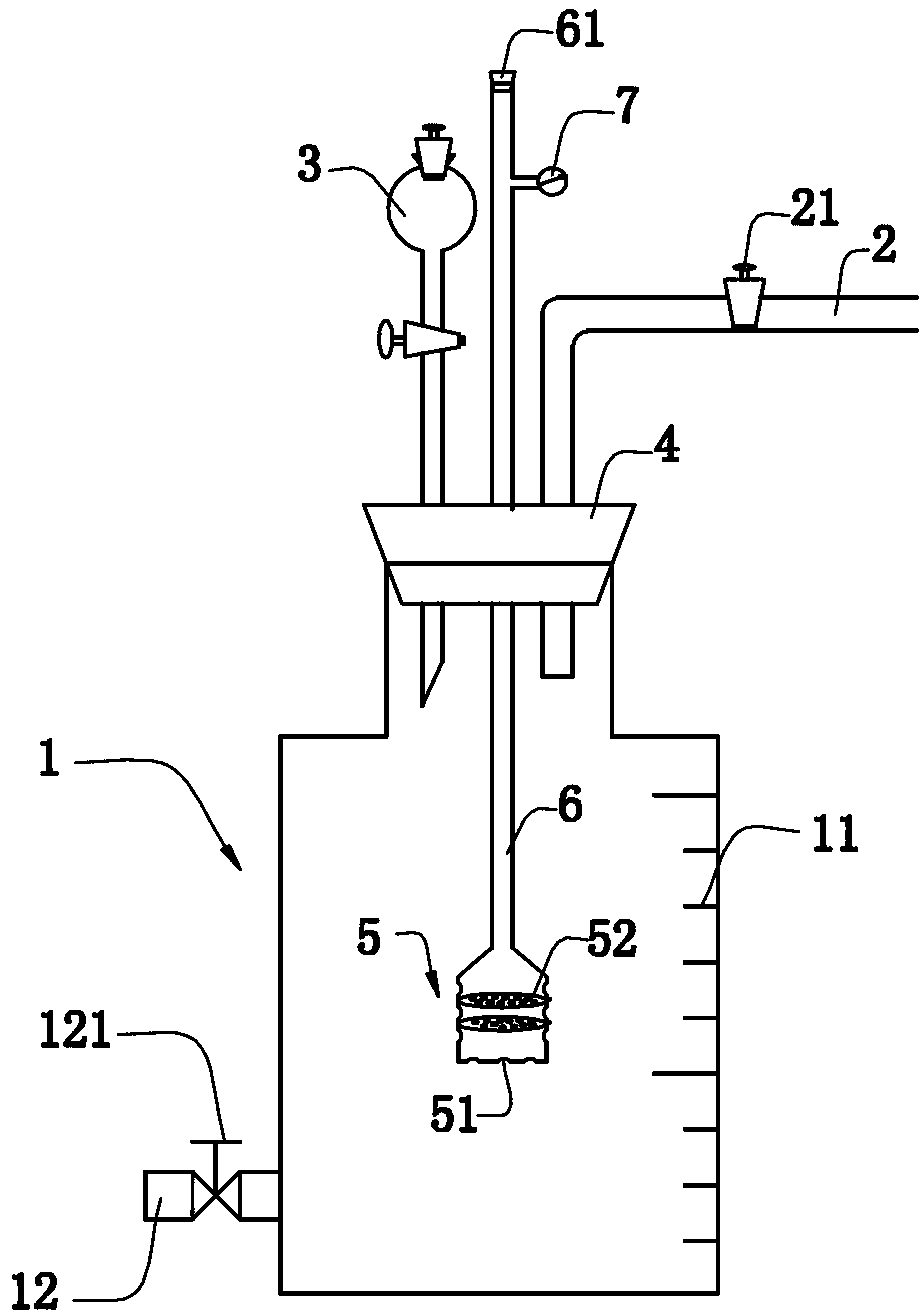

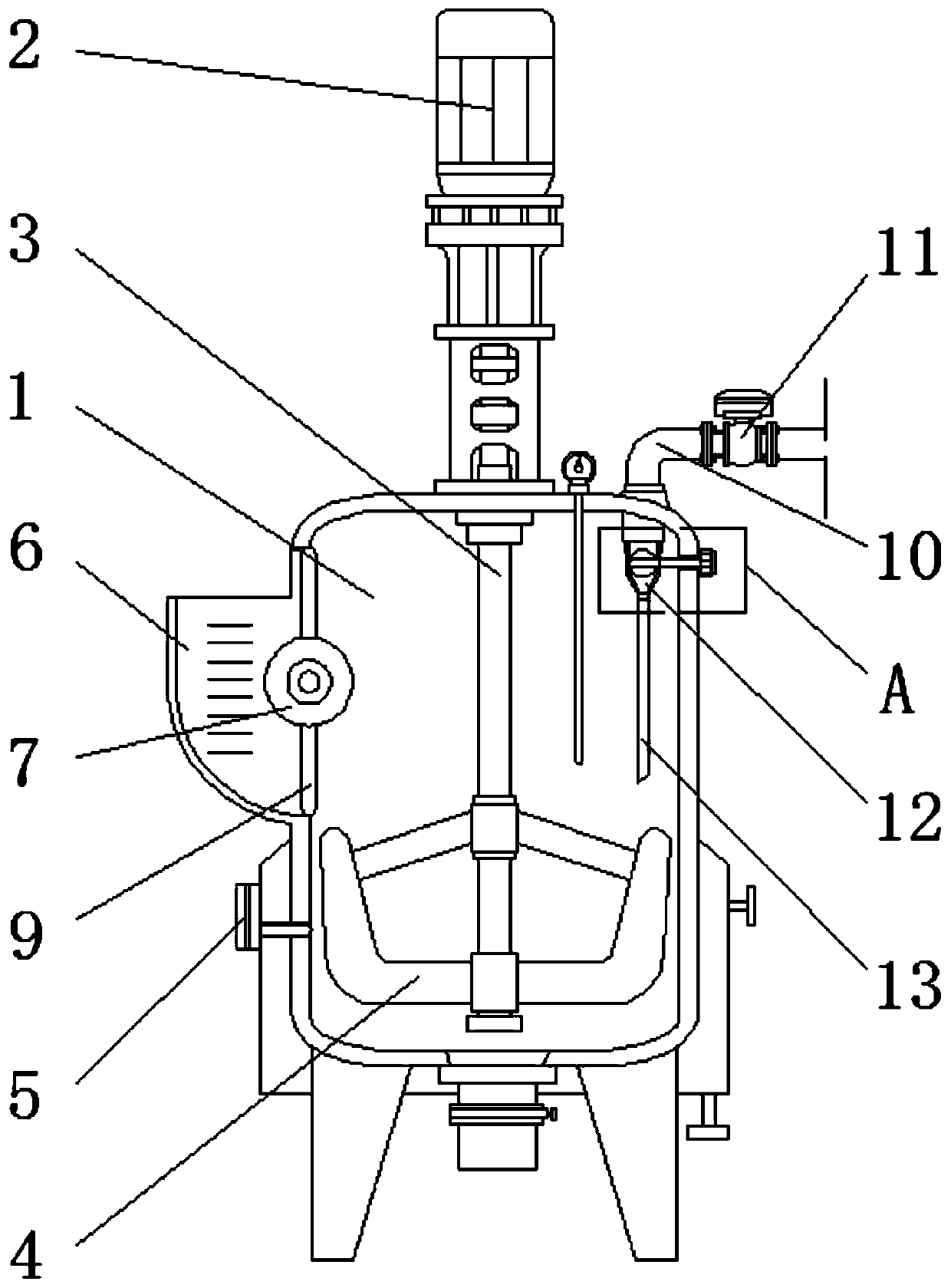

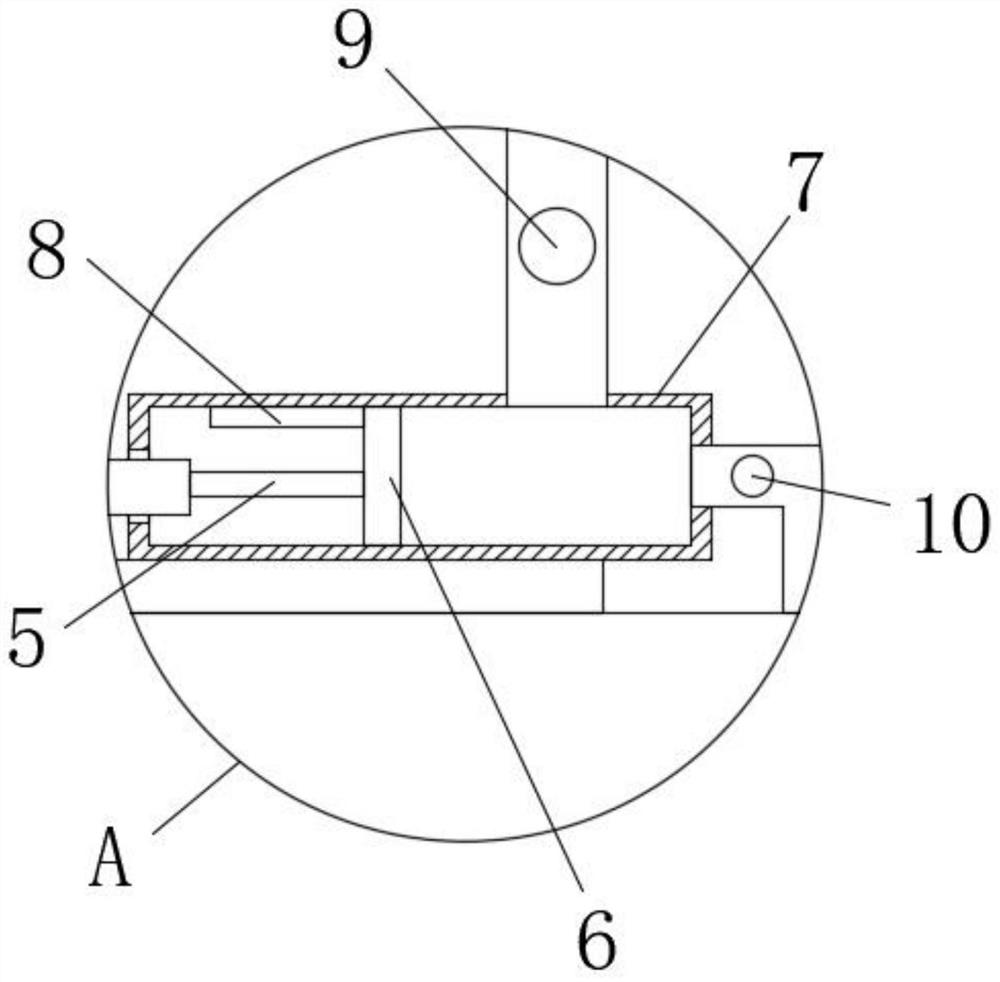

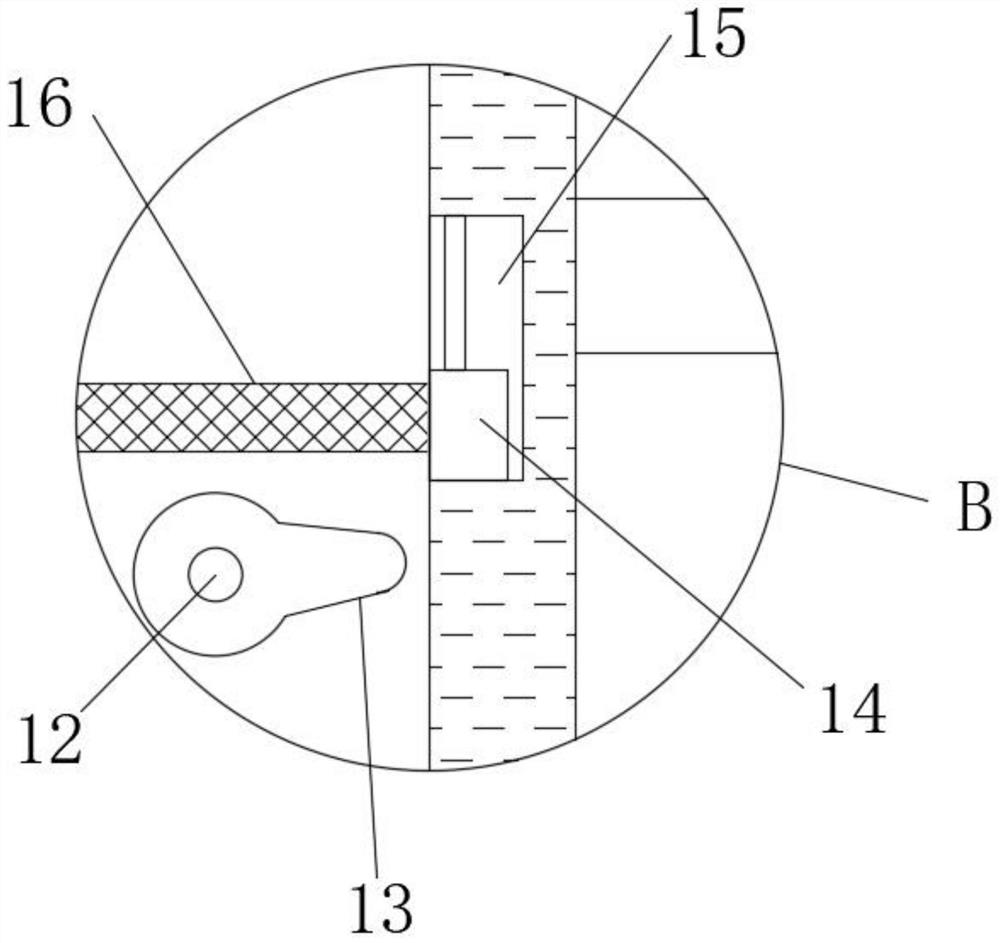

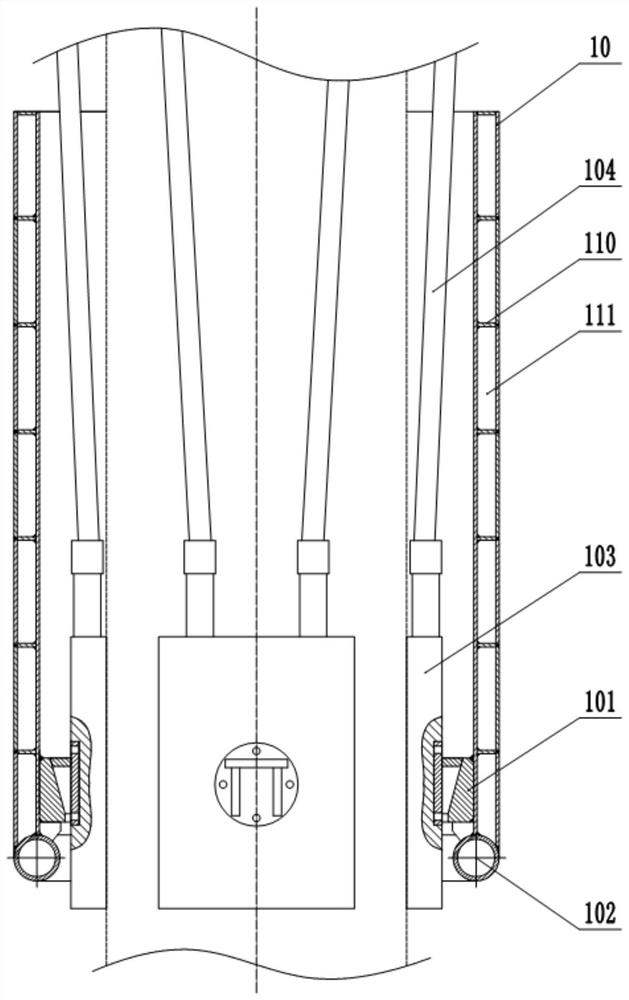

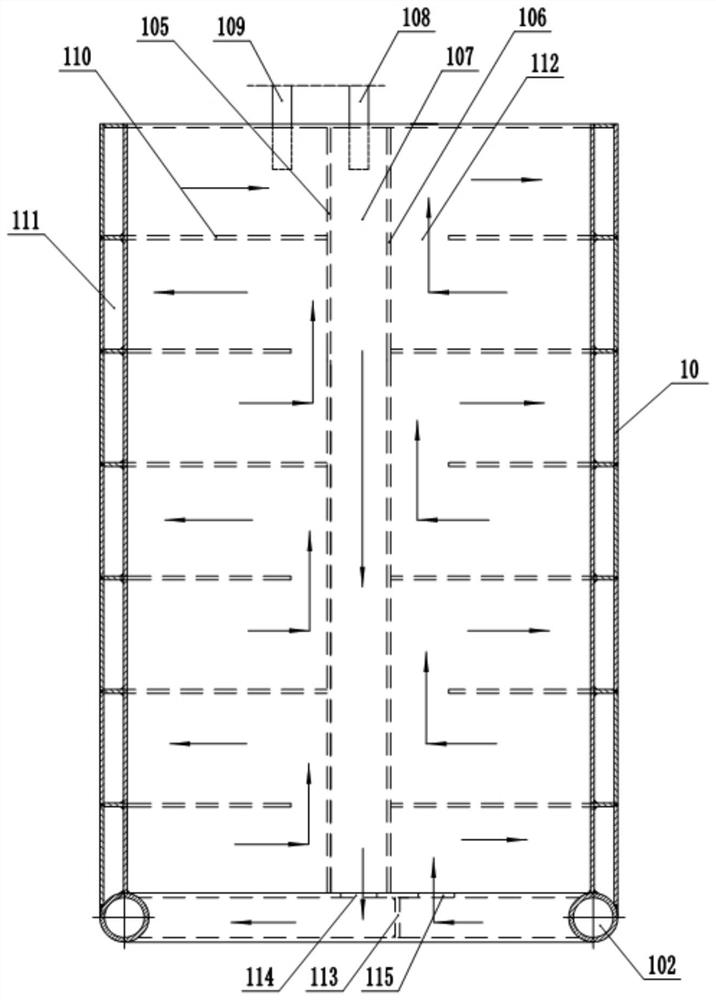

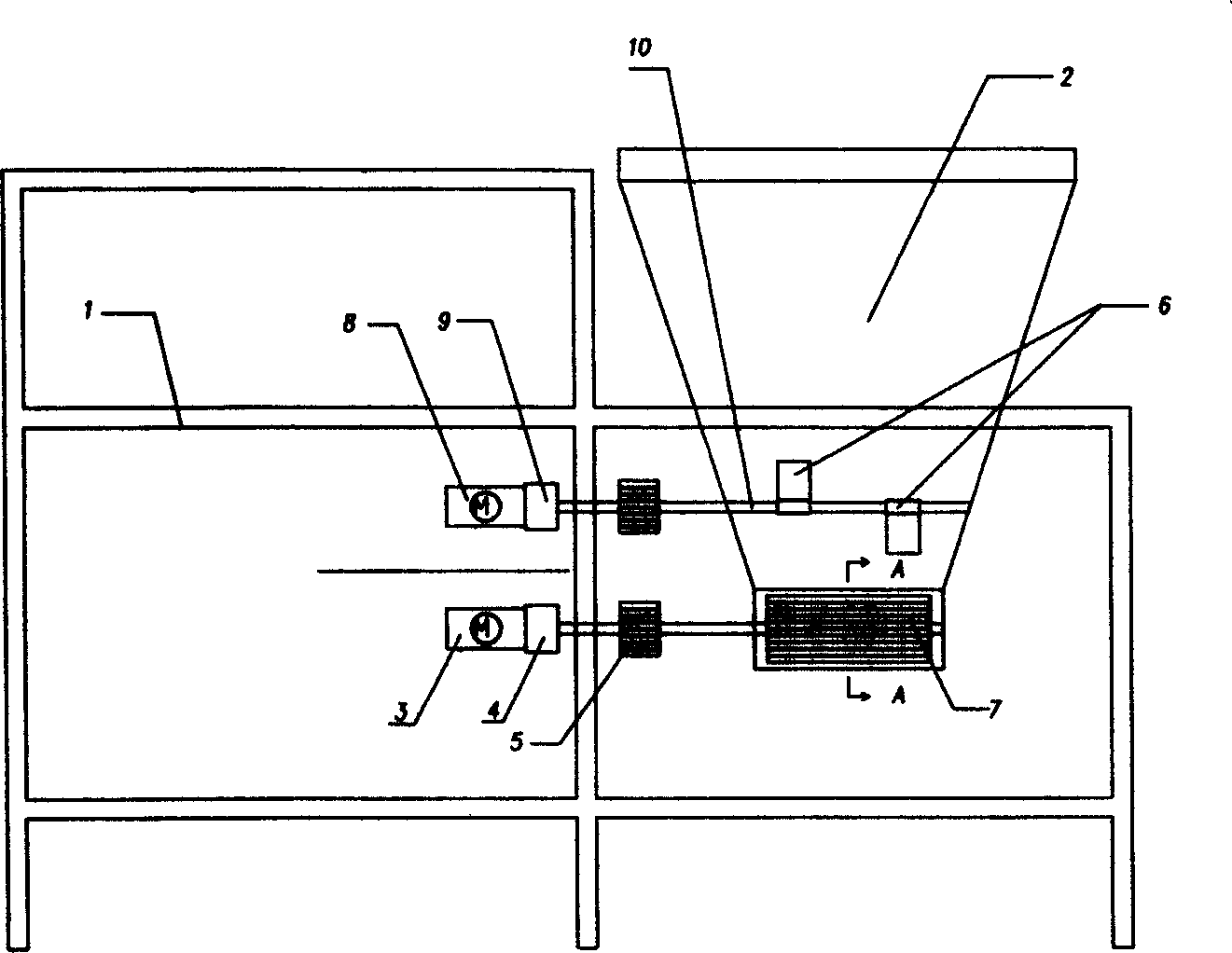

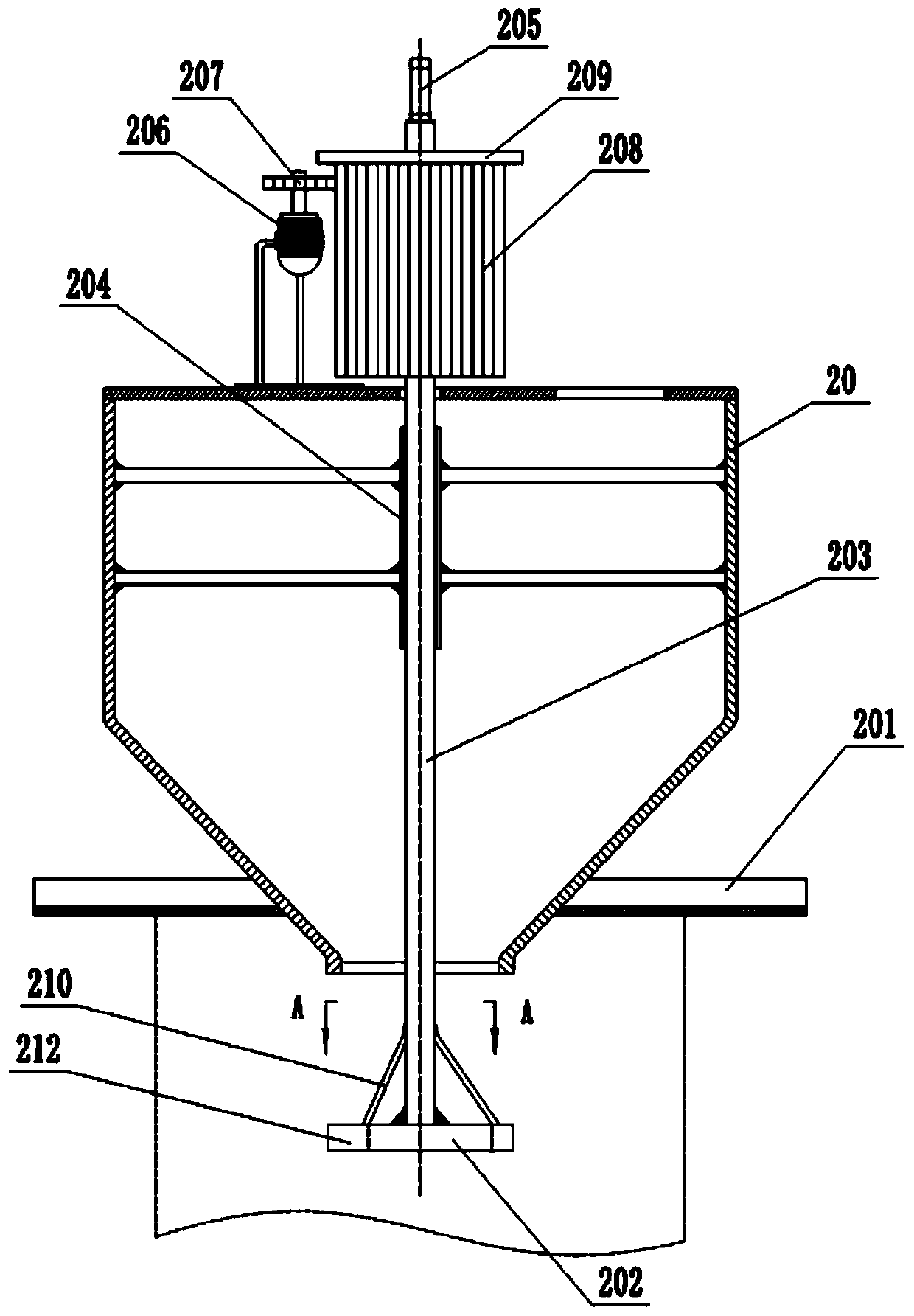

Catalyst dropwise adding system for alkaline phenolic resin synthesis

PendingCN111001357AAdd speed controlControl joining speedChemical/physical/physico-chemical stationary reactorsFeed devicesPtru catalystElectric machinery

The invention discloses a catalyst dropwise adding system for alkaline phenolic resin synthesis. The catalyst dropwise adding system comprises a reaction main body, a working motor, a pH value detector and an electric control valve, the working motor is mounted above the reaction main body; the PH value detector is arranged on the outer side of the lower part of the reaction main body; a feeding port is formed in the upper part of the left side of the reaction main body; and a rotary cylinder is arranged at the joint of the feeding port and the reaction main body, a catalyst pipeline is connected to the upper portion of the reaction main body, the electric control valve is connected to the periphery of the catalyst pipeline, a control knob is arranged outside the right side of the reactionmain body, and a speed limiting piece is arranged in a catalyst storage pipe. According to the catalyst dropwise adding system for alkaline phenolic resin synthesis, the PH value detector can effectively reflect the reaction process in the reaction main body, so that the adding speed of a catalyst is effectively controlled, and the volume of reaction raw materials entering the reaction main bodycan be controlled through the arrangement of the feeding port and a baffle.

