Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

395results about How to "Avoid quality impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

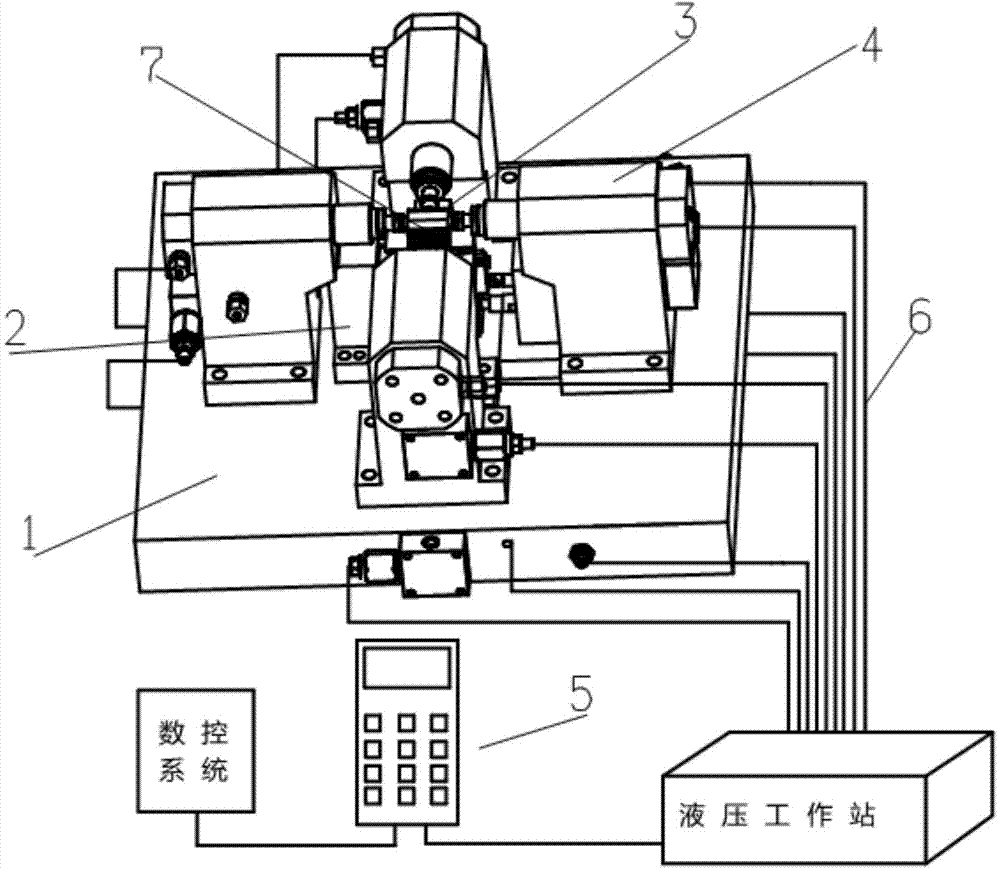

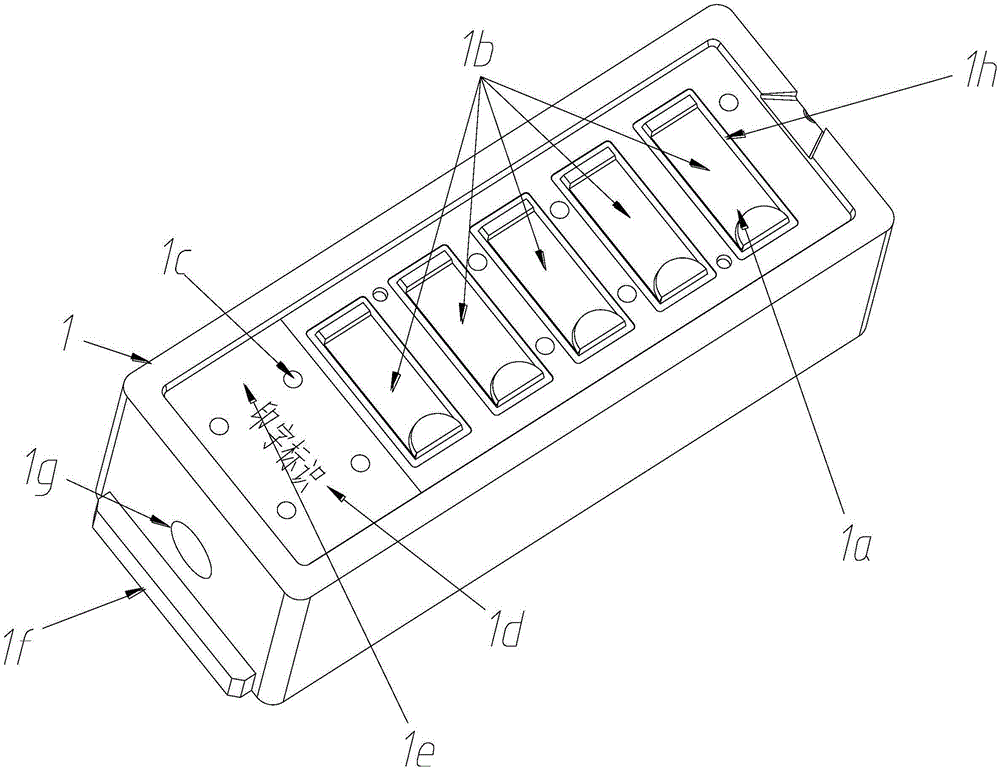

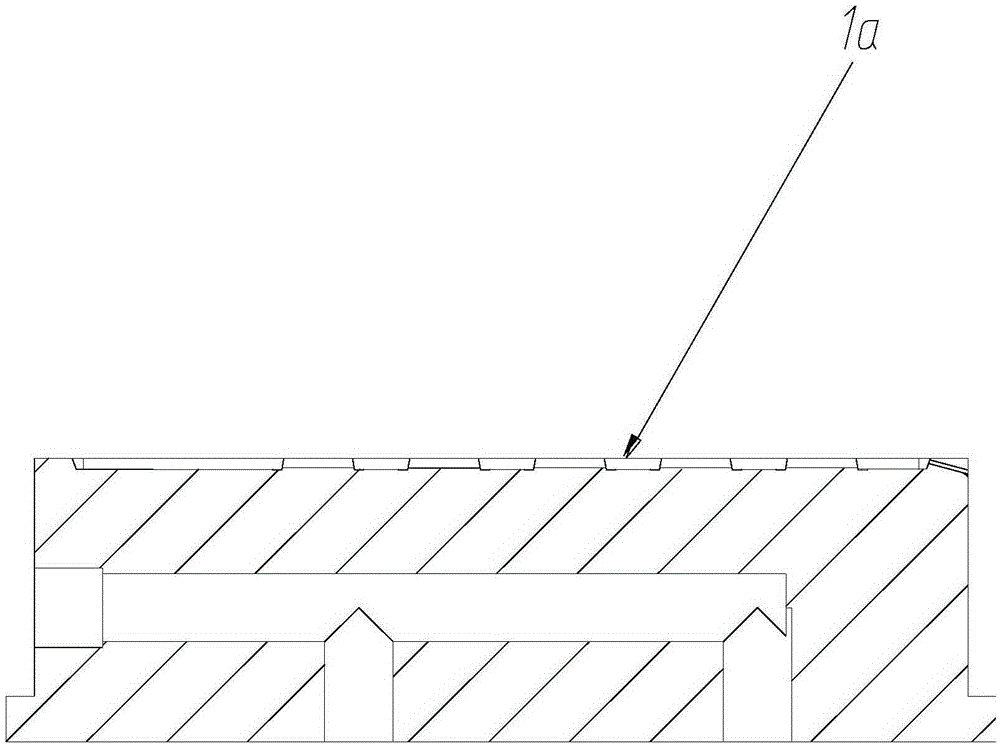

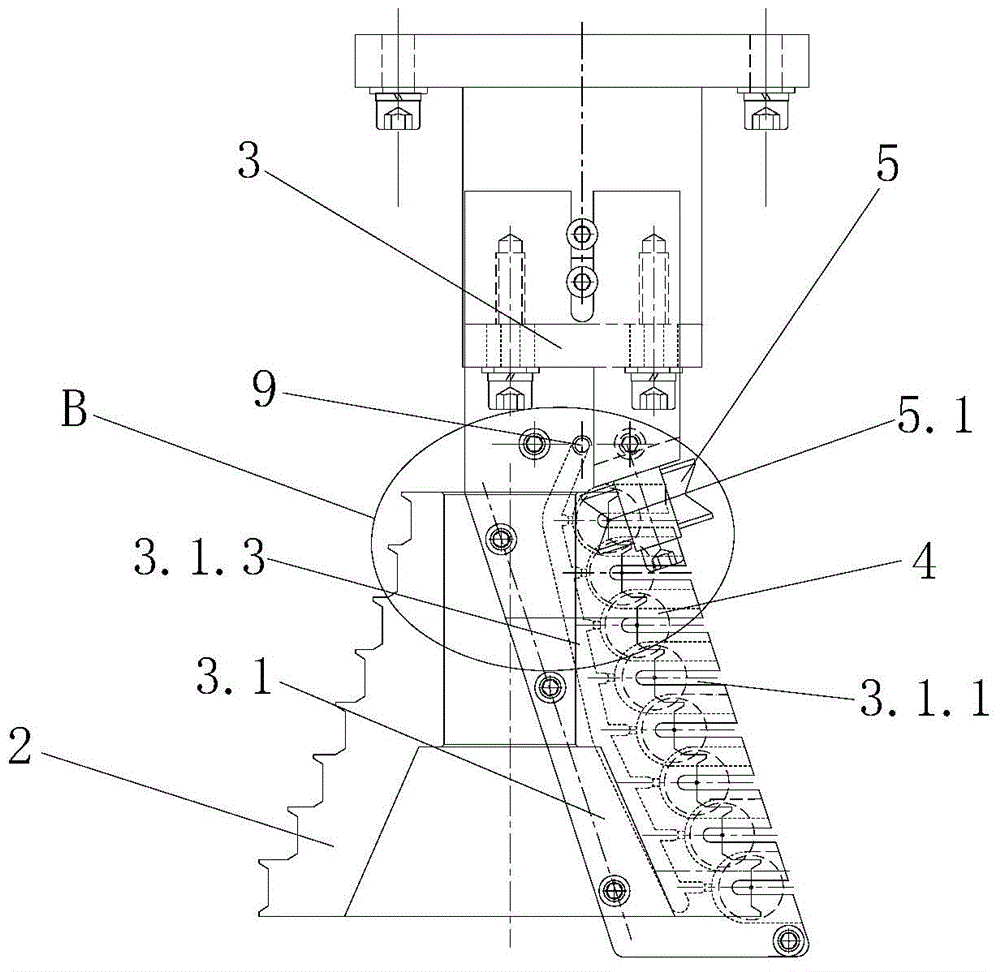

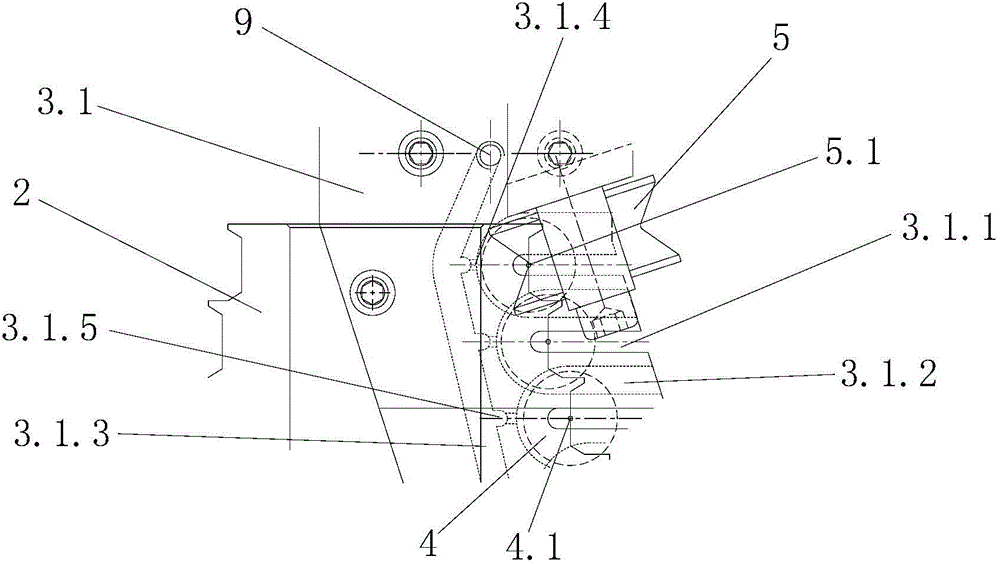

Needle type locating adjustable hydraulic type clamp for machining of tenon of precisely forged blade

InactiveCN103934713AGuaranteed stabilityImprove rigidityWork clamping meansPositioning apparatusNeedle typeSelf adaptive

The invention relates to a needle type locating adjustable hydraulic type clamp for machining of a tenon of a precisely forged blade. The needle type locating adjustable hydraulic type clamp comprises an installation base, a locating device, a clamping device, an auxiliary supporting device, a main controller and a control loop. As a blade body is located and clamped from multiple points, the locating and clamping stability is ensured, self-adaption auxiliary supporting is provided for the tenon, reactive force is provided, cutting deformation is offset, the rigidity of the blade is improved, machining is more stable, and the milling accuracy of the tenon is improved. Influence on the quality of the blade body from a traditional process can be avoided, machining efficiency is improved, and machining cost is lowered. The digital control technology is adopted, the degree of automation is high, operation is easy and convenient, and large-scale production is facilitated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

