Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

229results about How to "Avoid flaws" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing nano fiber endless tow

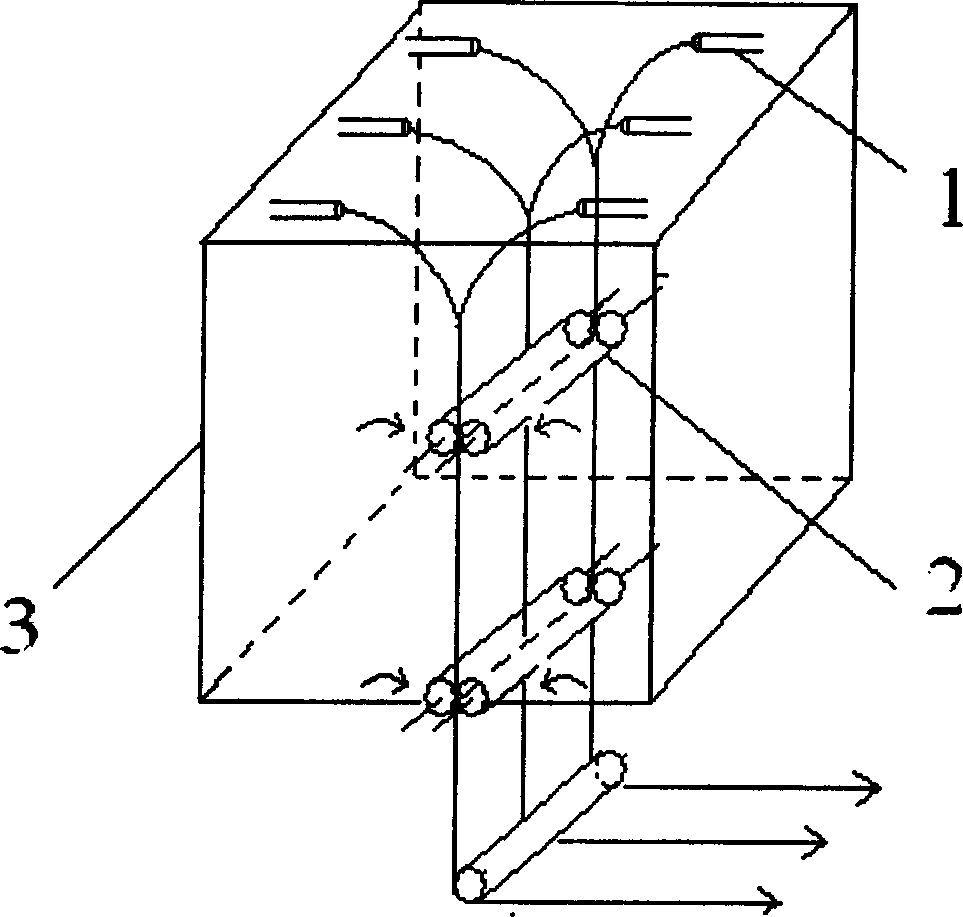

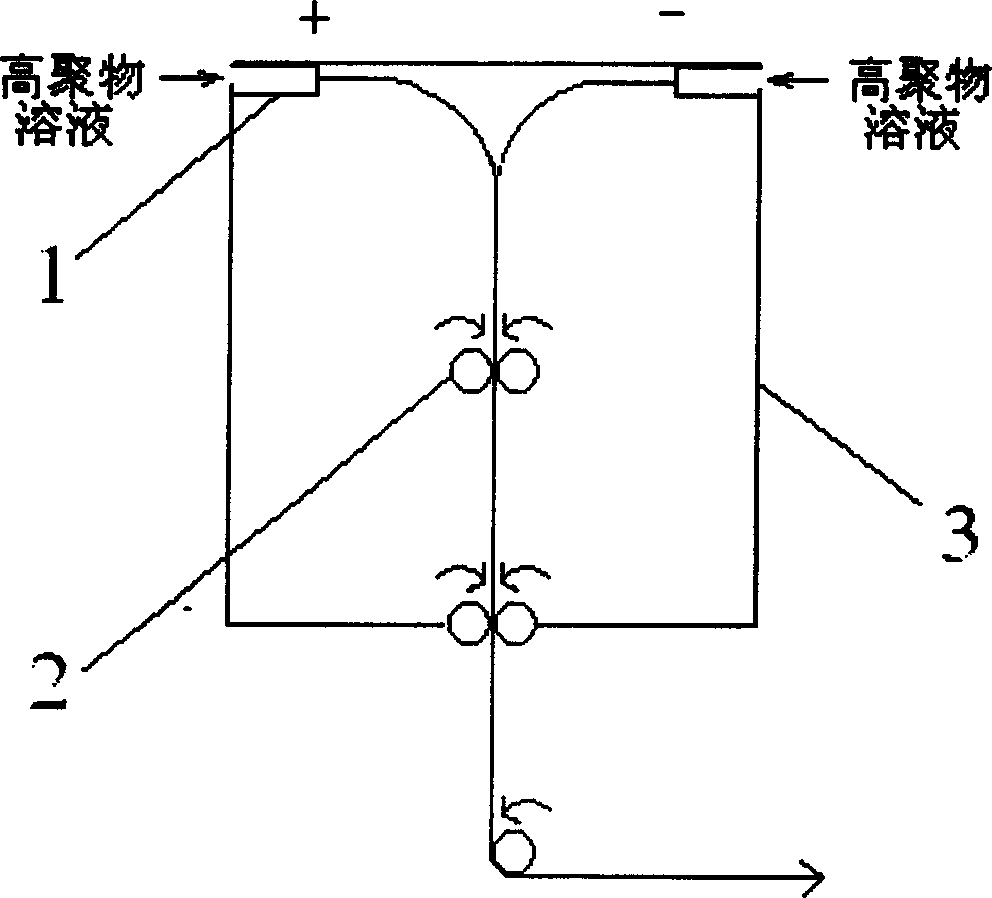

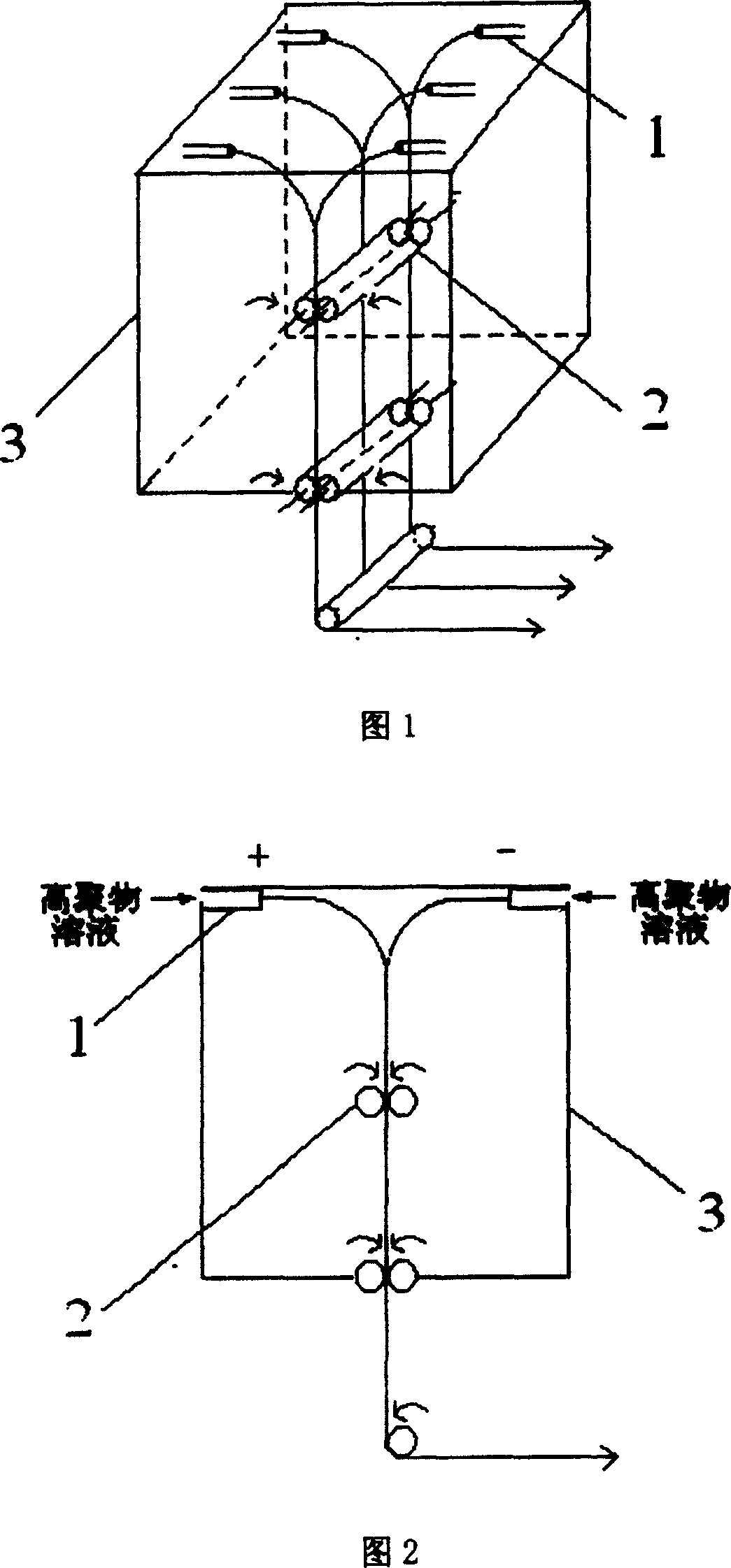

The production method of filament of nanofibers is a simply and high efficiency way. It adopts spinning trunk (3). There are two lines of nozzles (1) whose spout are opposite at the height of the top of the trunk. There are several group of pare of thread guide roller (2) in the trunk.. The distance between thread guide roller and nozzles are equal. The material process is: 1) Transport high polymer solution to nozzles in the trunk of filament of nanofibers; 2) Bring high-voltage DC of opposite polarity to bear to the nozzles. 3) High polymer solution at the top of the nozzles is stretched and whipping responded to form nanofibers which contain electric charge. The opposite nozzle spray nanofibers contains contrary electric charge. They are allure and collide in the air and form nanofibers. The nanofibers are stretched and towed by nozzle and filament of nanofibers comes into being. The operation is simple, highly effective and has no losing of nanofibers.

Owner:SOUTHEAST UNIV

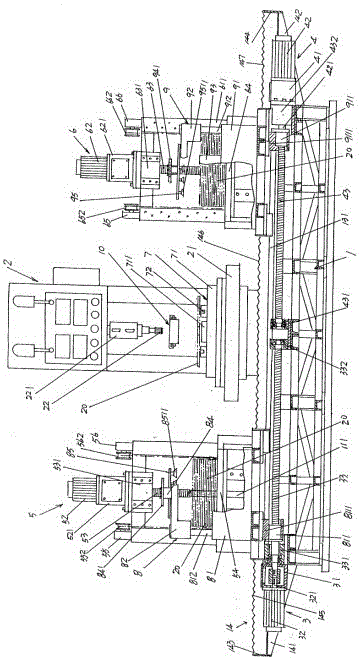

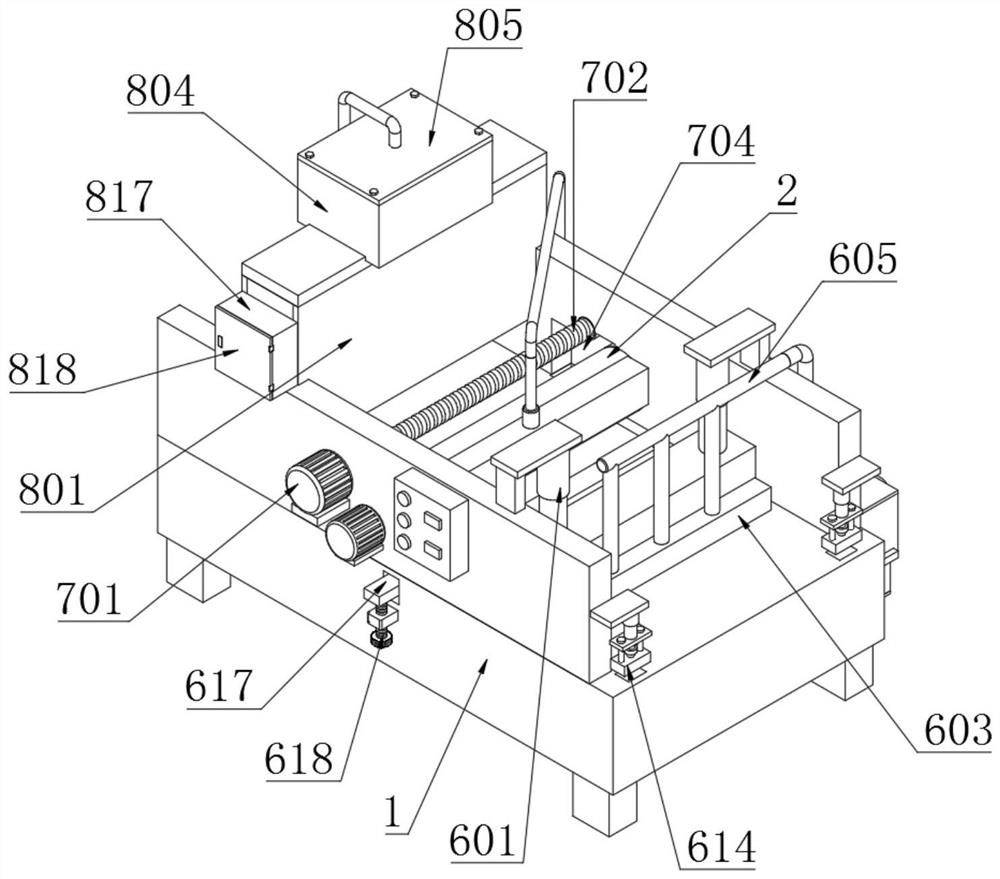

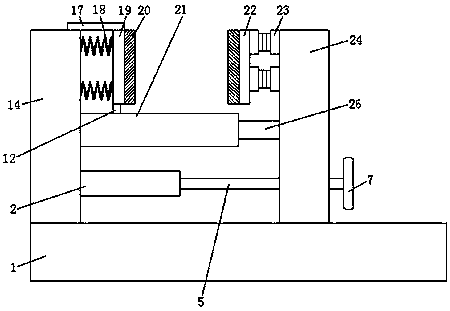

Glass container fire polishing machine

The invention relates to the technical field of glass processing, and especially relates to a glass container fire polishing machine, which solves technical problems in prior arts such as unreasonable design. The fire polishing machine comprises a frame, and a glass container conveyer belt arranged above the frame. The fire polishing machine is characterized in that: plural sets of fire polishing mechanism are arranged on the frame, wherein the fire polishing mechanisms are orderly arranged along the conveyer belt; each fire polishing mechanism is connected to the frame through an adjustable movable mechanism; the fire polishing mechanisms can move along the conveyer belt with the driving of the adjustable movable mechanism; while moving along the conveyer belt, the fire polishing mechanisms can be elevated in a vertical direction with the adjustable movable mechanism. Compared to prior arts, the glass container fire polishing machine has advantages of reasonable design, simple structure, high heat treatment temperature, and high speed. Meanwhile, flaws appeared during glass bottle production processes can also be solved by the machine. The processed glass containers have good surface fineness, no dust, and basically no pollution.

Owner:HANGZHOU ZHENHUA COSMETIC GLASS

Cutting dust suction apparatus and cutting method

InactiveCN103739191AProtection patternAvoid Product DefectsGlass severing apparatusEngineeringCutting glass

The invention discloses a cutting dust suction apparatus, which is arranged on a cutting machine and comprises the cutting machine and a dust suction device, wherein the dust suction device comprises a plurality of dust suction pipelines, the dust suction pipelines are positioned on the outer periphery of the cutting machine, one end of each dust suction pipeline is a dust suction port, the other end is a gas source port, the dust suction ports of the dust suction pipelines are positioned around the bottom of the cutting machine, and the dust suction pipelines suck debris generated during cutting through the dust suction ports during glass cutting. The invention further provides a cutting method of the cutting dust suction apparatus, wherein the method can be used for cutting thin glass substrates, the mechanical cutting machine is adopted, and the dust suction pipelines suck debris generated during cutting through the dust suction ports during glass cutting.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

