5-methoxyl-4,6-dichloropyrimidine preparing method capable of preventing temperature fluctuation phenomenon from occurring

A technology of sodium methoxypyrimidine and dichloropyrimidine, which is applied in the field of preparation of sulfonamide intermediates, and can solve problems such as cross temperature and unfavorable reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

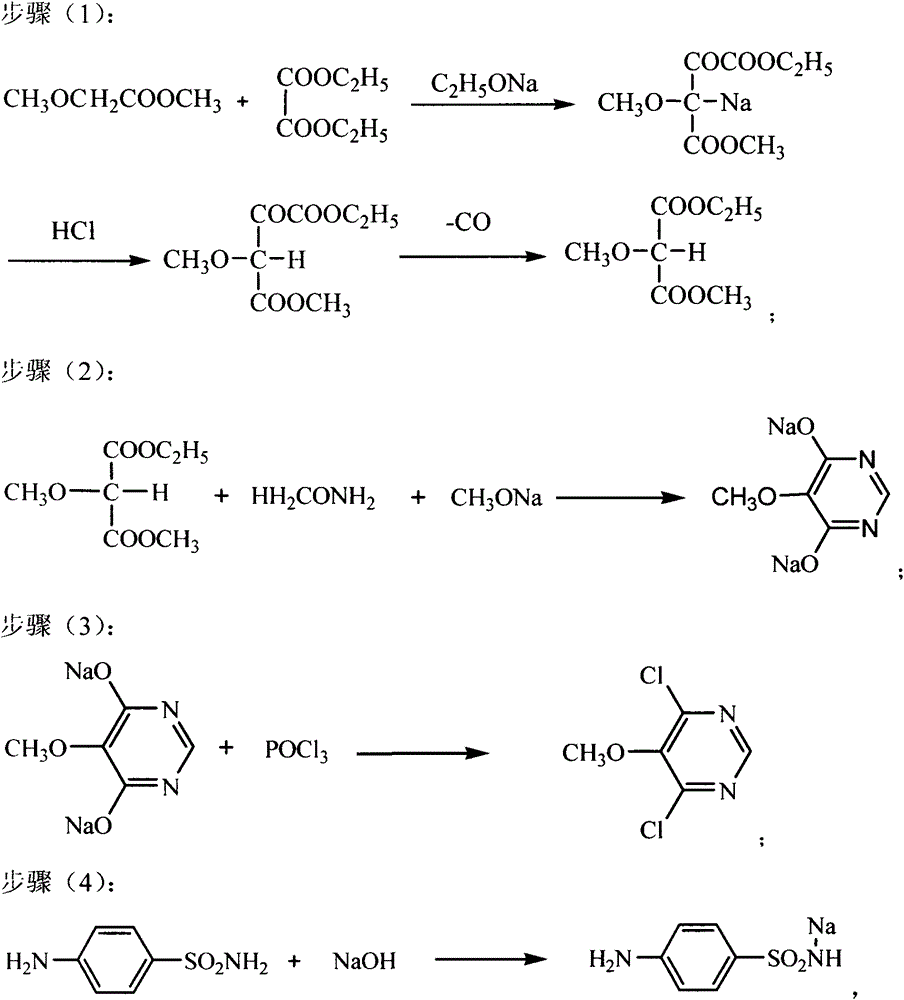

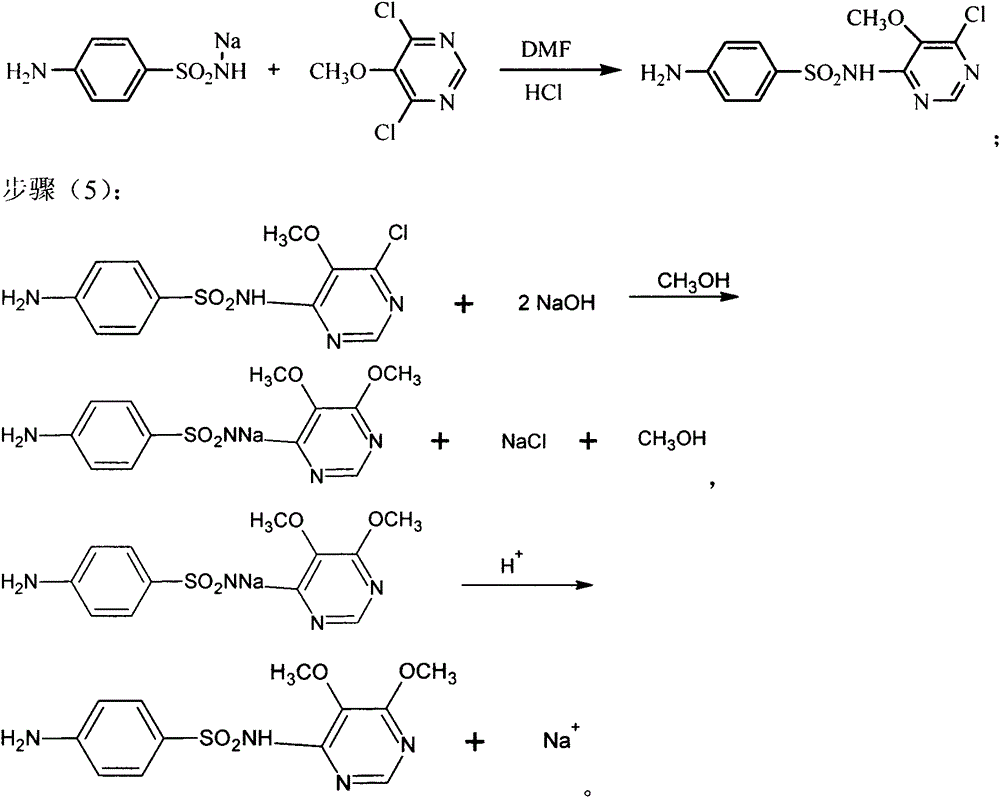

[0021] The preparation method of 5-methoxy-4,6-dichloropyrimidine which does not produce dust and cross-temperature phenomenon of the present invention comprises the following steps: (a) adding phosphorus oxychloride into the reaction vessel, and then adding dropwise therein containing 4, The organic solvent of 6-dihydroxy-5-methoxypyrimidine sodium is refluxed at 110-120°C for 2-6 hours to obtain a reaction mixture; (b) adding the reaction mixture to deionized water for hydrolysis, and standing Layering to form the first water layer and the first organic solvent layer; (c) adding lye to the first organic solvent layer to adjust the pH value to 6.5-7, and standing to form the second water layer and the second organic solvent layer again Two organic solvent layers; (d) take the second organic solvent layer and distill off the organic solvent therein. On the one hand, reflux reaction at 110-120°C for 2-6 hours, so that the reaction can fully proceed; 4,6-dihydroxy-5-methoxypyri...