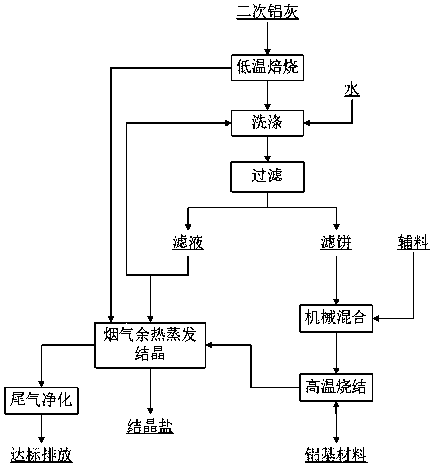

High-efficiency clean resource utilization method for quadratic aluminum dust

ActiveCN109179464AClean and efficient treatmentRealize high-value utilizationHuman health protectionCalcium aluminatesResource utilizationPotassium

The invention discloses a high-efficiency clean resource utilization method for quadratic aluminum dust. The method comprises the following steps: performing low-temperature roasting treatment on quadratic aluminum dust, removing harmful elements such as nitrogen, carbon and fluorine, pulping, washing, desalting and dehydrating the quadratic aluminum dust, removing sodium salt, potassium salt andother impurity components, washing brine and evaporating and crystallizing by utilizing flue gas waste heat. The purified quadratic aluminum dust can serve as a raw material to be directly utilized, and after the quadratic aluminum dust is mechanically mixed with auxiliary materials (calcium-based, silicon-based and magnesium-based), an aluminum based inorganic material is prepared at a high temperature, and the sintering exhaust gas realizes up-to-standard discharge by virtue of dust removal and dry defluorinated purification. According to the technology in the invention, the quadratic aluminum dust can be safely, cleanly and efficiently treated and converted into the high-value aluminum based inorganic material to the greatest degree, and environmental-friendly treatment and high-value resource utilization of the quadratic aluminum dust can be realized.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for preparing cryolite by alkaline leachate of cathode carbon block of aluminum electrolytic cell

The invention relates to a method for preparing cryolite by alkaline leachate of a cathode carbon block of an aluminum electrolytic cell, and belongs to a leachate preparation method. The method comprises the steps of grinding the cathode carbon block of the aluminum electrolytic cell to a certain particle size, mixing the ground cathode carbon block with alkaline liquid, carrying out size mixing, carrying out stirring leaching at a heating temperature of 20-90 DEG C, filtering to obtain first filtrate and a first filter residue, adding sodium fluoride and a small amount of Na3AlF6 solids into the first filtrate, controlling the introducing velocity of CO2-rich gas to generate precipitates while heating and stirring, after the reaction is finished, filtering to obtain second filtrate and a second filter residue, and drying the second filter residue at 100-150 DEG C, so as to obtain a cryolite product. According to the method, acidy leaching is replaced with alkaline leaching, so that the equipment requirements in the production process are reduced, processing processes such as flotation are omitted, an absorption process of hydrogen fluoride is omitted, and the processing process is simplified; a high-temperature processing process is saved, so that the energy consumption is reduced; and by adding crystal seeds, high-quality cryolite with the uniform particle size is generated when airflow rate is controlled. The method has the beneficial effects that the process is simple, a closed loop is utilized, the resource utilization rate is high, and the secondary pollution is avoided.

Owner:CENT SOUTH UNIV

Method for producing cryolites by using aluminum electrolytic cell cathode carbon block alkaline leaching solution

The invention relates to a method for preparing cryolites by using an aluminum electrolytic cell cathode carbon block alkaline leaching solution, and belongs to preparation methods of the cryolites. The method comprises the following steps: grinding aluminum electrolytic cell cathode carbon blocks finely to a certain particle size, performing slurry mixing with alkali liquor, and performing agitation leaching at a heating temperature of 20-90 DEG C; then performing filtration to obtain a first filtrate and a first filter residue; adding sodium fluoride and a small amount of Na3AlF6 solids into the first filtrate; then controlling the speed of introducing NH3-rich gas or adding NH4F to generate a deposit under the action of heating agitation; and after reaction, performing filtration to obtain a second filtrate and a second filter residue, and drying the second filter residue at 100-150 DEG C to obtain a cryolite product. According to the method provided by the invention, by replacing acid leaching with alkali leaching, the requirement of a production process on equipment is reduced, treatment processes including floatation are reduced, an absorption process of hydrogen fluoride is reduced, and the treatment process is simplified; a high-temperature treatment process is not used, so that the energy consumption is reduced; and by adding a crystal seed, high-quality cryolites with uniform particle sizes are generated under the condition that the airflow rate is controlled. The method provided by the invention is simple in process, achieves closed cycle, is high in resource utilization rate and avoids secondary pollution.

Owner:CENT SOUTH UNIV

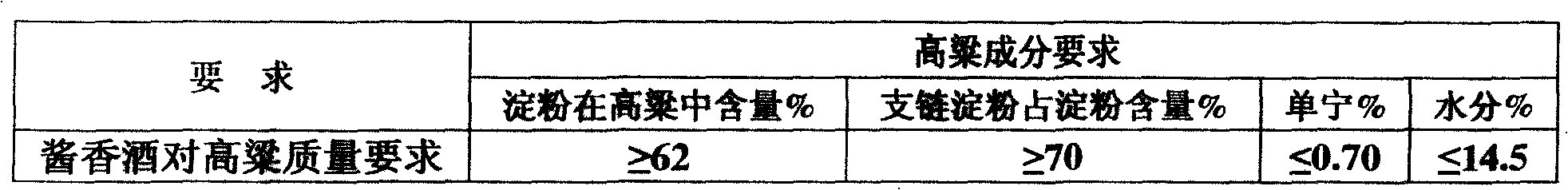

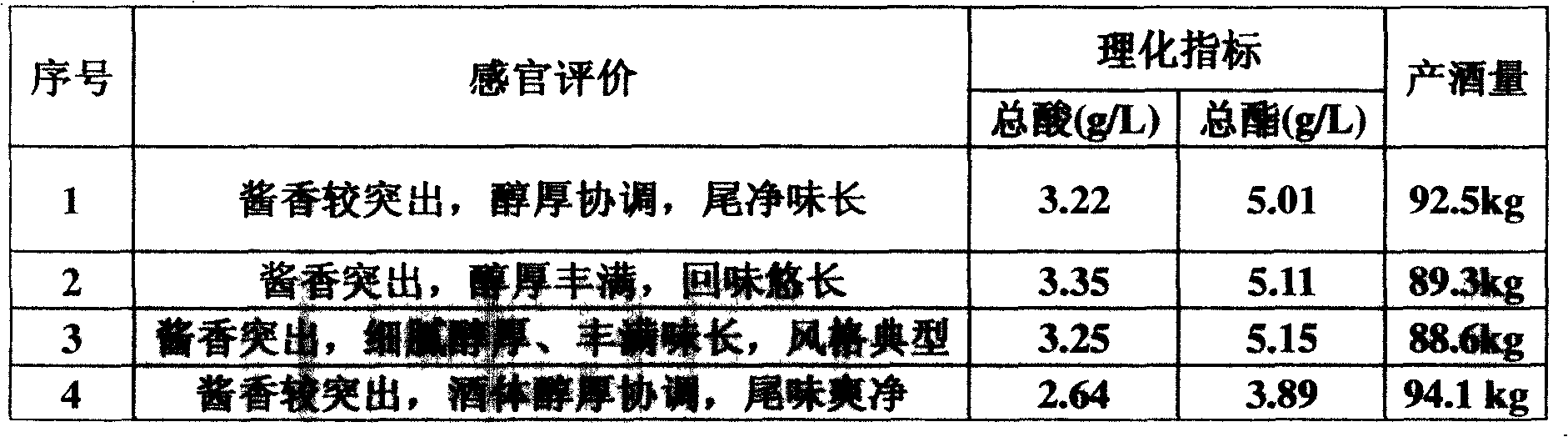

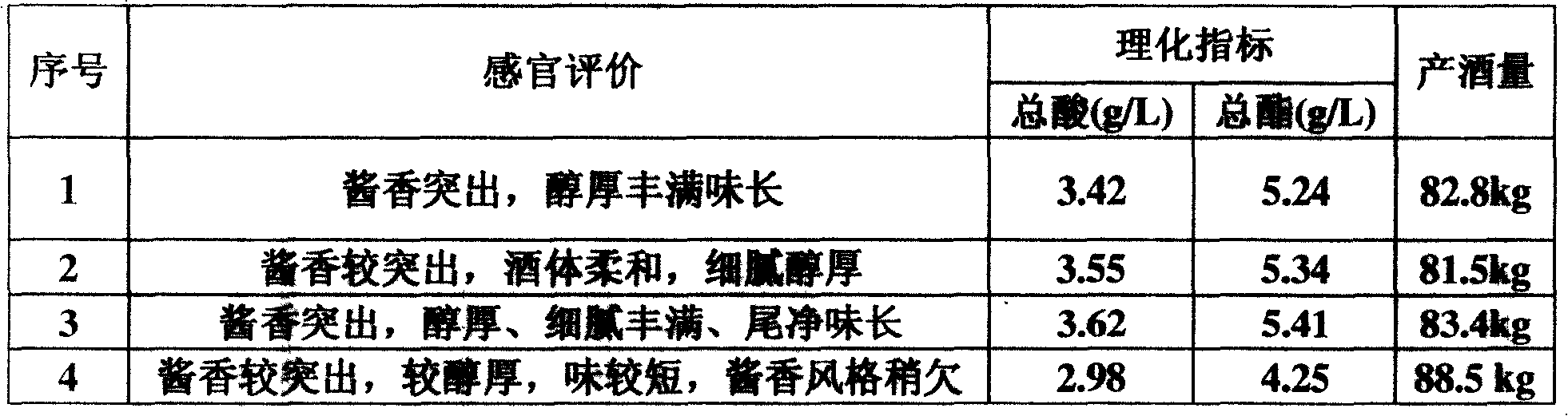

Method for producing maotai-flavor flavoring wine

The invention belongs to the liquor production field, in particular to a preparation method of Maotai-flavor liquor. The method of the invention comprises the following steps: a. fermented grains or double bottom fermented grains which are not extracted wine in the production process of common Maotai-flavor liquor are added to Maotai-flavor liquor yeast powder and mature hull for uniformly blending, and then adding fluid is added to acquire Maotai-flavor flavoring wine fermented grains; b. the fermented grains produced by common Maotai-flavor liquor is cellared, and the Maotai-flavor flavoring wine fermented grains acquired from step a is placed on the top; c. cellar mud is used for sealing the cellar, the Maotai-flavor flavoring wine fermented grains is taken out after fermentation to distill and extract wine, thus acquiring the wine. The method of the invention has simple steps and low cost, the product manufactured by the method has intense and mellow Maotai-flavor style, and the taste is better than the Maotai-flavor liquor prepared by the existing method, thereby having great application prospect.

