Pattern type powder coating and preparation method thereof

A powder coating and pattern technology, applied in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problem of high cost and achieve the effect of reducing the production cost of raw materials, good effect and low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

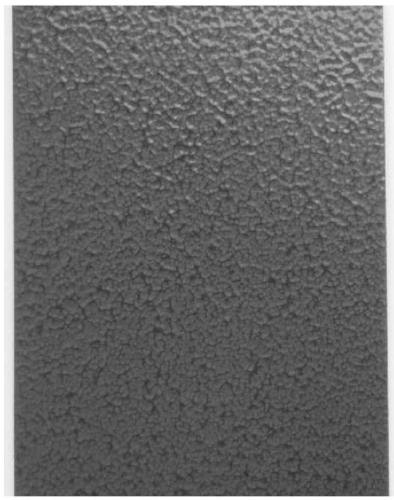

Image

Examples

preparation example Construction

[0012] In order to achieve the above object, the present invention provides a kind of preparation method of pattern type powder coating, described preparation method comprises the following steps: (1) polyester resin, epoxy resin, curing agent, pigment filler, defoamer and pigment Mix evenly; (2) Extrude the uniformly mixed material in an extruder, cool, tablet and pulverize; (3) Add a leveling agent to the pulverized material, mix it uniformly and then grind it.

[0013] Through the above-mentioned technical scheme, the present invention does not add patterning agent (texture agent), reduces purchase management and raw material production cost; Only need to change the addition amount of leveling agent and its addition order in preparation process, do not change the preparation of powder coating The main process can get the patterned powder coating; when the workshop uses this production line to produce flat products of the same color, it can omit the complicated steps of washi...

Embodiment 1

[0031] (1) Put 150Kg polyester resin, 150Kg epoxy resin, 80Kg precipitated barium sulfate, 26Kg light calcium carbonate, 20Kg titanium dioxide, 3Kg iron black powder, 1.50Kg benzoin, 0.90Kg imidazole into the mixing tank, stir for 20 minutes and mix Uniform;

[0032] (2) The mixed material is extruded through the extruder, the temperature of the machine cavity is 105°C, the temperature of the extruder head is 110°C, the average residence time of the material is not more than 30 seconds, cooling, tablet crushing, cooling tablet crushing;

[0033] (3) Add 1.50Kg leveling agent to the pulverized material, and then mix; the material after mixing again enters the pulverizer and grinds to 80 microns.

Embodiment 2

[0035] A kind of preparation method of decorative pattern type powder coating, described preparation method comprises the following steps:

[0036] (1) Mix 90kg of polyester resin with the corresponding amount of epoxy resin, imidazole, pigment filler, benzoin and pigment; the mass ratio of polyester resin to epoxy resin is 90:10;

[0037] The total mass of polyester resin and epoxy resin, the mass ratio of pigments and fillers to benzoin is 100:38:0.4; the mass ratio of epoxy resin to imidazole is 100:5; the epoxy equivalent of epoxy resin is 700; acid value It is 60mg KOH / g, and the number average molecular weight is 2600;

[0038] (2) Extrude the uniformly mixed material in an extruder, wherein the temperature of the cavity is 100°C, the temperature of the extruder head is 120°C, the average residence time of the material is not more than 30 seconds, cooled, tableted and pulverized;

[0039] (3) Add leveling agent in the pulverized material, the mass ratio of the total mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com