Owner:ZHEJIANG RONGKAI TECH DEV

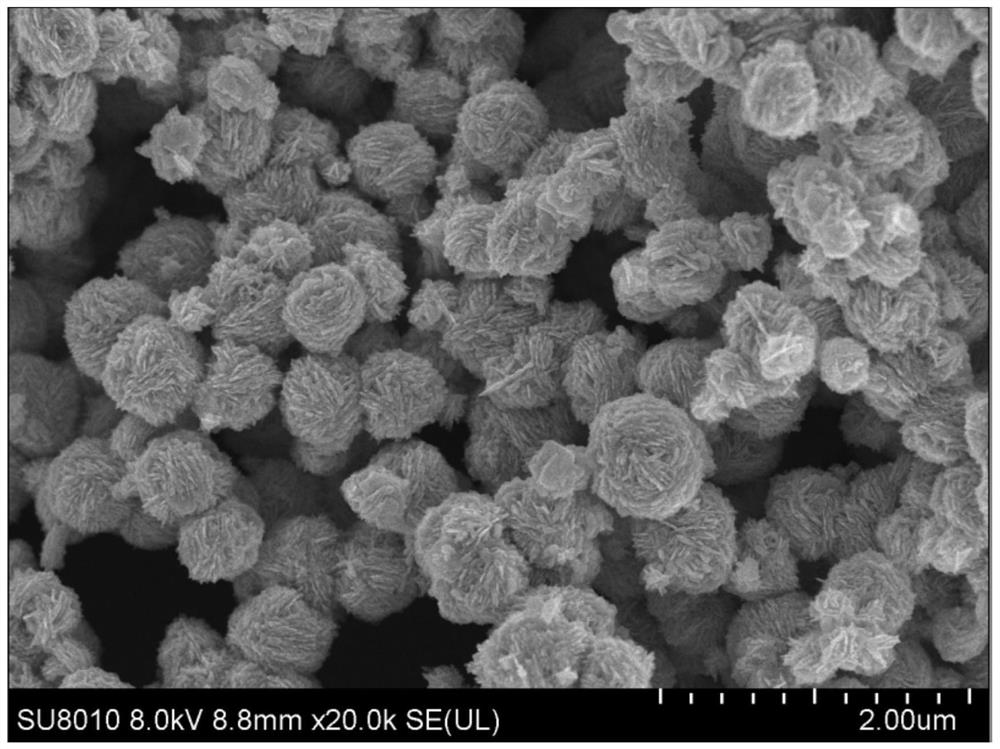

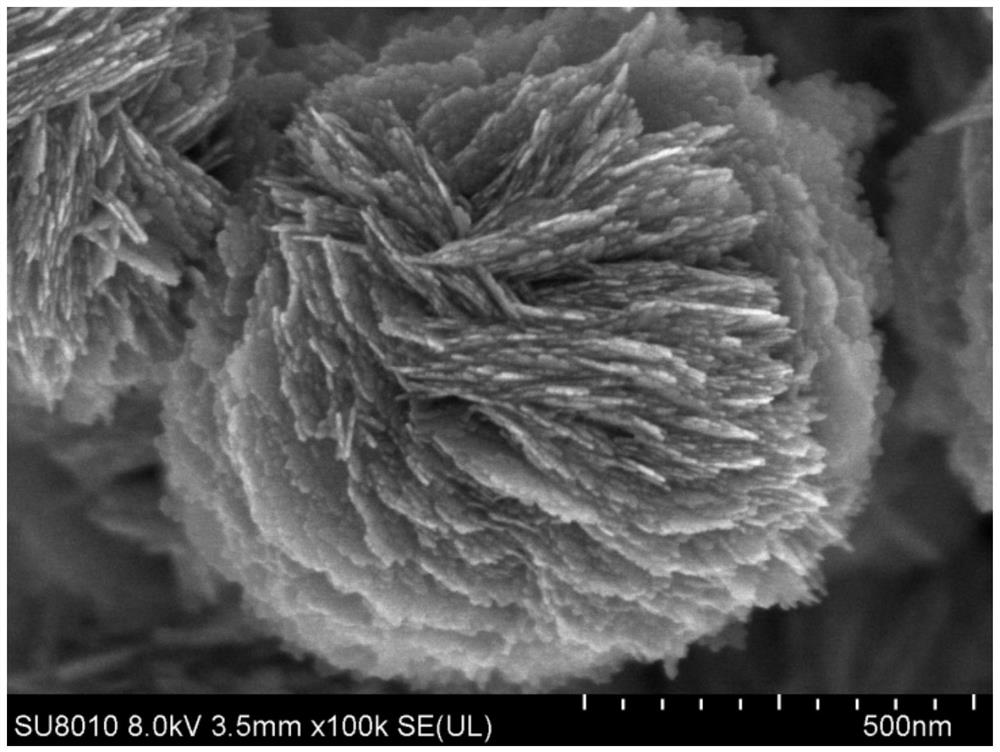

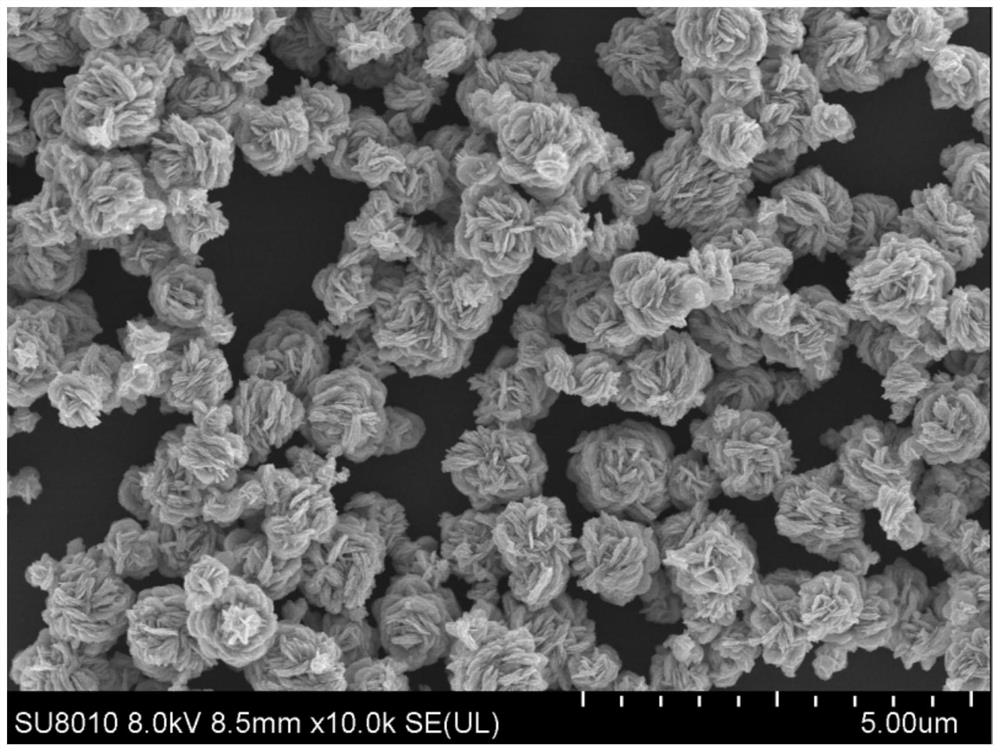

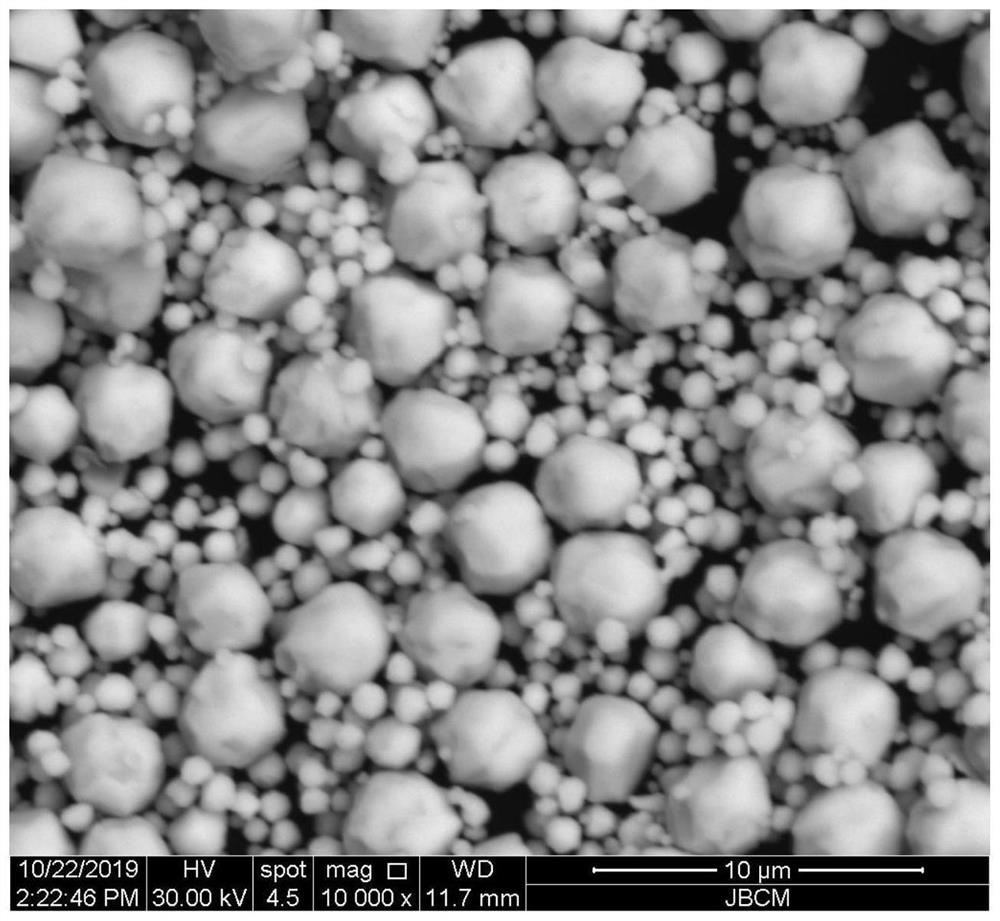

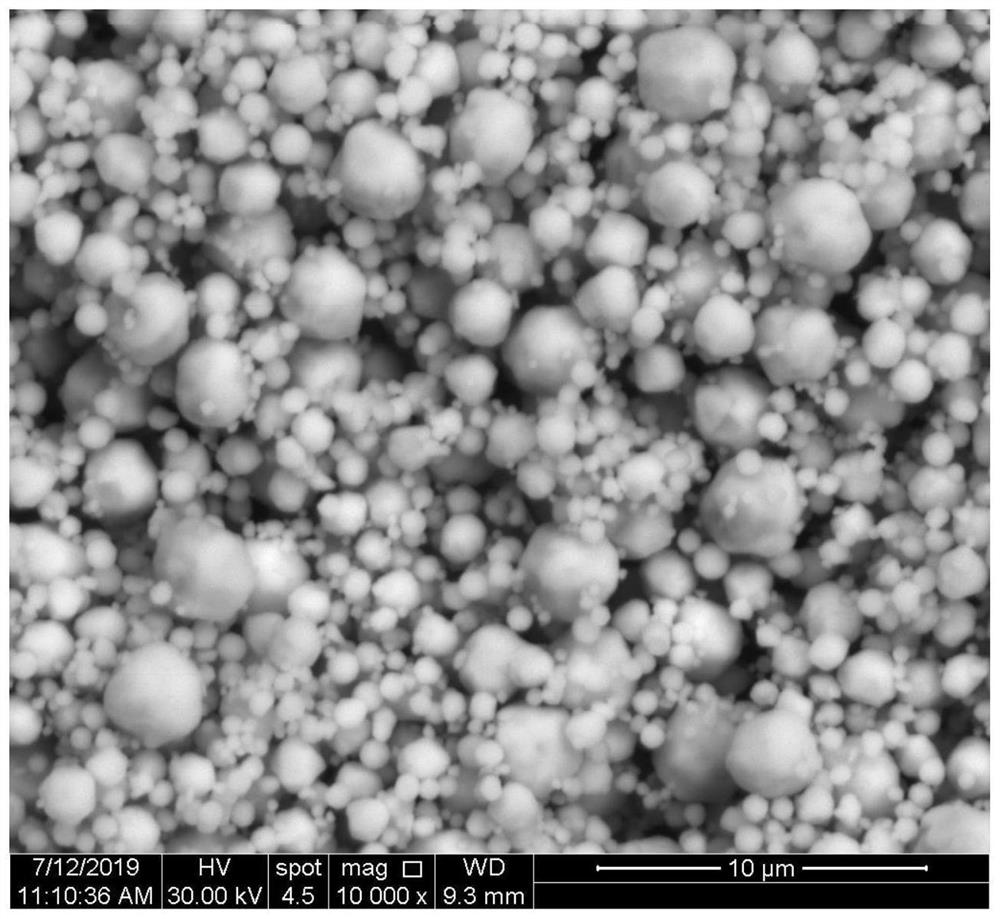

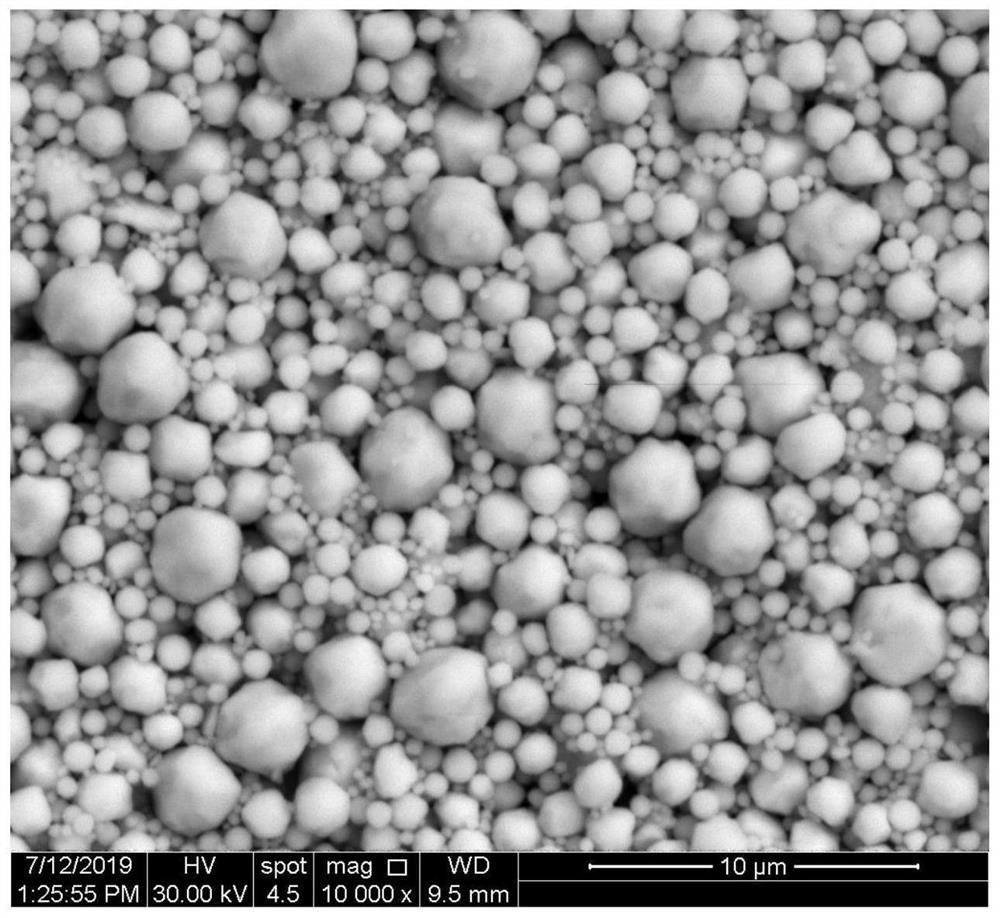

A kind of spherical silver powder with controllable particle size distribution and preparation method and application thereof