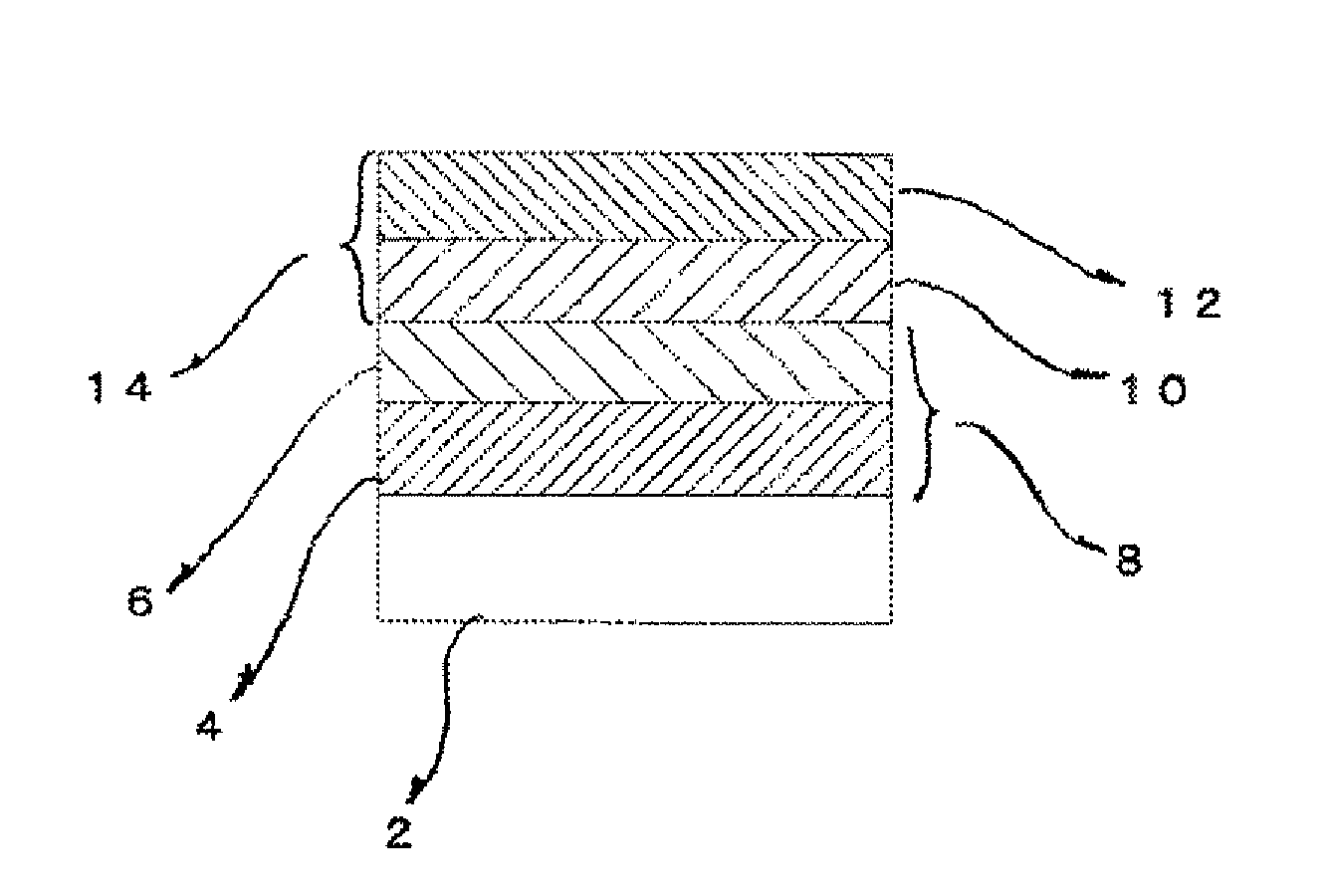

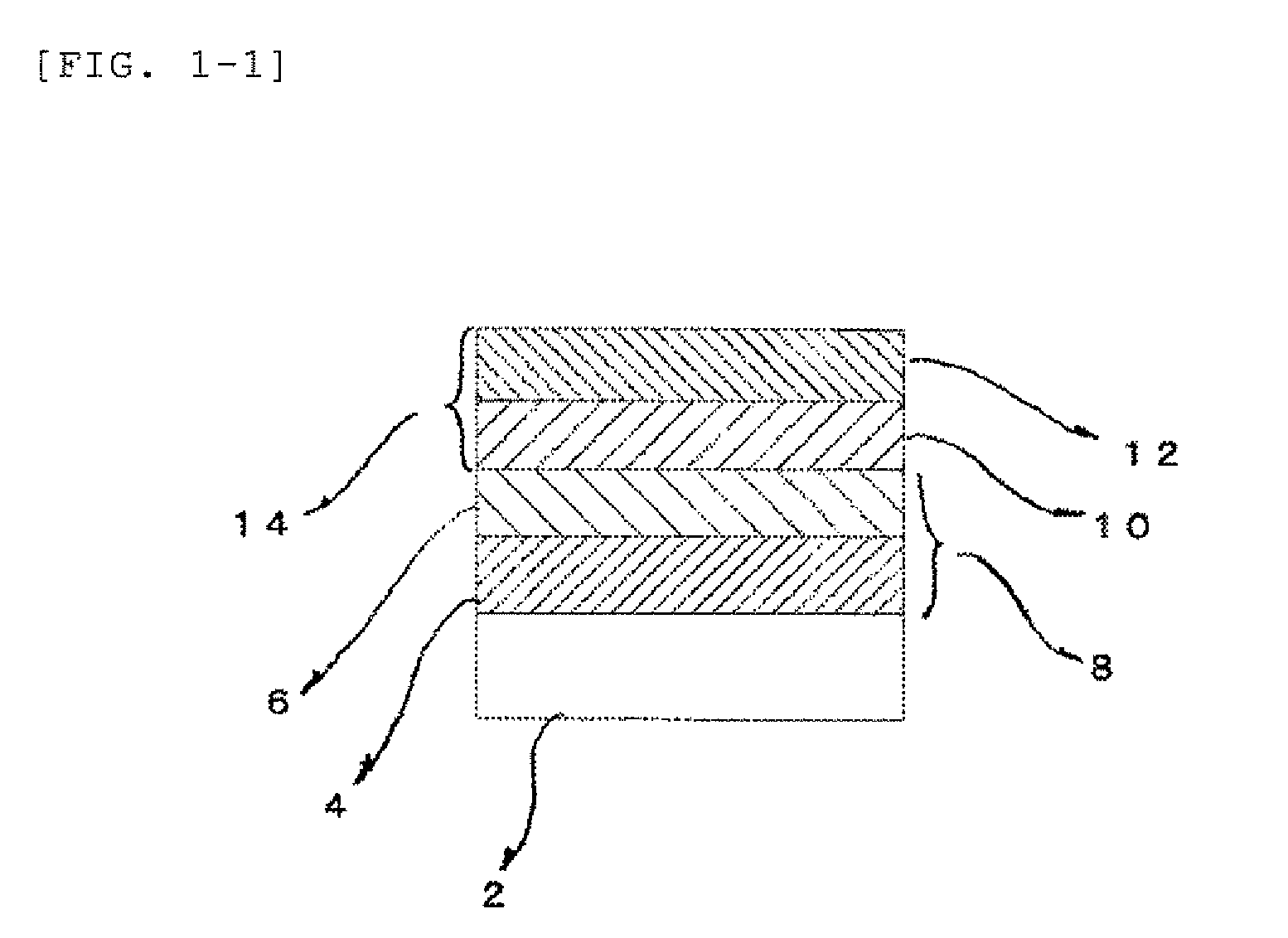

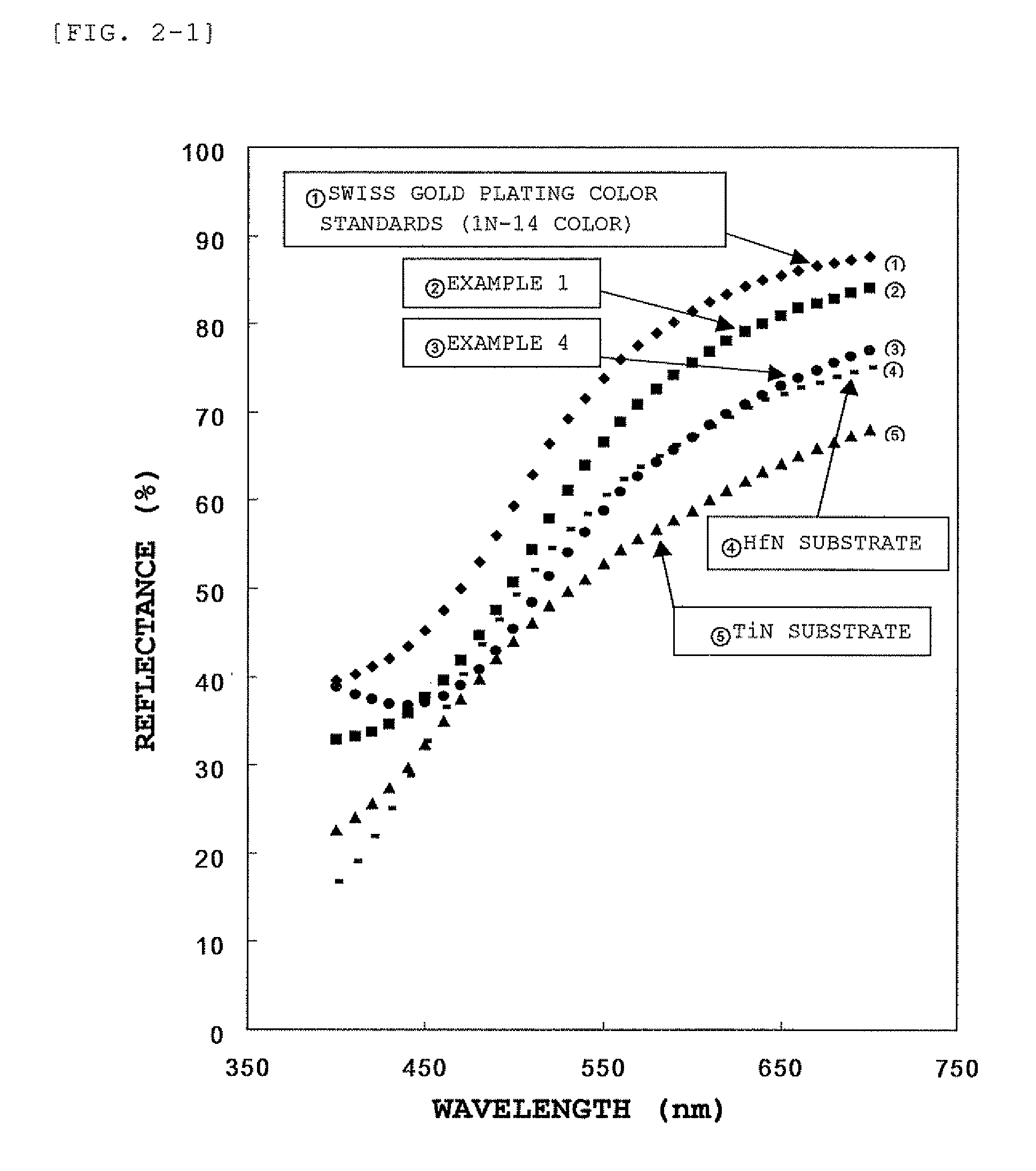

Decorative part and process for producing the same

ActiveUS8178222B2Efficiently provideSuppress visibilityVacuum evaporation coatingSputtering coatingTitaniumHafnium

A decorative part and a process for producing the decorative part. A first nitride layer containing at least one metal selected among hafnium, titanium, and zirconium is formed on the surface of a decorative part comprising a soft base made of a material selected among stainless steel, titanium and titanium alloys, brass, etc., and a second nitride layer containing at least one metal which is selected among hafnium, titanium, and zirconium and is different from that in the first nitride layer is formed on the first nitride layer to thereby form a primer layer. A multilayered hardened layer including a gold alloy layer is further formed as a finish layer on the primer layer.

Owner:CITIZEN WATCH CO LTD

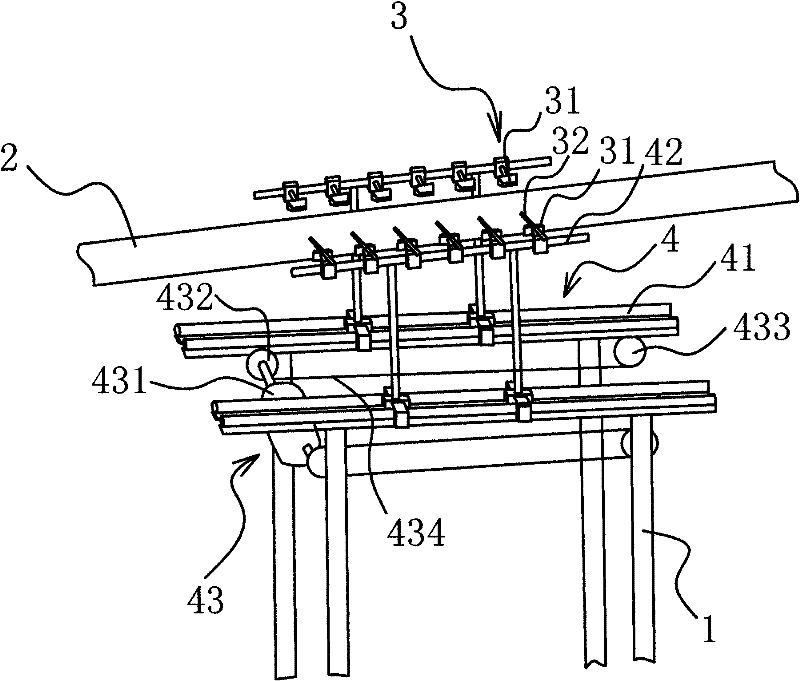

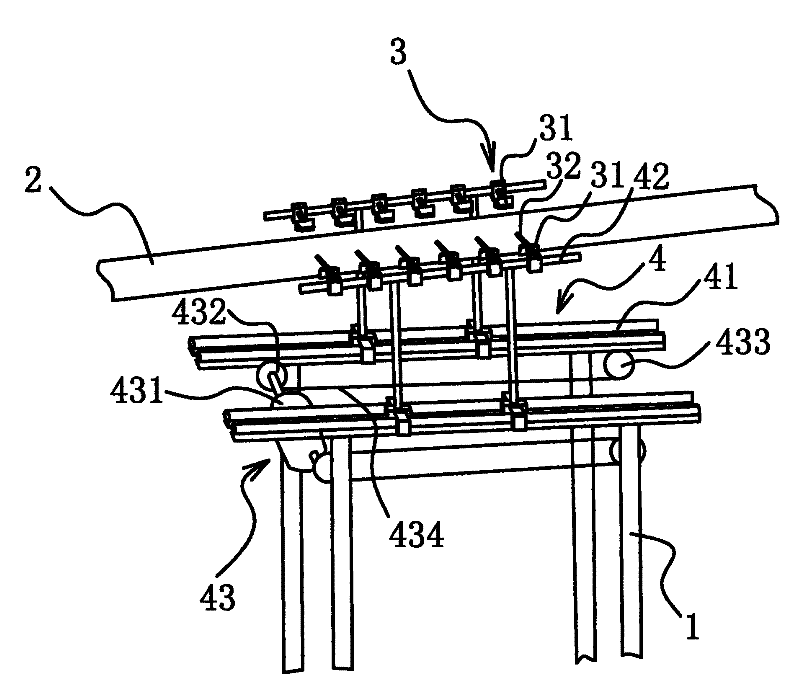

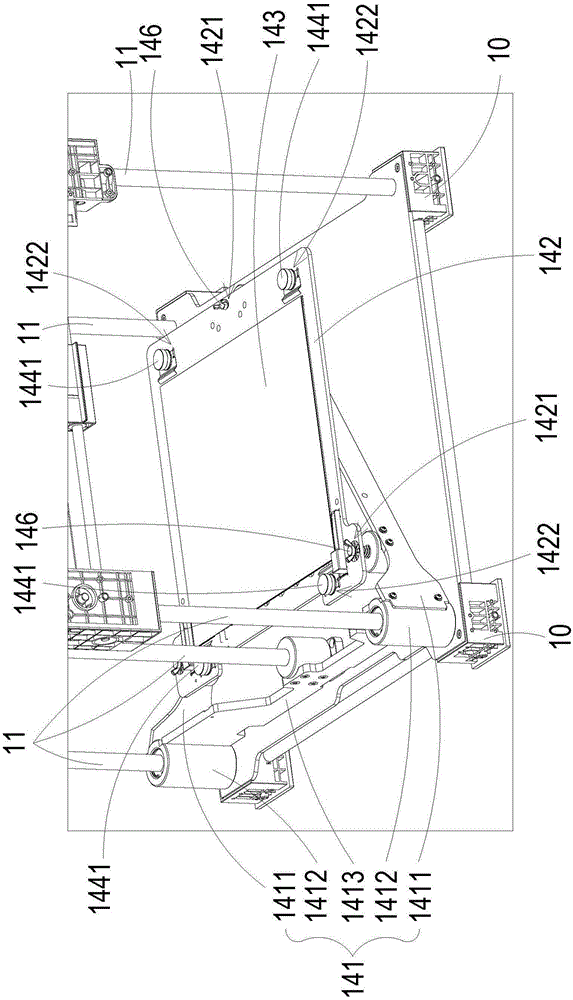

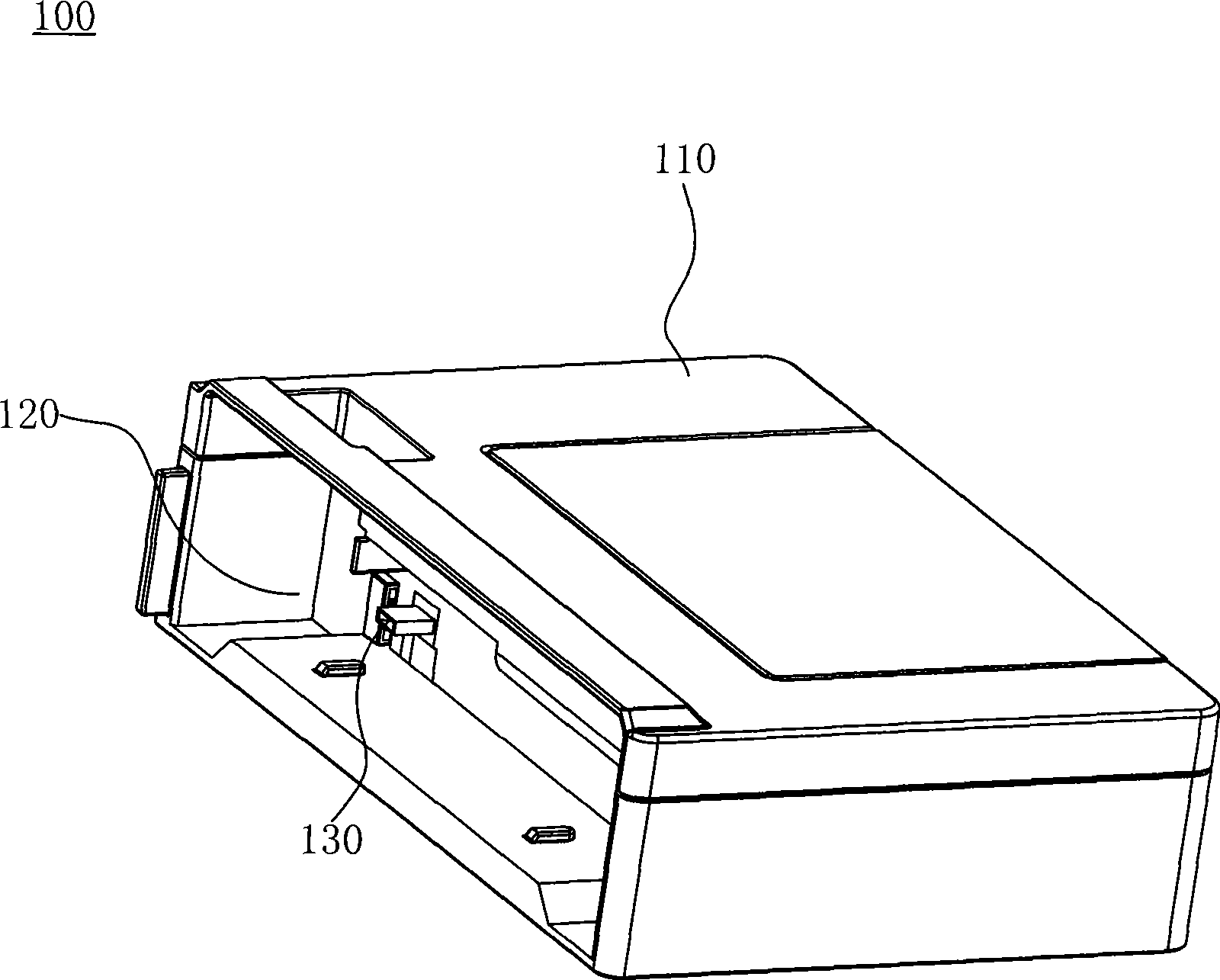

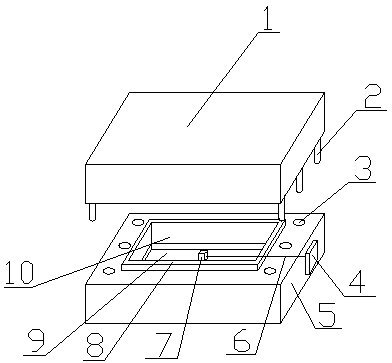

Supporting module for printing platform, and three-dimensional printer

ActiveCN106696294AEfficient print jobsAvoid flawsAdditive manufacturing apparatusComputer moduleEngineering

The invention relates to a supporting module for a printing platform, and a three-dimensional printer to which the supporting module is applicable. The supporting module for the printing platform comprises a bracing frame for the printing platform, the printing platform, a heating assembly, an adjusting module and a flat printing plate, wherein the printing platform is fixedly arranged on the bracing frame for the printing platform; the heating assembly is mounted on the printing platform; the adjusting module is installed on the printing platform and comprises a plurality of locking units; the flat printing plate is provided with a working surface and a setting surface arranged in a face-to-face manner; the setting surface butts against the heating assembly; and the flat printing plate is detachably arranged on the printing platform via locking and unlocking operations of the plurality of locking units. According to the invention, the detachable flat printing plate and a related fixing structure are additionally installed to overcome the problem that needs a great amount of time is needed in taking-out of a finished printed product, cleaning of the printing platform or replacing of an attached film during operation of a conventional three-dimensional printer, and printing of a next model can be efficiently carried out.