Owner:四川郎酒股份有限公司

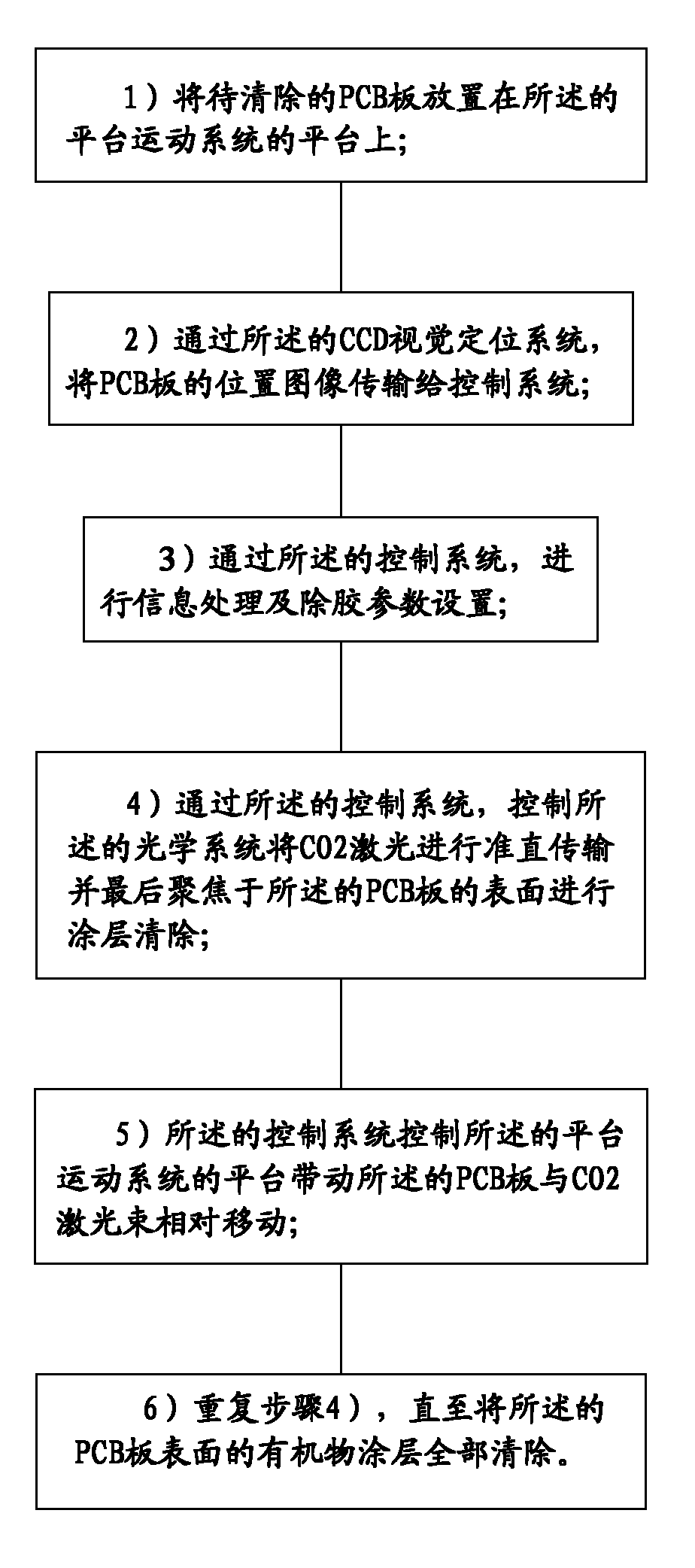

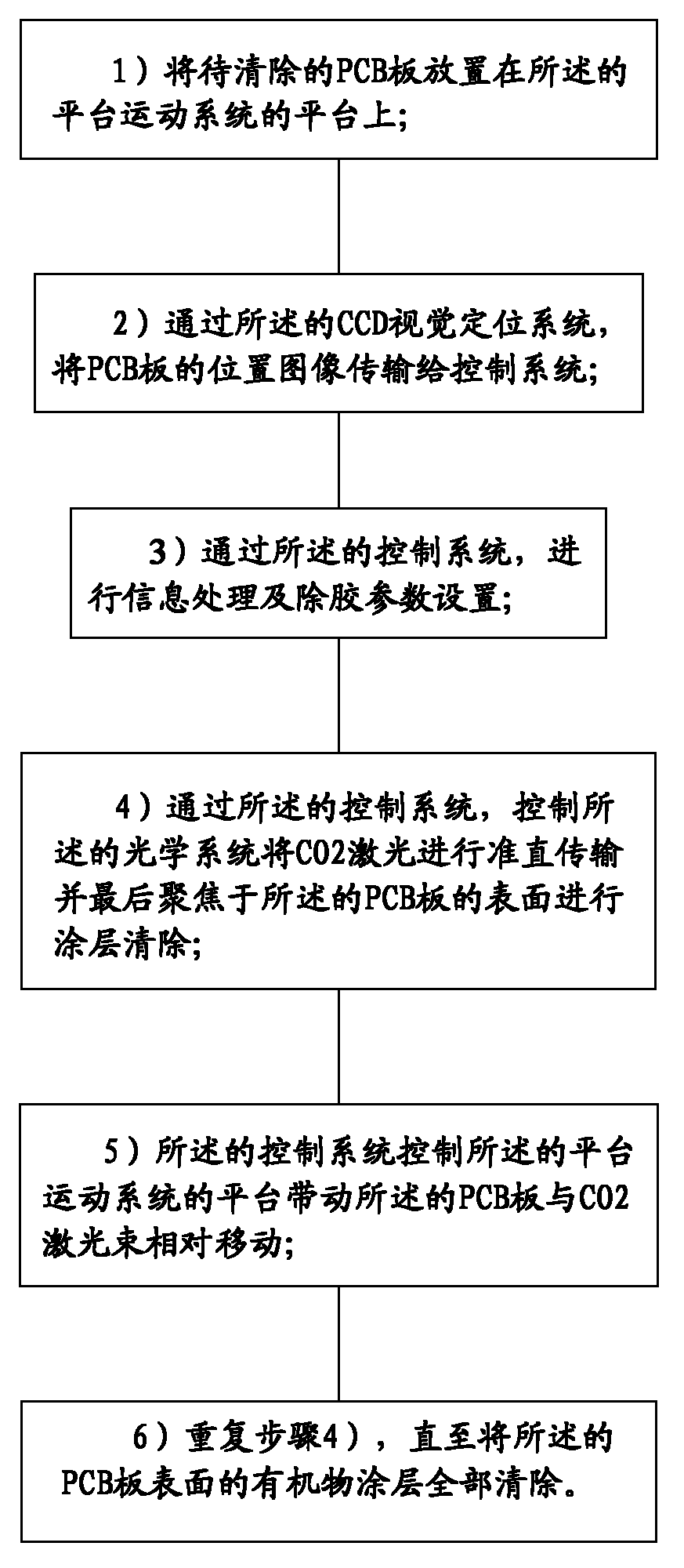

Device and method for degumming in SMT (surface mounting technology) industry

InactiveCN102164461AAvoid quality impactAddress stressPrinted circuit assemblingCleaning processes and apparatusCarbon dioxideMotion system

The invention discloses a device and a method for degumming in SMT (surface mounting technology) industry, which are used for removing a coating layer on a PCB (printed circuit board) board. The device comprises an optical system, a platform motion system, a CCD (charge coupled device) visual positioning system and a control system, wherein the optical system is used for performing the alignment transmission on CO2 (carbon dioxide) lasers and finally focusing on material surface and is used for walking along the laser track within the region through optical scanning; the control system is used for controlling the optical system, the platform motion system and the CCD visual positioning system; the platform motion system is used for performing the laser spanned degumming process through the matching motions of a numerical control platform along X and Y directions; the PCB board is arranged on the numerical control platform of the platform motion system; and the optical system is arranged above the numerical control platform of the platform motion system. By using the method and device provided by the invention, the defects of mechanical degumming, such as the influence of the mechanical degumming on the quality of the product, are avoided, the stress problem of the mechanical degumming is solved and the better degumming effect is achieved.

Owner:HANS LASER TECH IND GRP CO LTD +1

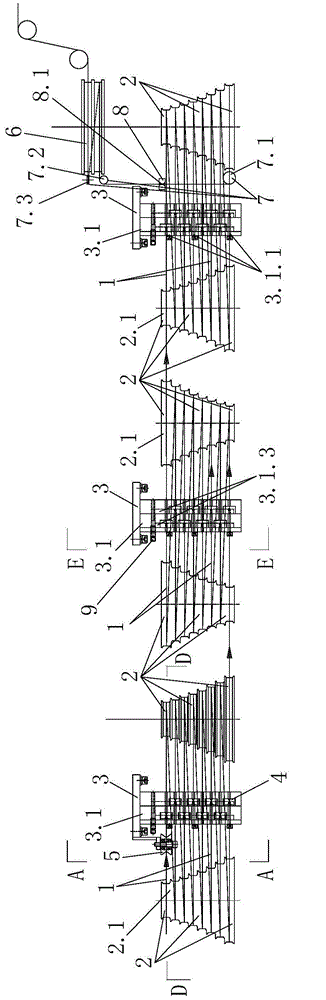

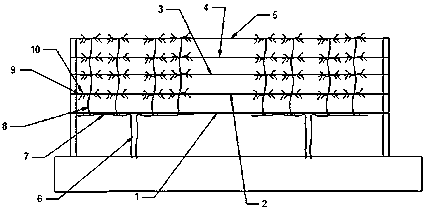

Aluminum or aluminum alloy conductor twisting and compressing process for cables

ActiveCN102800437AReduce resistanceReduce frictional resistanceCable/conductor manufactureSocial benefitsElectrical conductor

The invention provides an aluminum or aluminum alloy conductor twisting and compressing process for cables. The aluminum or aluminum alloy conductor twisting and compressing process comprises the following steps of: twisting aluminum or aluminum alloy single wires along the traction direction of the aluminum or aluminum alloy single wires; and compressing the twisted aluminum or aluminum alloy single wires by a compression roller, wherein a layer of twisting layer is formed after the aluminum or aluminum alloy single wires are twisted once and compressed by means of the compression roller, the subsequent twisting layer is twisted on the basis of the fore twisting layer, and the twisting direction of the last twisting layer is the same as that of the second last twisting layer. According to the aluminum or aluminum alloy conductor twisting and compressing process, the twisting directions of the outermost two layers of twisting layers are the same, the compression roller is combined with a nano diamond composite coating compression die, the phenomena of surface burrs of compressed round aluminum conductors, more aluminum scraps and wire fracture are prevented, the influence of alcohol which is continuously dripped for lubricating and cooling on the residual water inside or on the surface of the conductors is eliminated, the volume resistivity of the twisted and compressed cables is reduced by 0.5 to 2.0 percent, the production cost is saved, and the social benefit is higher.

