Short fiber feeding device for fiber reinforced thermoplastic plastics screw extruding machine

A thermoplastic and screw extruder technology, applied in the field of screw extrusion plastic processing, can solve the problems of slow melting process of raw resin, high energy consumption, and influence on production process, so as to avoid the problem of discontinuous feeding and simple structure of the device , to achieve the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

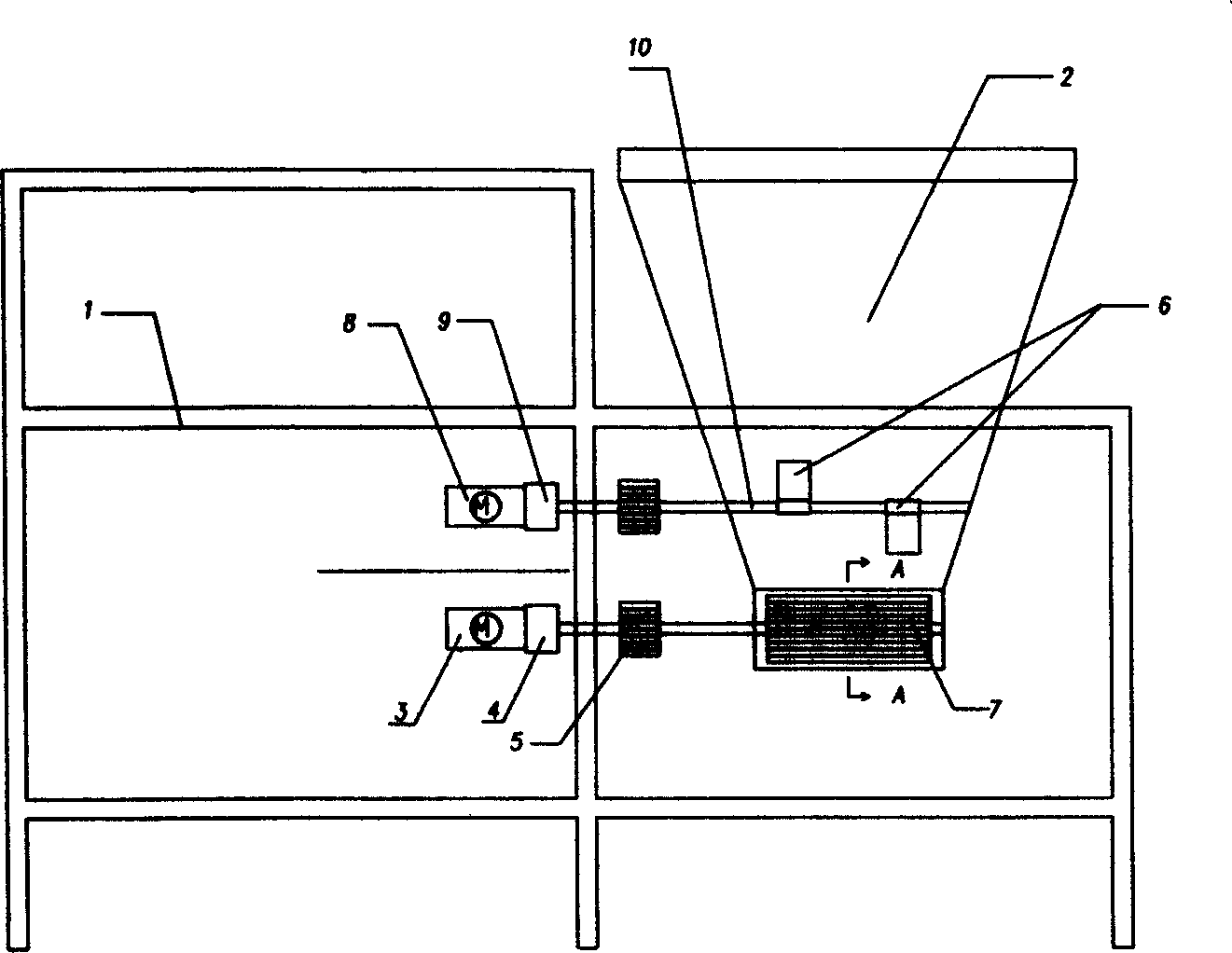

[0025] Fiber feeding unit for fiber reinforced thermoplastic screw extruders is used for twin screw extruders.

