Mixing system favorable for improving cattle and sheep culture feed mixing degree

A technology of mixing system and mixing degree, which is applied in the field of cattle and sheep breeding, can solve problems such as insufficient mixing of powder materials, lack of uniformity of compound feed, and influence on the absorption of nutrients in cattle and sheep breeding, so as to facilitate management and reduce The effect of human input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

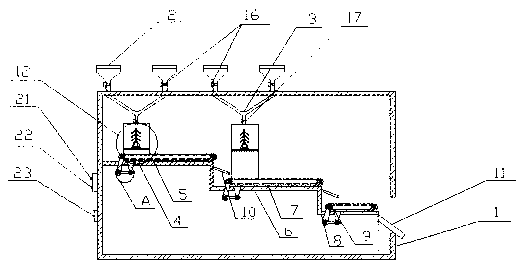

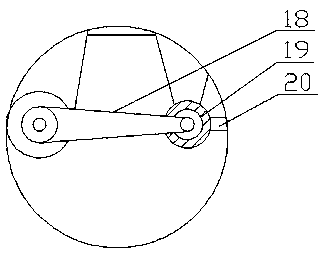

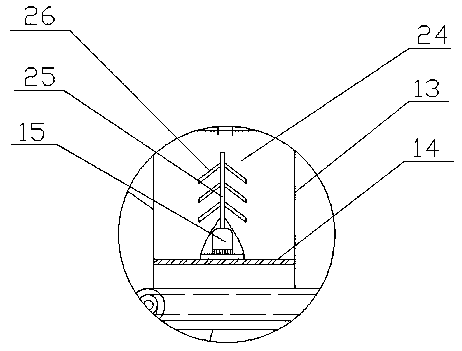

[0017] A mixing system beneficial to improving the mixing degree of cattle and sheep breeding feed, an embodiment. It includes a frame body 1, a feed hopper 2 is provided on the upper side of the frame body 1, and the two feed hoppers 2 are connected by a Y-shaped pipe 3. A first platform 4 is provided inside the frame body 1, and a first platform 4 is provided on the first platform 4. A conveyor belt 5, the first platform 4 side is provided with the second platform 6, the second platform 6 is provided with the second conveyor belt 7, the second platform 6 side is provided with the third platform 8, the third platform 8 is provided with the second platform Three conveyor belts 9; the first platform 4, the second platform 6 are provided with a dispersing device 12, and the dispersing device 12 compri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com