ActiveCN113658739BWide range of particle size distributionLarge specific surface areaMetal/alloy conductorsPhotovoltaic energy generationSilver pasteElectrical battery

Owner:山东建邦胶体材料有限公司

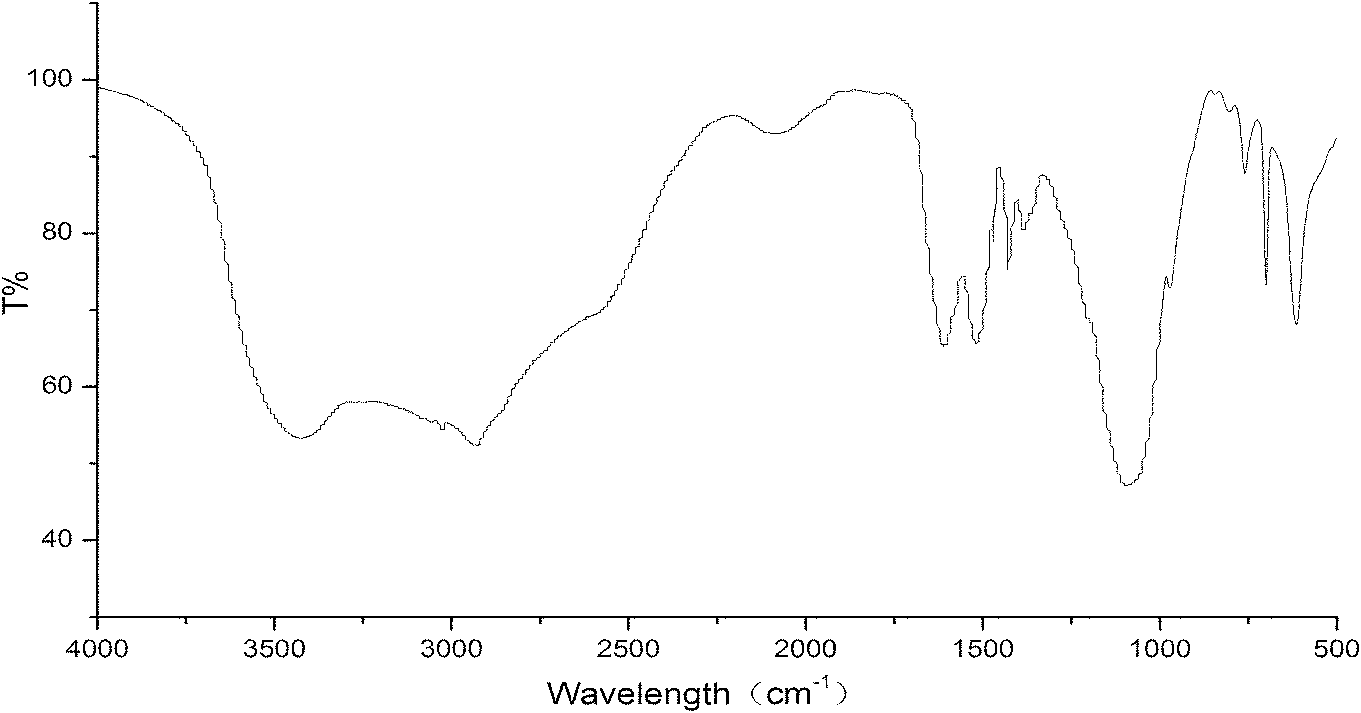

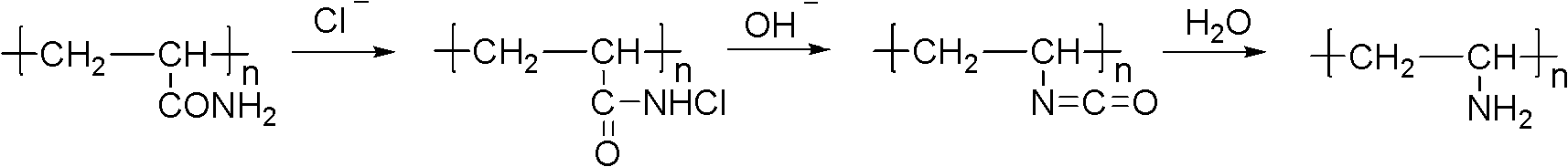

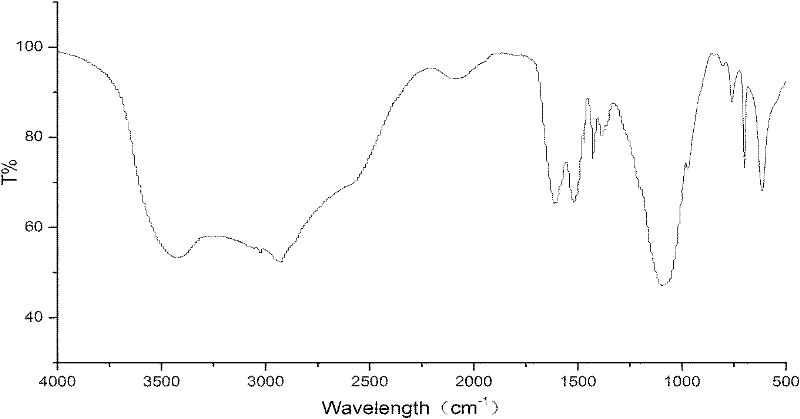

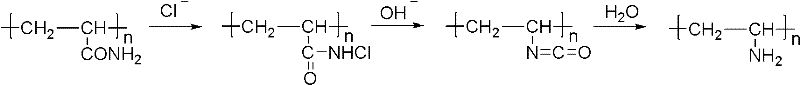

Preparation method of polyvinylamine

InactiveCN102127179AReduce surface tensionQuickly dissolve and disperseHydrolysisRearrangement reaction