Owner:TECO IMAGE SYST

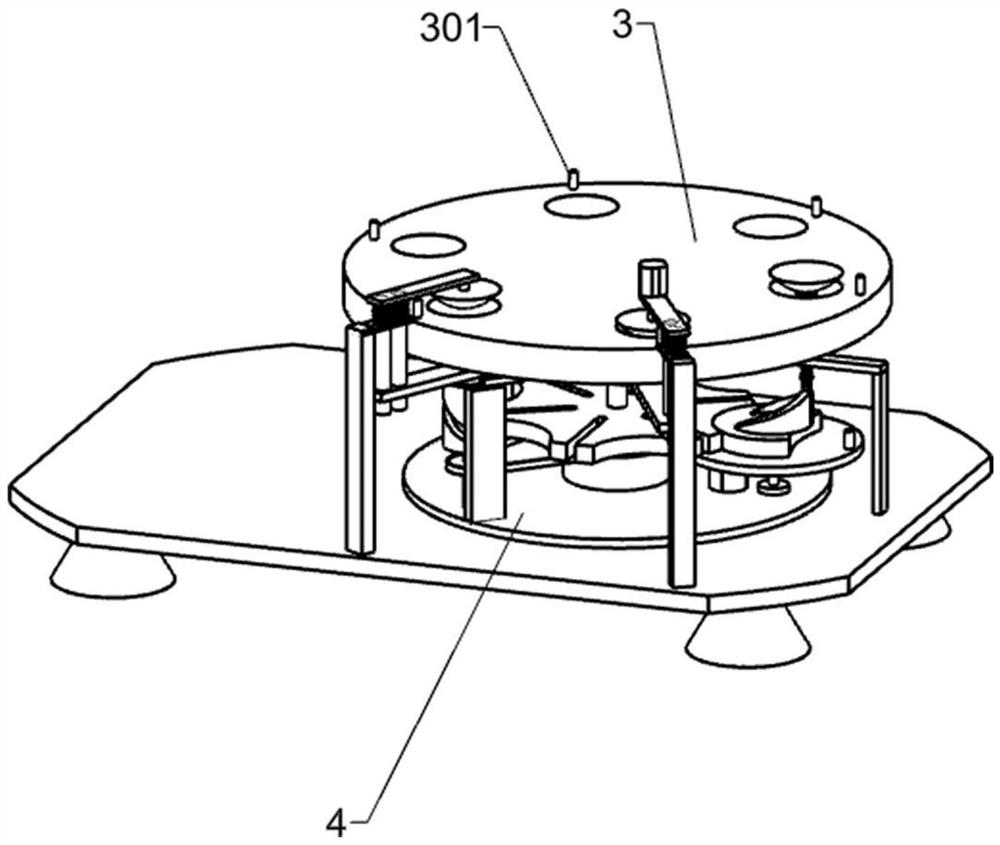

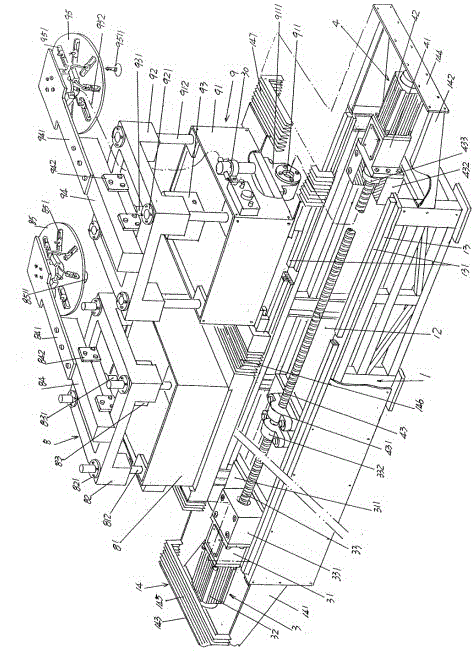

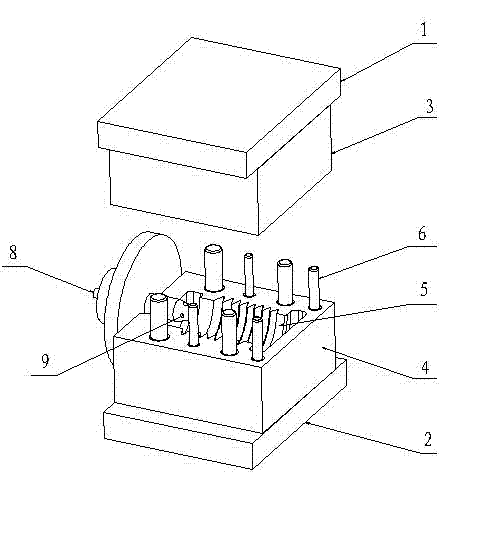

Automatic ceramic bowl blank forming machine

InactiveCN112060306AAvoid flawsQuality assuranceDischarging arrangementCeramic shaping plantsBatch productionManufacturing engineering

The invention relates to a forming machine, in particular to an automatic ceramic bowl blank forming machine. The technical problem to be solved is to provide a universally-applicable automatic ceramic bowl blank forming machine which improves the production efficiency and can realize batch production while ensuring the certain production quality. The automatic ceramic bowl blank forming machine is characterized in that the automatic ceramic bowl blank forming machine comprises a bottom plate, supporting blocks, a workbench, blocking columns, a first supporting plate, a supporting column, an intermittent mechanism, a forming mechanism, an edge scraping mechanism, an ejection mechanism, a mold feeding-in mechanism and the like, wherein the multiple supporting blocks are distributed on one side of the bottom plate in an array mode, the first supporting plate is fixedly connected to the side, away from the supporting blocks, of the bottom plate, a first supporting table is fixedly connected to the first supporting plate, and the supporting column is rotatably connected to the first supporting table. The automatic ceramic bowl blank forming machine structurally adopts bowl-shaped moldblocks, uniform specifications are provided for the bowl shape, and the automatic ceramic bowl blank forming machine can be universally suitable for bowl making devices.

Owner:王艳伟

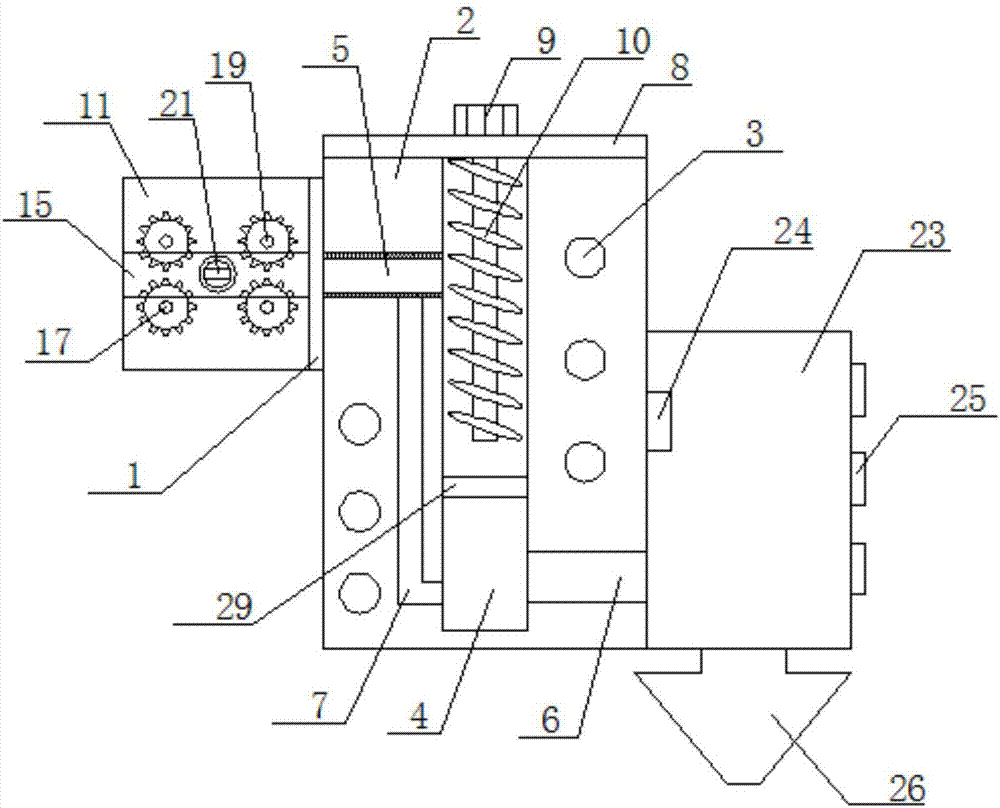

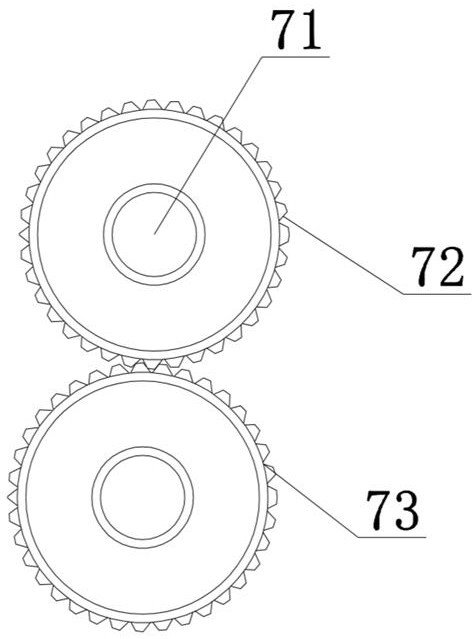

3D printing nozzle with raw material full melting function

InactiveCN107471626AIngenious designHigh feasibility3D object support structuresManufacturing data aquisition/processingSpray nozzleThermal insulation

The invention relates to a 3D printing nozzle with the function of fully melting raw materials, including a feeding mechanism, a heating mechanism and a discharging mechanism. The heating mechanism includes a main body, a stirring assembly arranged on the main body, and several first heaters. It has a mixing chamber, a feeding pipe, a discharging pipe and an overflow prevention pipe. The stirring assembly includes a heat shield, a first motor and a screw. The feeding mechanism includes a feeding plate and a first conveying assembly set on the feeding plate, a cutting component, and the second conveying component, in the 3D printing nozzle with the function of fully melting the raw material, the feeding mechanism uses two sets of gears to assist feeding, and a blade for cutting the raw material wire is installed between the two sets of gears, which can prevent heat transfer. The heating mechanism can fully melt the incoming raw materials and store them in the storage room of the feeding and discharging mechanism. The nozzle converts the existing real-time feeding into intermittent feeding, preventing the printing from being flawed due to unmelted materials, and preventing Nozzle is blocked.

