Blow mold for thermoplastic elastomer

A thermoplastic elastomer and blow mold technology, applied in the field of blow molding processing equipment, can solve the problems of inconvenience in stretching, poor processing effect, and unreachable tensile properties, and achieve inconvenience in stretching, simple structure, and avoidance of connection. unreliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

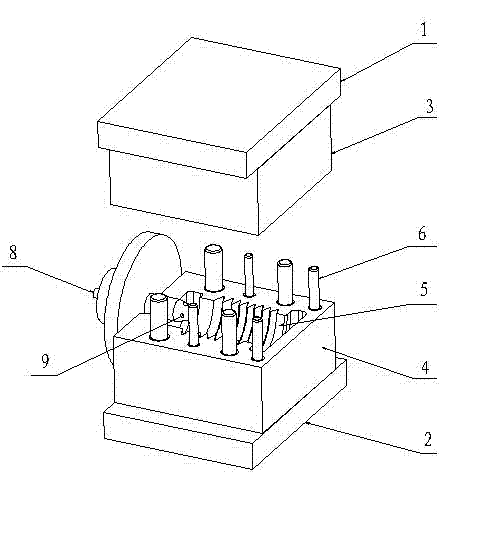

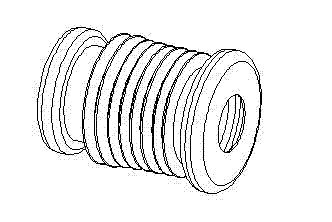

[0016] Such as figure 1 and 2 As shown, a thermoplastic elastomer blow mold includes upper and lower upper molds 3 and lower molds 4, the upper surface of the lower mold 4 is provided with several positioning columns 6, and the lower surface of the upper mold 3 is provided with several depressions The positioning hole 7 is matched with the positioning column 6; the upper mold 3 and the lower mold 4 are provided with a concave cavity 5; one side of the cavity 5 is equipped with a feed port 8, and the feed port 8 extends into the There are several small holes 9 in the part of the cavity 5. The small holes 9 are not only the main entrance of the raw material, but also the gas entrance. Under the action of the high-pressure gas, the plastic melt is fully attached to the surface of the cavity, so that image 3 product shown.

[0017] In addition, an upper bottom plate 1 is installed on the top of the upper mold 3, and a lower bottom plate 2 is installed on the bottom of the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com