The invention discloses a preparation method of polyvinylamine. In the method, degradation reactions including chlorination, a rearrangement reaction, separation and purification are undergone on polyacrylamide serving as a raw material. In the chlorination, a nonionic surfactant is added into a mixed solution of sodium hydroxide and sodium hypochlorite, polyacrylamide serving as the raw material is added in batches at the temperature between 10 DEG C below zero and 0 DEG C for reacting for 1 hour by stirring, and the dosage of the surfactant is 3-5 percent by weight of the weight of the raw material. In the rearrangement reaction, chlorination mixed liquor is slowly added into a sodium hydroxide solution with the concentration of 20-50 percent by mass at the temperature between 10 DEG C below zero and 0 DEG C at the speed between 15 millimeters per minute and 35 millimeters per minute for reacting for 5-8 hours by stirring, and at least 5 times of excessive alkali liquor is used according to the mass of polyvinylamine serving as the raw material. By adopting the nonionic surfactant in the method, the surface tension of the solution is lowered, stretching of a main chain is promoted, an amido group is fully shown and is fully chlorinated in time, and hydrolysis is reduced. Meanwhile, an alkali-containing mother liquor can be recovered and reused.

Owner:HEFEI UNIV OF TECH

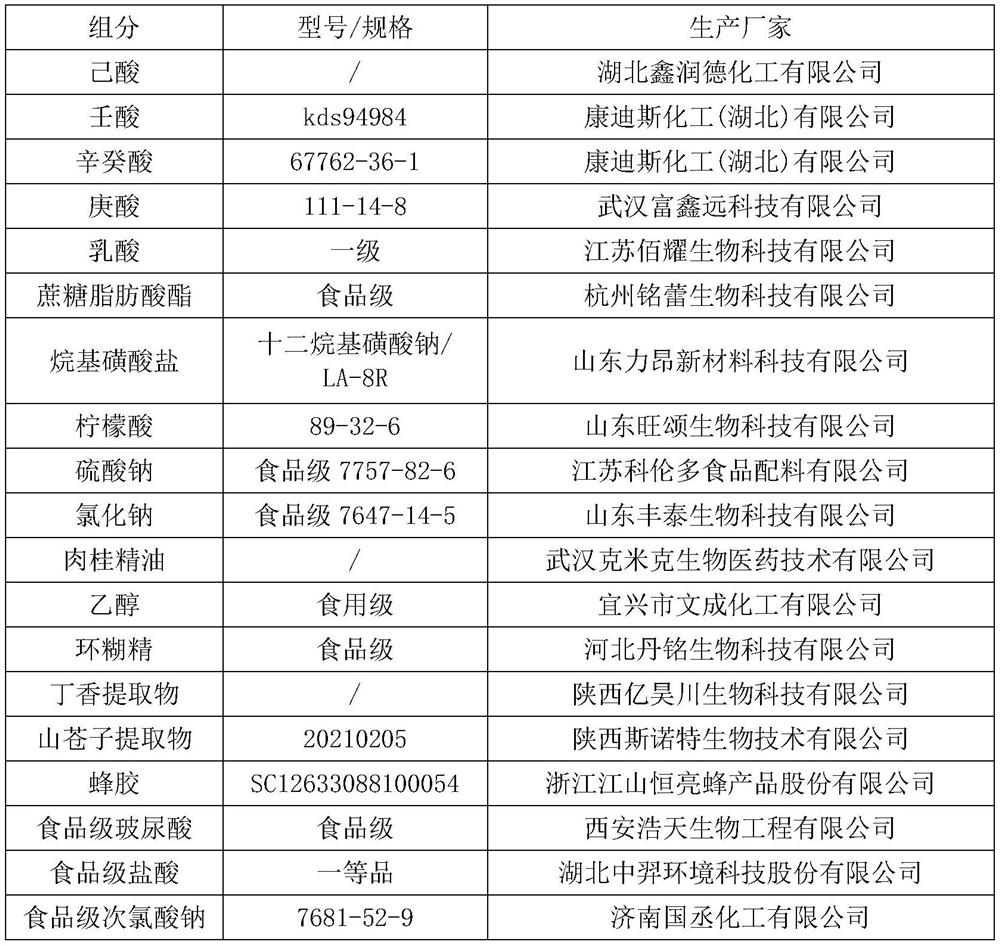

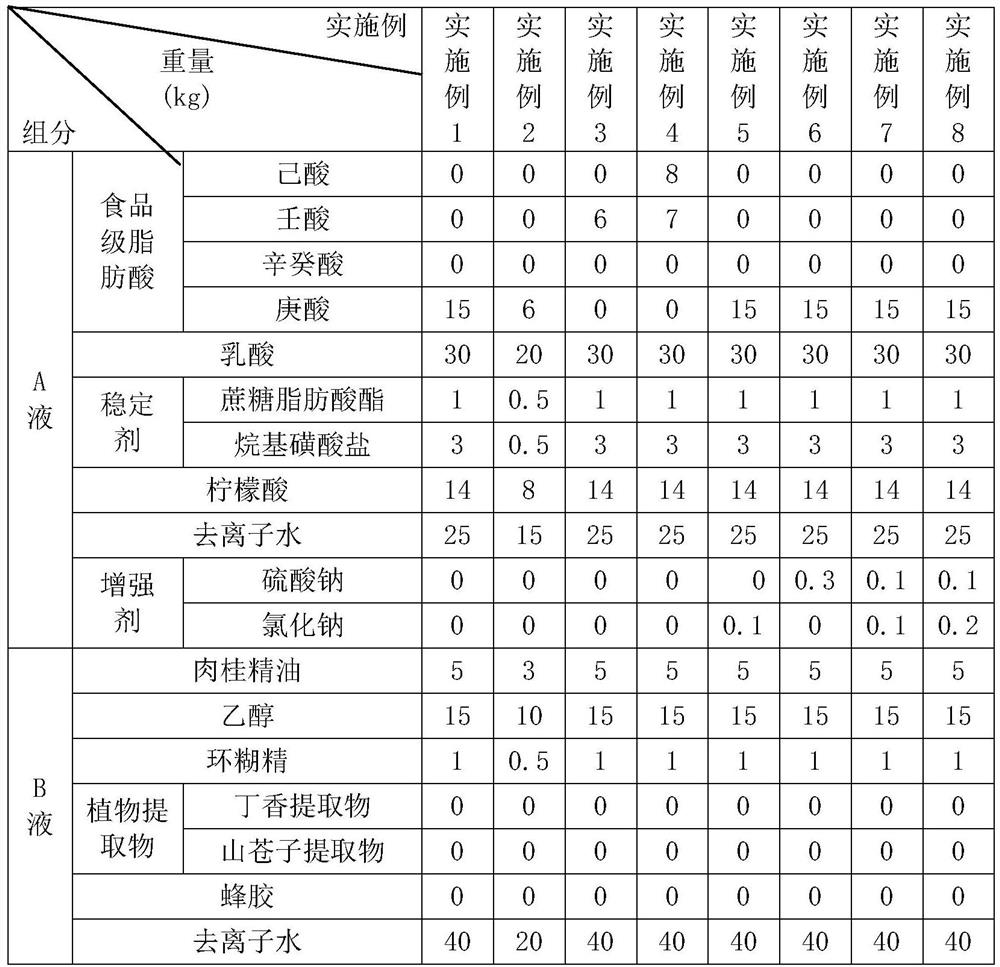

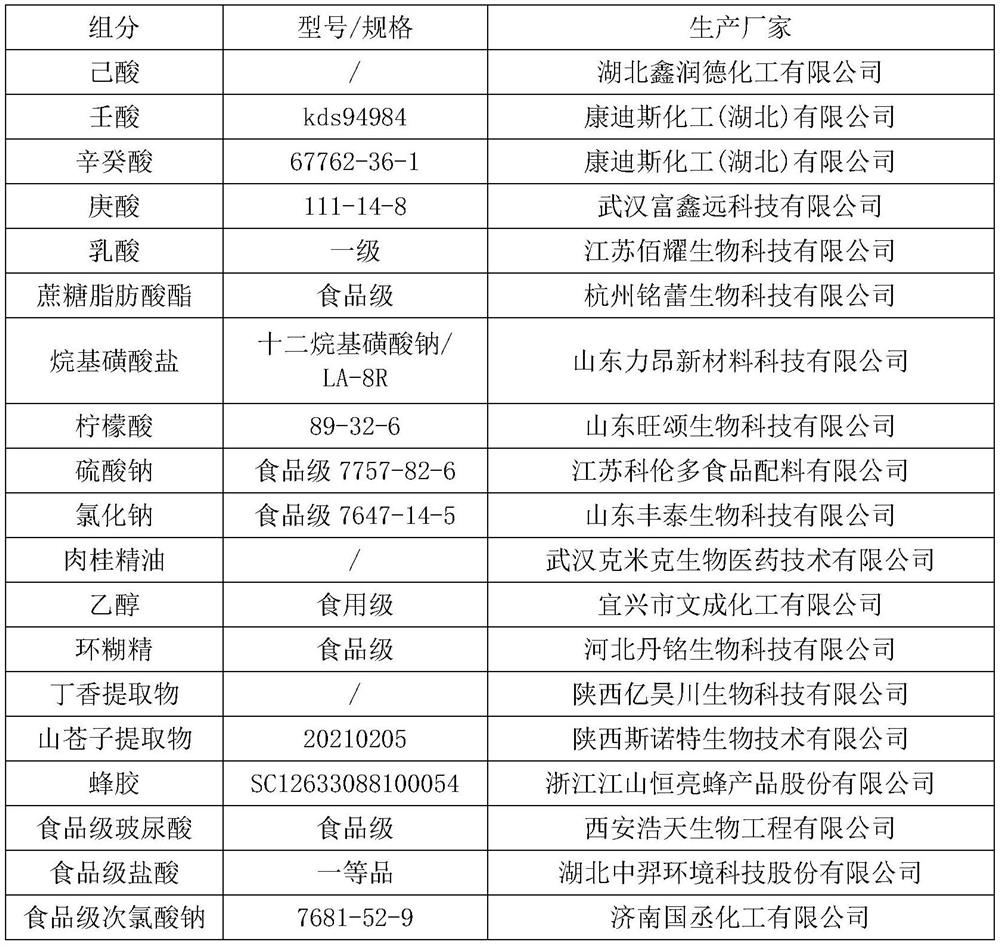

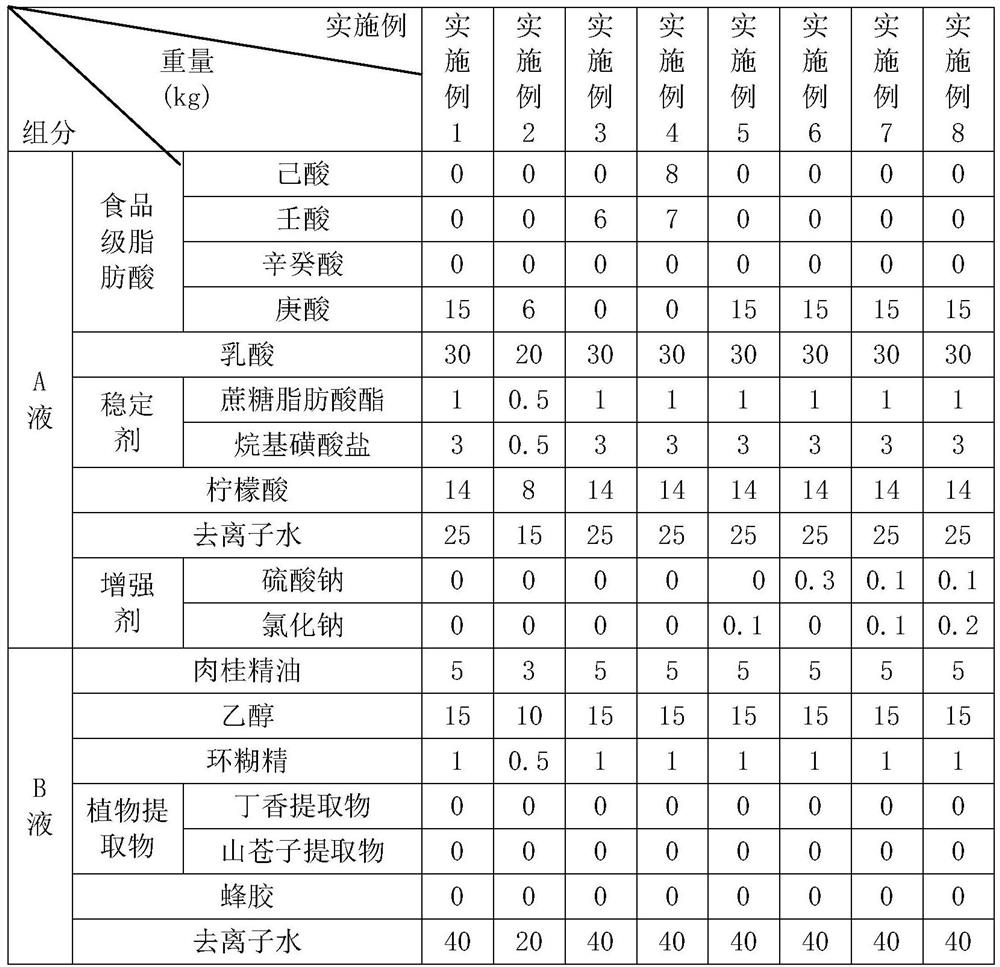

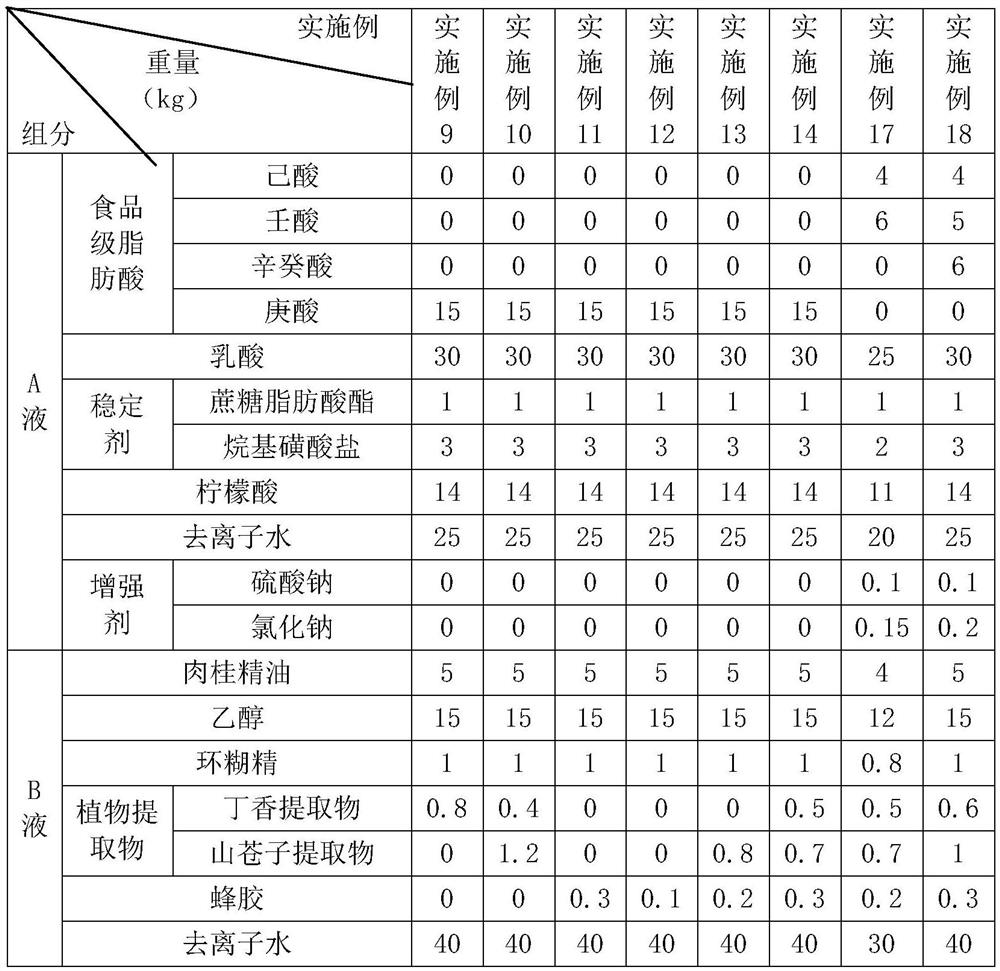

A kind of stable disinfectant and preparation method thereof

ActiveCN113475530BImprove stabilityPrevent affecting the disinfection effectBiocideFungicidesSucroseFood grade

Owner:杭州龙能科技有限公司