Owner:葛顺英

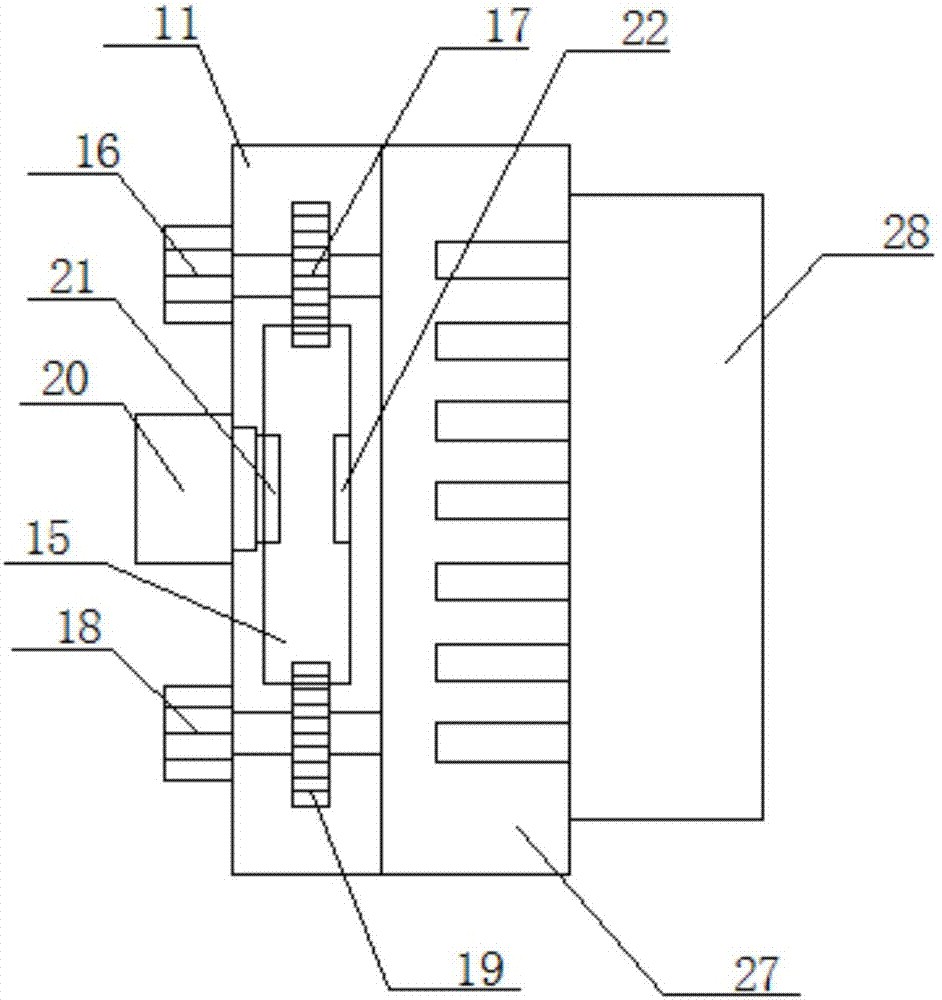

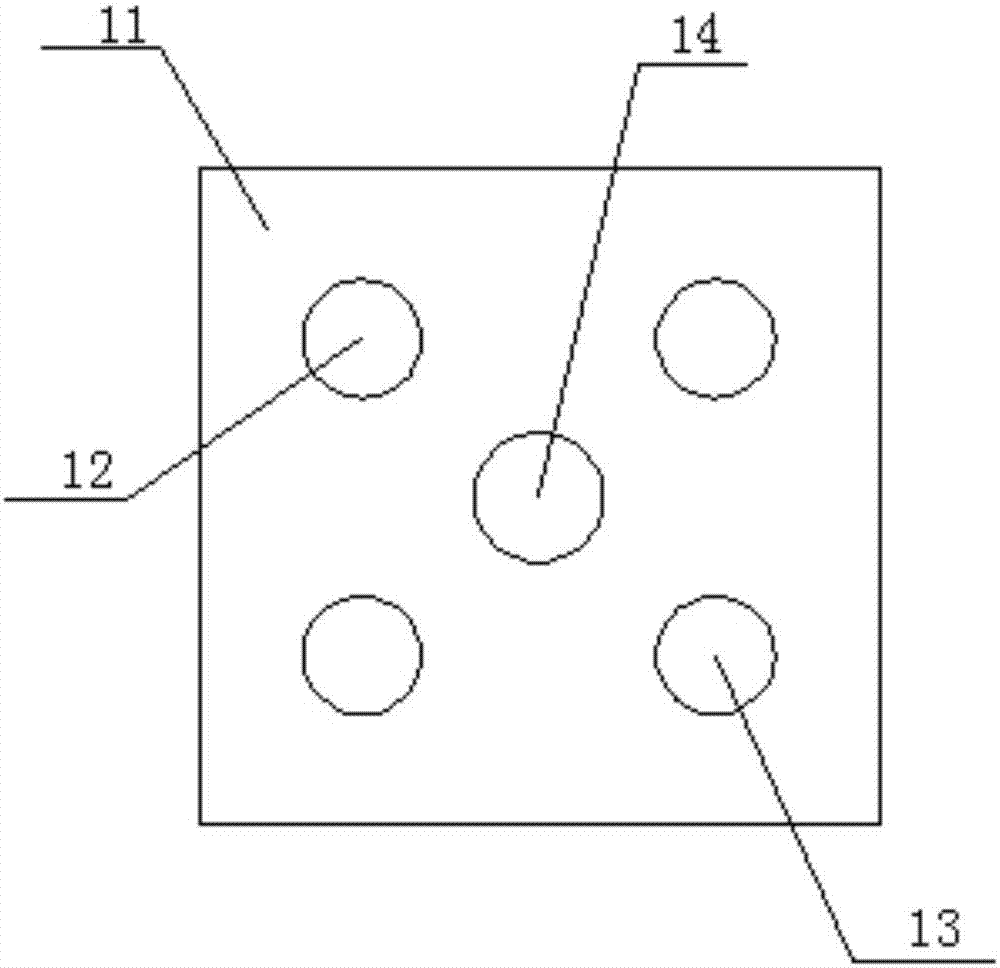

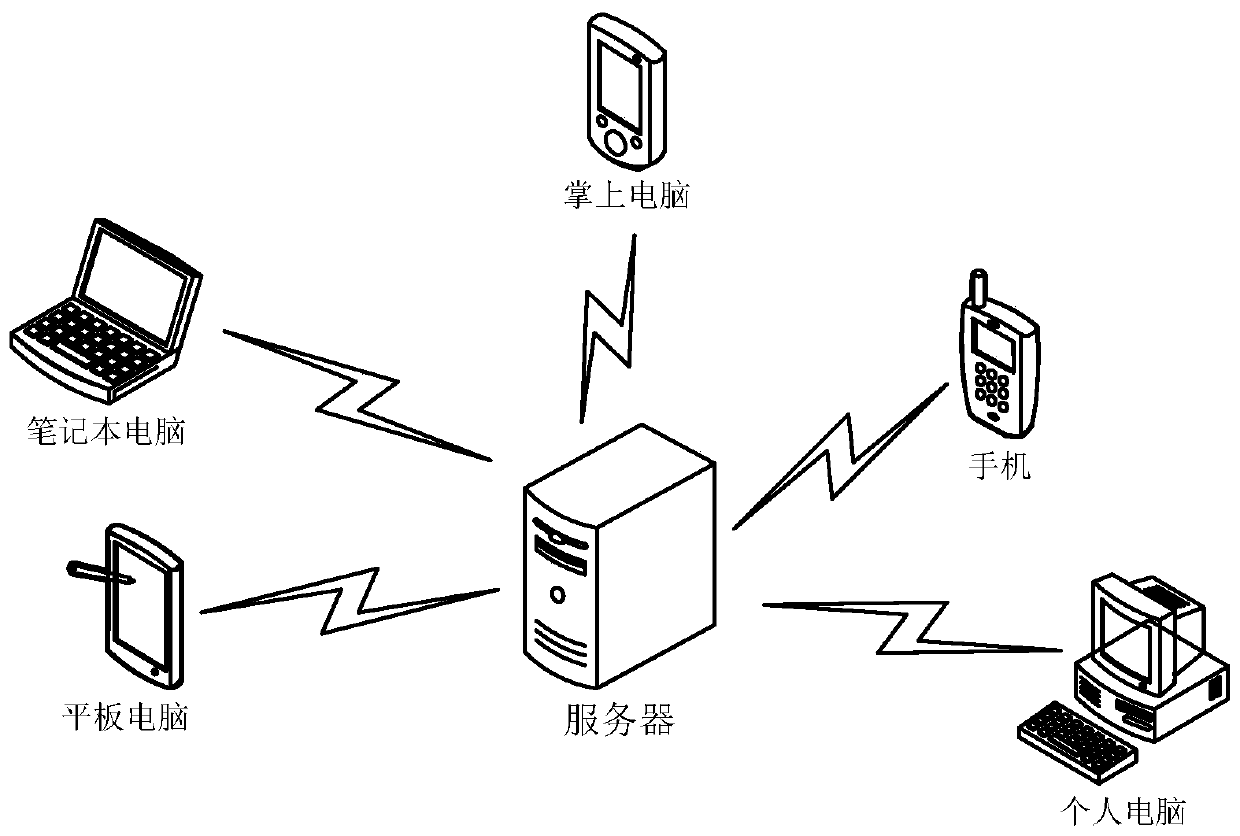

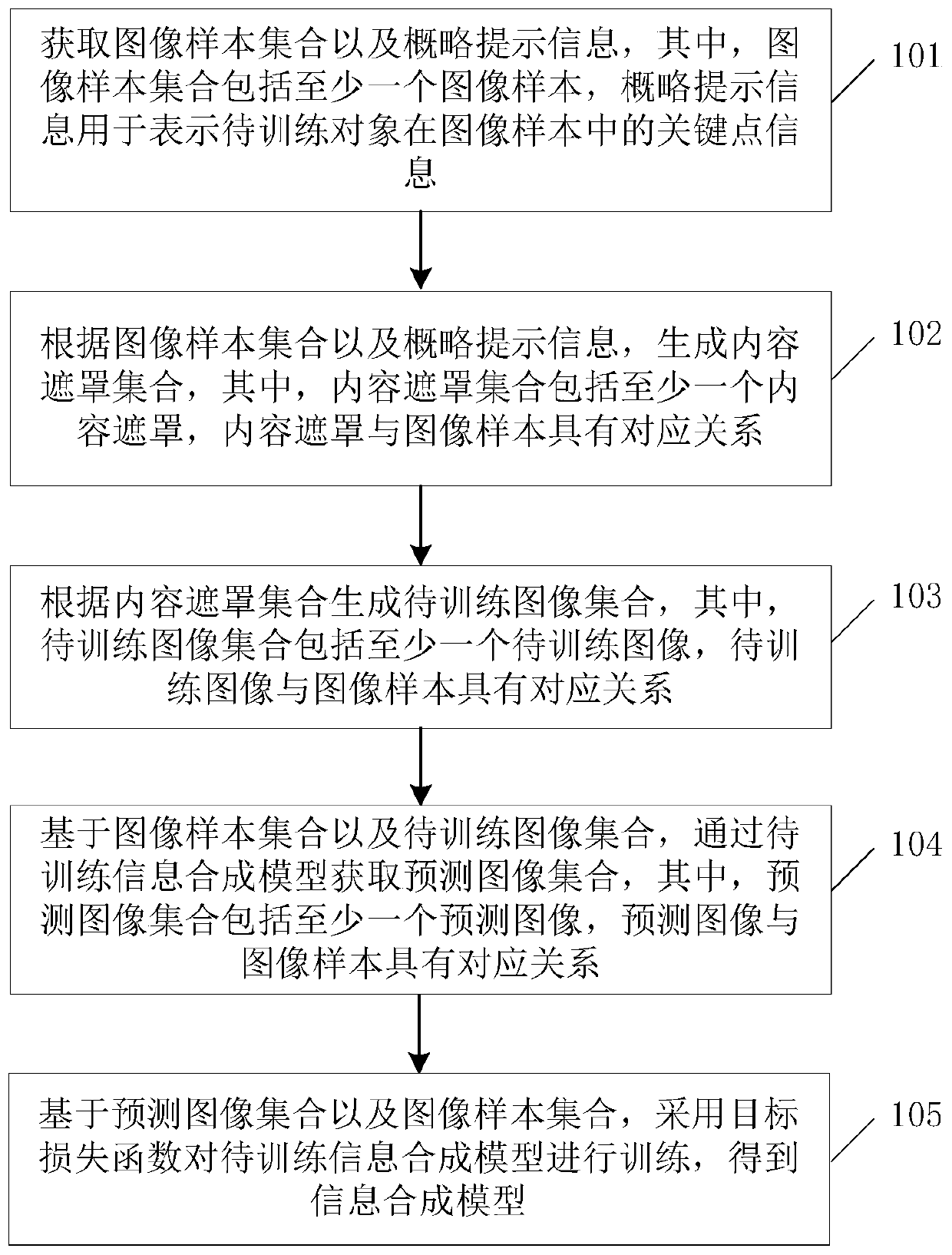

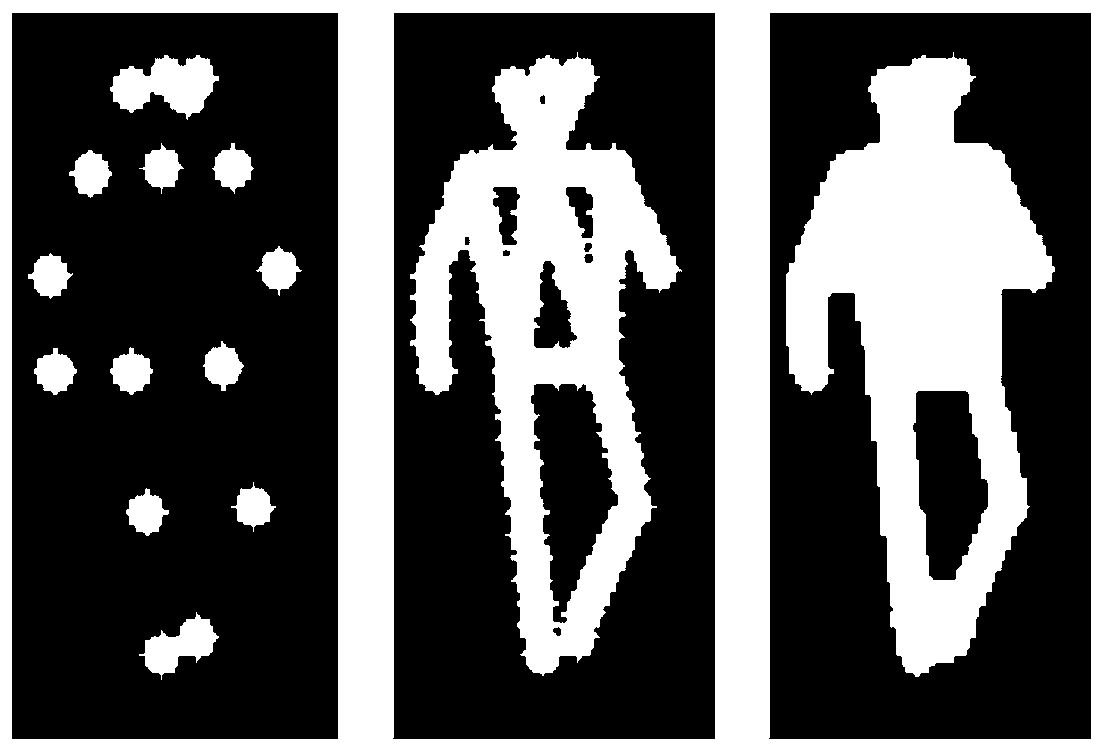

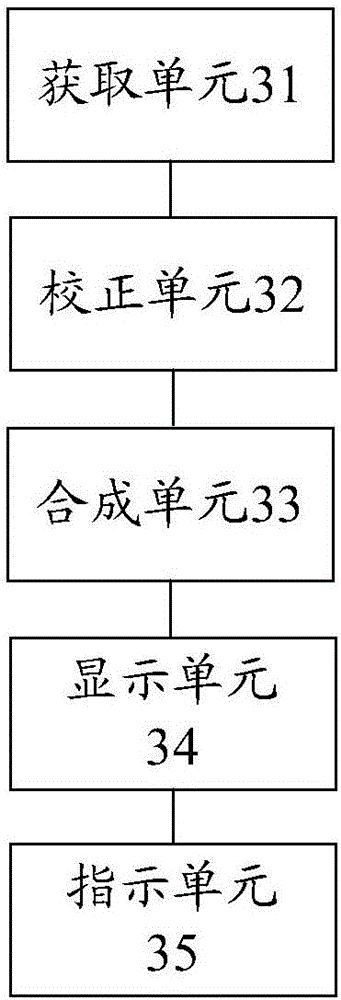

Model training method and media information synthesis method and device

ActiveCN110852942AIncrease authenticityAvoid flawsGeometric image transformationCharacter and pattern recognitionPattern recognitionMediaFLO

The invention discloses a model training method and a media information synthesis method and device, a to-be-trained image can be generated by using a content mask, and the coverage range of the content mask is greater than the range of a to-be-trained object, so that a part between the image content and the background can be generated by an information synthesis model, and the authenticity of a synthesized video is improved. The method provided by the invention comprises the following steps: acquiring an image sample set and general prompt information, obtaining an image sample set accordingto the image sample set and general prompt information; and generating a content mask set, generating a to-be-trained image set according to the content mask set, obtaining a prediction image set through the to-be-trained information synthesis model based on the image sample set and the to-be-trained image set, and training the to-be-trained information synthesis model by adopting a target loss function to obtain an information synthesis model.

Owner:TENCENT TECH (SHENZHEN) CO LTD

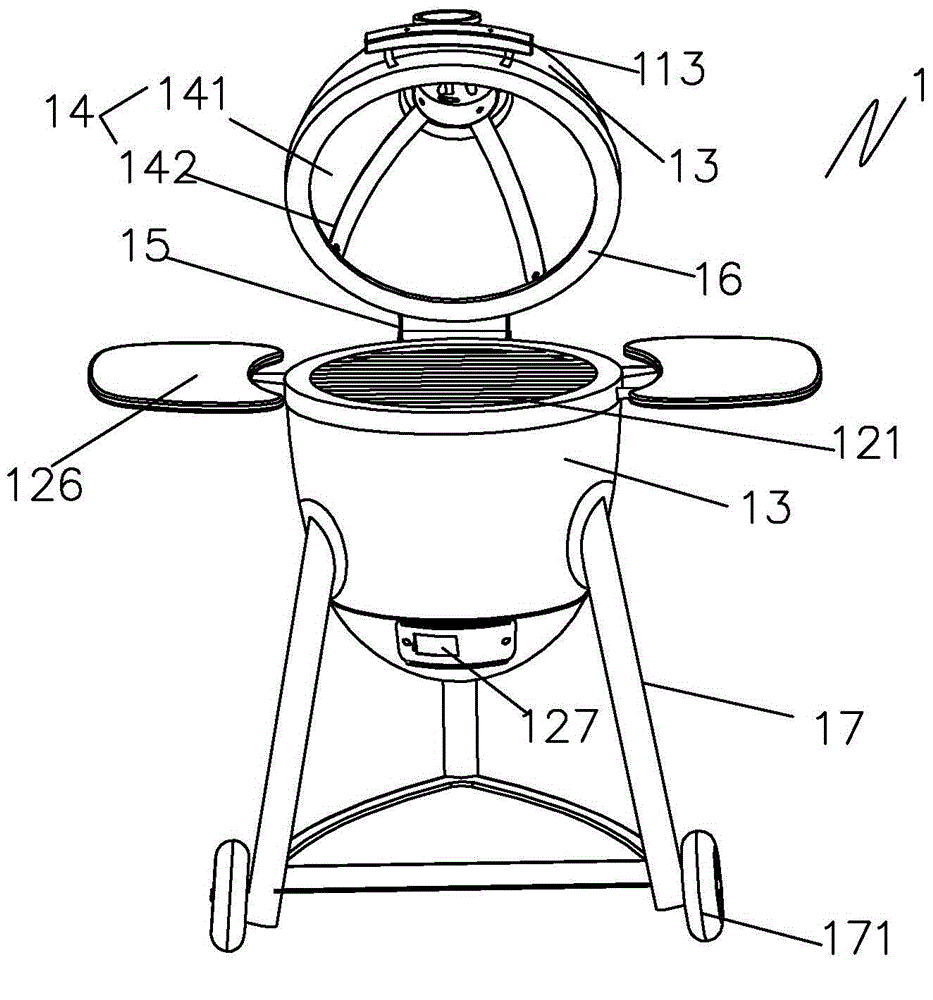

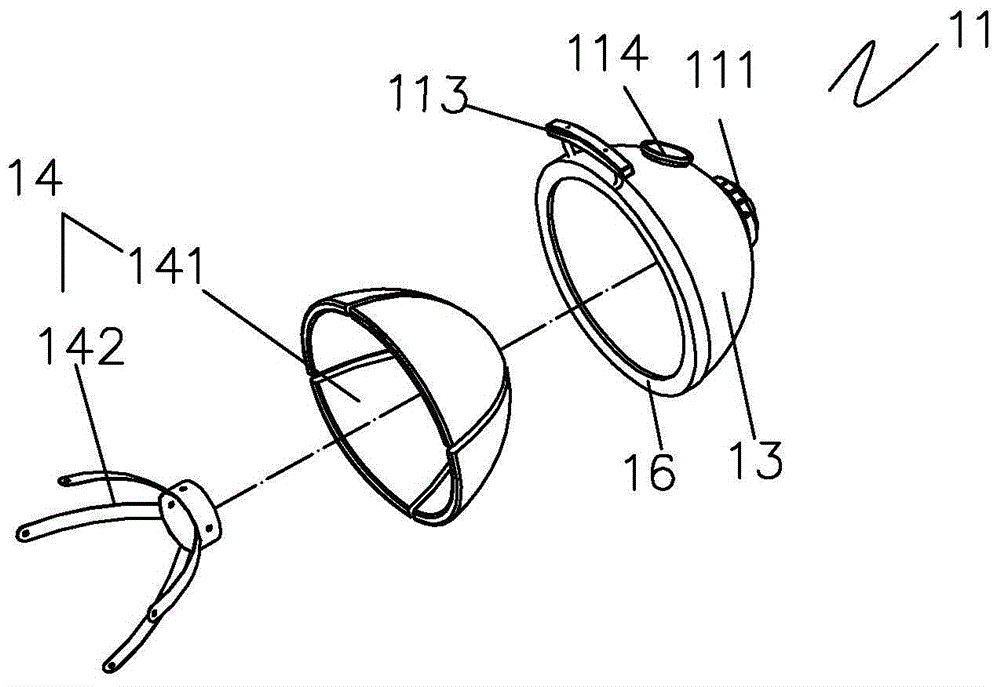

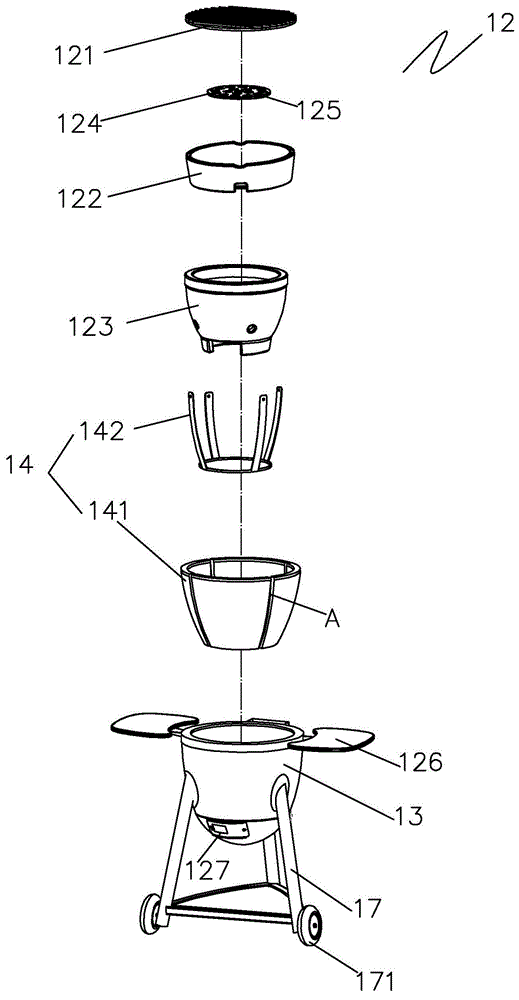

Barbecue oven

InactiveCN104856581AGood lookingGive full play to heat retentionRoasters/grillsThermal insulationEngineering

The invention provides a barbecue oven which comprises an upper cover and a lower oven. The upper cover and the lower oven each comprise a shell and an inner wall. A heat insulation and preservation layer is arranged between each shell and the corresponding inner wall. Each inner wall is formed in the mode that a plurality of ceramic pieces with the same shape and size surround the corresponding shell, wherein every two adjacent ceramic pieces are adhesively connected and cover the corresponding heat insulation and preservation layer, and the inner wall is provided with a plurality of pressing pieces which are tightly attached to the ceramic pieces at intervals and cover the adhesive joint between every two adjacent ceramic pieces. The barbecue oven has the advantages that the exquisite appearance and the standard and uniform size can be ensured, the constant temperature and heat preservation effect of the barbecue oven can be ensured, the product yield is improved, the production cost is reduced, and batch production and machining are facilitated.

