Aluminium strip anode oxidized surface pre-treatment equipment

A surface pretreatment and anodic oxidation technology, which is applied in metal processing equipment, grinding/polishing equipment, surface polishing machine tools, etc., can solve the problems of oil stains on aluminum strips, affecting the quality of oxidation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

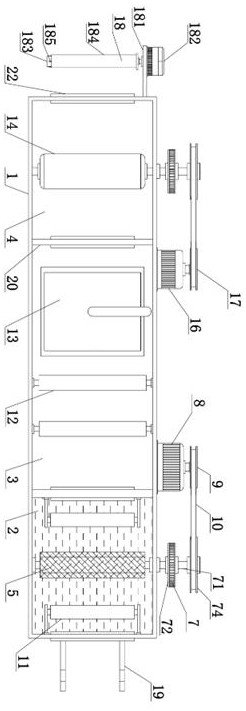

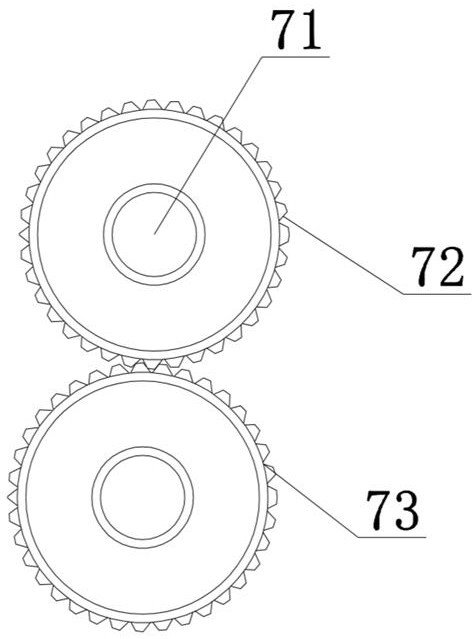

[0036] see Figure 1-Figure 2 , an aluminum strip anodized surface pretreatment equipment, including a device body 1, the inside of the device body 1 is provided with a degreasing chamber 2, a drying chamber 3 and a polishing chamber 4, and the drying chamber 3 is located on the device body 1 In the middle, the degreasing chamber 2 and the polishing chamber 4 are respectively arranged on the right side and the left side of the drying chamber 3, and the aluminum strips are processed in order to facilitate the cleaning of the surface treatment of the aluminum strips after the processing is completed. The degreasing chamber 2 The inner wall is rotatably connected with a first cleaning roller 5 and a second cleaning roller 6, and the degreasing chamber 2, the drying chamber 3 and the polishing chamber 4 are all separated by a partition 20, and the upper side walls of the partition 20 are provided with A belt feeder 21, the inside of the belt feeder 21 is connected with a drive rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com