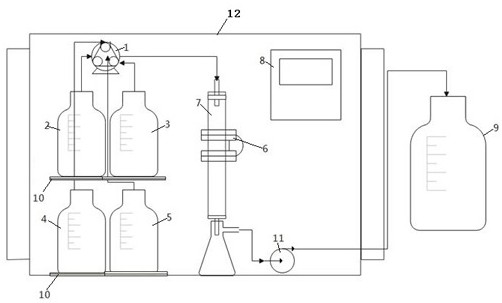

Full-automatic ion exchange resin pretreatment device for laboratory

PendingCN113083379APrecisely control the amount addedAccurate control of joining speedIon exchange regulation/controlIon-exchange column/bed processesPeristaltic pumpControl system

The invention relates to a full-automatic ion exchange resin pretreatment device for a laboratory. The full-automatic ion exchange resin pretreatment device comprises liquid bottles, a peristaltic pump, an exchange column, a control system, a waste liquid bottle and a waste liquid pump, wherein the peristaltic pump is a multi-channel peristaltic metering pump; a plurality of the liquid bottles are arranged for containing liquids with different concentrations or different types; the number of the liquid bottles is equal to the number of channels of the peristaltic pump; the channels of the peristaltic pump are connected with the liquid bottles through pipes, and the liquid bottles connected with the channels of the peristaltic pump are different; the control system is in communication connection with the peristaltic pump and is used for controlling multi-channel switching of the peristaltic pump so as to extract the liquids with different concentrations or different types; and one end of the exchange column is connected with the peristaltic pump, the other end of the exchange column is connected with the waste liquid pump, and the waste liquid pump is connected with the waste liquid bottle. According to the invention, program control is used, different flow speeds and flows can be set for liquid, the purpose of optimizing experiment steps is achieved, and a new experiment scheme is provided.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Preparation method of polyvinylamine