Owner:SICHUAN MINGXING CABLE

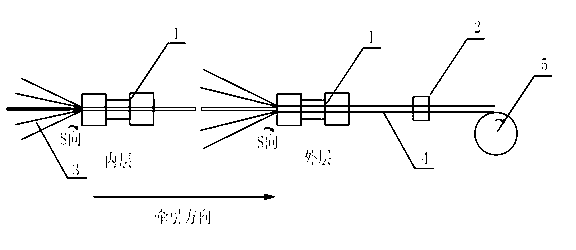

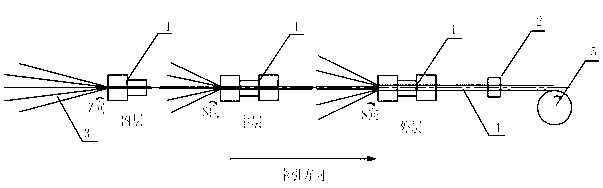

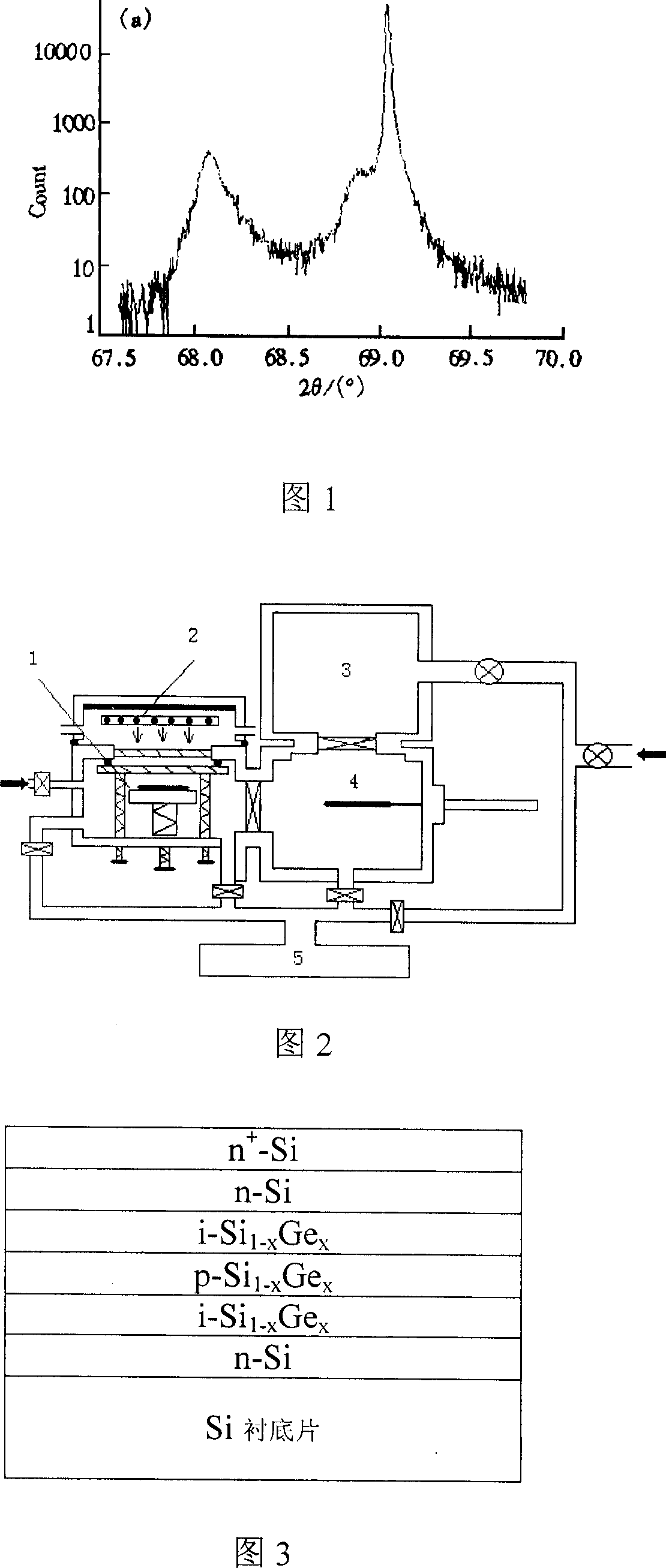

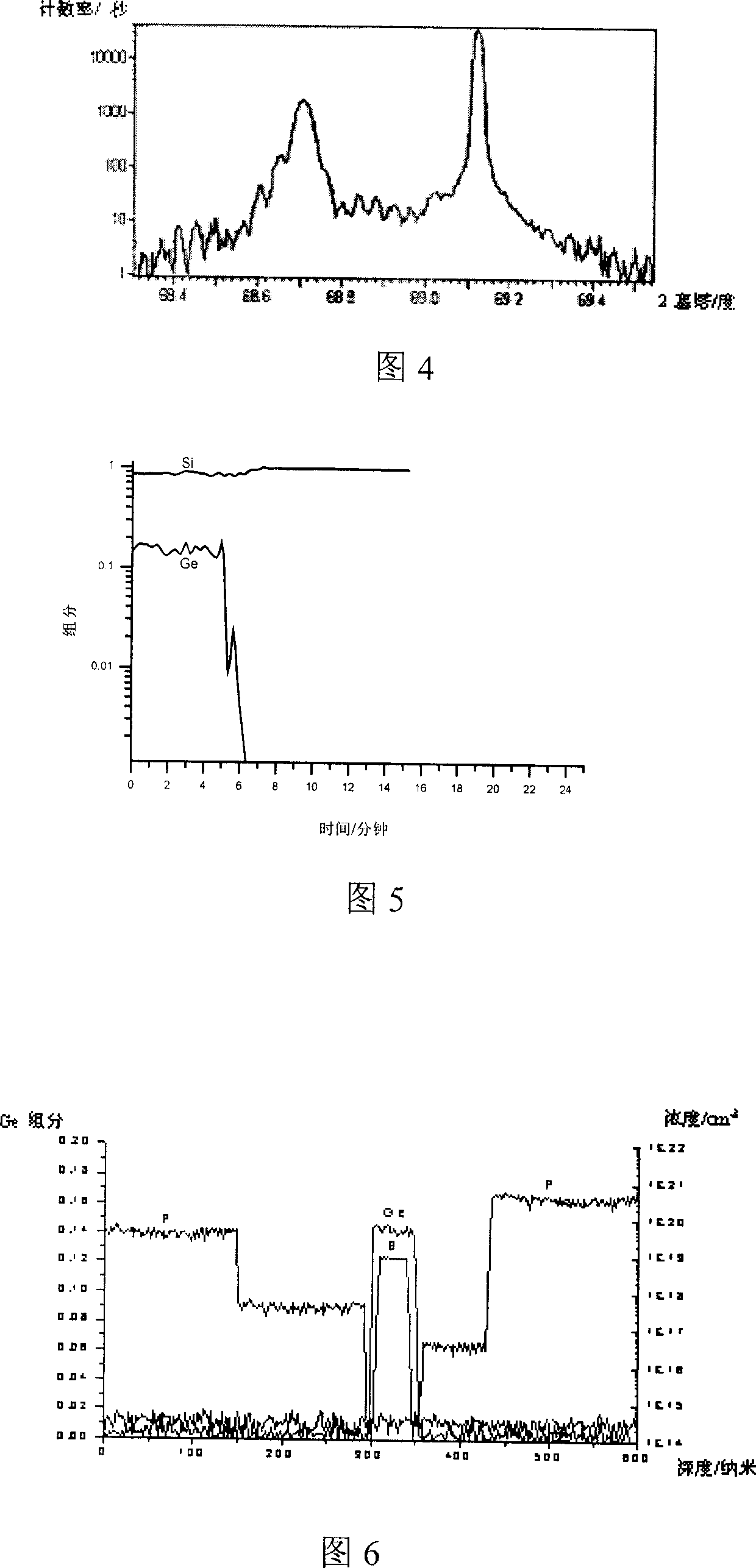

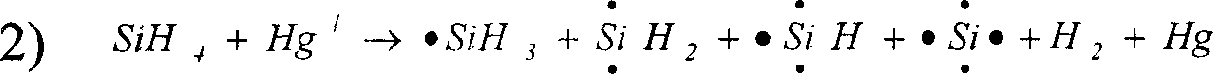

SiGe/Si Chemical vapor deposition growth process

InactiveCN1417844AAvoid unclear material interfaceReduce material interface unclearSemiconductor/solid-state device manufacturingMaterial growthSilicon-germanium

The present invention discloses an epitaxial growth process of SiGe / Si material with optochemical vapor deposition equipment in low-temperature and high-background vacuum environment. The main feature of the present invention is organic combinatino of UHV / CVD technology and CVD technology. The SiGe / Si material is grown through reaction in background vacuum superior to 1E(-7) Pa, reaction temperature of 400-450 deg.c and reaction pressure of 1-10 Pa. The SiGe / Si material growth in the process of the present invention has less tress, complete crystal structure, good interface characteristic andhigh practicability.

Owner:XIDIAN UNIV

A wild growth imitating cultivation method for astragalus propinquus

InactiveCN106105611AGuaranteed medicinal qualityReduce the interference of human factorsPlant cultivationCultivating equipmentsDiseaseLivestock manure

The invention provides a wild growth imitating cultivation method for astragalus propinquus. The method comprises the steps of 1) land selection and soil preparation: digging planting holes after selecting a plantation, drying dug-out weeds and root hair to prepare natural fertilizer, mixing river sand, the natural fertilizer and land soil uniformly and placing the mixture in the planting holes; 2) base fertilizer application: feeding water into the holes thoroughly before transplanting and spreading mixed fertilizer with a thickness of 2-3mm after the water permeates soil thoroughly, wherein the mixed fertilizer is formed by mixing livestock manure, plant ash, urea, calcium ammonium nitrate and vermiculite power; 3) transplanting; 4) field management; 5) disease and pest control; 6) harvesting and processing. The method selects shady wasteland in mountainous areas or half-mountainous areas, does not occupy fertile farmland, selects growing environment similar to that of wild astragalus propinquus, enables astragalus propinquus to grow naturally and reduces human factor interference as much as possible, thereby guaranteeing the original medicinal purpose quality of astragalus propinquus. With the planting method, astragalus propinquus has the advantages of high survival rate, high medicinal material quality, high yield and low disease and pest damage incidence rate.

Owner:李海东

Method for improving survival rate of rice field eels in transportation process

InactiveCN102578014AAvoid quality impactImprove survival rateClimate change adaptationAnimal feeding stuffAnti stressVitamin C

The invention relates to a method for improving the survival rate of rice field eels in the transportation process and belongs to the technical field of fish culture. The method comprises the following steps: (1) temporary culture of the rice field eels, i.e. transferring the rice field eels to be transported into a temporary culture net cage to carry out temporary culture for one day, stopping feeding and placing few loaches into the temporary culture net cage; (2) preparation and bagging of water for transportation, i.e. dissolving vitamin C and astragalus polysaccharides in water, wherein the vitamin C being added is in an amount of 10g / m3, and the astragalus polysaccharides being added are in an amount of 3g / m3, simultaneously regulating the pH value into 7.0 to 7.5, placing the rice field eels and the water for transportation into a special oxygen bag for aquatic products according to a ratio of 1:1, filling oxygen and sealing, wherein the oxygen content is 6mg / L; and (3) the transportation of the rice field eels, wherein the water is changed for once at intervals of 6 hours in the transportation process so as to ensure that the dissolved oxygen content of the water in the bag is always over 6mg / L and ensure that the pH value is always in the range of 7.0 to 7.5. According to the invention, the vitamin C and the astragalus polysaccharides are added into the water for transportation of the rice field eels, so that the anti-stress capacity of the rice field eels is improved, the stress response, the injury and the death of the rice field eels in the transportation process are effectively avoided, the survival rate of the rice field eels in the transportation process is successfully improved, and a reliable transportation technology is provided for solving the problem of a rice field eel artificial propagation technology and improving the economic benefit of the rice field eels.

Owner:FRESHWATER FISHERIES RES CENT OF CHINESE ACAD OF FISHERY SCI

Color-protecting and fresh-keeping method for fresh-cut potatoes

InactiveCN103070226AAvoid quality impactExtended shelf lifeFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by freezing/coolingBiotechnologyChipped potatoes

The invention discloses a color-protecting and fresh-keeping method for fresh-cut potatoes. The method includes selecting fresh or stored potatoes as the raw material, washing cleanly, peeling, cutting into chips with thicknesses of 0.5-1.0mm, adding a composite color-protecting fresh-keeping solution having the same mass with the potato chips, and soaking for 10-30min at 20 DEG C-30 DEG C; then fishing out the potato chips from the composite color-protecting fresh-keeping solution, washing cleanly with water, soaking in water at 10-150w ultrasonic power and 10-50kHz ultrasonic frequency for 10-30min of ultrasonic time; fishing out the potato chips and draining off, processing for 10-30min under the condition of subzero 0.01MPa-subzero 0.09MPa of vacuum degree; and finally taking the potato chips out of the vacuum environment and soaking immediately into an arbutin solution with the concentration of 0.05-0.3mmol / L, soaking for 5-15min, taking the soaked potato chips out and draining for 1-3min, performing decompression packaging immediately, and storing at an environment of subzero 4 DEG C to zero DEGC. The method adopts ultrasonic and vacuum cooperative processing as well as the Chinese herb extract arbutin as the color-protecting fresh-keeping agent to inhibit enzyme and microbial activities, is better in effect compared with the prior art, and ensures that various potato processed products are prevented from brown stain in a cold storage process for more than 10 days.

Owner:SHANXI AGRI UNIV

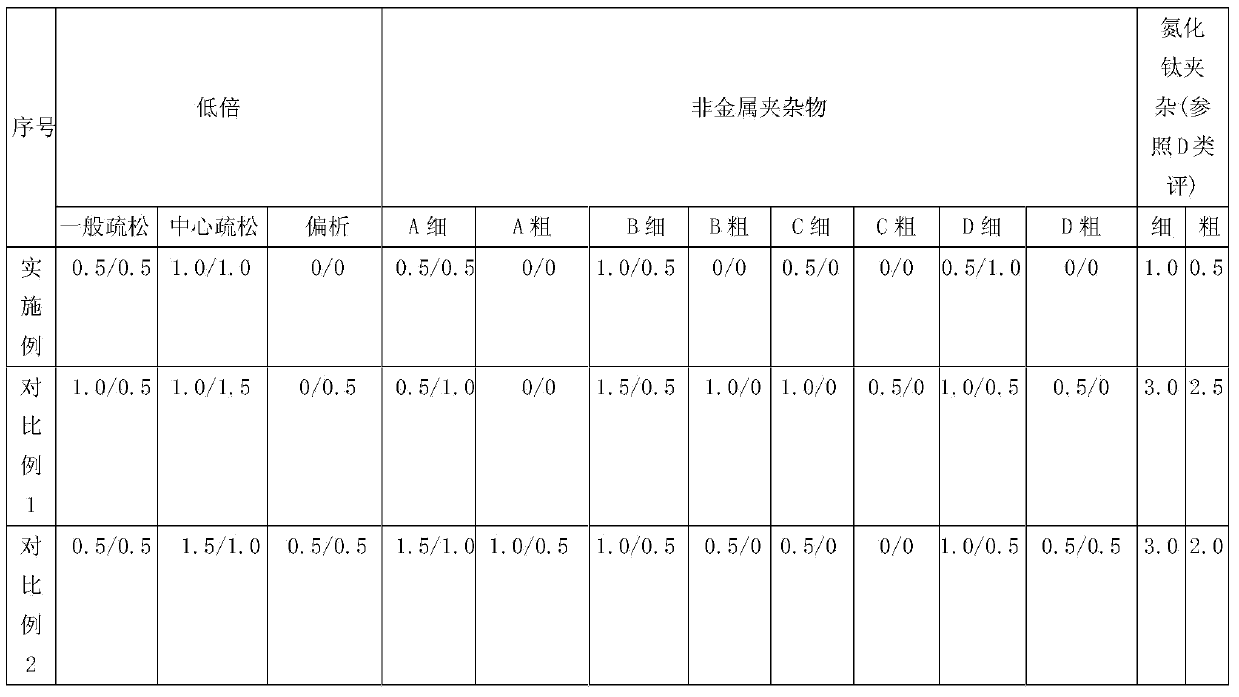

Control method for titanium nitride inclusion of gear steel bar material

InactiveCN104212934AReduce precipitationIncrease cooling intensityManufacturing convertersTitanium nitrideMolten steel

The invention discloses a control method for a titanium nitride inclusion of a gear steel bar material. The control method adopts a production process of converter smelting-LF refining-RH refining-rectangular blank continuous casting, and comprises the following specific operation steps: (1) converter smelting: molten iron and waste steel are added in a converter; and the weight ratio of the molten iron to the waste steel is greater than 15: 1; (2) LF refining: the LF refining is performed for the molten steel to prevent the molten steel from being contacted with air; (3) RH vacuum refining: the vacuum degassing treatment is performed for the molten steel; the treatment time is kept not lower than 15 minutes under high vacuum degree not higher than 66.7 Pa; and an titanium-iron alloy is added in the period; and (4) continuous casting: after the RH refining is finished, the molten steel ladle is continuously cast; and in the continuous casting process, a crystallizer electromagnetic mixing technology with low superheat degree not higher than 35 DEG C, constant temperature and constant casting speed is adopted, and the argon sealing is performed. Thereby, the separated concentration product of titanium nitride is controlled.

