High-temperature resistance wear-resistant BOPP film used for cigarettes, and preparation method thereof

A technology of high temperature resistance and cigarettes, which is applied in the direction of chemical instruments and methods, applications, household appliances, etc., can solve the problems of cigarette packs such as whitening in pieces, whitening in pieces, and easy grinding, so as to prevent whitening in pieces and Grinding, improving the coefficient of friction, and eliminating blemishes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

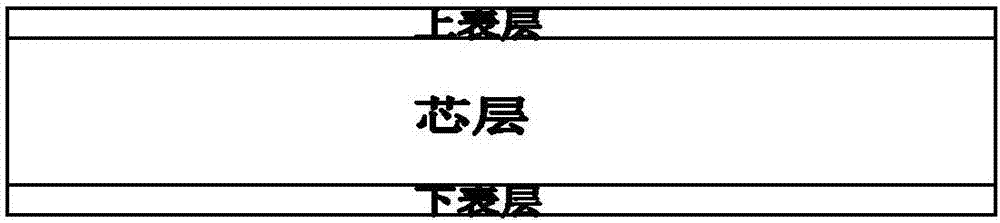

[0029] The BOPP film for high-temperature and wear-resistant cigarettes involved in this example is made by direct co-extrusion compounding of the three-layer structure of the upper surface layer, the core layer and the lower surface layer. The main component of the upper surface layer is polypropylene copolymer, and the main component of the core layer structure is The composition is polypropylene homopolymer, and the main component of the lower surface layer structure is polypropylene copolymer; based on 100 parts by weight, the material components of the upper surface layer are: 90 parts by weight of copolymer polypropylene, and 8 parts by weight of slip agent masterbatch , 2 parts by weight of anti-adhesive masterbatch; the material components of the core layer are: 79 parts by weight of homopolymer polypropylene, 18 parts by weight of stiffener masterbatch, and 3 parts by weight of static agent masterbatch; the material components of the lower surface layer It is: 100 part...

specific Embodiment 2

[0047] The characteristics of this specific embodiment 2 are: the material components of the upper surface layer are: in terms of 100 parts by weight, 89 parts by weight of copolymer polypropylene, 10 parts by weight of slip agent masterbatch, and 1 part by weight of anti-tack agent masterbatch; The carrier of slip agent masterbatch and anti-adhesive masterbatch is polypropylene copolymer, the active ingredient of slip agent masterbatch is silicone resin, the concentration is 10%; the active ingredient of anti-adhesive masterbatch is silicon dioxide particles, the concentration is is 5%. The material components of the core layer are: based on 100 parts by weight, 75 parts by weight of homopolymer polypropylene, 22 parts by weight of stiffener masterbatch, 3 parts by weight of antistatic agent masterbatch; stiffener masterbatch and antistatic agent masterbatch The carrier of the material is homopolymer polypropylene, the active ingredient of the stiffener masterbatch is hydroge...

specific Embodiment 3

[0050] The characteristics of this specific embodiment 3 are: based on 100 parts by weight, the material components of the upper surface layer are: 86 parts by weight of copolymer polypropylene, 10 parts by weight of slip agent masterbatch, and 4 parts by weight of anti-sticking agent masterbatch; The material components of the layer are: 71 parts by weight of homopolymer polypropylene, 25 parts by weight of stiffening agent masterbatch, and 4 parts by weight of static agent masterbatch; the material components of the lower surface layer are: 100 parts by weight of copolymer polypropylene. All the other are with specific embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com