InactiveCN102127179BReduce surface tensionQuickly dissolve and disperseHydrolysisRearrangement reaction

The invention discloses a preparation method of polyvinylamine. In the method, degradation reactions including chlorination, a rearrangement reaction, separation and purification are undergone on polyacrylamide serving as a raw material. In the chlorination, a nonionic surfactant is added into a mixed solution of sodium hydroxide and sodium hypochlorite, polyacrylamide serving as the raw materialis added in batches at the temperature between 10 DEG C below zero and 0 DEG C for reacting for 1 hour by stirring, and the dosage of the surfactant is 3-5 percent by weight of the weight of the raw material. In the rearrangement reaction, chlorination mixed liquor is slowly added into a sodium hydroxide solution with the concentration of 20-50 percent by mass at the temperature between 10 DEG C below zero and 0 DEG C at the speed between 15 millimeters per minute and 35 millimeters per minute for reacting for 5-8 hours by stirring, and at least 5 times of excessive alkali liquor is used according to the mass of polyvinylamine serving as the raw material. By adopting the nonionic surfactant in the method, the surface tension of the solution is lowered, stretching of a main chain is promoted, an amido group is fully shown and is fully chlorinated in time, and hydrolysis is reduced. Meanwhile, an alkali-containing mother liquor can be recovered and reused.

Owner:HEFEI UNIV OF TECH

Stable disinfectant and preparation method thereof

ActiveCN113475530AImprove stabilityPrevent affecting the disinfection effectBiocideFungicidesSucroseCyclodextrin

The invention relates to the technical field of disinfection products, and particularly discloses a stable disinfectant and a preparation method thereof. The stable disinfectant is formed by mixing a solution A and a solution B. The stable disinfectant comprises, by weight, the solution A: 6-15 parts of food-grade fatty acid; 20-30 parts of lactic acid; 1-4 parts of a stabilizer; 8-14 parts of citric acid; 15-25 parts of deionized water; wherein the stabilizer is composed of sucrose fatty acid ester and alkyl sulfonate, and the weight ratio of sucrose fatty acid ester to alkyl sulfonate is 1: (1-3); and solution B: 3-5 parts of cinnamon essential oil; 10-15 parts of ethanol; 0.5-1 part of cyclodextrin; and 20-40 parts of deionized water; the preparation method comprises the following steps: uniformly mixing the food-grade fatty acid, the lactic acid, the citric acid and the deionized water, adding the stabilizer, and uniformly mixing to obtain the solution A; uniformly mixing ethanol and cinnamon essential oil, adding cyclodextrin and deionized water, and uniformly mixing to obtain the solution B; uniformly mixing the solution A and the solution B to obtain the stable disinfectant; and the stable disinfectant provided by the invention has the advantage of good stability.

Owner:杭州龙能科技有限公司

Hollow brick raw material stirring device

InactiveCN112720838AControl joining speedImprove the mixing effectMixing operation control apparatusClay mixing apparatusBrickElectric machine

The invention discloses a hollow brick raw material stirring device. The hollow brick raw material stirring device comprises a base, wherein the top of the base is fixedly connected with a stirring box; the outer side wall of the stirring box is fixedly connected with a first motor; the output end of the first motor is fixedly connected with a stirring shaft through a shaft coupler; the outer side of the stirring shaft is fixedly connected with a plurality of stirring rods; the top of the stirring box is fixedly connected with an electric cylinder; the output end of the electric cylinder is fixedly connected with a push rod; the other end of the push rod is fixedly connected with a piston; the outer side of the piston is in sliding sealing connection with a piston pipe; the side edge of the piston is fixedly connected with a water stopping plate; and the top of the piston pipe is fixedly connected with a water inlet pipe. The invention relates to the technical field of hollow brick production devices; the hollow brick raw material stirring device is simple to operate and convenient to use; and a feeding pipe is arranged and a material shaking mechanism is arranged in the feeding pipe, so that the adding speed of raw materials is controlled and large-block raw materials can also be filtered and isolated, and furthermore, the subsequent stirring effect is improved.

Owner:临泉县睿鑫建材股份有限公司

Brown corundum self-baking electrode for smelting brown corundum in a dumping furnace and its production process

The invention relates to the technical field of electric furnace metallurgy, and specifically discloses a brown corundum self-baking electrode for smelting brown corundum in a dumping furnace. It is fixed in the fixed sleeve, so that the copper tile in the fixed sleeve hugs the electrode cylinder tightly, and the electrode cylinder is fixed on the load-bearing steel platform through the holding system; the electrode paste feeding mechanism is used to add electrode paste to the electrode cylinder for roasting, and the height of the electrode paste column Controlled at 300-500mm; when the electrode paste in the electrode cylinder is roasted, cooling water is passed into the fixed sleeve to form a diameter of 690-710mm and a bulk density of 1.3-1.5g / cm 3 self-baking electrodes. The self-baking electrode that does not suspend or lose lumps is prepared by adopting the technical scheme in the present invention, which is suitable for smelting brown corundum and is worthy of vigorous promotion.

Owner:重庆市赛特刚玉有限公司

Method for producing barium carbonate with barium hydroxide production wastewater

ActiveCN103663533AControl joining speedControl settling timeCalcium/strontium/barium carbonatesSodium bicarbonateFiltration

The invention relates to the field of industrial wastewater recycling, in particular to a method for producing barium carbonate with barium hydroxide production wastewater. The method comprises the following steps of: pumping the wastewater generated during barium hydroxide production into a stirring kettle, adding 98% sodium bicarbonate during stirring, after wastewater clarification, stopping stirring, settling for 30min, injecting into a press filter for press filtration at the pressure of 8-10 atmospheres, after the press filtration, cleaning dregs of the press filter, and obtaining barium carbonate. The method has the benefits that: according to the method, an appropriate amount of sodium bicarbonate is added, and the adding velocity and settling time are controlled, so that the final purity of barium carbonate in a technology can reach above 90%, and the recovery rate of barium ions in the wastewater reaches above 95%.

Owner:滨州坤宝化工有限责任公司

Stirring device for white spirit distiller's yeast manufacturing process

PendingCN114272845AEasy to mix and handleDosage controlRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses a stirring device for a white spirit distiller's yeast manufacturing process. The detachable cover body is arranged at an opening in the top end of the stirring barrel body; the bottom plate is arranged at the bottom of the inner side of the stirring barrel body and is obliquely arranged; the discharging structure is arranged on the stirring barrel body and is close to the downwards inclined end of the bottom plate; one end of the stirring structure is arranged on the cover body, and the other end of the stirring structure penetrates through the cover body and is arranged in the stirring barrel body; the raw material inlet is formed in the cover body and penetrates through the cover body, the auxiliary material feeding structure is arranged on the cover body and penetrates through the cover body, the controller is arranged on the cover body and is electrically connected with the auxiliary material feeding structure, and connecting lugs are arranged on the two sides of the upper end of the cover body; according to the present invention, the structure has characteristics of convenient operation and strong practicality, can well mix the raw material, the bacterial koji liquid and the treatment liquid, and can effectively control the using amount and the adding speed of the bacterial koji liquid and the treatment liquid so as to ensure the mixing uniformity and the mixing quality.

Owner:湖南锦江泉酒业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for preparing 3-(2-chloroethyl)-2-methyl-4H- naphthyridine[1,2-a]pyrimidine-4-ketone Method for preparing 3-(2-chloroethyl)-2-methyl-4H- naphthyridine[1,2-a]pyrimidine-4-ketone](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/66e463d3-6b68-4f8c-ba0d-0330a3f12b24/a20081005550700041.PNG)

![Method for preparing 3-(2-chloroethyl)-2-methyl-4H- naphthyridine[1,2-a]pyrimidine-4-ketone Method for preparing 3-(2-chloroethyl)-2-methyl-4H- naphthyridine[1,2-a]pyrimidine-4-ketone](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/66e463d3-6b68-4f8c-ba0d-0330a3f12b24/a20081005550700042.PNG)

![Method for preparing 3-(2-chloroethyl)-2-methyl-4H- naphthyridine[1,2-a]pyrimidine-4-ketone Method for preparing 3-(2-chloroethyl)-2-methyl-4H- naphthyridine[1,2-a]pyrimidine-4-ketone](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/66e463d3-6b68-4f8c-ba0d-0330a3f12b24/a20081005550700051.PNG)

![Method for preparing 3-(2-chloroethyl)-2-methyl-4H- naphthyridine[1,2-a]pyrimidine-4-ketone Method for preparing 3-(2-chloroethyl)-2-methyl-4H- naphthyridine[1,2-a]pyrimidine-4-ketone](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d3c9d818-16e6-4197-8d78-2de0472beef6/S2008100555071D00011.PNG)

![Method for preparing 3-(2-chloroethyl)-2-methyl-4H- naphthyridine[1,2-a]pyrimidine-4-ketone Method for preparing 3-(2-chloroethyl)-2-methyl-4H- naphthyridine[1,2-a]pyrimidine-4-ketone](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d3c9d818-16e6-4197-8d78-2de0472beef6/S2008100555071D00012.PNG)

![Method for preparing 3-(2-chloroethyl)-2-methyl-4H- naphthyridine[1,2-a]pyrimidine-4-ketone Method for preparing 3-(2-chloroethyl)-2-methyl-4H- naphthyridine[1,2-a]pyrimidine-4-ketone](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d3c9d818-16e6-4197-8d78-2de0472beef6/S2008100555071D00021.PNG)