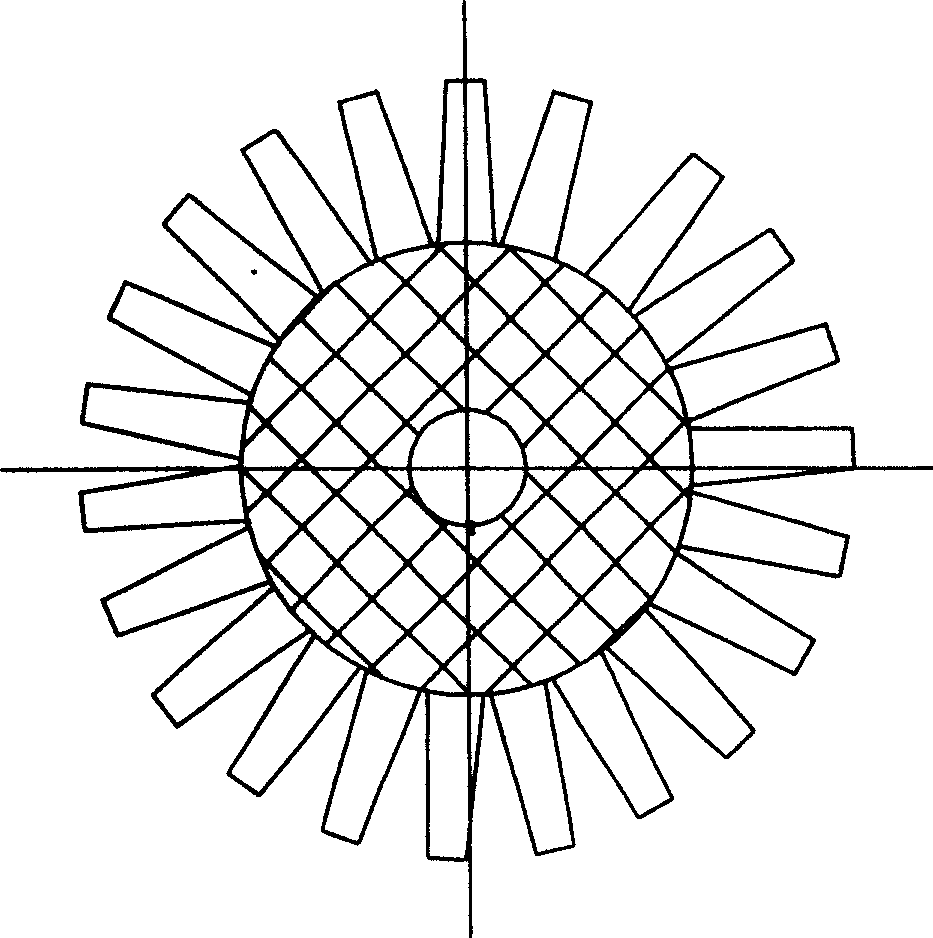

[0026] like figure 1 As shown, the fiber feeding device of a fiber-reinforced thermoplastic screw extruder includes a hopper 2 with an opening at the bottom fixed by a bracket 1, a motor 3, a transmission 4, and a drum 7 with opening grooves uniformly arranged on the outer circumference, specifically connecting The two shafts of the transmission 4 and the drum 7 are connected through a connector 5 . Motor 3 is fixed on support 2, and is connected with speed changer 4, and speed changer 4 is connected with drum 7 by shaft, and drum 7 is positioned at the lower end inside hopper 2 and cooperates with the open groove at the bottom of hopper 2 . The fiber feeding device of the fiber-reinforced thermoplastic screw extruder also includes a fiber stirring device. The fiber stirring device includes a motor 8, a transmission 9, a rotating shaft 10, and blades 6. In this emb...

Embodiment 2

[0033] The fiber feeding unit for fiber reinforced thermoplastic screw extruders is used for single screw extruders. The structure is the same as in Embodiment 1, except that the blade 6 of the stirring device is three pieces, and the blade is fan-shaped, and the opening groove of the drum 7 is a rectangular groove. Its application effect is the same as embodiment 1.

Embodiment 3

[0035] Fiber feeding unit for fiber reinforced thermoplastic screw extruders is used for twin screw extruders. The structure is the same as that of Embodiment 1, except that the blade 6 of the stirring device is one, and the blade is fan-shaped, and the opening groove of the drum 7 is an inclined groove. Its application effect is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com