Device and process for preparing graphene heat transfer enhanced organic silicon resin composite pipe

A technology for preparing equipment and resin compounding, which is applied in spraying equipment, equipment for coating liquid on the surface, paint spraying room, etc., which can solve the problem of poor corrosion resistance, poor thermal and electrical properties of bimetallic composite pipes, and unsuitable composite pipes. and other problems, to achieve the effects of good electrical and thermal conductivity, good electrical properties and thermal stability, and improved cleanliness and roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

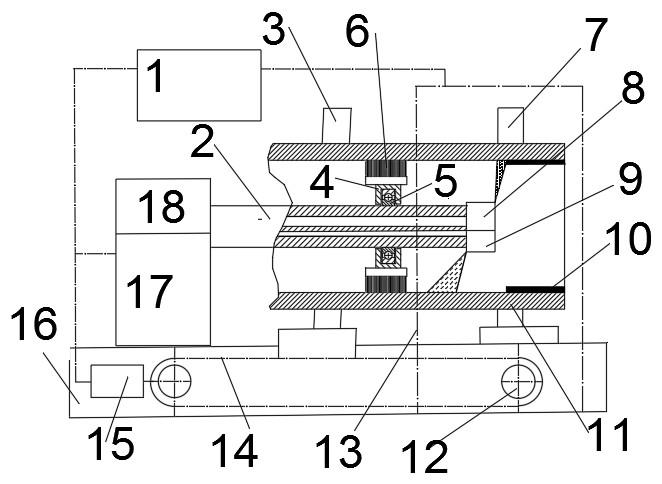

[0035] figure 1It is a schematic diagram of the device of the present invention. In the figure (1) is the operation and control system, and the control system adopts the PLC method; (2) is a hard tube, the mixed resin uses a metal tube, and the compressed gas uses a rubber tube; (3) is a metal tube that rotates (4) is a retaining ring, made of metal; (5) is a hard tube support bearing; (6) is a wire brush; (7) is a metal tube support frame; (8) is a composite resin nozzle; (9) ) is a compressed gas nozzle; (10) is a composite resin layer after spraying; (11) is a metal tube; (12) is a transmission wheel, using a synchronous pulley; (13) is a heating and curing device; (14) is a transmission belt, Synchronous belt is used; (15) is a mobile motor, using a three-phase AC motor; (16) is a moving guide rail, made of metal; (17) is a resin pump, using a gear pump; (18) is a compressed air source, using a compressed air source machine form.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com