Owner:SGIS SONGSHAN CO LTD

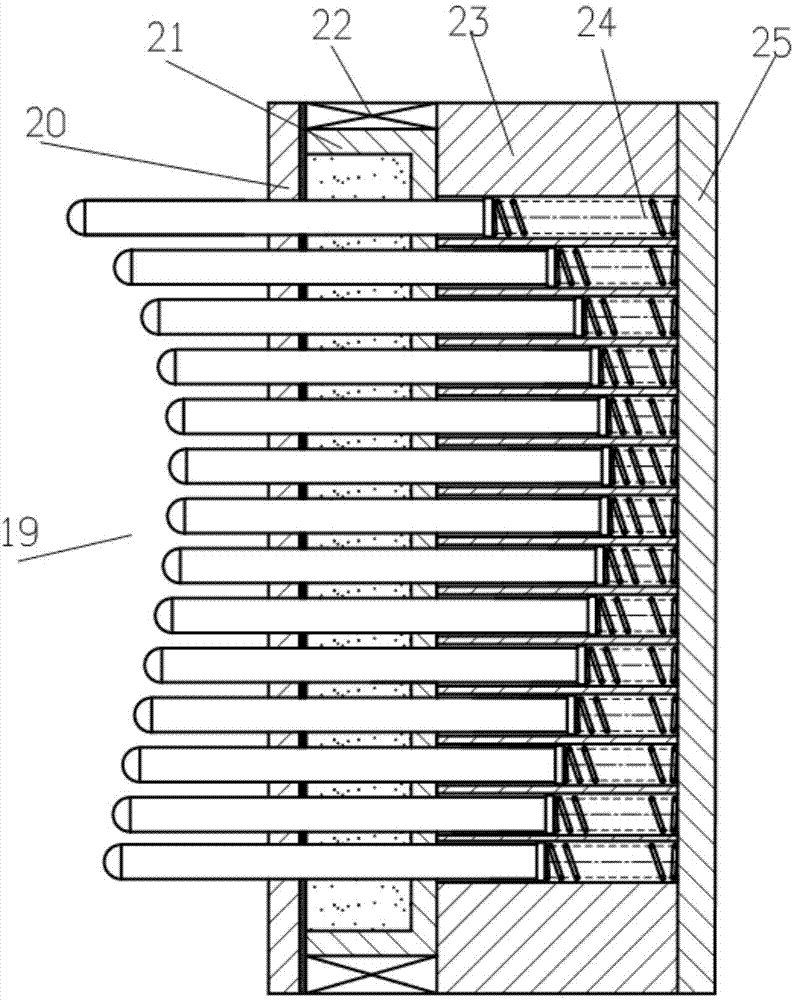

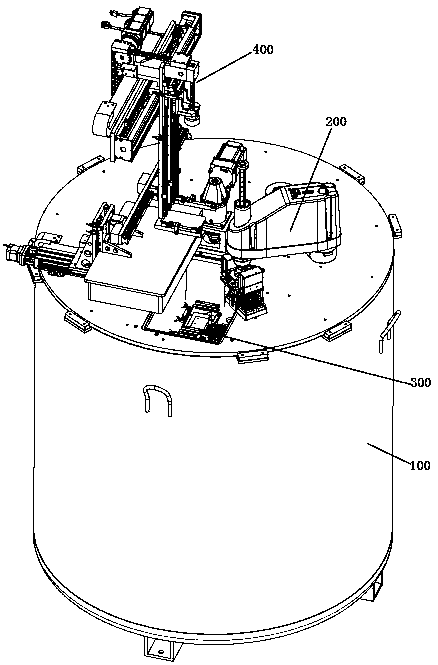

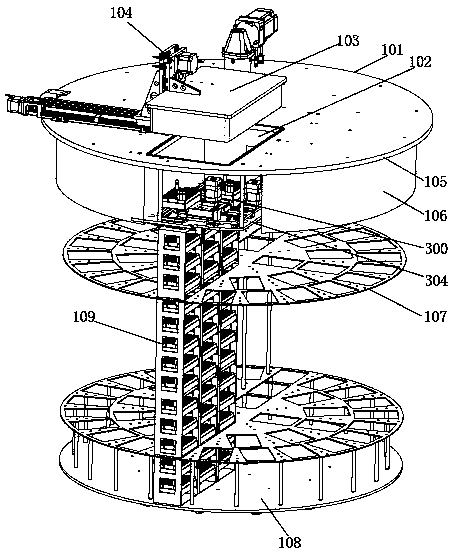

Biological sample low-temperature extraction method and extraction system

The invention discloses a biological sample low-temperature extraction method and an extraction system, and belongs to the technical field of biological sample low-temperature extraction. The method comprises the following steps: a first mechanical arm outside a low-temperature storage tank puts a transfer sample box on the upper part in the low-temperature storage tank; B, a second mechanical armin the low-temperature storage tank takes out a target sample box in a sample storage rack in the low-temperature storage tank and puts the target sample box on the upper part in the low-temperaturestorage tank; and C, a sample to be taken out in target sample box in the low-temperature storage tank is put in the transfer sample box, or a sample to be stored in the transfer sample box in the low-temperature storage tank is put in the target sample box. The whole sample extraction process is conducted in the tank body, the tank body provides a good low-temperature environment for the sample in the sample storage rack and the sample to be stored in the transfer sample box, and high activity of the sample is guaranteed.

Owner:GENEPOINT BIOLOGICAL TECH (CHENGDU) CO LTD

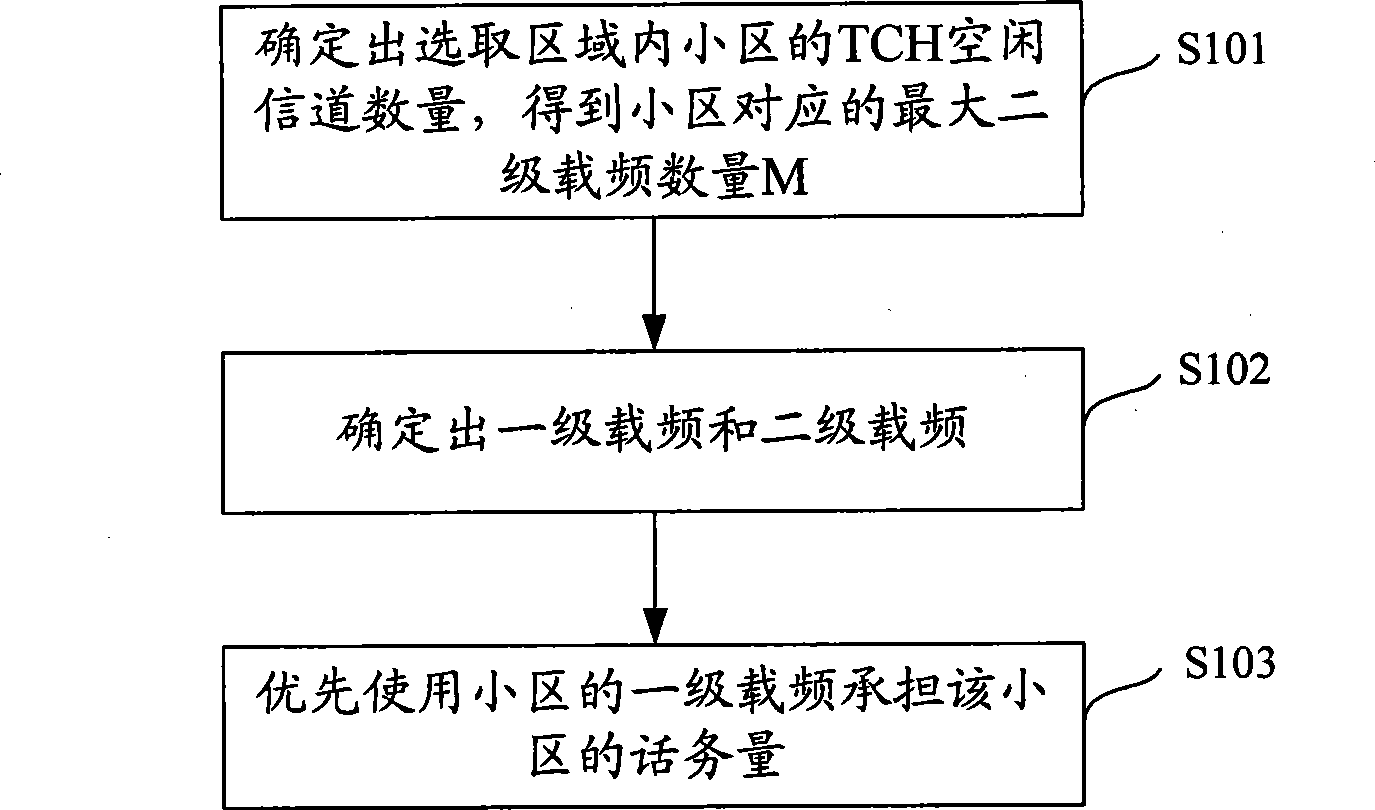

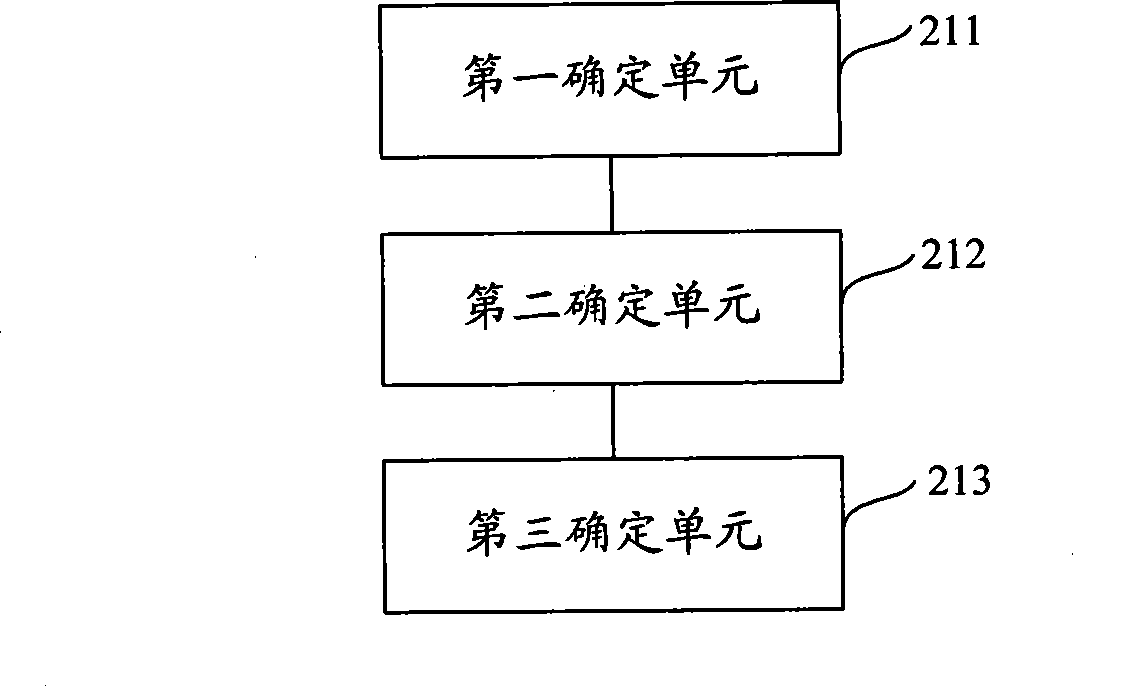

Method and device for using carrier frequency

ActiveCN101466100AAvoid quality impactMake up for limitationsNetwork planningTelecommunicationsFrequency reuse

The invention discloses a carrier frequency applied method and a device thereof. The method comprises the steps as follows: determining the TCH idle channel number of the voice channel in the subdistrict of the selected area, and obtaining the maximum secondary carrier frequency number M in a way that each carrier frequency channel number is divided by the TCH idle channel number; leading the carrier frequencies allocated to the subdistrict except for the set special carrier frequencies to be arrayed in a reusing time method in the selected area according to the corresponding frequency points thereof, and selecting out N carrier frequencies as the secondary carrier frequencies according to the reusing number from big to small; determining the rest carrier frequencies as the first level carrier frequencies after selecting out the secondary carrier frequencies; wherein, the N is less than or equal to the maximum secondary carrier frequency number M; and the first level carrier frequency is preferentially utilized to bear the telephone traffic in the subdistrict. Adopting the method and the device can effectively reduce the frequency reuse degree in the selected area, reduce the in-band frequency interference, and improve the network quality.

Owner:CHINA MOBILE GRP BEIJING

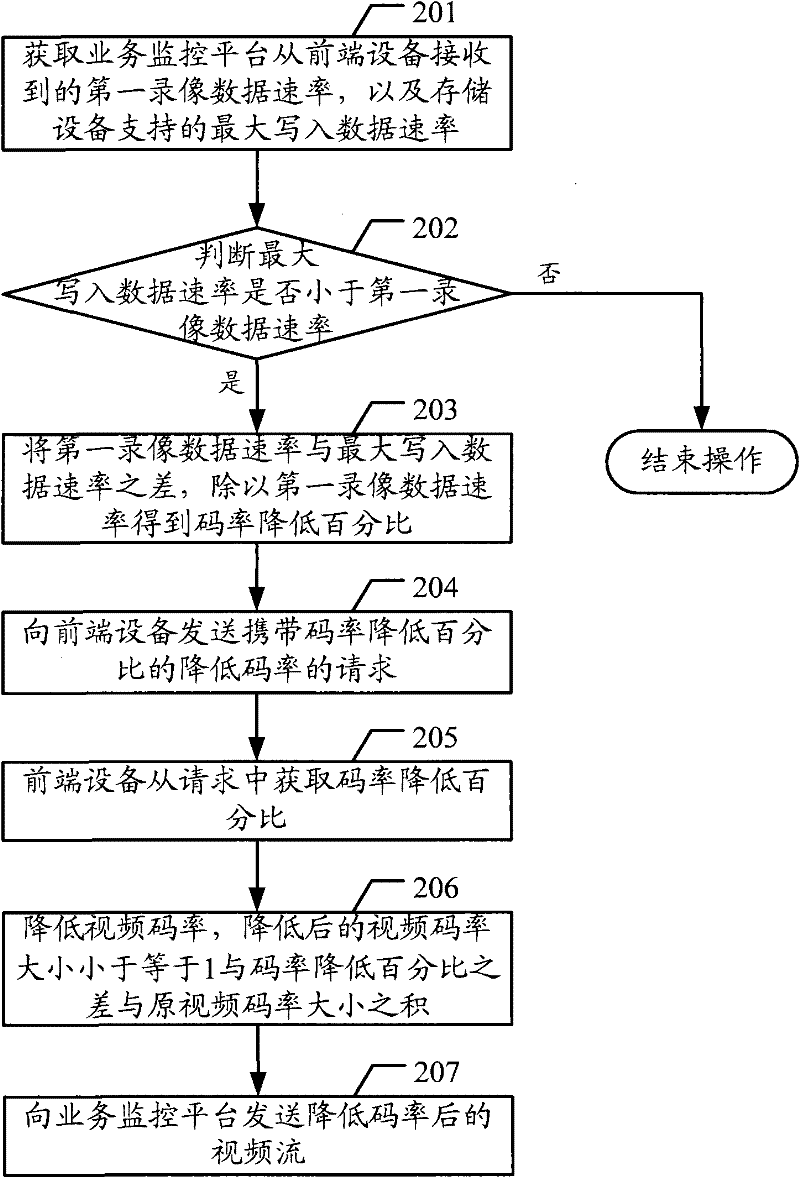

Implementation method and related equipment and system for reducing code rate

ActiveCN102264003ALower performance requirementsImprove satisfactionSelective content distributionNetwork packetData rate

The embodiment of the invention discloses a realization method for lowering a code rate. The method comprises the following steps of: obtaining a first video data rate received from front-end equipment by a service monitoring platform; storing the maximum written-in data rate supported by the equipment; judging whether the maximum written-in data rate is less than the first video data rate; and if so, sending a request for lowering a code rate to the front-end equipment so that the front-end equipment lowers the video code rate. The embodiment of the invention also provides a corresponding equipment system. According to the embodiment of the invention, the phenomenon that the performance of the storage equipment is lowered can be detected; performance requirements for the storage equipment can be adaptively lowered so as to improve the degree of satisfaction of the storage equipment to the performance requirement of video recording service; service monitoring platforms are reduced, even the phenomenon that data packets are randomly abandoned is avoided, and influence on video quality is reduced and avoided.