Owner:阿普莱斯(福建)投资集团有限公司

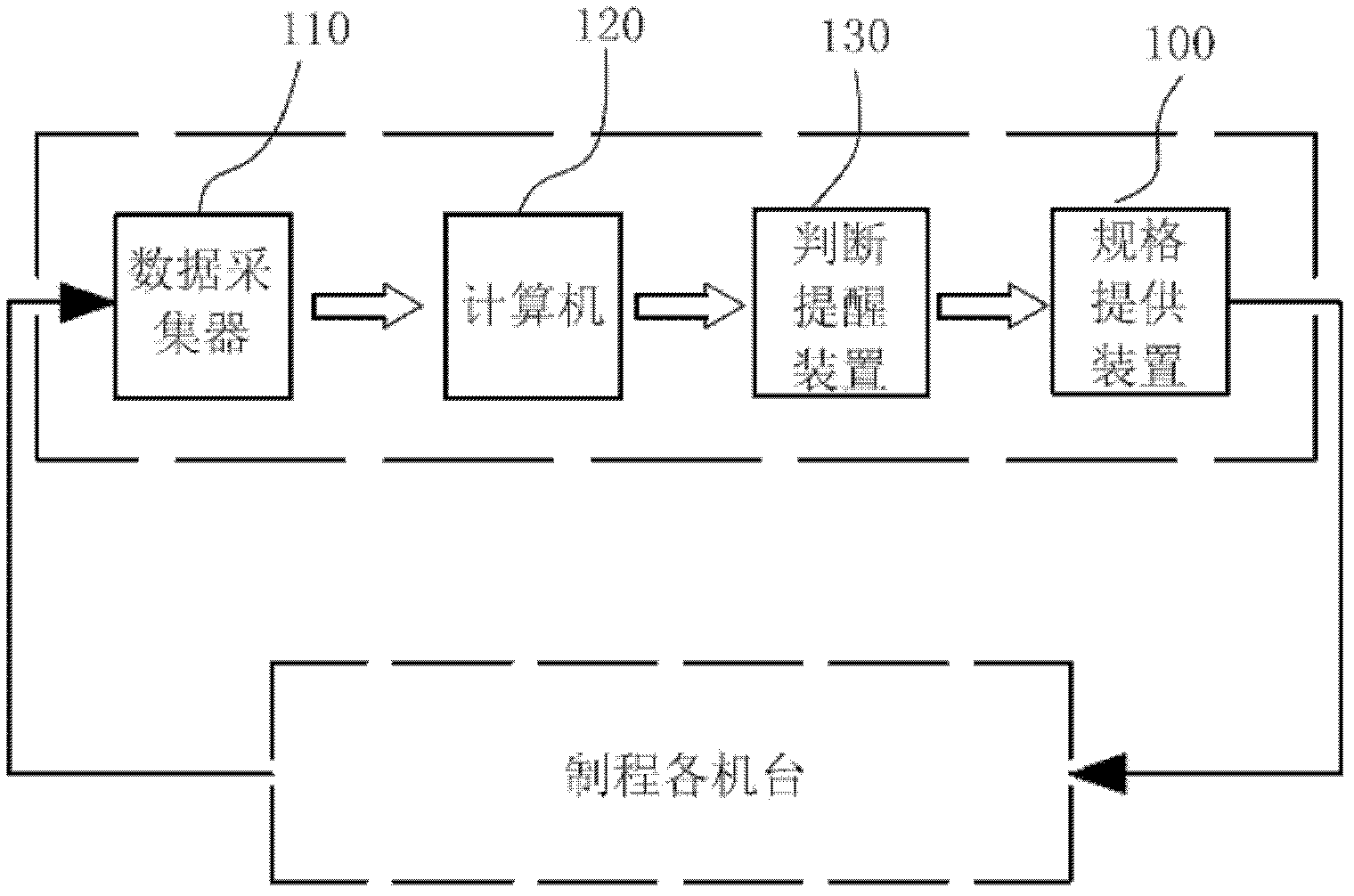

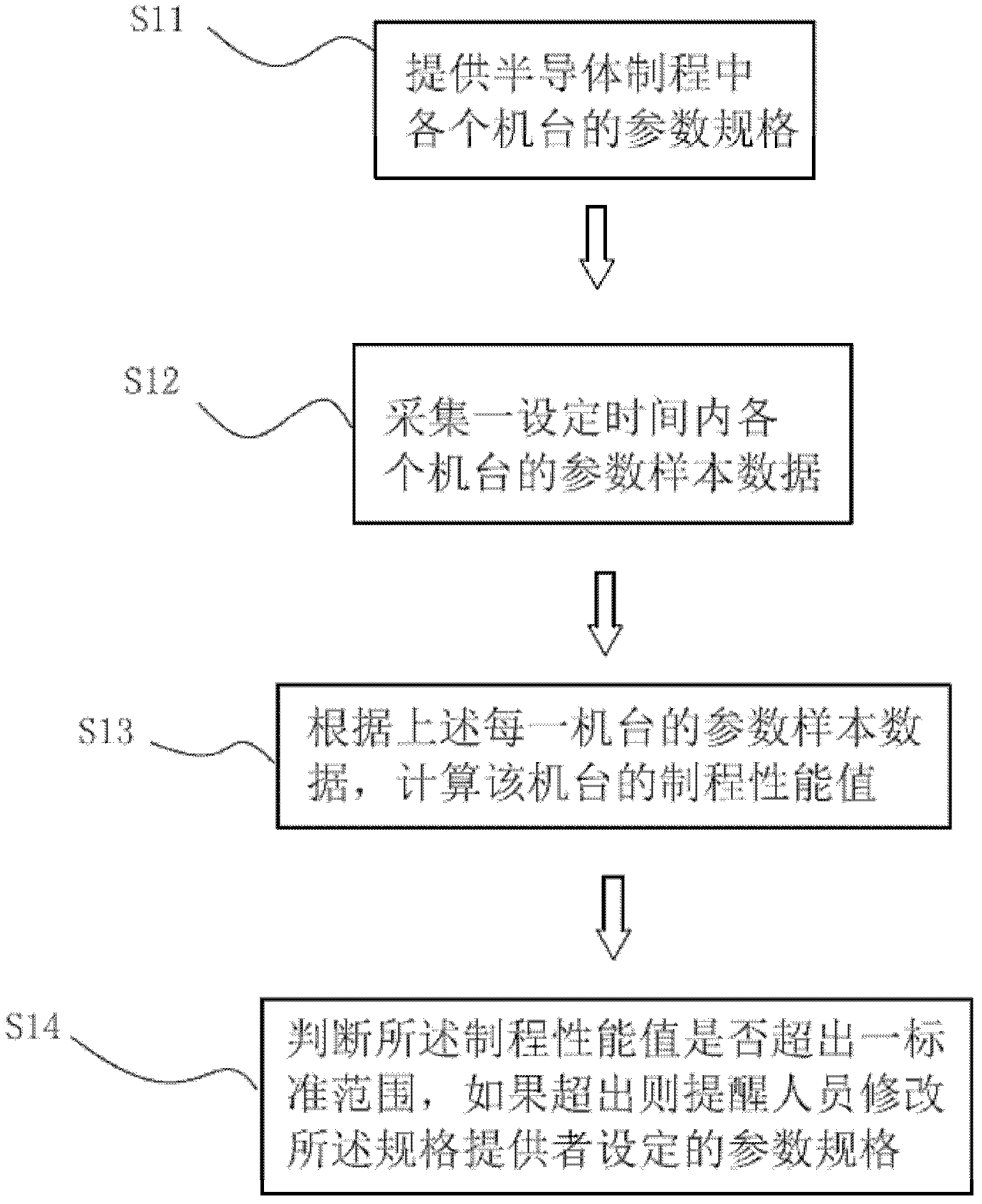

Semi-conductor processing management system and method

InactiveCN103107117AAvoid flawsSemiconductor/solid-state device manufacturingData acquisitionComputer science

Provided is a semi-conductor processing management system and a method. The semi-conductor processing management system comprises a specification providing device, a data collector, a computer and a judging and reminding device. On the basis of an existing flippy disc controller (FDC), the semi-conductor processing management method increases a function which can analyze the range of standard performance evaluation corporation (SPEC), thereby enabling the FDC to calculate the value of complex process capability index (CPK) under the appropriate range of the SPEC, so that support staff can correctly analyze working conditions of various computers, problems can be timely and effectively discovered and reasonability and effectiveness of the entire processing are guaranteed.

Owner:CSMC TECH FAB2 CO LTD

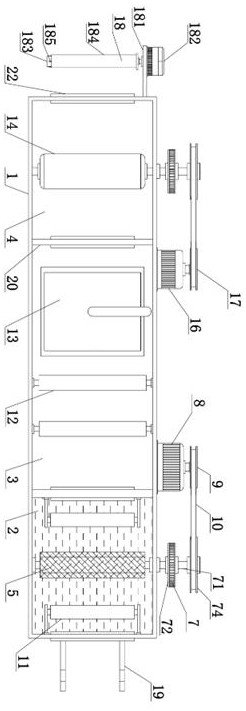

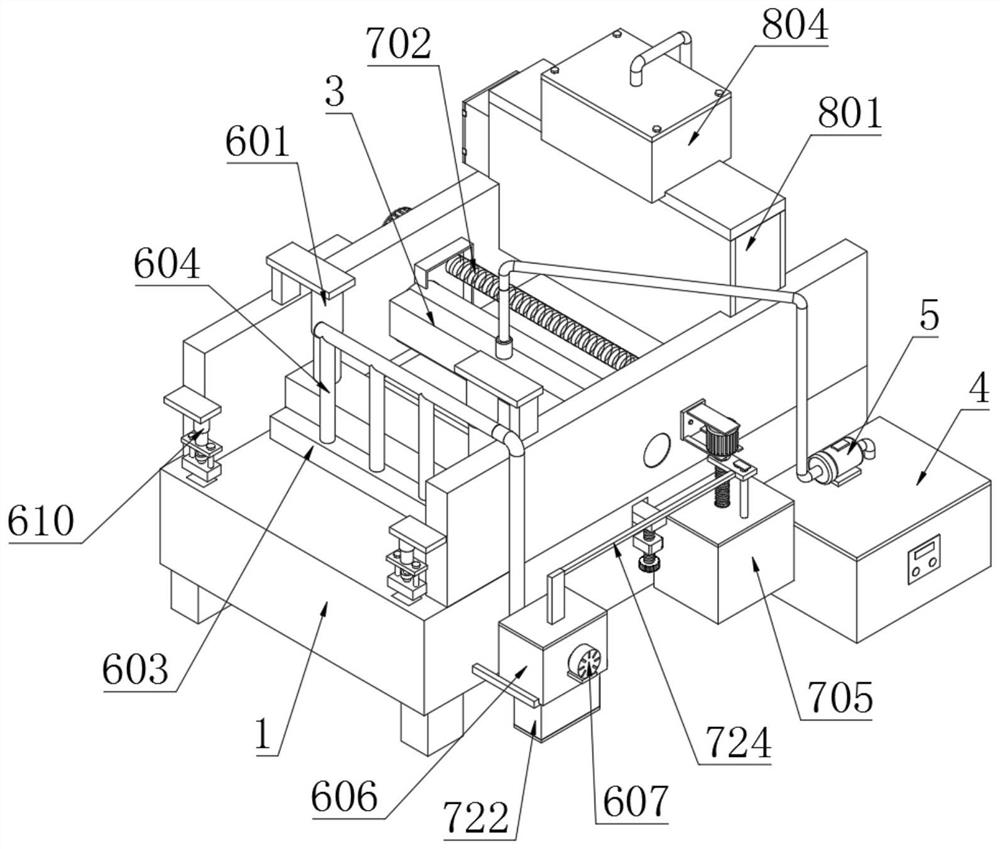

Aluminium strip anode oxidized surface pre-treatment equipment

InactiveCN111809212AEasy to cleanImprove oxidation capacityPolishing machinesGrinding drivesElectric machineryPre treatment

The invention discloses aluminium strip anode oxidized surface pre-treatment equipment and belongs to aluminium strip anode oxidization. The aluminium strip anode oxidized surface pre-treatment equipment comprises a device body; an oil removing chamber, a drying chamber and a polishing chamber are formed in the device body; the oil removing chamber in the device body removes oil from an aluminiumstrip first; a first washing roll and a second washing roll in the oil removing chamber are driven by a first motor to rotate to wash off oil stains on the surface of the aluminium strip so that the aluminium strip is conveniently cleaned; the washed aluminium strip is driven into the drying chamber; an adsorption liquid in the drying chamber adsorbs liquid, brought from the oil removing chamber,on the surface of the aluminium strip; and then the aluminium strip passes through the interior of the drying chamber to be dried for the second time so as to prevent the surface of the aluminium strip from being wet to affect oxidization; the dried aluminium strip enters into the polishing chamber to be polished so that the surface of the aluminium strip is clean and smooth; during the follow-upoxidization of the aluminium strip anode, the aluminium strip oxidization effect is improved to avoid flaws.

Owner:王东亮

Method for preparing nano fiber endless tow

The production method of filament of nanofibers is a simply and high efficiency way. It adopts spinning trunk (3). There are two lines of nozzles (1) whose spout are opposite at the height of the top of the trunk. There are several group of pare of thread guide roller (2) in the trunk.. The distance between thread guide roller and nozzles are equal. The material process is: 1) Transport high polymer solution to nozzles in the trunk of filament of nanofibers; 2) Bring high-voltage DC of opposite polarity to bear to the nozzles. 3) High polymer solution at the top of the nozzles is stretched and whipping responded to form nanofibers which contain electric charge. The opposite nozzle spray nanofibers contains contrary electric charge. They are allure and collide in the air and form nanofibers. The nanofibers are stretched and towed by nozzle and filament of nanofibers comes into being. The operation is simple, highly effective and has no losing of nanofibers.

Owner:SOUTHEAST UNIV

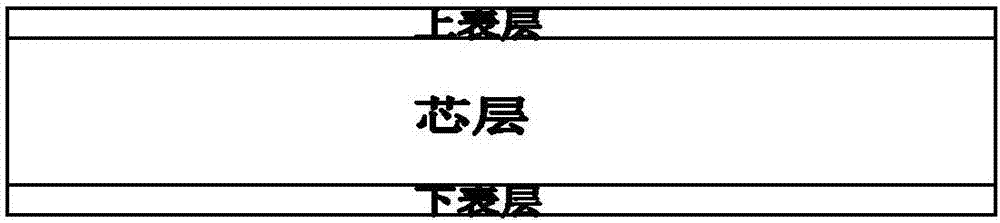

High-temperature resistance wear-resistant BOPP film used for cigarettes, and preparation method thereof

InactiveCN107042671AReduce coefficient of frictionImprove high temperature resistanceSynthetic resin layered productsLaminationSurface layerPolymer science

The invention relates to a high-temperature resistance wear-resistant BOPP film used for cigarettes, and a preparation method thereof. The high-temperature resistance wear-resistant BOPP film used for cigarettes is prepared via direct co-extrusion combination of three structures including an upper surface layer, a core layer, and a lower surface layer; the upper surface layer is mainly prepared from a polypropylene copolymer, the core layer is mainly prepared from a polypropylene homopolymer, and the lower surface layer is mainly prepared from the polypropylene copolymer; 100 weight parts of the upper surface layer comprises, by weight, 86 to 93 parts of copolymer polypropylene, 6 to 10 parts of a slipping agent master batch, and 1 to 4 parts of an antisticking agent master batch; the core layer is prepared from 71 to 83 parts of the homopolymer polypropylene, 15 to 25 parts of a stiffening agent master batch, and 2 to 4 parts of an electrostatic agent master batch; and the lower surface layer is prepared from 100 weight parts of copolymer polypropylene; the slipping agent master batch possesses an organic round ball structure, is capable of reducing upper surface layer friction factor and improving surface high temperature resistance. The high-temperature resistance wear-resistant BOPP film possesses wear resistance and high temperature resistance, and is capable of resisting whitening and wearing.

