Needle type locating adjustable hydraulic type clamp for machining of tenon of precisely forged blade

A blade mortise and hydraulic technology, which is applied in the field of needle-type positioning adjustable hydraulic fixtures, can solve problems affecting processing quality, safety production, blade quality, and processing accuracy, so as to avoid the impact of blade body quality and benefit Large-scale production and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

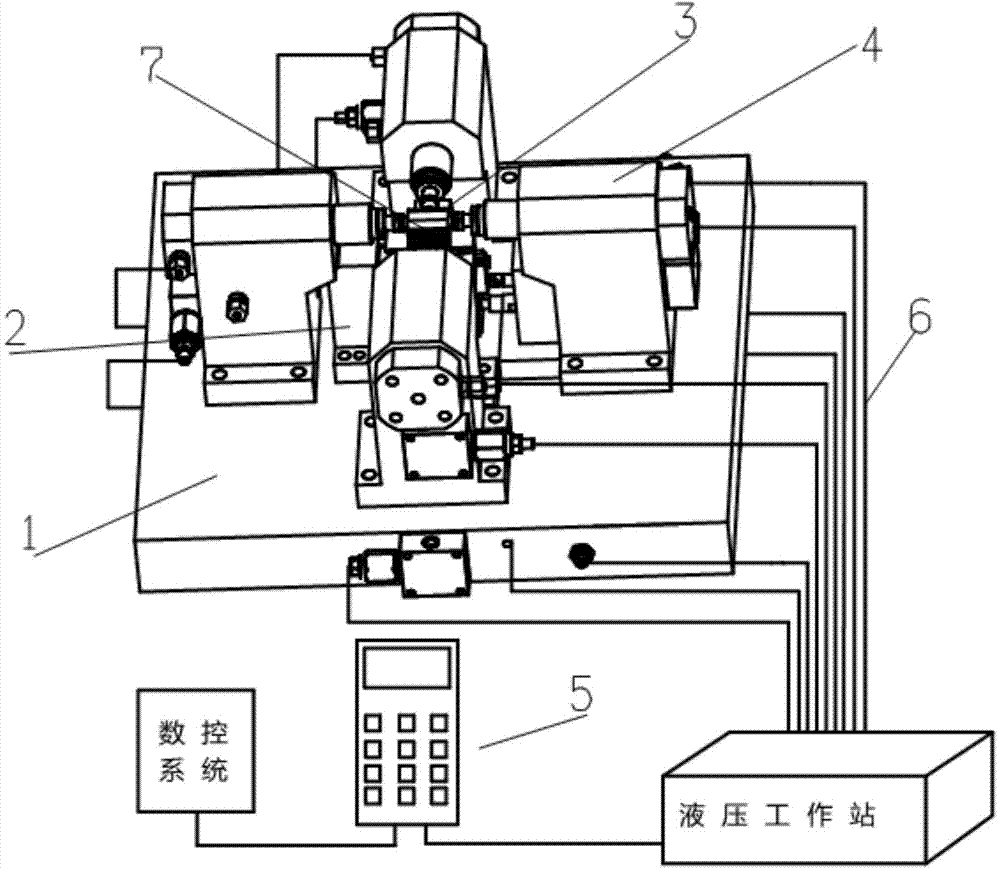

[0024] A needle-type positioning adjustable hydraulic clamp for precision forging blade tenon processing, including a mounting base 1, a positioning device 2, a clamping device 3, an auxiliary support device 4, a main controller 5 and a control circuit 6.

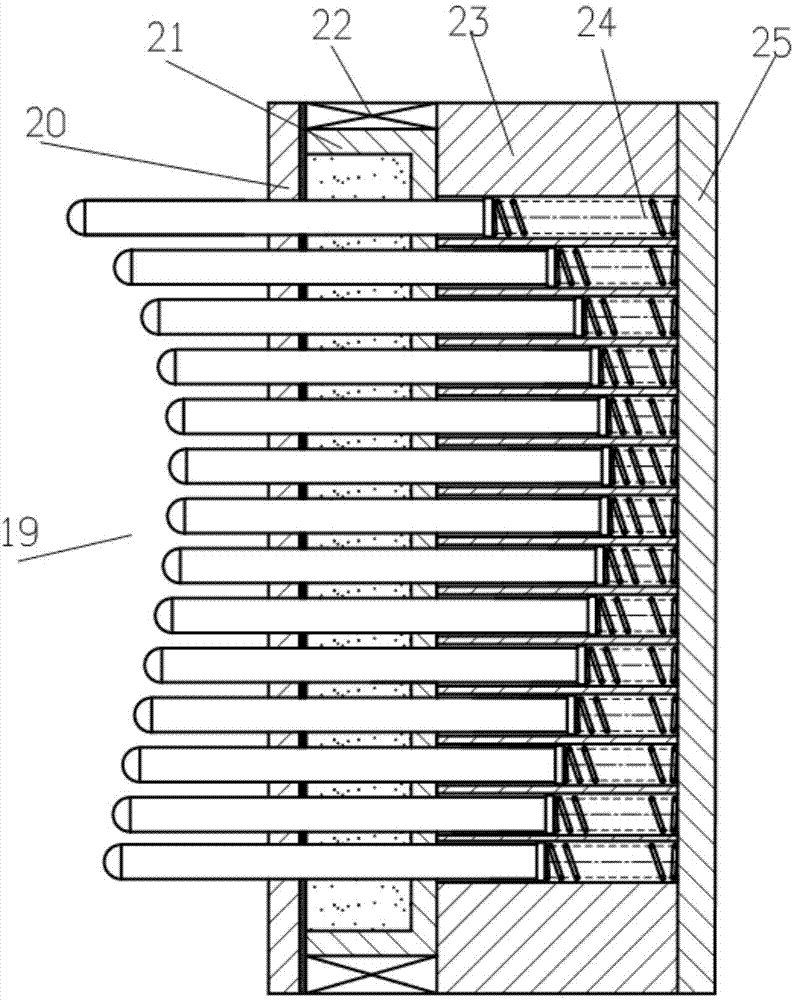

[0025] The positioning device 2 is used for positioning the blade body curved surface of the blade 7, including a thimble matrix positioning part 8, two positioning pins 9 and a positioning block 10, wherein the thimble matrix positioning part 8 is fixed on the installation base 1 and is in contact with the blade body of the blade 7 , the positioning pin 9 is fixed on the installation base 1 and is in contact with the air intake edge of the blade 7 , and the positioning block 10 is fixed on the upper end of the thimble matrix positioning member 8 and is in contact with the inner side of the blade root of the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com