Owner:深圳华为云计算技术有限公司

High-mirror processing method for mould insert core of convex slide mould

ActiveCN105328425AGuaranteed Manufacturing RequirementsReduce scrap rateEngineeringMechanical engineering

The invention discloses a high-mirror processing method for a mould insert core of a convex slide mould. According to the high-mirror processing method, by optimizing a processing process and processing steps, high-mirror processing on the mould insert core is used as a final processing process, so that influence of each process to mirror polishing quality is completely avoided, and a rejection rate of the mould insert core is reduced.

Owner:SUZHOU LICHUANG PRECISION MOLD TECH CO LTD

Biological acid reduction method for red bilberry wine

ActiveCN101440340AImprove taste qualityAvoid quality impactAlcoholic beverage preparationYeastFruit wine

The invention discloses a method for biological deacidification of blueberry wine, which comprises the following steps: preparation of blueberry juice, fermentation, separation, post-fermentation, clarification and bottling. The method adopts the prior fruit wine brewing process to prepare raw blueberry wine, and then uses pombe fission yeast to ferment so as to perform the biological deacidification. Compared with the prior method for brewing the blueberry wine, the method has the following advantages: (1) improving the mouthfeel quality of the blueberry wine; (2) leading the active components from blueberry berry to the blueberry wine; (3) avoiding the influence of chemical deacidification on the quality of the blueberry wine; and (4) guaranteeing that the brewed wine is full-juice blueberry wine.

Owner:吉林森工集团泉阳泉饮品有限公司

Method for making flat green tea

ActiveCN102696794AReduce breakage rateImprove integrityPre-extraction tea treatmentGreen teasEngineering

The invention discloses a method for making flat green tea. The method comprises the steps of spread cooling of fresh leaves, green killing, spread cooling, reshaping, spread cooling and air drying, fragrance increasing and handpicking, wherein at the spread cooling and air drying step, the reshaped tea leaves are taken out of the pan and uniformly spread in a spread cooling slot, the thickness of the tea leaves is 1 to 2cm, the air is continuously blown to dry the tea leaves until the water content of the tea leaves reaches 8 to 9 percent, and finally the spread cooling and air drying process is completed. By the spread cooling method of air-blow drying, the water content of the tea leaves is greatly lowered, therefore the method has the advantages that (1) by the processing method, the broken tea and tea dust generated in the drying process are reduced, and the breaking rate of bud-tea shoot tips is lowered, so that the integrity of the bud-tea is improved; (2) the processing cost is lowered by nearly 25 percent and the energy is saved by nearly 30 percent; and (3) the color of green tea is brightened, and because the spread cooling and air drying process is adopted in the drying process, the color of green tea is kept all the time, and the influence of fluctuating temperature in the drying process on the quality of tea leaves is completely avoided.

Owner:湄潭银柜山茶业有限公司

Method for extracting peony oil from peony seeds

A method for extracting peony oil from peony seeds comprises the following steps: after peony seed stock is rinsed and cleaned, water is drained off, and the drained peony seed stock is placed into a drying cabinet for drying; peony seeds are placed into a shucking machine for shucking, and peony seed kernels are screened out; the peony seed kernels are placed into a frying-pan for roasting; peony oil is extracted from the peony seeds; the drying temperature in the drying step is 60 DEG C, after drying, the water content of the peony seeds is 15 wt percent, the roasting time in the roasting step lasts is 40 to 70 min, the roasting temperature is 70 to 110 DEG C, the method for extracting peony oil from peony seeds further comprises the steps of grinding to be thick liquid, water adding, alkali refining, centrifugal separation, raw oil mixing and the like. The method has the advantages that the process is simple, the operation is convenient, the promotion is easy, resolvent residue is avoided, the manufacturing cost is reduced, and original nutritional quality of the peony oil can be further kept.

Owner:北京同仁堂安徽中药材有限公司

Method for manufacturing recombined hardwood

InactiveCN102172942AWiden tree age limitShort growth cyclePlywood pressesVeneer pressesSizingHardwood

The invention discloses a method for manufacturing recombined hardwood. The method is characterized by comprising the following steps of: a, selecting gum wood with thickness of between 0.5 and 3 millimeters and width of between 5 and 100 millimeters; b, sizing; c, assembling, namely arranging and assembling the gum wood along the length direction; d, performing cold pressing, namely conveying the gum wood into a die of a press to perform cold pressing, wherein the pressure is more than 20MPa; and e, curing, namely heating the die filled with the blank to cure the blank. The sheared or rotary-cut fast-growing low juvenile gum wood or aspen wood of a made forest is used as a production raw material in the method, and the production raw material can be felled in 4 to 8 years, so the using cycle is greatly shortened, and the economic benefit is improved.

Owner:李和麟

Method for smelting ferritic stainless steel from total molten iron

This invention relates to a molten iron smelting method of ferritic stainless steel which includes: a) temperature-controlled smelting. The temperature is raised to 1580~1600 deg.C before converting. Ferrosilicon containing 4~15kg of steels per ton is added followed by temperature-raising. b) When temperature in molten pool is raised to 1670~1720 deg.C, chromium-iron alloy is added at a rate of 2~3 ton per minute with a total amount of up to 250~280 kg per ton of steel. Then hold the temperature. c) Decarbonization, when it is finished, the carbon concentration is 0.03~0.05% and the temperature is held at 1700~1730 deg.C. d) Reduction and desulfurization. This invention adopts hot metal smelting all through the process and avoids the influences of impure waste iron. Besides the AOD direct smelting technique doesní»t need any crude stainless steel liquid in electric furnace.

Owner:BAOSHAN IRON & STEEL CO LTD

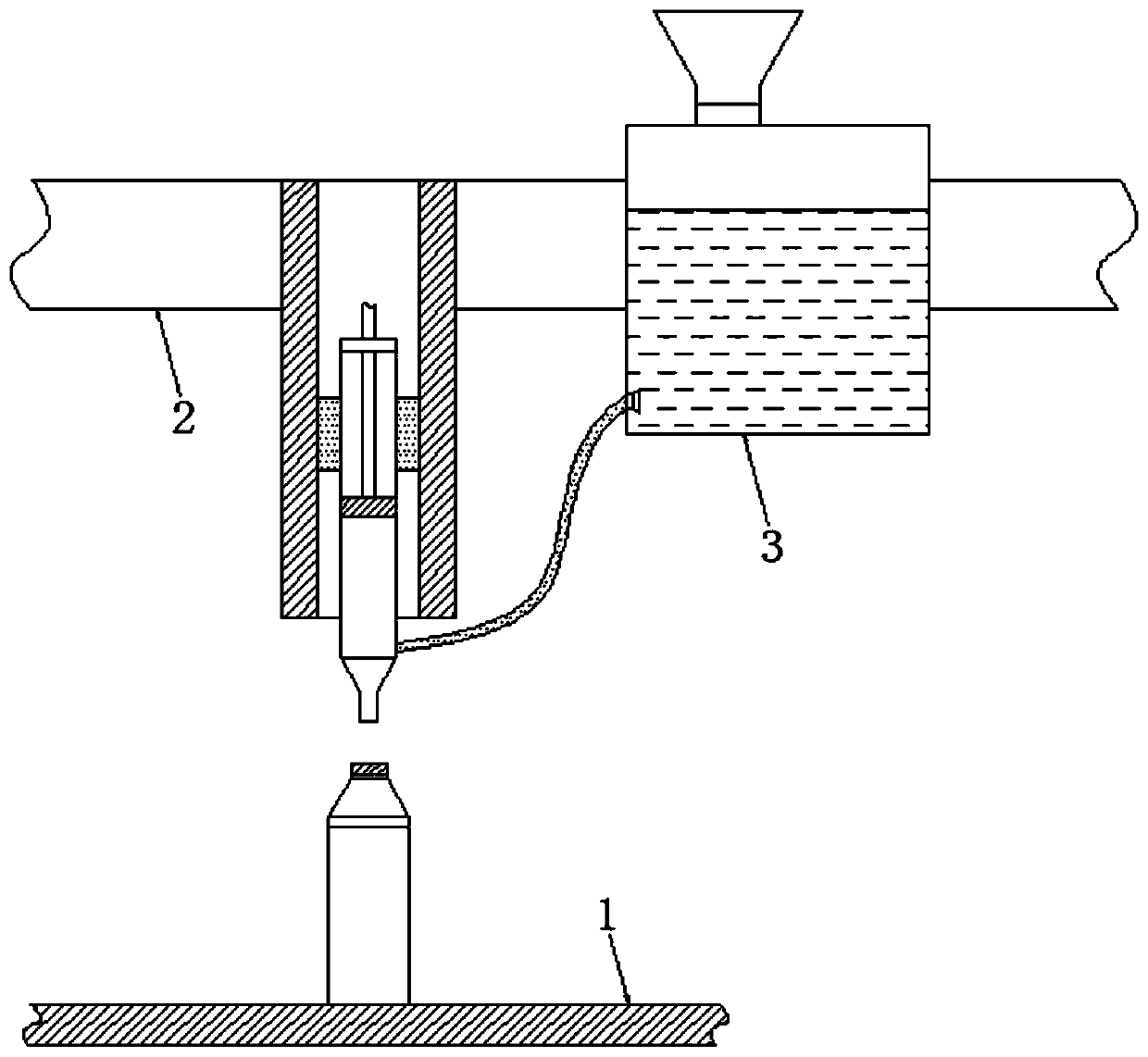

Full-automatic traditional Chinese medicine decoction preparation device

InactiveCN105342856AMeet the requirements of frying first and then servingReduce particulate matterPharmaceutical product form changeDomestic articlesMedicinal herbsMedicine

The invention relates to a full-automatic traditional Chinese medicine decoction preparation device which comprises more than one set of a medicine feeding and decocting device, a concentrating and condensing device, a packaging mechanism and a control system, wherein the medicine feeding and decocting device comprises a main medicine soaking tank, a subsequently-added medicine feeding tank, an extracting tank and a first condenser; and the main medicine soaking tank and the subsequently-added medicine feeding tank are arranged in parallel and are fixed above the extracting tank. The full-automatic traditional Chinese medicine decoction preparation device is provided with the main medicine soaking tank, the subsequently-added medicine feeding tank and the extracting tank, wherein the main medicine soaking tank is used for soaking the firstly-decocted medicines, the subsequently-added medicine feeding tank is used for containing the subsequently-added medicines or soaking the subsequently-added medicines, and the extracting tank is used for decocting, so that batched and staged feeding can be realized by combining the tanks, and the requirements of firstly decocting and then adding are met.

Owner:南京迦南众心和医药科技有限公司

Method for extracting tylosin by tylosin fermentation broth

ActiveCN102746354AComplete crystal formEfficient removalSugar derivativesSugar derivatives preparationSolubilityOrganic solvent

A method for extracting tylosin by tylosin fermentation broth is characterized by including steps of firstly pretreating the tylosin fermentation broth to obtain tylosin filtrate, then subjecting the tylosin filtrate to extracting, reextracting, decolorizing filtering, crystallizing, ageing, rinsing and vacuum drying to obtain the tylosin. The method is used for directly extracting the tylosin by the tylosin fermentation broth serving as raw materials, tylosin solubility of intermediates of the tylosin accords with quality standards of Chinese Veterinary Pharmacopoeia. The integral method is mild in production conditions, simple to operate, safe and reliable in preparation process and low in loss of organic solvent and has the advantages of energy conservation, consumption reduction, low production cost, high work efficiency and the like.