Owner:ZHANJIANG PACKAGING MATERIAL ENTERPRISES

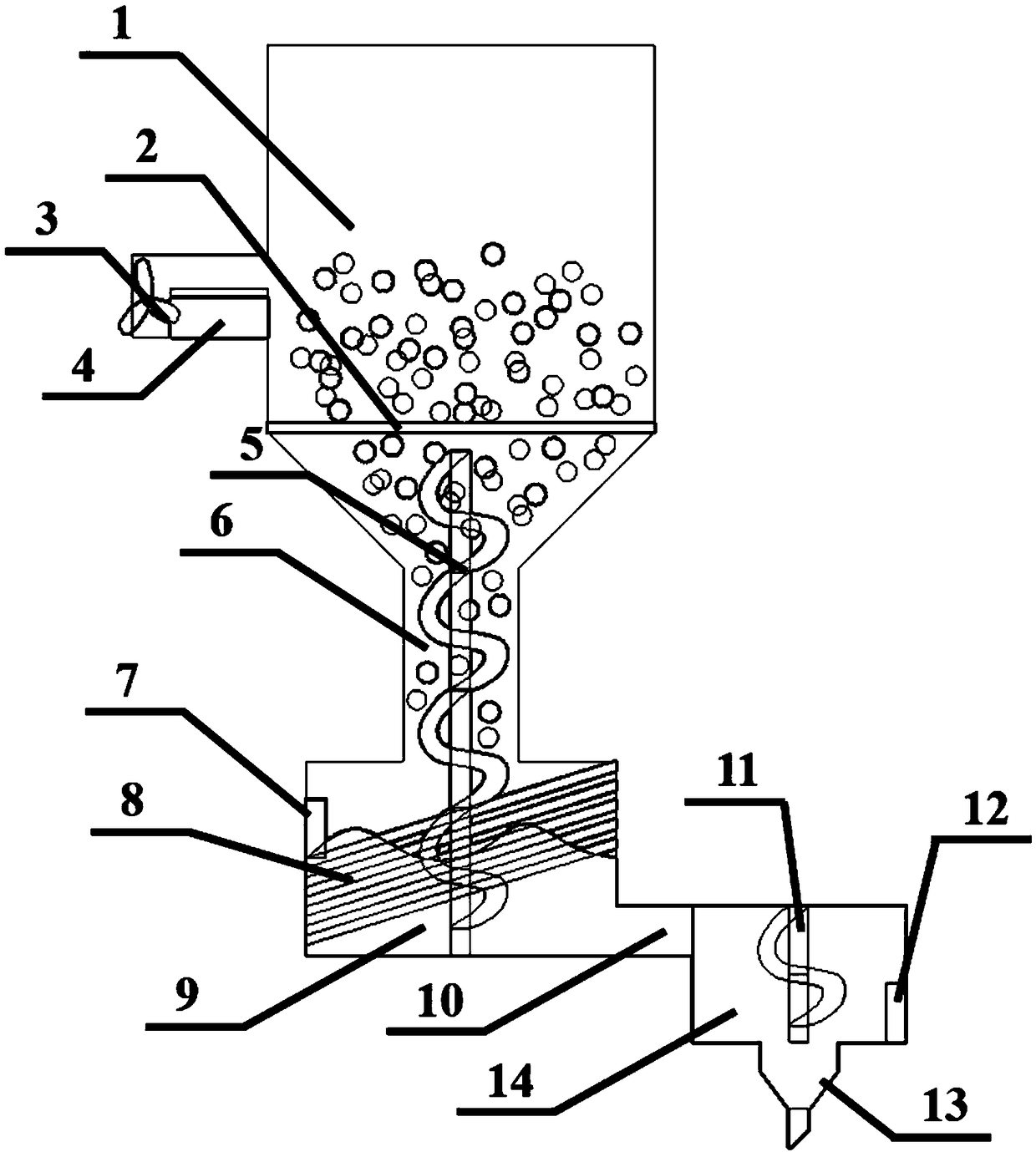

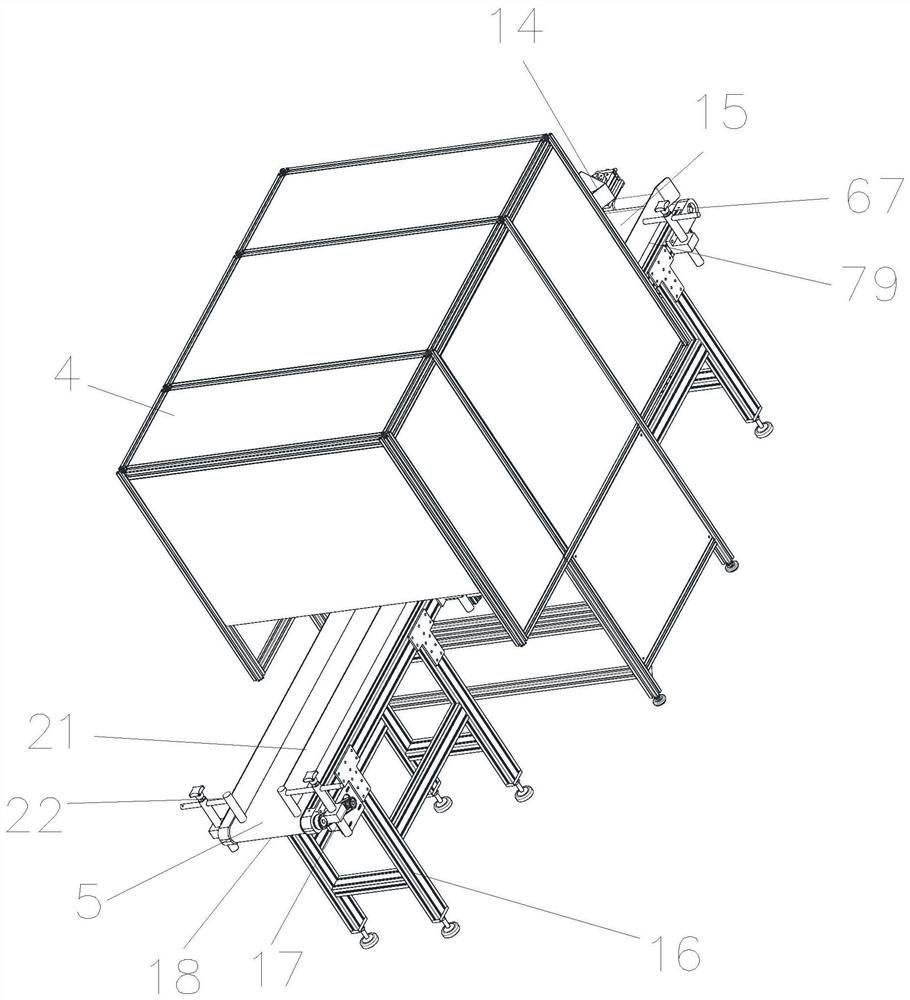

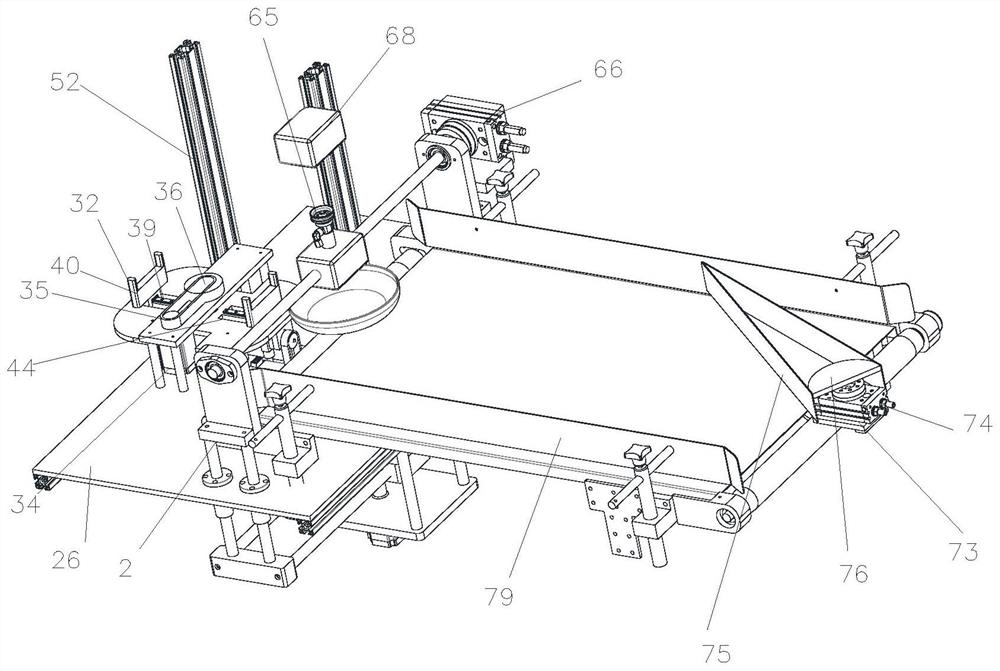

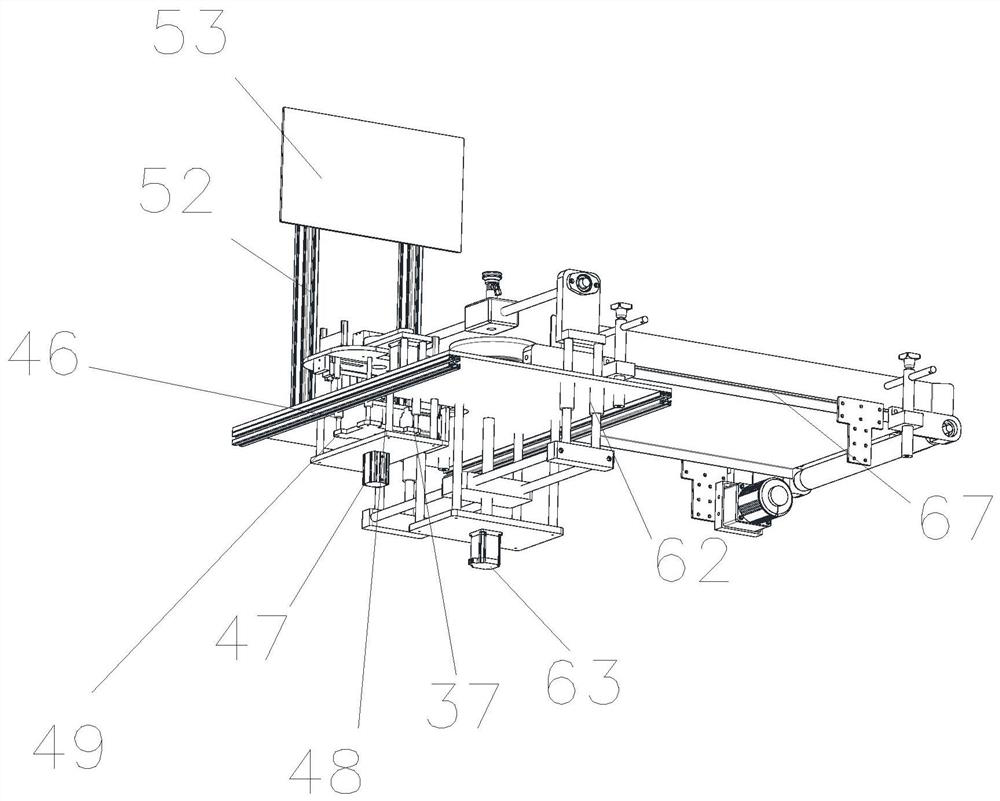

Dual-sprayer rapid forming system for environmentally sensitive function gradient materials

ActiveCN108790157AImprove mechanical propertiesImplementing Functional GradientsManufacturing driving meansManufacturing heating elementsSprayerGradient material

The invention discloses a dual-sprayer rapid forming system for environmentally sensitive function gradient materials. The dual-sprayer rapid forming system for the environmentally sensitive functiongradient materials comprises a control unit, a printing platform, a box rack and two sprayer units; each sprayer unit comprises a feed mixing mechanism, a heating mechanism and an extrusion mechanism;each mixing mechanism comprises a feeding hopper, a toner box, a toner blower, a feed partition board, a feeding pipe and a stirring conveying screw rod; each toner box is installed on the side wallof the corresponding feeding hopper; the side of a discharging outlet of each toner box communicates with the interior of the corresponding feeding hopper; each toner blower right faces an air inlet of the corresponding toner box; and each heating mechanism inside the corresponding feeding hopper and below the corresponding toner box comprises a heating chamber, a discharging pipe, a temperature sensor and a heater wound around the heating chamber. The system can print intelligent structures with temperature expansion gradients in mixing and melt extrusion modes, and the problems that the requirements for raw materials are high and the forming precision is high in the manufacturing process of 3D printing environmentally sensitive function gradient materials are effectively solved.

Owner:HEBEI UNIV OF TECH

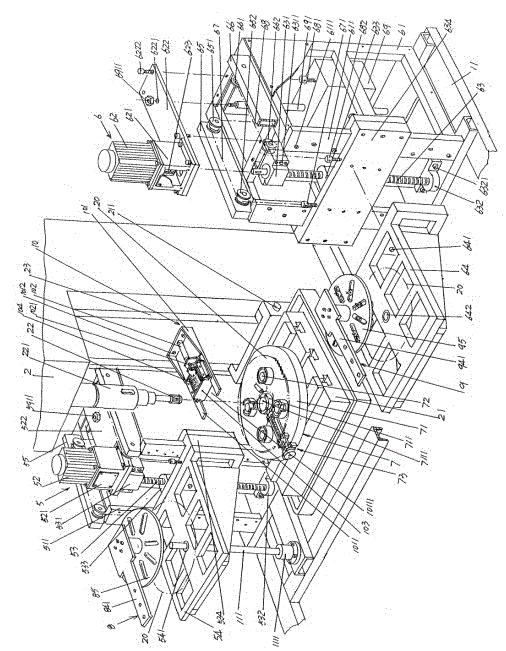

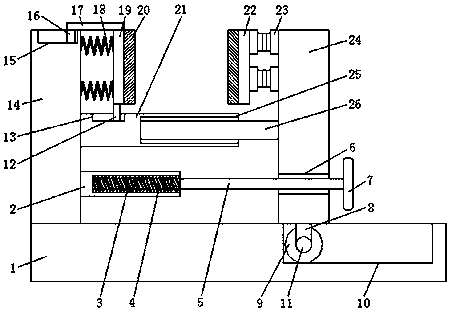

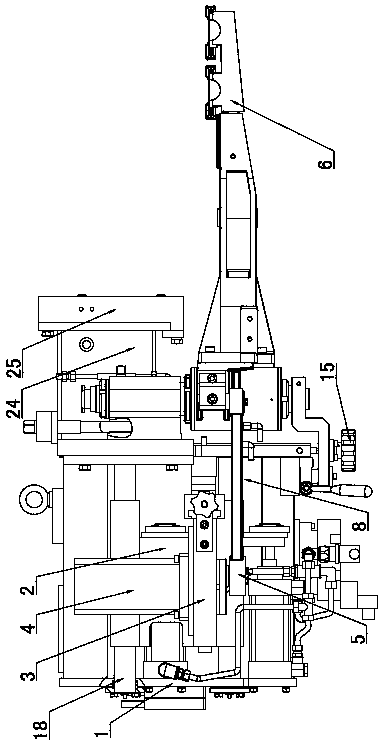

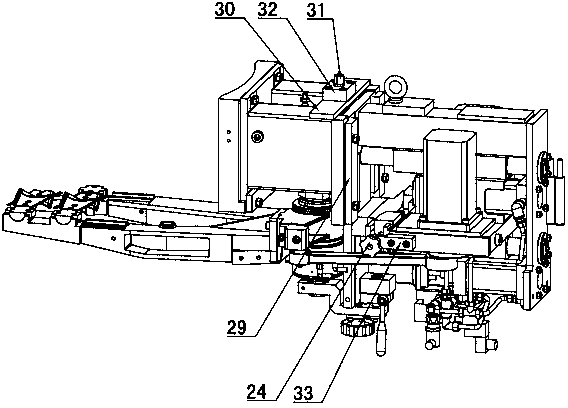

Automatic reaming device for center hole of circular saw blade

InactiveCN104308268BEnsure reaming qualityEnsure job safetyReaming devicesMetal working apparatusCircular sawReamer

The invention discloses an automatic reaming device for the center hole of a disc saw blade, and belongs to the technical field of metal saw blade processing machinery. The automatic reaming device comprises a base, a vertical drilling machine, a material feeding mechanical arm translation driving mechanism, a material receiving mechanical arm translation driving mechanism, a material feeding lifting mechanism, a material receiving lifting mechanism, a reaming saw blade carrying mechanism, a material feeding mechanical arm and a material receiving mechanical arm. The vertical drilling machine is provided with a drilling machine worktable and a reamer; the material feeding mechanical arm translation driving mechanism and the material receiving mechanical arm translation driving mechanism are arranged on the base and on the left end and the right end of the base in the length direction; the material feeding lifting mechanism and the material receiving lifting mechanism are arranged on the back side of the left end of the base and the back side of the right end of the base; the reaming saw blade carrying mechanism is arranged on the drilling machine worktable; the material feeding mechanical arm is in sliding fit with the upper part of the left end of the base and is in connection with the material feeding mechanical arm translation driving mechanism; the material receiving mechanical arm is in sliding fit with the upper part of the right end of the base and is in connection with the material receiving mechanical arm translation driving mechanism. The equipment input quantity is reduced, and the labor resource is saved; the operation safety of workers is ensured; the operation intensity is reduced; the reaming quality of the center hole of the disc saw blade is ensured, and flaws are eradicated; mechanized automatic reaming is realized, the environment of a workplace where the workers work is standard and orderly.

Owner:广州市鸿铨模具制造有限公司

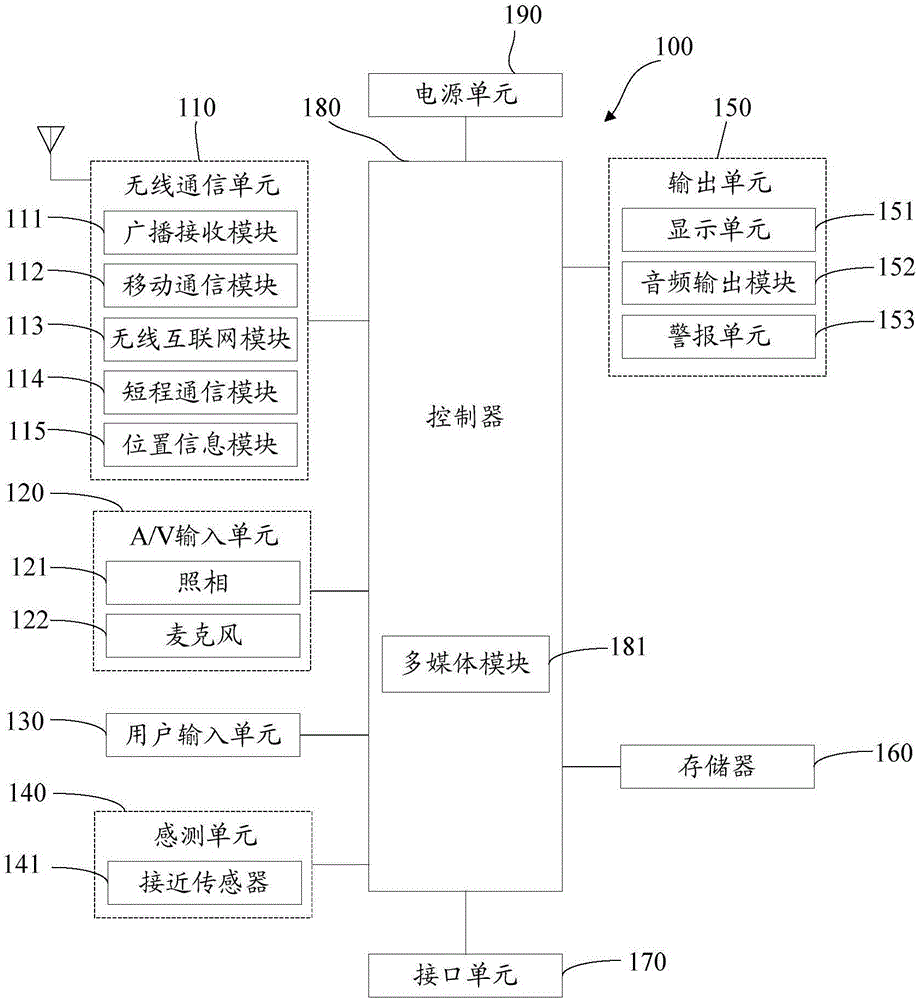

Shooting device and method as well as mobile terminal

ActiveCN106791367AAvoid flawsQuality improvementTelevision system detailsColor television detailsComputer terminalImage display

Owner:NUBIA TECHNOLOGY CO LTD

Novel injection mold

Owner:杨永明

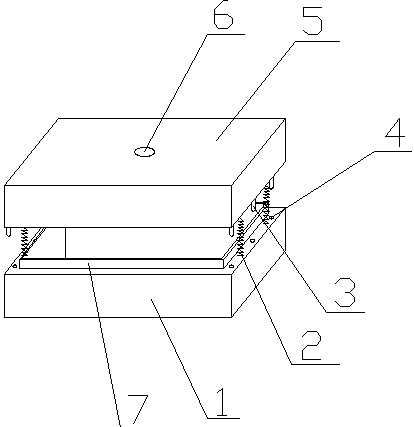

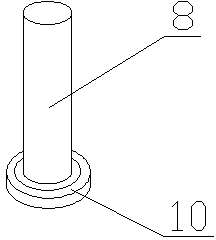

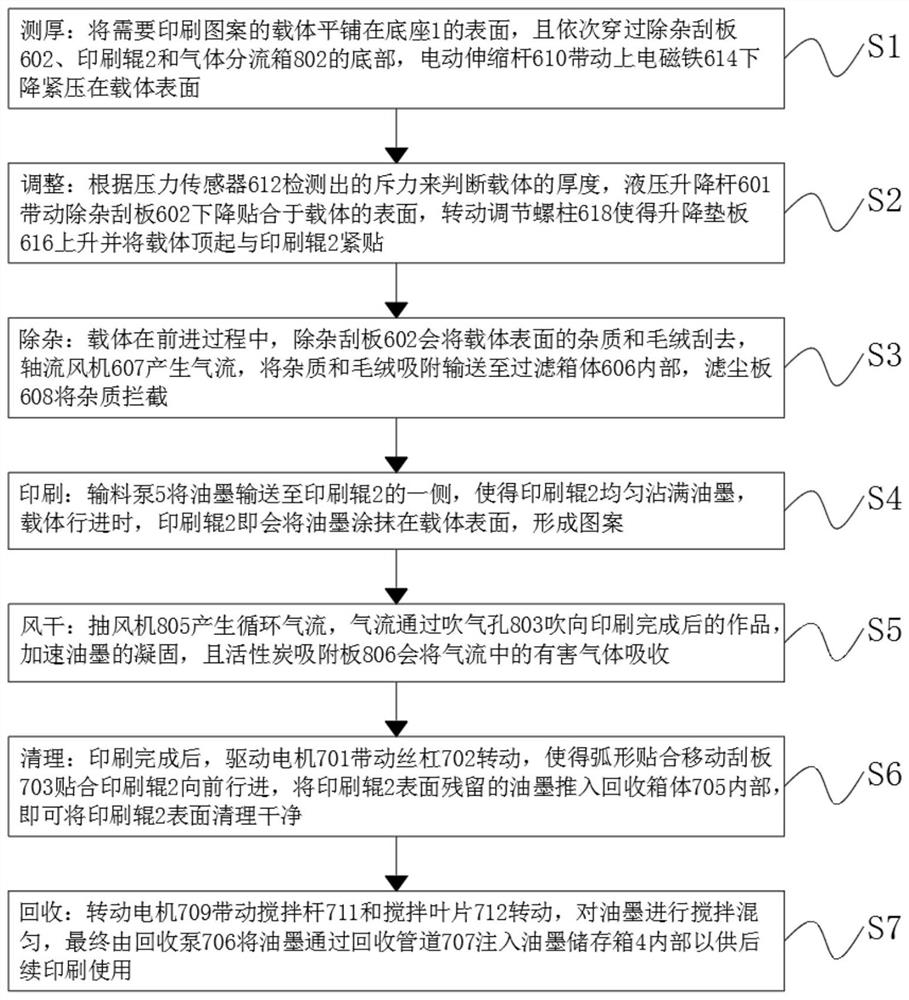

Environment-friendly green printing method

PendingCN114083895AScientific and reasonable structureSafe to useDispersed particle filtrationRotary stirring mixersPaper sheetPrinting ink

The invention discloses an environment-friendly green printing method which comprises the steps: impurity removal: in the advancing process of carriers, an impurity removal scraper can scrape impurities and plush on the surfaces of the carriers, an axial flow fan generates airflow, the impurities and the plush are adsorbed and conveyed into a filtering box body, and a dust filtering plate intercepts the impurities. The carriers such as paper, cloth or plastic used for printing can penetrate through the bottom end of the impurity removal scraper when moving forwards along the base, and the impurity removal scraper can conduct scraping and impurity removal treatment on the surfaces of the carriers, so that the plush and impurities adhering to the surfaces of the carriers in the production and transportation process are removed, the surfaces of the carriers are kept clean and flat, the situation that printing ink cannot be normally bonded to the surfaces of the carriers due to impurities and plush residues, and consequently printed patterns have flaws is avoided, it is ensured that printed works are kept complete, airflow is generated through an axial flow fan, the airflow flows upwards to directly suck and adsorb the plush and impurities scraped during impurity removal into a long-strip-shaped box body, and one side of the impurity removal scraper is always kept clean.