Embodiment 1

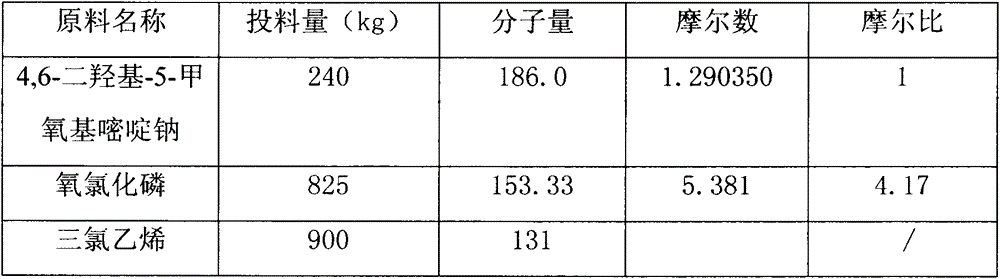

[0025] This example provides a preparation method of 5-methoxy-4,6-dichloropyrimidine, and the specific feeding ratio is shown in Table 1:

[0026] Table 1 Reaction raw materials and their feeding ratio

[0027]

[0028] The specific operation process is as follows:

[0029] (a) Add 825kg of phosphorus oxychloride into the dry chlorination reaction pot, turn on the reflux and hydrogen chloride gas absorption device, heat the chlorination reaction pot to 70°C with steam, turn off the steam and naturally heat up to 80°C; no dripping containing 4,6-dihydroxy-5-methoxypyrimidine sodium trichlorethylene control feeding time is 0.5-1.5 hours, so that the internal temperature is controlled at 80-95 ° C; heating, reflux at 110-120 ° C for 4 hours;

[0030] (b) Add the reaction mixture formed above into deionized water for hydrolysis, control the temperature not to exceed 60°C, let stand to separate layers to form a water layer and a trichlorethylene layer, extract the water layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com