Owner:宁夏泰瑞制药股份有限公司

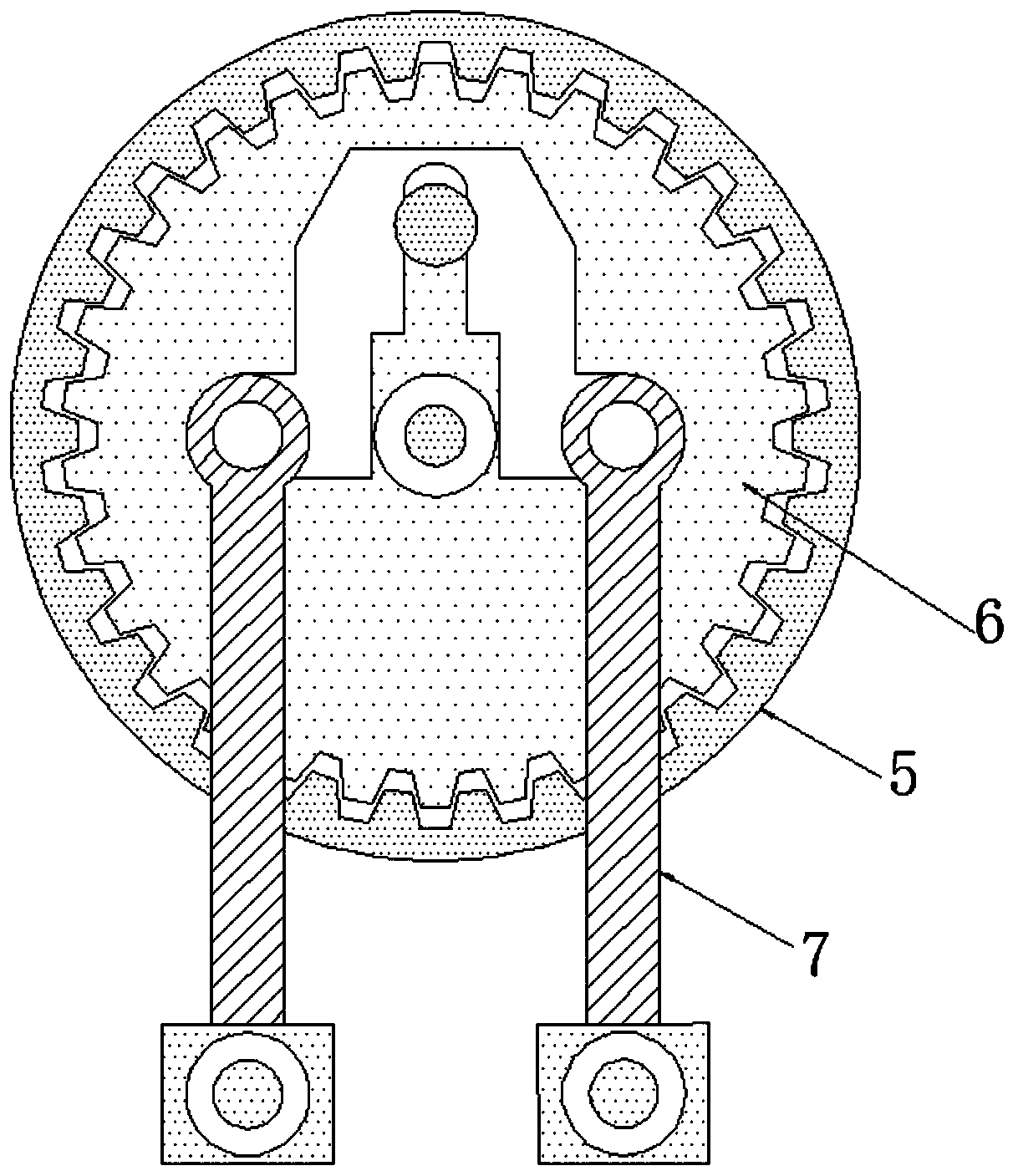

Product filling device suitable for different concentrations based on displacement differential motion principle

The invention relates to the technical field of kitchen utensils, and discloses a product filling device suitable for different concentrations based on the displacement differential motion principle.The product filling device comprises a supporting seat, and the upper portion of the supporting seat is movably connected with a cross rod. A filling barrel and a storage bin are supported, and the product filling device moves inwards to clamp a filling bottle; a bottle body is prevented from inclining or falling down in the filling process, and the stability of the bottle body is increased; and afirst rotary shaft rotates to drive a first gear to vibrate in a second gear, and therefore vibration of the filling bottle is driven, and it is avoided that bubbles are generated in the filling process, and consequently the product quality is influenced. By means of cooperative use of the filling barrel, a sliding plate, a push rod and a second rotary wheel, the filling barrel is driven to movedownwards into the filling bottle, so that filling is more precise, and raw materials are prevented from being spilled; the subsequent push rod moves downwards, and therefore filling is completed; anddue to the fact that the movement time of the push rod is kept consistent all the time, it is guaranteed that quantitative filing is completed.

Owner:蒋瑞雪

Device for unidirectional straight drawing forming of high-strength metal wire

The invention discloses a device for unidirectional straight drawing forming of a high-strength metal wire. The device comprises cone pulley sets composed of cone pulleys. A wire drawing mold box with a mounting base is arranged between the cone pulley sets. An embedded wire-drawing mold with an embedded wire-drawing axle hole is arranged on the mounting base. The central axis of the embedded wire-drawing axle hole is arranged horizontally. A wire passing groove is arranged on the mounting base. The lower part of the mounting base has inclined gradient the same as the cone pulley set gradient. A wire-pressing wire-passing pulley is arranged between the cone pulley sets at a wire-inlet end and the embedded wire-drawing axle hole. The inner tangent line of the wire-pressing wire-passing pulley, the side wall tangent lines of the cone pulleys and the central axis of the embedded wire-drawing axle hole are coincident. The cone pulley having the largest diameter in the cone pulley sets at a wire-outlet end is connected to a traction wheel by a metal wire rod. The device can reduce torsion deformation in a drawing process, reduce additional stress produced by non-uniform drawing, has a low sliding coefficient, can produce the high strength metal wire rod and is widely suitable for metal wire rod deep-processing equipment.

Owner:湖北三江航天江北机械工程有限公司

Fishy smell removing process for conditioned duck meat

The invention belongs to the field of food processing, and in particular relates to a fishy smell removing process for conditioned duck meat. The process adopts cooking wine, edible organic acid, ginger, onion, Chinese prickly ash and other materials as a blocker, and duck meat is processed by the blocker through a special process, so that the strong fishy smell in butchering and processing of ducks is solved, the bottleneck in production and sale of conditioned duck meat is eliminated, the consumers and sales range of products are enlarged, the output and sales volume of duck meat products are increased, and meanwhile the development of related industries of ducks can be greatly promoted.

Owner:张瑞菊

Shaping and pruning method for plum trees and apricot trees

ActiveCN111108949AIncrease productionSmall footprintCultivating equipmentsHorticulture methodsFruit treeAlcohol sugars

The invention relates to the technical field of fruit farming, in particular to a shaping and pruning method for plum trees and apricot trees. According to the shaping and pruning method for plum trees and apricot trees, the first year growth period: seedlings are planted in autumn or early spring, and primary main branches are cultivated; the first year dormancy period: secondary main branches are cultivated; the second year growth period: the secondary main branches are established; the second year dormancy period: lateral branches are cultivated; the third year growth period: the lateral branches are established; the third year dormancy period: fruiting branches are cultivated; overdense weak branches of the primary main branches, the secondary main branches and the lateral branches aresparsely separated from the base, leaving a short cut of 2-5 cm when over 1 / 2 of the thickness of a raw branch; in the fourth year of growth, potassium dihydrogen phosphate and sugar alcohol boron are sprayed once in June and July respectively to ensure flower buds differentiation in summer and fruit bearing in the next year; and in the fourth year of dormancy, tree shape is kept, and excessive branches and overdense branches disturbing the tree shape are removed to ensure that the thickness of branches is progressively reduced. The shaping and pruning method can make full use of cubical space, save land resources and prone to managing.