Owner:陈彩莲

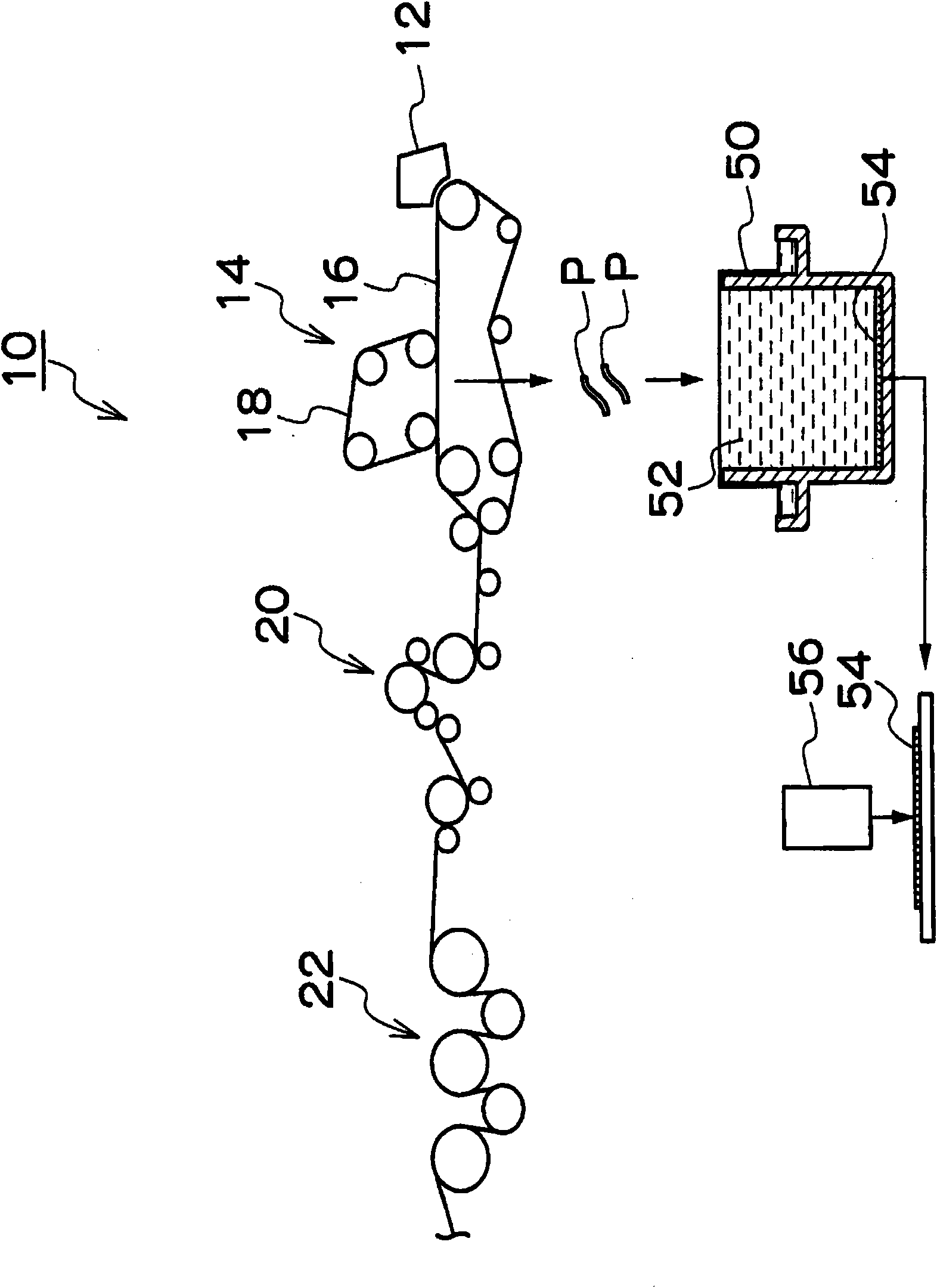

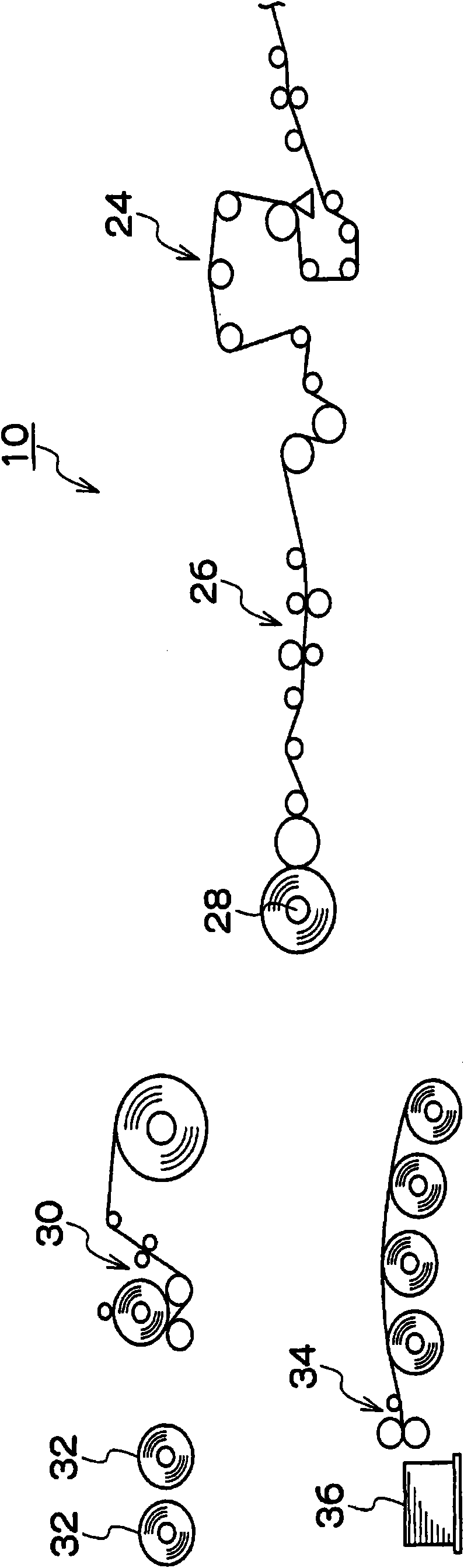

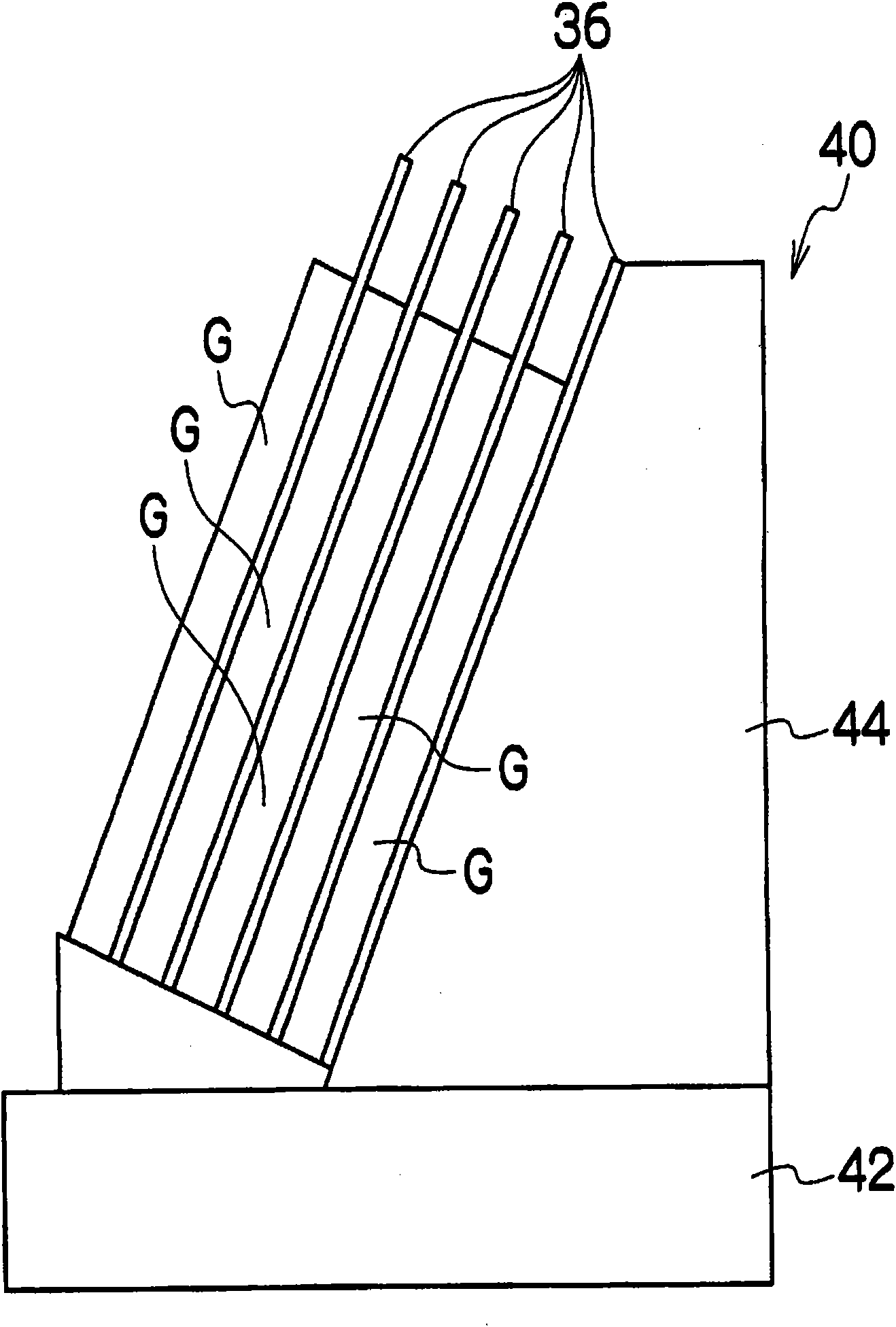

Paper quality management method and glass substrate backing paper making method

InactiveCN102418298AProductivity impactAvoid flawsSpecial paperPaper/cardboardFlat panel displayPapermaking

The invention provides a paper quality management method and a glass substrate backing paper making method. The paper quality management method is characterized in that a water spray nozzle is used for cutting off paper to selectively make the edge part (P) of the paper on a paper machine (10) at a papermaking process, the size of foreign matters contained in the edge part (P) is detected and determined, and quality management is conducted to the paper (36) made by the paper machine (10) according to the inspection result of the size of the foreign matters contained in the edge part (P). In other words, the specific size of the foreign matters causing flaws to a glass substrate (G) is taken as a threshold and classification management is conducted to the paper (36) batch by batch. The threshold, i.e. the threshold of the specific size of the foreign matters causing the flaws to the glass substrate (G) is 200mum according to experiments. Therefore, the selected paper with the edge part (P) containing the foreign matters with the size being below 200mum can be used as transport backing paper for the glass substrate (G) for a flat panel display, and the backing paper and other paper can be managed batch by batch.

Owner:ASAHI GLASS CO LTD

Preparation method of dedicated polyvinyl alcohol of optical material

The invention relates to high-molecular compound and specifically discloses a preparation method of dedicated polyvinyl alcohol of an optical material. The preparation method comprises the following steps: (1) preparing crude polyvinyl alcohol; (2) adding methyl alcohol into a reaction kettle I, stirring and adding the crude polyvinyl alcohol obtained in the step (1) while stirring; (3) warming to 30 to 50 DEG C and then adding a NaOH alcoholic solution; (4) adding acetic acid after reaction finishes, adjusting a pH value to 5 to 7, then switching on a discharging bottom valve to discharge materials and separating the materials to obtain complete alcoholysis type polyvinyl alcohol; (5) adding purified water into a reaction kettle II, introducing nitrogen, starting stirring, then adding the polyvinyl alcohol and washing the polyvinyl alcohol; (6) switching on a discharging bottom valve of the reaction kettle II to discharge the materials after washing and then dewatering the obtained polyvinyl alcohol. The polyvinyl alcohol obtained by the preparation method disclosed by the invention has concentrated polymerization degree and alcoholysis degree distribution and high cleanness and can be applied to the field of optical materials.

Owner:CHINA PETROCHEMICAL CORP +1

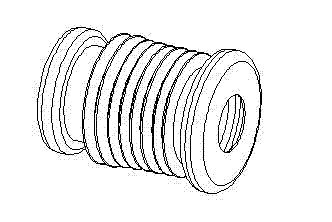

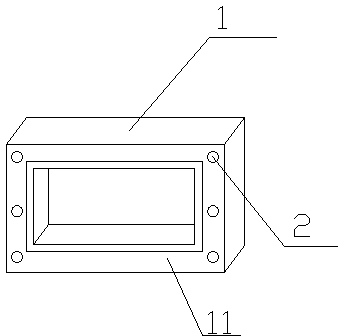

Blow mold for thermoplastic elastomer

The invention relates to a blow mold for thermoplastic elastomers, belonging to the field of blow molding processing equipment. The blow mold for the thermoplastic elastomers is characterized in that the blow mold comprises an upper mold and a lower mold which are arranged from the top to the bottom, a plurality of positioning columns are arranged on the upper surface of the lower mold, a plurality of depressed positioning holes are arranged on the lower surface of the upper mold, and the positioning holes are matched with the positioning columns; the upper mold and the lower mold are respectively provided with a depressed cavity; and a feed inlet is installed on one side of the cavity. The blow mold for the thermoplastic elastomers has the advantages that the structure is comparatively simple, the upper mold and the lower mold are matched with each other through the positioning columns and the positioning holes, the upper mold and the lower mold are perfectly fit with each other, and the problem of product defects caused by deviation because common molds are manually calibrated only is avoided.

Owner:芜湖市佳美橡塑制品有限公司

Wire drawing belt, method for manufacturing metallic glass plate by using wire drawing belt and metallic glass plate

InactiveCN109502990AGuaranteed drawing effectImprove structural stabilityCoatingsWoven fabricAluminium oxide

The invention provides a wire drawing belt, a method for manufacturing a metallic glass plate by using the wire drawing belt and the metallic glass plate. The wire drawing belt comprises a substrate material and an abrasive material; the substrate material is a non-woven fabric, the abrasive material is aluminium oxide or silicon carbide, and the grain size of the abrasive material is 50-600 meshes; and the abrasive material adheres to the substrate material. The method for manufacturing the metallic glass plate by using the wire drawing belt comprises the following steps: selecting transparent glass as a glass substrate; successively drawing long wires and broken wires on the surface of the glass substrate by using the wire drawing belt to obtain a wire drawing layer; printing brighteninggloss oil resin on the surface of the precisely treated wire drawing layer, and then sintering to obtain a wire drawing brightening layer; and printing protecting coloring resin on the surface of thewire drawing brightening layer, and then sintering to obtain the metallic glass plate. The metallic glass plate is manufactured by the method. The wire drawing belt and the metallic glass plate obtained by the method for manufacturing the metallic glass plate are suitable in color and good in surface wire drawing effect, and are attractive.

Owner:JIANGSU XIUQIANG GLASSWORK CO LTD

Metal cutting machine tool clamping device facilitating clamping

InactiveCN109955084AEasy clampingReduce vibrationPositioning apparatusMetal-working holdersMetal machiningLap joint

The invention provides a metal cutting machine tool clamping device facilitating clamping, and relates to the field of metal machining machine tools. The metal cutting machine tool clamping device facilitating clamping comprises a base, a fixing plate is fixedly connected to the upper surface of the base, an adjusting rod is fixedly connected to the right side of the fixing plate, and a threaded groove is formed in the right end of the adjusting rod and is internally in threaded connection with a screw. The end, away from the threaded groove, of the screw is fixedly connected with a rotation rod. The upper surface of the base is in lap joint with a movable plate. A movable hole communicating with the right side is formed in the left side of the movable plate. According to the metal cuttingmachine tool clamping device facilitating clamping, through leather pads arranged on the surfaces of a first clamping plate and a second clamping plate, after a workpiece is clamped, workpiece surface damage is avoided; and through springs arranged between the fixing plate and the first clamping plate, vibration of the workpiece during machining is buffered, and it is guaranteed that defects areavoided after the workpiece is machined.

Owner:朱爱芳

Pattern type powder coating and preparation method thereof

ActiveCN109096881AGood effectAvoid flawsPowdery paintsEpoxy resin coatingsPolymer scienceFirming agent

The invention discloses a pattern type powder coating and a preparation method thereof. The preparation method comprises the following steps: step (1) of evenly mixing a polyester resin, an epoxy resin, a curing agent, a pigment filler, an antifoaming agent and a pigment; step (2) of extruding the evenly mixed materials from an extruder, and performing cooling, pressed into pieces and smashing; step (3) of adding a leveling agent in the smashed materials, evenly mixing the materials and grinding the materials. The pattern type powder coating can be prepared without adding a pattern agent and can be completed under existing production conditions, and there is no need to add any device; existing overall production processes are not changed; and the powder spray curing conditions of the pattern type powder coating do not need to be changed. The novel process for preparing the pattern type powder coating is low in cost and good in effect.