Owner:SICHUAN AAS HORTICULTURE RES INST

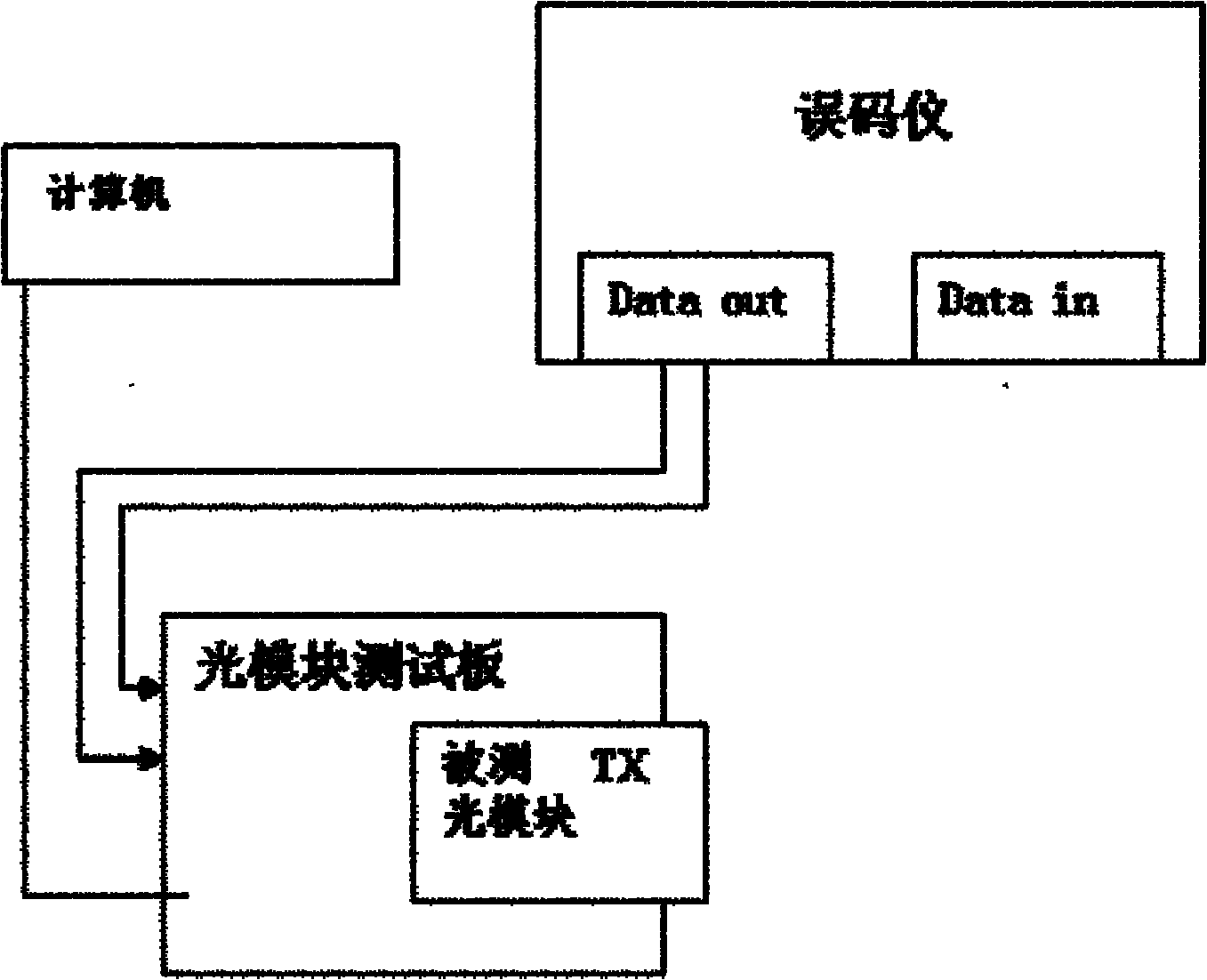

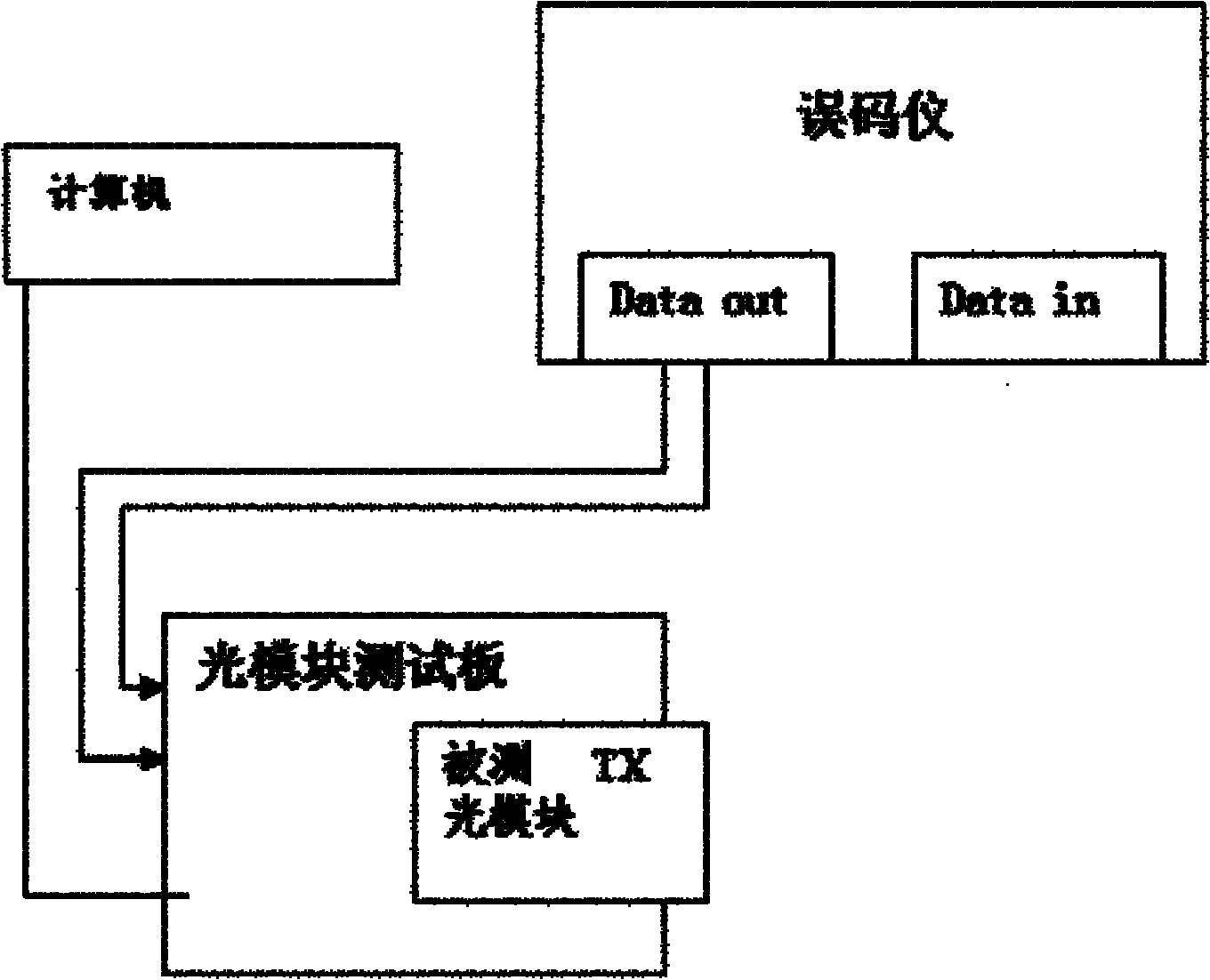

Automatic debugging method for optical eye diagram of optical module

InactiveCN102013624AAvoid quality impactReduce manufacturing costExcitation process/apparatusSemiconductor lasersPower flowOptical Module

The invention provides an automatic debugging method for an optical eye diagram of an optical module. In the method, threshold current of a laser is obtained firstly and bias current of the optical module is set as the sum of the threshold current and a balance coefficient by a computer, so that the optical eye diagram is debugged automatically without artificial debugging; and Compared with the prior art, the method can prevent the influence of subjective factors of human on quality, realize debugging without using expensive data analyzers and reduce production cost simultaneously.

Owner:JIANGSU ALLRAY

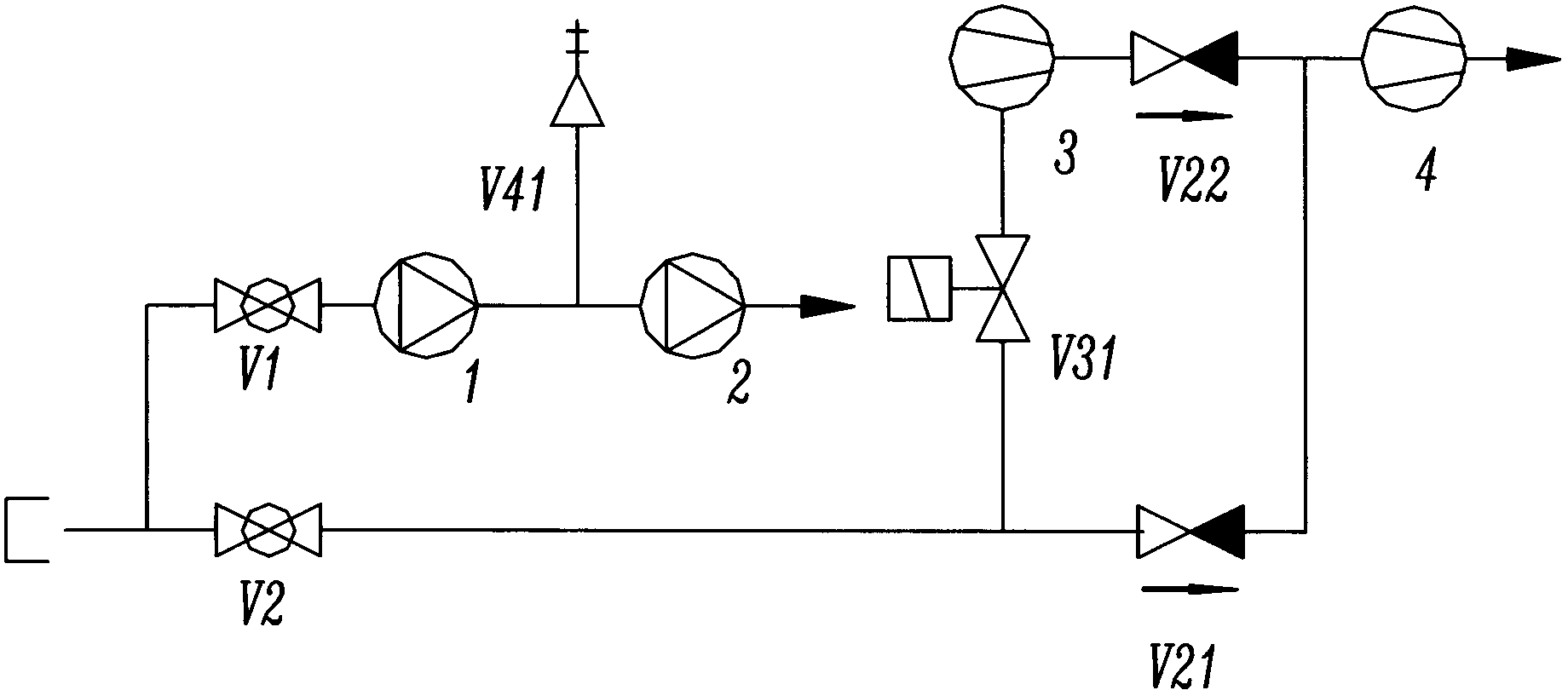

Whole-series oil-free SF6 gas recovering and filling device

The invention discloses a whole-series oil-free SF6 gas recovering and filling device. The whole-series oil-free SF6 gas recovering and filling device comprises a first vacuum pump, a second vacuum pump, a first ball valve, a second ball valve, a first check valve, a second check valve, a negative-pressure recycling machine, a compressor, an electromagnetic valve, a safety exhaust valve and pipelines, wherein an inlet of the first ball valve is connected with an inlet of the second ball valve, an outlet of the first ball valve is connected with the suction end of the first vacuum pump, an exhaust end of the first vacuum pump is connected with the suction end of the second vacuum pump, the inlet end of the safety exhaust valve is connected to the pipeline between the first vacuum pump and the second vacuum pump, the exhaust end of the second vacuum pump is open, an outlet of the second ball valve is connected to an inlet of the electromagnetic valve, an outlet of the electromagnetic valve is connected with the negative-pressure recycling machine through the pipeline, the negative-pressure recycling machine is connected with an inlet of the compressor through the second check valve and the pipeline, the inlet end of the first check valve is connected with the inlet pipeline of the electromagnetic valve, and the exhaust end of the first check valve is connected to the inlet pipeline of the compressor. The whole-series oil-free SF6 gas recovering and filling device has the advantages that SF6 gas is prevented from being in contact with oil, and the influence of the oil on the quality of the SF6 gas is avoided in theory.

Owner:SHAANXI GUANDI GENERAL ELECTRIC

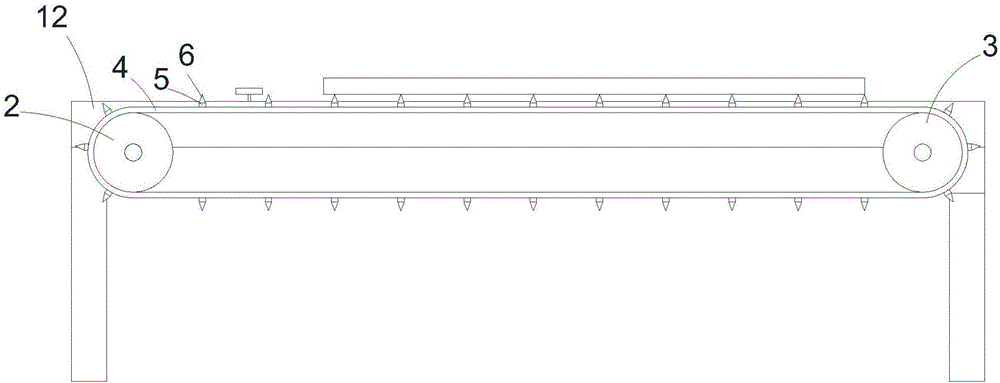

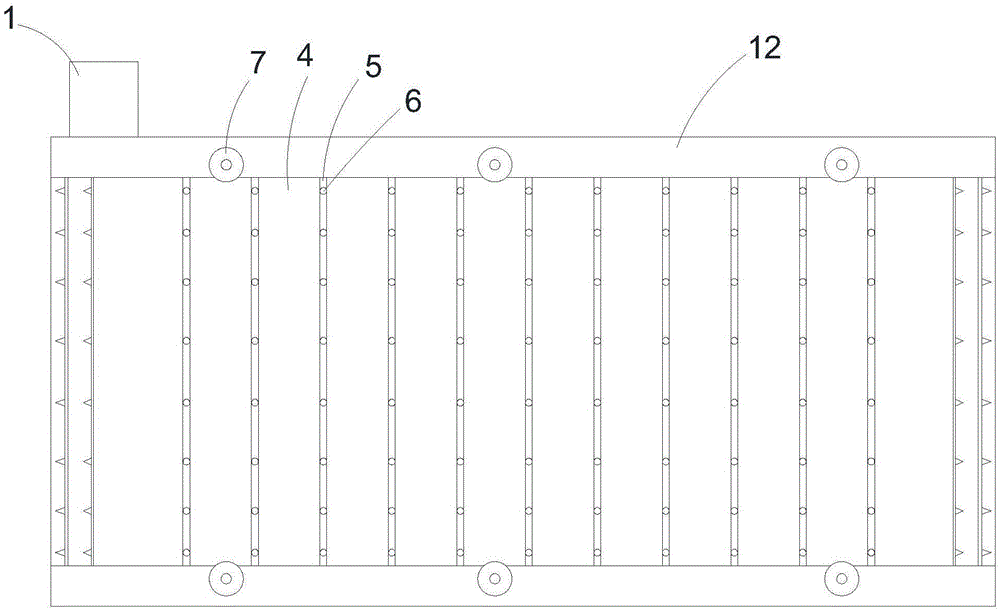

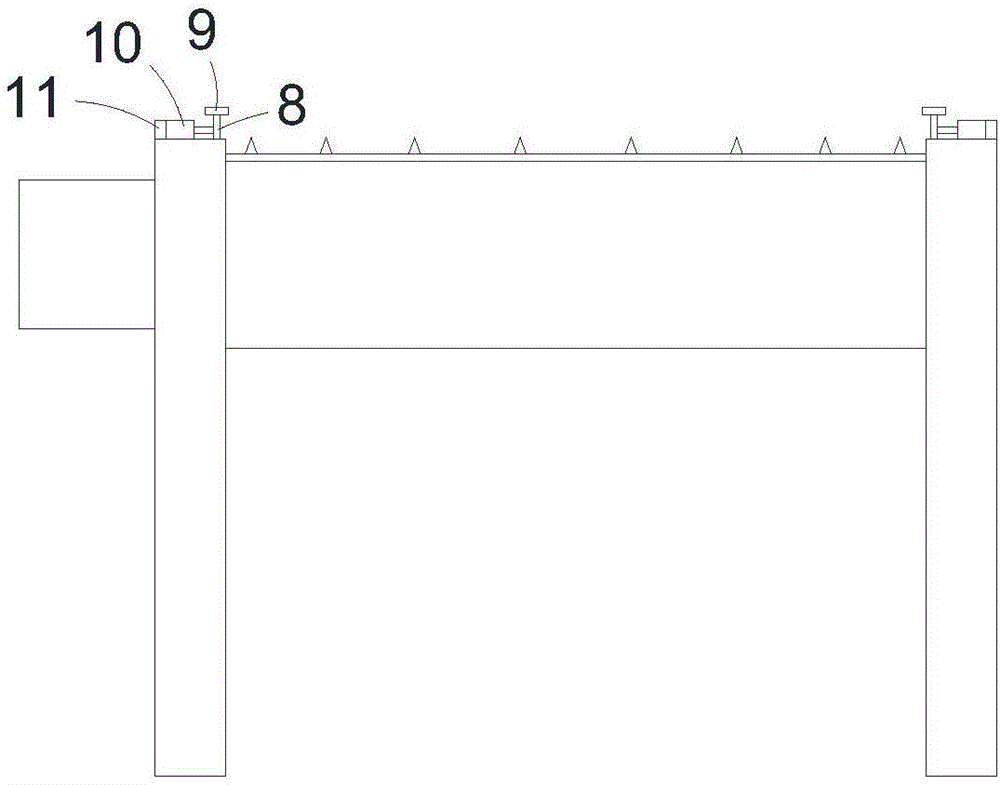

Glass substrate conveying mechanism

InactiveCN106743662AReduce contact areaReduce frictionConveyorsCharge manipulationEngineeringMechanical engineering

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com