Owner:WUHU INST OF TECH

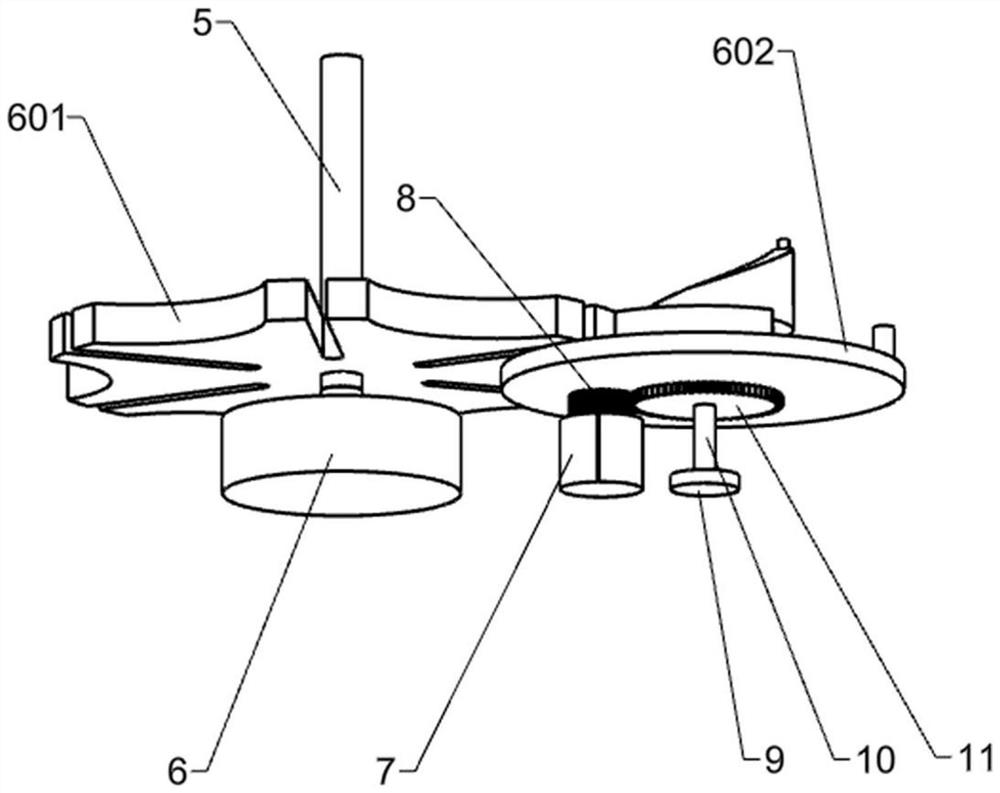

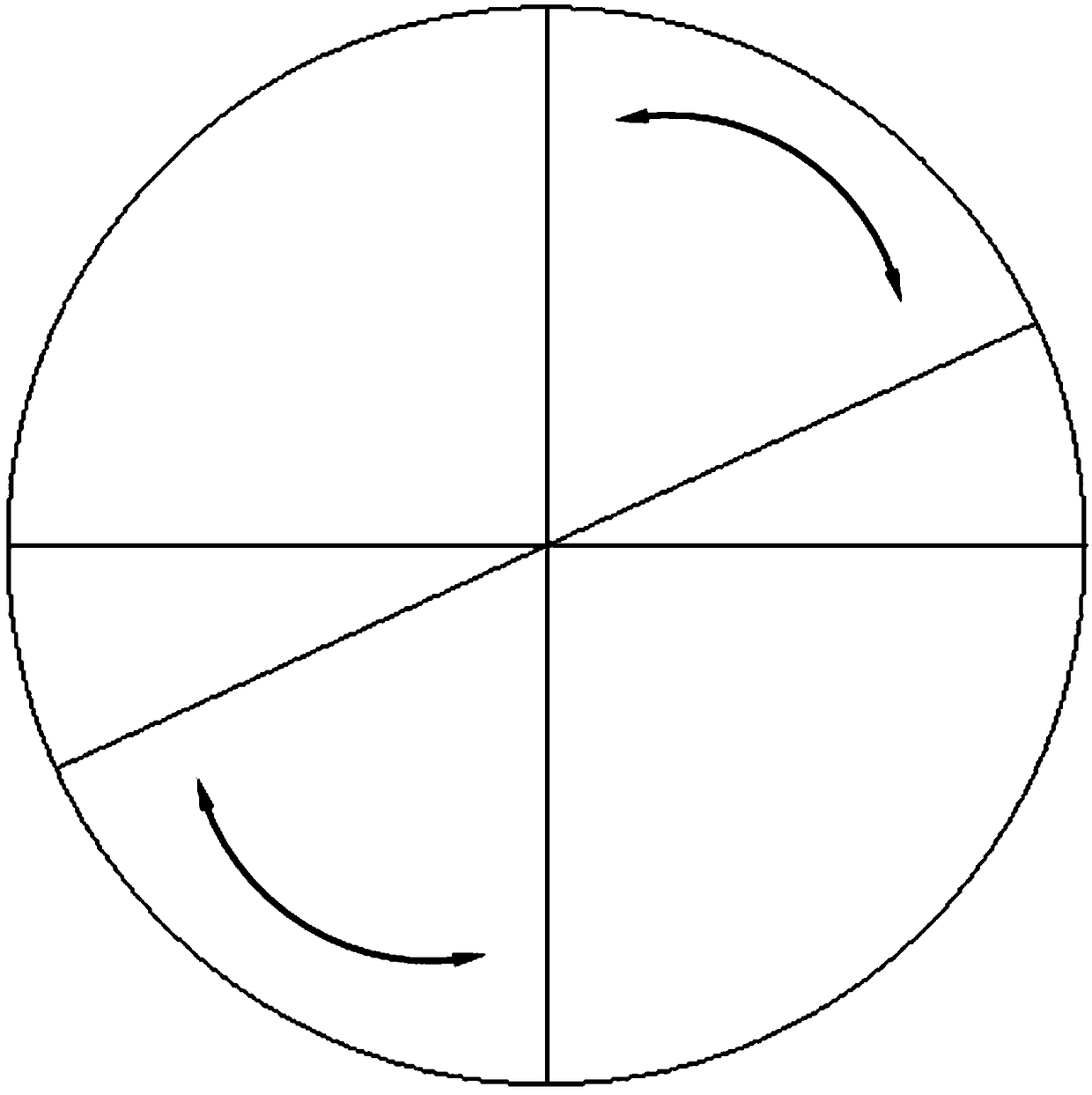

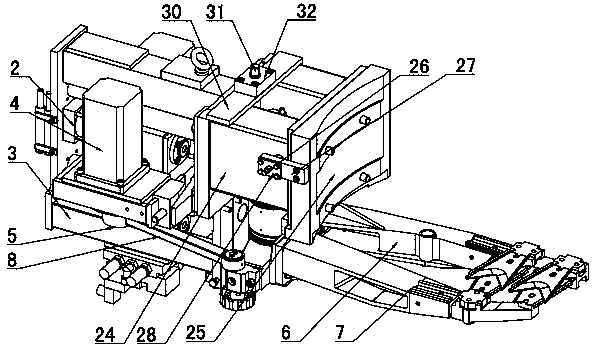

Dual-servo-motor angle shear machine

The invention discloses a dual-servo-motor angle shear machine and belongs to the field of feeding machines of glass bottle machinery. The dual-motor servo angle shear machine is characterized in that a support frame comprises a support bracket (1) and a motor bracket (3); a shear device comprises two servo motors (4), a left connecting rod mechanism, a right connecting rod mechanism, shear arm support devices, a left shear arm (6) and a right shear arm (7); the two servo motors (4) are mounted on the motor bracket (3); the output ends of the servo motors (4) vertically and downwardly extend out of the lower plane of the motor bracket (3) and are connected with two cranks (5) respectively; the two cranks (5) are connected with the left connecting rod mechanism and the right connecting rod mechanism respectively; the other end of each of the left connecting rod mechanism and the right connecting rod mechanism is connected with each shear arm support device; the shear arm support devices are connected with the left and right shear arms (6, 7) which can be occluded with each other. According to the dual-servo-motor angle shear machine, the shearing operation is stable, the reversing motion cannot be made, the shearing quality is good, and the shearing position can be adjusted.

Owner:SHANDONG SANJIN GLASS MASCH CO LTD

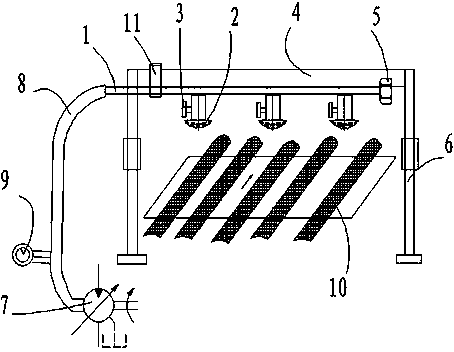

Mist spray humidifying device of opener

InactiveCN103590147AAvoid flawsEasy to adjustCarding machinesLiquid spraying apparatusFiberAgricultural engineering

The invention discloses a mist spray humidifying device of an opener. The mist spray humidifying device comprises a nozzle, a high-pressure pump and a nozzle fixing pipe, wherein the water inlet end of the nozzle fixing pipe is connected with the high-pressure pump through a high-pressure pipe, the water outlet end of the nozzle fixing pipe is connected with the nozzle, a water inlet of the high-pressure pump is connected with a water outlet of a water box through a water inlet pipe, a water outlet of the high-pressure pump is provided with a filter, and the high-pressure pipe is provided with a pressure gage. The mist spray humidifying device is characterized in that the nozzle fixing pipe is arranged on a fixed pipe support which comprises two side stand columns, the two side stand columns are connected with each other through an upper transverse beam, the nozzle fixing pipe is connected with the transverse beam, the nozzle is arranged above opening fibers, a switch valve is arranged between the nozzle and the nozzle fixing pipe, the water inlet end of the nozzle fixing pipe is higher than the water outlet end of the nozzle fixing pipe, and the tail end of the nozzle fixing pipe is provided with a screwed plug. The mist spray humidifying device is simple in structure and good in humidification uniformity, mist spray quantity is convenient to regulate, assembly, disassembly and maintenance are convenient, flaws of the fibers caused by long-time accumulation of water in a water pipe are avoided, and the mist spray humidifying device meets the requirement for scale production.

Owner:SHANDONG PROVINCE WINSON NON WOVEN MATERIALS

Continuous paper feed scanning method and continuous paper feed device

InactiveCN101370063ARealize automatic continuous paper feedingAvoid flawsPictoral communicationPulp and paper industryPaper sheet

The invention relates to continuous paper-feeding, scanning method and continuous paper-feeding device. The continuous paper-feeding device and scanning device are employed in the inventive method. A paper-picking roller and paper-separating roller of continuous paper-feeding device rotates forward, paper-picking roller picks scanning piece from stacked paper and paper is separated by paper-separating roller; when front end of scanning piece gets to scanning device, paper-picking roller stops rotating, paper-separating roller continues to rotate forward, scanning roller of scanning device rotates to pick paper and scan; when scanning module completes scanning for the scanning piece, scanning roller stops rotating. The inventive continuous paper-feeding device can effectively avoid paper jam and scanning image defect during continuous paper-feeding, and prevent scratch and protect delicate scanning piece such as photo, accomplish good butt with portable scanner and automatic continuous paper-feeding, properly extend function of portable scanner, provide convenience for portable scanner to process scanning image.

Owner:QISDA SUZHOU

Intelligent wearable net membrane welding and splicing technique

ActiveCN105643084ANo whiteningNo cloggingMetal working apparatusNon-electric welding apparatusHot meltEngineering

The invention discloses an intelligent wearable net membrane welding and splicing technique. The intelligent wearable net membrane welding and splicing technique comprises the following steps that A, a hot-melt acoustic net membrane is cut to be of the preset size through a cutting machine, so that a membrane piece is formed; B, a waterproof test is conducted on the membrane piece obtained in the step A; C, a breathability test is conducted on the membrane piece obtained after the step B is completed; D, the sound loss degree of the membrane piece obtained after the step C is completed in the sound transmission process is tested; and E, the membrane piece obtained in the step D is fixed to the outer surface of intelligent wearable equipment or an opening communicating with the outside through hot melting by means of a servo hot melting machine, and cooling is conducted, so that a machined product is obtained. By the adoption of the technique, the rate of finished products is high, the net membrane is prevented from being blocked, the machining cost is low, and the technique is easy to apply and popularize.

Owner:DONGGUAN FUJIA MACHINERY CO LTD

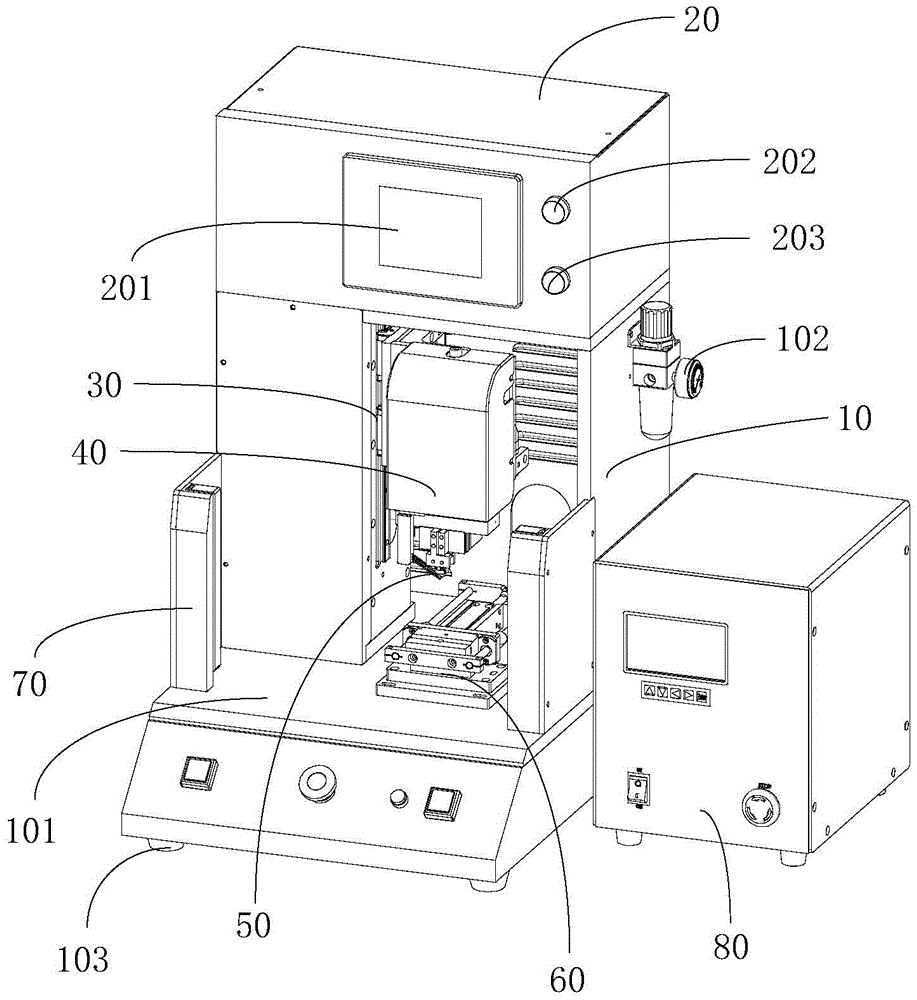

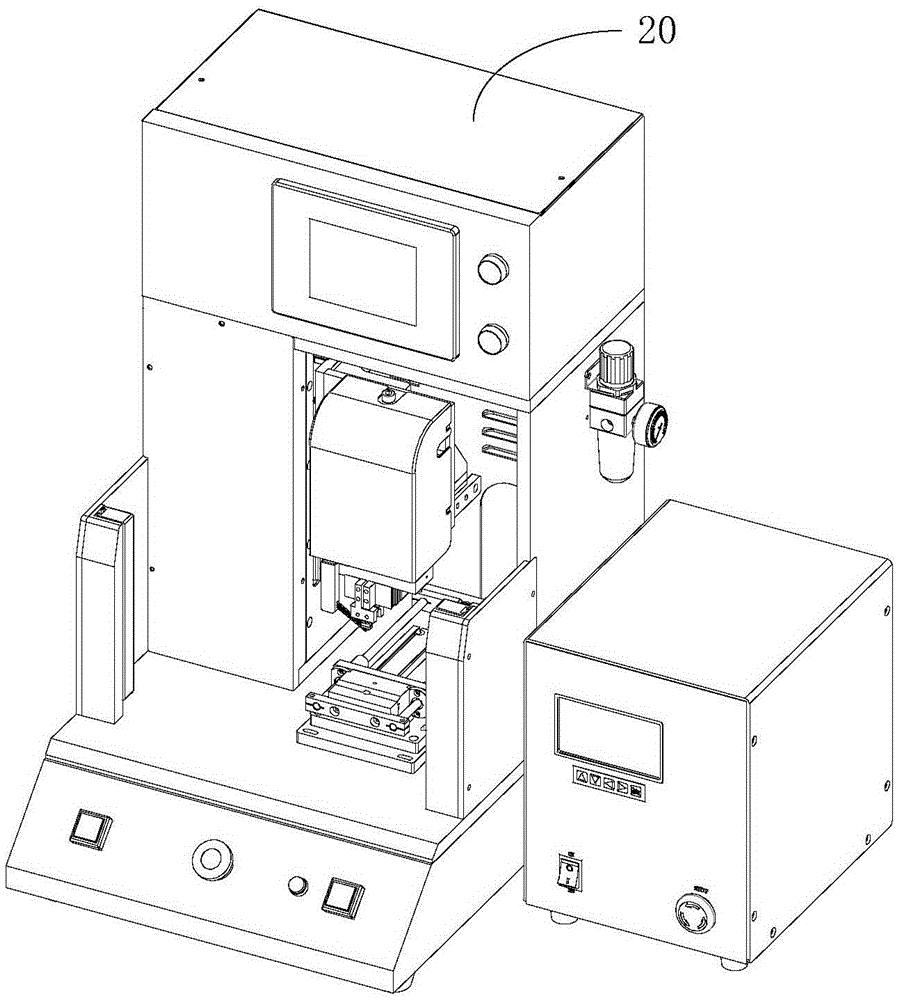

Laser marking equipment

ActiveCN113353595AThorough protectionImprove securitySortingLaser beam welding apparatusEngineeringIdentification device

The invention provides laser marking equipment. One end of a feeding device is a feeding opening; the other end of the feeding device is a first transferring opening; a laser marking device is arranged behind the first transferring opening; a connecting and shunting device is arranged behind the laser marking device; a positioning rotary table and a conveying device for conveying products from the first transferring opening to the positioning rotary table and then conveying the products to the laser marking device are arranged between the first transferring opening and the laser marking device; and a product identification device is arranged on the side of the positioning rotary table. The laser marking equipment has the advantages that the products are thoroughly protected, the safety is high, the orientations of the products are automatically adjusted by recognizing the shapes and the pattern orientations of the products, the laser marking equipment is used for marking according to the patterns and the orientations, and the marking efficiency is improved.

Owner:上海首坤智能科技有限公司

Novel positioning mold

The invention discloses a novel positioning mold. The novel positioning mold comprises an upper mold, a lower mold, positioning pins, an outer positioning plate, positioning holes, an inner positioning plate, a mold cavity, a thin-wall plate, a vibration motor, a wire and an electric accumulator, wherein the positioning pins are arranged at two short side edges of the upper mold; the outer positioning plate is arranged on the bottom surface of the upper mold; the positioning holes are formed in two short side edges of the lower mold; the inner positioning plate is arranged on the surface of the lower mold; the mold cavity is formed in the middle of the lower mold; the thin-wall plate is arranged at the bottom of the mold cavity; the vibration motor is arranged at the bottom of the thin-wall plate; the wire is connected with the vibration motor; the electric accumulator is connected with the wire. The novel positioning mold is simple in structure and reasonable in design; with the adoption of the positioning pins, the positioning holes and inner and outer positioning ribs, accurate positioning can be realized in an assembly process of the upper mold and the lower mold, and the defects of a product caused by inaccurate positioning are prevented; with the adoption of the vibration motor, raw materials can be uniformly distributed in a filling process, and instability of the internal quality of the product caused by non-uniform laying is avoided. The novel positioning mold is suitable for energetic popularization and application.

Owner:杨永明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com